When building a house with two or more floors on your own, it becomes necessary to make a staircase with your own hands. If you have the skills to work with the material chosen for the construction of such a structure, this is possible. In order for the staircase to turn out not only attractive in appearance, but also reliable, safe, it is important to correctly perform the calculations, take into account the basic requirements, nuances. Master classes with step-by-step instructions will help with this.

The content of the article:

-

The main parts of the structure

- Parts of stairs

- Material selection

-

How to calculate dimensions

- Staircase width

- Height

- span height

- steepness

- steps

- Length

-

How to make a ladder - step by step instructions

- Stringer Assembly

- Mounting the bowstring

- Installation of steps and risers

- Installation of fences

- Stair safety and helpful tips

The main parts of the structure

In terms of shape and design, interfloor stairs are divided into mid-flight, bolt and spiral. The first option is a design of one or more groups of steps, separated by platforms or turning steps.

In private houses, marching stairs are most often made with their own hands. They are distinguished by reliability, ease of use, ease of manufacture.

Marching structures differ in shape:

- Direct. Single-march is the easiest to do. They include up to 18 steps and do not have a turntable. The use of this form is possible if the ceilings in the house are low.

- L-shaped. The most convenient and compact option for a private home. Marches (groups of steps) are usually placed along two adjacent walls. Between them is a small platform or turning steps.

- U-shaped. Such stairs consist of two marches and a large platform (the form is used in the entrances of multi-storey buildings). The lift takes up more space. Suitable for private houses with high flows. There is often enough space on the site to put large flower pots with indoor plants or a comfortable chair.

- T-shaped. Consist of 3 marches. The first group of steps starts on the first floor, and the next 2 flights diverge from the platform between them to the left and right. The rise looks majestic, but takes up a lot of space.

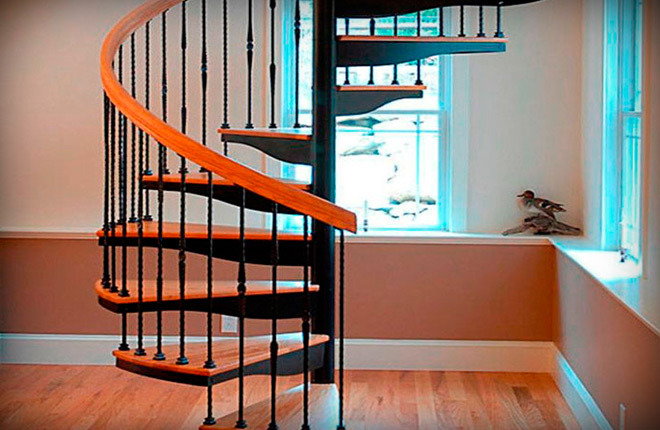

Spiral staircases are structures with a base in the form of a support column and turning steps around it. Such a lift looks impressive, but it is difficult to install. In addition, it is less convenient to use.

Stairs on bolts are frameless, they consist of steps that are mounted directly on the wall. Due to this, they look airy and weightless. This is an easy to use and operate option. Make it easy.

It's interesting for you! Metal staircase to the second floor. How to make a ladder to the attic in a private house. roof ladders.

Parts of stairs

To make a staircase in a private house with your own hands, you need to know the main parts of the structure. Its basis depends on the type of product.

| Type of stairs | Base |

| Marching stairs |

Bowstring. Inclined beams supporting steps on the sides. On the inside of the bowstring there are grooves into which the ends of the steps are inserted. The stronger the bowstring, the more reliable the design. Kosour. These are the side parts of the lifting structure with a stepped edge. When using such a foundation, I lay the steps on top. Sometimes supplemented with a support beam. This basis is considered more reliable. |

| Spiral staircase | Rack. A rod to which wedge-shaped steps are attached in a spiral. |

| Boltsevaya ladder | Boltsy. Metal fasteners that are mounted directly on the wall. I attach steps to them. |

An important part of the stairs is the step. The horizontal part is called the tread. It bears the brunt of the load.

An optional element is the riser. This is a vertical bar that connects the treads. It adds reliability and attractiveness to the design.

The shape of the steps are:

- Direct. They have the shape of a regular rectangle. Used in mid-flight and bolt ladders.

- Zabezhnye. They have a semicircular shape, narrowed on one side. They are used to make turning parts and spiral staircases.

- Arcuate. Semicircular large steps with a rounded front edge. Used at the base of the structure for decorative purposes.

Marching stairs consist of marches and platforms. Marches usually include 9-11 steps. Between them are platforms, or turning steps.

