The IBC container (or eurocube) is widely used for the transportation of all kinds of liquids. The plastic container turned out to be so strong and reliable that the owners of summer cottages began to massively build reservoirs, pools and showers from it. It is not difficult to build a pool from a Eurocube with your own hands, but you will need to show a little skill and ingenuity.

The content of the article:

- Advantages and disadvantages of a eurocube pool

-

What materials and tools will be needed?

- materials

- Tools

-

Step-by-step instruction

- Pit preparation

- Insulated hole option

- Cold pool option

- Pit option for quick pool construction

- Container preparation

- Drawings and diagrams

- Installing the cube in the pit

- Final works

- Is it possible to make a cube yourself

- Results

Advantages and disadvantages of a eurocube pool

An IBC is a nearly cubic container placed on a metal or wooden pallet. Inside the crate made of steel bar is a plastic container-box made of high-density low-density polyethylene.

Water container capacity:

- The standard one is 1000 l, but you should always specify the capacity and material, as there are models for non-food products with reinforced walls in the back of the container.

- Reduced (for food liquids) 600 l, 640 l each. They are clearly not suitable for the pool due to their small dimensions.

- Increased for non-food - 1200 liters or 1500 liters.

You can find a Eurocube with a capacity of up to 2000 liters. They are mainly used for storing liquids or as septic tanks. Wall thickness - up to 6 mm, container length - 130-140 cm. These models are best suited for building a mini pool. But the cost of the new Eurocube is too high - up to 15 thousand rubles. rub. Whereas a standard pool with a reinforced polypropylene liner 180 cm long will cost 12 thousand rubles. rub.

Advantages of using a Eurocube for building a pool:

- durability, the material will last at least 30-40 years;

- high chemical resistance of ND polyethylene, withstands temperatures from -60OC to 40OWITH;

- easy to process, cut without cracks, impact resistant.

Of the shortcomings of the Eurocube, only the small dimensions of the container can be noted. That is, it turns out a bath, more suitable for hardening or water procedures after a steam room.

But, despite its small size, the Eurocube will make a good swimming pool for self-swimming schoolchildren aged 9 to 13 years.

Another disadvantage is that deposits of salts and organic matter falling out of the water are clearly visible on the white polyethylene walls. But you can make a pool of black polyethylene eurocube.

Healthy: How to make a pool with your own hands.

What materials and tools will be needed?

Before you make a pool from a Eurocube, you need to choose a suitable place. A sandy area is best suited for arranging a bathing area, preferably with shading and protection from rainwater. For example, under a tree or near the house, next to the gazebo.

materials

Eurocube itself can already be used as a font or a small basin. You just need to cut off the top of the container and ennoble the edge. But using the pool in this form will be inconvenient due to the high sides. Therefore, the best solution would be to install the container in the pit.

This will require:

- Red brick;

- masonry mortar;

- bituminous mastic;

- thick polyethylene film;

- plates penoplex;

- crushed stone and cement-sand mortar.

Tools

From the tools you will need a grinder, a welding inverter, a building hair dryer, an electric jigsaw, a measuring tool, a solution container. In addition, you will need a garden wheelbarrow and a shovel. For the construction of the pool, it is best to choose areas with heavy dense soil. As a rule, in such soils, water is located at a depth of more than two meters, so drainage under the pool can be omitted.

Step-by-step instruction

First of all, a path must be made to the place of the future construction of the pool. For example, make a sand and gravel cushion and lay out concrete tiles. This will simplify the process of transporting the eurocube to the pit and removing the soil with a wheelbarrow.

Pit preparation

Initially, you need to mark the site. You can simply fill out the contours of the future pit with dry sand or use a special tool to mark out the foundation pits for buildings.

Since the dimensions of the pit are only 150x150 cm, it will be enough to drive four pegs in the corners, pull a cord between them and adjust the shape of the square, measuring the length of the diagonals with a tape measure.

The next step is digging the hole. First, we remove the top layer of turf with the roots of plants and take it out with a garden wheelbarrow outside the site. The depth of the pit must be at least 120 cm. We level the walls with a shovel.