To climb to the second floor was convenient and safe, the stairs are supplemented with railings. They consist of:

- handrails. The upper part of the fence, which is a horizontal crossbar. It needs to be made smooth so that it is comfortable to lean on it with your hand.

- Support pillars. Vertical supports on which the handrail rests.

- Baluster. Crossbars located between the steps and the handrail. Provides additional fall protection.

The distance between the balusters should be made such that the head of the child does not fit into it.

Material selection

The construction of interfloor stairs is possible from different materials. The following options are common:

- Wooden. The most popular material for the construction of interfloor structures with their own hands. Differs in simplicity of installation, attractive appearance, availability of materials, durability. The disadvantage is the need for periodic updating of the varnish coating. If this is not done, the steps will look worn. Without a protective layer, they begin to rot.

- Concrete. These are stairs made of inexpensive material, characterized by reliability and long service life. Minus - unattractive appearance. Making them yourself is difficult.

- From natural stone. Structures made of granite or marble look majestic, durable, hopeful. The disadvantage is the high cost, as well as the impossibility of self-assembly without experience in such work.

- Metal. Metal stairs are durable. If you have welding skills, they are easy to manufacture. Such structures do not look organically in all interiors. With high humidity, they rust over time. If you make a ladder of stainless metal or cover all the elements with an anti-corrosion compound, then such a problem can be avoided.

- Glass and ceramic. They look stylish and unusual. It is difficult to make a staircase from such materials on your own. Steps can be enough how many.

Of all the materials presented, wood is most often chosen for private houses. Coniferous, deciduous and hardwood species are used.

The durability of the product depends on the quality of the wood. For interfloor stairs, the following breeds are chosen.

| Breed | Characteristics |

| Larch | Strong, durable material. Differs in saturated color, fire resistance, ease of processing, resistance to rotting. |

| Oak | Durable rock with high strength and high moisture resistance. It has a noble appearance, rich color. The disadvantage is the high cost. |

| Fur tree, pine tree | The most budget breeds. The disadvantage is softness, low wear resistance. During processing and from time to time, wood changes its shade and appearance. To ennoble the structure, you can make a registration with a colored stain. |

| Birch | It has an average density, which is superior to pine, but inferior to oak. The rock withstands loads, local pressure. |

| Maple | It is difficult to process, since the absorption of any wood products is slow. The bright beautiful shade, high durability attracts the consumer. |

| Ash | The strength of the breed is even higher than that of oak. Beautiful color, unusual pattern of wood make it a luxurious material for a private home. The advantage is wear resistance and impact resistance. The disadvantage is low resistance to high humidity and microorganisms. To level this shortcoming, they make a registration with moisture protective agents. |

| Beech | Strong and durable breed with a uniform shade of the core. Differs in simplicity of processing. Needs moisture protection. |

How to calculate dimensions

To make a staircase with your own hands, you need to make the right calculations. This will ensure the reliability and attractive appearance of the product.

If the staircase is designed together with the house, then they use time-tested parameters for the rise height and tread width: 150,160,170 mm for height and 290-300 mm for width.

When designing a structure in an already finished building, you will have to calculate each parameter separately. Otherwise, the finished structure may be larger than the space prepared for it or not reach the second floor.

To make calculations faster, use an online calculator or tables with ready-made values.

Staircase width

The width of the stairs in a private house should be such that 2 people can comfortably move along it at the same time. But if there is not enough space in the room, the design is adapted for one person, only this reduces its convenience. Also, it will not be possible to lift assembled furniture and other large items along a narrow lift.

Most projects assume the width of the steps from 110 to 150 cm. These parameters are considered the most suitable for private houses.

Common parameters for the width of flights of stairs:

- 80-100 cm. An option for those who do not want to take up space with a lifting structure. 2 people cannot climb such a ladder at once, but it does not take up much space and requires less material.

- 100-125 cm. A comfortable structure that can be climbed by two. These are the most popular parameters for interfloor rises. They are more expensive than the previous version, but more convenient to use.

- 125-150. For the construction of such a rise, more material is required. But the design looks impressive, 2 people can climb it at once, without embarrassing each other.

Steps with smaller dimensions will be inconvenient to climb even for one person. Wider marches require more financial investments, take up a lot of space, and make the interior heavier.

Height

In order for the stairs to turn out to be the desired height, measurements should be taken correctly. To do this, measure the distance from the floor of the first floor to the floor of the second floor, along with the thickness of the jumpers and the finish floor.

If you change the distance from floor to ceiling, then the stairs will be short. It will be problematic to complete the missing step so that the rise is comfortable and looks harmonious.

span height

The flight height must be such that the distance from the bottom step to the ceiling is not less than 2 m. Moreover, such parameters must be maintained on any part of the stairs. Otherwise, tall people will have to rise bent over, which is not only inconvenient, but also unsafe.

steepness

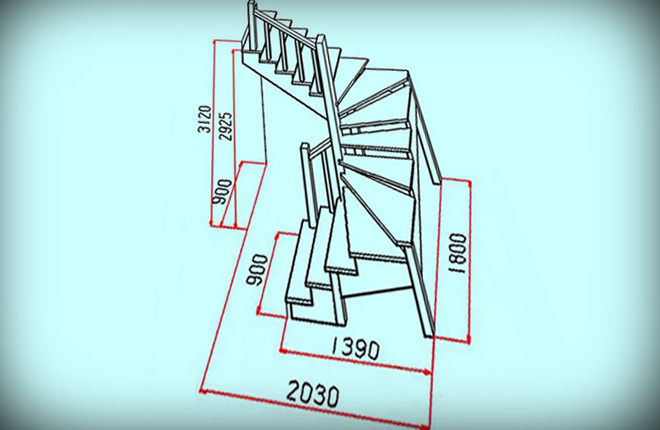

The steepness or angle of the stairs is measured in degrees. Parameters from 35 to 45 degrees are considered optimal. It is convenient to climb such stairs, but at the same time they do not take up much space.

There are rises with a smaller angle of inclination - 25-30 degrees. Such ladders are safer, more convenient for small children and the elderly. However, they take up a lot of space and not everyone has a room that allows them to make such a building.

The angle of inclination of the stairs is easy to calculate. To do this, you need to make a diagram on a piece of paper. The drawing is made on a scale of 1:10. Draw a vertical line corresponding to the distance from the floor to the ceiling. From the bottom point of the vertical segment, a horizontal line is drawn, the length of which is equal to the length of the space allocated for the installation of the lifting structure. The ends of the segment are connected to form a triangle.

Measure the angle between the end of the horizontal segment and the hypotenuse (slanted line). This will be the slope of the stairs.

If you get an angle of more than 45 degrees, then the stairs are too steep and uncomfortable. In this case, make several flights.

steps

In order for the climb to be safe, the steps must be comfortable. If the staircase is laid at the design stage of the building, then the staircase can be made according to generally accepted standards. In this case, the width of the tread will be 29-30 cm, and the height of the riser will be 15-18 cm.

If the stairs are made after the construction of the house, then one of the formulas is used:

- The first is called the safety formula. According to it, the difference between the width of the tread and the height of the rise is 12 cm, and the sum is 45 cm. Of course, it is almost impossible to accurately maintain such proportions, so you need to try to keep the deviations to a minimum.

- Another calculation option is called the Blondel formula. According to it, the sum of the width of the tread and the square of the height of the rise varies between 60-64 cm.

Length

To calculate the number of steps, the height of the ceiling is divided by the height of the rise. If the value is fractional, then the remainder is distributed among all the steps, or you need to make the lower step already.

The number of steps in one march should not exceed 18 pcs. Otherwise, you need to make several spans or add winder steps. This complicates the installation of the structure, but increases its safety.

How to make a ladder - step by step instructions

To make a wooden staircase with your own hands, you need to follow the sequence of work, follow the step-by-step instructions. Begin work with load-bearing elements.

It is important after assembling each element to check its level. This will help avoid distortion.

The master class is dedicated to the wooden staircase. This material is the easiest to work with, it does not require expensive equipment and specific skills.

At the first stage of assembling the stairs, you need to make support pillars. They can be cylindrical or square. These elements must be made of strong, smooth wood without knots or other damage. There is a significant load on the bearing element.

The supporting pillars are attached to the floor of the first floor at the base of the stairs. The height depends on the shape of the building. For straight single-march buildings, support poles are sometimes made from floor to ceiling. The supporting structure resting against the lower and upper floors is reliable. However, more often this element ends at the level of the railing handrail.

If the rise involves two marches, then the upper ends of the supporting pillars should be at the level between the march platform and act as a support for this part.

Support poles are attached using metal corners, zip bolts, studs, etc. Often the main method of fastening is combined with wood glue for greater structural reliability.

In the supporting pillars, pairs are made under the stringers. If high structures are used that reach the ceiling, then a groove is made under the railing handrail.