A layer of gravel with sand at least 10 cm thick is poured at the bottom, red brick is laid out on top. The joints are covered with a dry mixture of cement and sand. Next, on top of the brick, we fill the screed with a cement-sand mortar with a thickness of at least 5 cm and let it grab for 4 days.

Next, we lay a plastic film on the bottom of the pit, two panels crosswise. The film should lie on the walls, and the edges should be lifted onto the sides of the pit. At the corners of the pit, you need to glue the panels with tape.

Insulated hole option

Heavy soils have high thermal conductivity. The wall of the eurocube 5-6 mm thick is too thin to reliably keep the heat in the pool. Therefore, the pit needs to be insulated, otherwise the water in the Eurocube will cool down very quickly, even in the summer heat.

The walls of the pit are insulated in two layers, each plate 25 mm thick. Insulation sheets are laid on the walls with a run of seams. Penoplex is attached with standard fungi. Dowels of 120 mm are placed on the bottom, 150 mm on the walls. The joints between the plates must be glued with adhesive tape.

Cold pool option

Often, the owners of the future pool believe that it is not necessary to insulate the walls of the container with the help of penoplex. For example, if it is planned to make a summer pool out of the eurocube for hardening procedures after visiting the steam room. In this case, the pit will need to be equipped in a reinforced version, based on jumping into the water from the shore.

In this case, the dimensions of the pit must be increased. If the dimensions of the eurocube are 120x140 cm, then the pit will need to be dug to a depth of 170 cm with a side size of 160x150 cm. At the same time, along the perimeter of the pit, it is necessary to cut off the edges with a tape up to 30 cm wide and up to 20 cm deep. The tape must be backfilled with a mixture of gravel screenings and sand, the layer thickness is 5 cm.

Two layers of gravel are poured at the bottom of the future pool, first 5-7 cm of crushed stone 2 cm in size. The top layer is poured from gravel screenings. A concrete screed with a thickness of at least 7 cm is poured on top.

Next, you need to lay the waterproofing. It is laid with one wide panel on the bottom, walls and edges of the pit. On the edges of the panel laid along the perimeter of the pit, gravel screenings are poured and cement-sand tiles are laid.

The walls of the pit are laid out with bricks to the level of the sides of the future pool. It is desirable to insulate the bottom, otherwise in winter the water will freeze and destroy the base of the pool. It is enough to lay one sheet of foam plastic with a thickness of 20-30 mm on the bottom.

The walls and bottom are rubbed with cement mortar with the addition of liquid glass. This makes the concrete waterproof. If foam 8-10 mm thick is glued onto the walls and floor with mastic, then the Eurocube can, if necessary, be removed from the pit and returned to its place.

Pit option for quick pool construction

Often, a capital reservoir is not needed in a summer cottage, it is enough to build a European cube pool for games in one day in the country. In this case, they dig a hole for the installation of the eurocube exactly according to the dimensions of the container, plus the size (height) of the wooden europallet from each side is added. Accordingly, the depth of the pit must also be increased by the same amount.

All that needs to be done is to cover the entire space of the pit with a waterproofing film. The eurocube will be installed in the foundation pit on europallets, they will need to be treated in advance with oil impregnation or drying oil, and then dried in the sun until tacky.

Healthy: How to make a pool in the country with your own hands.

Container preparation

The Eurocube will be installed in the pit as is, without the steel crate and the base "tray". Therefore, when preparing a container with a grinder, you need to get rid of all metal parts. After a few months or at most a year, the steel grating will rust and become a source of problems for the waterproofing of the pool. From the Eurocube, only a plastic container with a lid will remain.

Important! If the Eurocube pool is planned in an insulated or cold version, then the upper part of the container with a lid cannot be cut off until it is installed and fixed in the pit.

In addition, you need to plug the drain valve at the bottom of the tank.

If the pool is planned to be installed on wooden pallets, then the eurocube needs to be finalized:

- A lid is screwed onto the container and placed on a Euro pallet.

- Wooden pallets pre-cut to size are installed on the walls, leveled and fixed with adhesive tape.