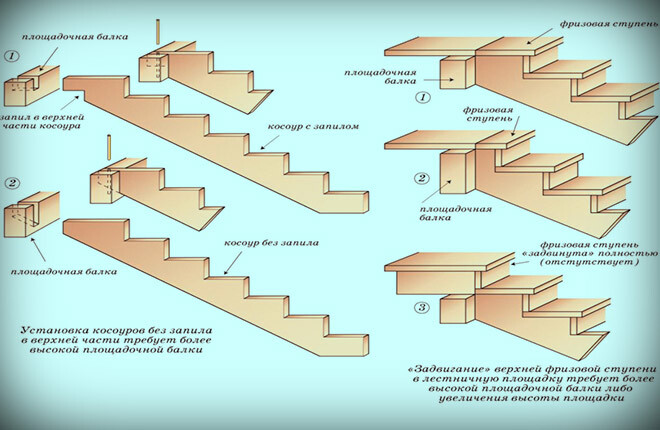

Stringer Assembly

For a single-flight staircase, two stringers are used. This supporting element is more convenient for self-assembly compared to a bowstring.

Stringers are made from thick boards. A stepped edge is made at the top of the element. Treads will be laid on the ledges.

In order to independently cut the recesses, the height of the riser and the amount of tread are laid on the board. From the calculated indicators hugs 2-4 cm. The horizontal parts of the recesses should be parallel to each other, and the vertical ones should be located at right angles to them.

According to the marking, the board is cut out using an electric jigsaw. To facilitate installation work, you can order ready-made stringers.

Installation begins with the last kosour. First, make and check the level markings on the wall. Installation consists of 3 stages:

- The installation starts from the lower edge of the stringer. To do this, it is inserted into the groove in the support post, fixed with wood glue.

- Then install the upper part of the kosour. It is attached to a pre-prepared groove in the upper floor using corners, bolts, studs or anchors.

- After installing the upper and lower edges of the element, the main part of the part is attached to the wall according to a pre-prepared marking using dowels or anchors.

During the installation process, it is important to constantly check the fasteners with a building level.

To increase the reliability of fastening, the groove in the support column and the “key” of the kosour are abundantly smeared with carpentry glue, then the key is dipped into fine sawdust and only after that is inserted into the groove.

The installation of the external stringer also begins with its attachment to the groove of the opera pole. I mount the upper part to the upper ceiling in the same way as in the case of the wall stringer. If the upper step is located below the ceiling, the missing distance is compensated by supporting steel plates, metal corners, or even a reinforced furniture board.

When installing, it is important to ensure that the stringers are strictly parallel to each other.

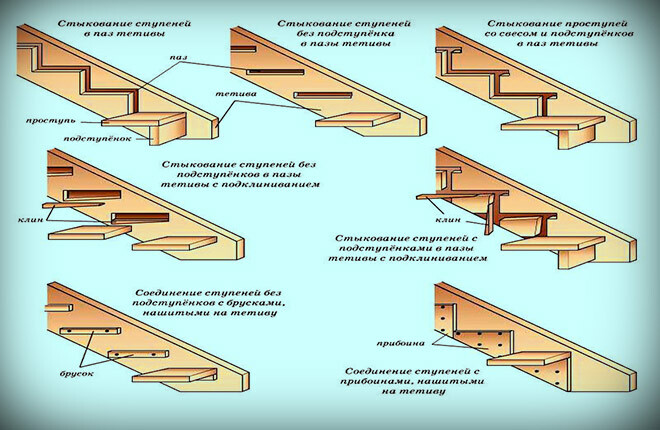

Mounting the bowstring

Some projects involve the installation of bowstrings rather than stringers as a supporting structure. These elements differ in the way the steps are fastened.

If the kosour has stepped protrusions, on which I lay the steps on top, then the bowstring is a flat board with grooves into which the steps are inserted. This mounting method is more difficult.

To make a bowstring on your own, cuts are made in the boards, the length of which is equal to the width of the steps, and the width is equal to the thickness of the treads. The distance between the pairs is calculated according to the height of the steps.

When using a bowstring, support posts are not needed. Installation of steps in the bearing elements is carried out before the structure is attached to the upper and lower floors.

First, all steps are inserted into the grooves on the first bowstring. Before this, the parts of the connection are coated with carpentry glue. Then a second bowstring is placed on the free edge of the steps. All joints are coated with wood glue and tapped with a wooden or rubber mallet.

The finished march is put in the right place. The lower part is fixed to the floor with glue, bolts, metal corners, etc.

The upper part of the bowstring is installed in the grooves of the upper ceiling or turntable.

The advantage of designs on a bowstring is greater strength. However, due to the fact that the tree shrinks over time, the sidewalls move apart, uniform adhesion to the side parts of the treads disappears. To level this shortcoming, every five steps the march is reinforced with metal or wooden strands.

Otherwise, the process of mounting the stairs on stringers and bowstrings is no different.