- With a screwdriver and self-tapping screws, wall pallets are pulled together and with a bottom euro pallet. The container must be firmly fixed in place.

- With the help of a grinder, cut off the upper part with a lid, make cuts at the corners.

Next, you need to heat the upper edge of the cut Eurocube container and bend it with your hands to the end of the wall pallet.

In this form, the eurocube can be used for the rapid construction of a pool.

Drawings and diagrams

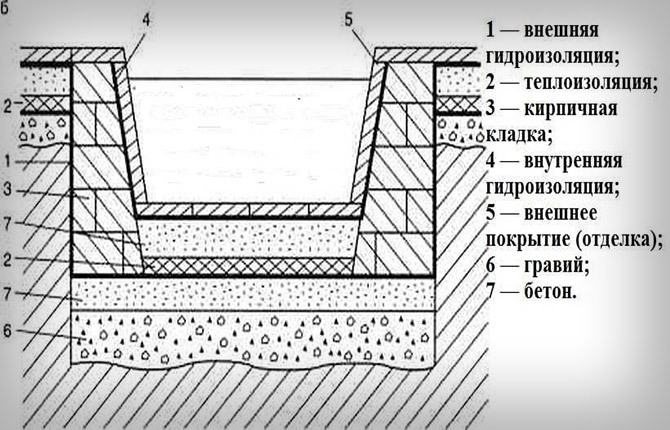

The preparation of the pit before installing the eurocube depends on the characteristics of the soil, the presence of surface water and the required level of pool insulation. The scheme below is universal for any soil.

The only exception is an area with a high level of groundwater. In this case, a drainage pipe will need to be laid under the base of the pool, otherwise, over time, the Eurocube may sink by 10-15 cm. To remove water, a drainage well can be connected to the pipes. The only condition is that it must be lower in level than the depth of the Eurocube base.

Installing the cube in the pit

This is the most difficult stage in the construction of the pool. The eurocube has thin walls made of HDPE, so during the installation process you can easily damage them.

The easiest way is to install a cube for an insulated pool. The plastic container is hung with cords by the lid to the pole and raised above the pit of the excavation. Next, you need to lay down the eurocube in the pit. To do this, remove the pole (leave the cords), remove the lid and fill the container with water from a hose.

The future pool, under the weight of water, smoothly settles into the pit. Before the container finally falls into place, you need to cut off the top of the eurocube and, if possible, bend the edges outward.

It is a little more difficult to install a container with strapping walls with pallets. The weight of the plastic insert itself is no more than 15-20 kg. The total weight of four euro pallets is 65-70 kg. In total, up to 90 kg is obtained. Therefore, the eurocube is installed in a pit on canvas belts by a group of at least 4 people.

Final works

After the pool bowl has been installed in place, it is necessary to wash the walls, disinfect and ennoble the area around the reservoir. Initially, the container is filled with water with hydrogen peroxide for a day, covered with foil and boards.

During this time, it is necessary to strengthen the edges of the pit, fill in the waterproofing film, lay tiles, cut and fix a decorative rim made of lath or decking boards around the perimeter of the pool. It can be laid directly on the ground, the material made of pressed chips and polypropylene is not afraid of water.

Is it possible to make a cube yourself

There is a scheme for building a pool based on a eurocube with a hopelessly damaged plastic container. The most common cause is a damaged side or corner area of the tank.

In this case, the bottom of the container and a steel crate with a tray will be used to make the pool. The metal frame is carefully treated with polyester resin and dried to allow the coating to thicken.

Next, a web of geotextile is wound on the outer surface, previously smeared with polyester resin. You need to make at least 6 layers and roll each layer tightly to squeeze out the air. If you follow the technology, you get an impromptu Eurocube without the top. But it can be used to build a pool.

Reading: Organization of pool ventilation.

Results

It is quite possible to build a pool from a Eurocube with your own hands. The quality of the reservoir directly depends on the invested funds and how accurately the excavation technology was followed. If desired, many useful buildings can be made from the eurocube: from a caisson to a home-made bioseptic tank.

Tell us about your experience building a swimming pool. How successful is the reservoir? Share the article on social networks and bookmark it so that you and your friends have it at hand.