Installation of steps and risers

Installation begins with the installation of risers. They should be 2-3 mm less than the height of the steps. This is done because, depending on the humidity of the room, the tree may swell or shrink. The gap will not allow the entire structure to warp.

Treads and risers are sanded before installation.

If stringers were used as load-bearing elements, then it will be easy to install the risers. They are fastened with self-tapping screws to the vertical parts of the notches using self-tapping screws, the caps of which are sunk as deep as possible.

When mounting risers to a march on a bowstring, each wooden plank is fastened with edges to the top and bottom of the tread. Installation can be done with self-tapping screws.

Straight treads are easy to make. To do this, wooden boards are attached to the horizontal protrusions of the stringers, sinking the heads of the self-tapping screws as deep as possible. The width of the tread should be 2-3 cm more than the protrusion on the stringer. Such a side will provide an attractive appearance of the structure and make it safer.

To make winder steps more difficult, 2 methods are used for this:

- Under the treads, non-through grooves are made in the support column. In this case, the width of the grooves must be made a couple of millimeters less than the thickness of the board. This will make the mount as strong as possible. The grooves must be cut in accordance with the location of the rotary elements.

- Under the steps, through holes are made in the opera column. The cut should be equal to the thickness of the board. The elements are connected using wood glue and a metal stud inside the support post.

In both cases, the outer part of the step is attached to the frame of winder stringers or support pillars using self-tapping screws and wood glue. After carrying out the work, you need to check using the building level.

Installation of fences

At the last stage of the assembly of the interfloor stairs, railings are installed, which consist of balusters and handrails. This part of the building provides a convenient rise, protects against falling.

First you need to do the installation of balusters. They must withstand a person of any build leaning on the railing. To do this, it is important to follow the recommendations.

Balusters are made of durable smooth wood without knots and damage. Their height varies between 90-110 cm, which corresponds to the needs of a person of average height. At the same time, children and tall people can also hold on to the handrail.

So that the design does not make the space heavier, but at the same time remains safe, you need to make a gap between the balusters within 15-20 cm. Such a gap will not allow even a child to fall down the stairs.

The lower edge of the balusters is attached to the steps. To do this, use different fasteners. Here is a list of the advantages and disadvantages of each option:

- Steel pins. The most reliable method of fastening, which is only suitable for stairs on stringers. These are metal rods that are smooth and threaded. To install on the first variety, a hole is made in the baluster, the diameter of which is equal to the diameter of the stud and a depth of at least 4 cm. Liquid nails are poured into the hole, studs are knocked out. Then the baluster with the hairpin is attached to the step in the same way. When using a threaded stud, the hole is made 1 mm smaller than the diameter of the rod, then I screw it onto the baluster and step using a lock nut.

- Concealed reducing fastener. This method of fastening allows you to make the connection strong and invisible. The fastener is a metal plate with holes for the corners and for the bolt in the center. The plate is attached to the recesses on the steps with self-tapping screws. A bolt is screwed into the bottom edge of the baluster. Then the bolt head is lowered into the recess in the center of the plate and driven into the narrow part with a hammer.

- Wooden dowels. Such a mount is also called a chopik. Mounting on wooden rods is reliable, but not collapsible. To make the installation, a hole is drilled in both the step and the baluster. The cap is dipped in carpentry glue and small sawdust, then driven into the prepared recesses.

Fastening balusters with self-tapping screws is not recommended. If this is done, the design will turn out to be unreliable, since the attachment points loosen over time.

After installing the balusters, a handrail is attached. To do this, the upper part of the supporting vertical elements must be made at an angle equal to the slope of the stairs.

The handrail is attached to the balusters with steel studs or wooden dowels. To do this, the rod is inserted into the holes in the lower part of the handrail and the upper end of the baluster. Can be glued with free glue and mounted on a steel or wooden rod through one baluster.

The use of self-tapping screws for fastening the handrail is not recommended. Otherwise, it will not work to make the railing absolutely smooth.

After the installation of the stairs is completed, the recesses from the caps of the self-tapping screws are puttied or covered with decorative plugs.

The stairs are cleaned of dust and sawdust. Then they are covered with several layers of varnish or impregnated with protective agents and a special oil for wood products is applied.

Stair safety and helpful tips

It is very important to make the stairs reliable and safe. Therefore, the recommended design parameters must be observed. This is especially true for the width and height of the steps, the step between the balusters.

The lift must be fireproof. To do this, use special impregnations, place the stairs away from electrical and gas appliances.

It is not difficult to make a ladder with your own hands, if you prepare the correct drawing, read the step-by-step instructions. To make your work easier, you can order ready-made structural elements. In this case, it remains only to assemble and install.