High-speed gasoline engines installed on Stihl chain saws require constant attention and periodic adjustment. Otherwise, it will not be easy to achieve stable operation of the motor. The company's engineers tried to make the screws for adjusting the carburetor of the Stihl chainsaw as convenient as possible. Therefore, it is possible to adjust the operation of the motor even for an inexperienced user.

The content of the article:

-

The device and principle of operation of the Stihl 180 carburetor

- Fuel pump

- distribution chamber

- Nozzle

- throttle valve

- air damper

-

Main types of faults

- Chainsaw won't start

- RPMs fluctuate at idle

- Loss of power, high gas mileage

- Stihl 180 chainsaw carburetor adjustment

The device and principle of operation of the Stihl 180 carburetor

Most of the components and parts of the Stihl chainsaw are made in China. The quality of the motor has decreased slightly, but not particularly critical. Some of the most important components, such as carburetors, continue to be produced in Europe. Therefore, on sale you can find Stihl chainsaws with "native" carburetors, as well as with the Chinese version.

On the original SHTIL MS 180 carburetor, the adjustment screws rotate quite accurately throughout the life of the chainsaw. For Chinese, at first, the adjustment screws also look quite decent, you can adjust the operation of the chainsaw to an acceptable level of fuel consumption, without failures in work. But the quality of the membrane is lower, so the adjustment of the carburetor of the Stihl chainsaw may not always be stable.

The original Stihl 180 uses a replica of the successful Japanese ZAMA model. It is clear that in the Chinese Calm, the chainsaw carburetor device is already a copy from a copy.

ZAMA is one of the most reliable and economical in its segment. This means that there is nothing complicated in adjusting the carburetor with screws. Like any other Japanese technique, it is quite simple to set up. The worker will only need to be careful when turning the adjustment screws with their own hands and a thoughtful approach to choosing the operating mode of the chainsaw.

How ZAMA works - the pump lifts gasoline from the tank, throws it through the channel into the main chamber and then into the diffuser. Under the pressure created by the pump, the fuel is pushed through the jet or nozzle into the air stream sucked by the piston through the carburetor.

In theory, if the fuel and air consumption are correctly selected, then this is enough for the chainsaw to work, and quite steadily, but at the same speed and without load. The Stihl 180 model is distinguished by a minimum number of transients, therefore it starts up well and keeps revs stably even when cold.

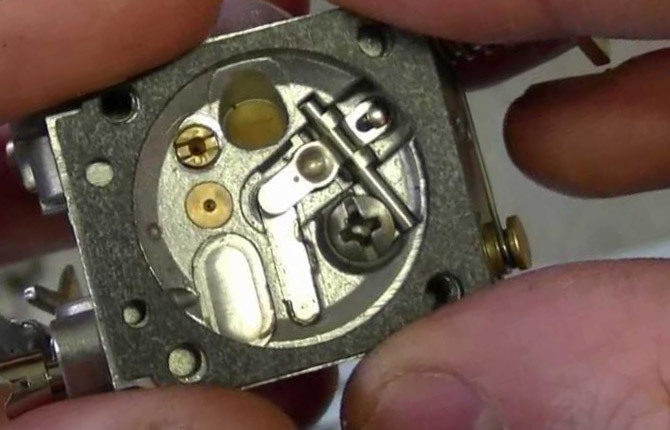

In addition to the pump, diffuser, jet, nozzle, auxiliary elements are used in the carburetor:

- control diaphragm with rocker arm and valve;

- needle valve;

- throttle and air damper.

The position of the elements is set with screws. They are needed to regulate the mixing of air with gasoline, control the operation of Calm at different speeds, at different air-fuel temperatures. A simple increase in air or gasoline consumption would cause the chainsaw to stop.

Fuel pump

The main element of the carburetor is the fuel supply pump. In Calm, it is of the membrane type. This is both good and bad at the same time. The membrane provides a more uniform supply of gasoline than a spring rod, but at the same time it is gradually destroyed under the influence of fuel vapors.

To drive the membrane, a channel is used that connects it to the crankcase of the chainsaw engine. Every time the piston moves up and down, a vacuum is created inside the crankcase, which is transmitted through the channel to the membrane, causing it to move. In one cycle, the membrane rises, sucks gasoline from the tank (through the valve), and then, lowering, pushes it further along the channel in the carburetor body.

distribution chamber

The main, or distribution, cavity-chamber of the carburetor accumulates gasoline. But further supply to the nozzle (diffuser) occurs under the control of another membrane element connected to the rocker arm. The latter can raise and lower the needle valve. From the adjustments of this chain (membrane-rocker-valve needle) the consumption of gasoline in the carburetor depends, the stability and throttle response of the chainsaw under load is determined. As well as the efficiency of Calm work.

The membrane is forced to move by the vacuum created by the air flow in the carburetor diffuser. The higher the air speed (stronger vacuum), the higher the membrane raises the valve needle, and more fuel is dispensed into the nozzle. This automatically adjusts the air-petrol ratio or mixture quality.

Some chainsaw models have two mixture adjustment screws. With their help, you can adjust the cross section of the channel from the membrane to the nozzle. This improves the efficiency of the motor. Stihl 180 has no separate adjustment screws. It is believed that additional screws are not necessary. Instead, a flow adjustment screw is used on the jet, which is responsible for idling Stihl.

Such an adjustment scheme is considered to be more resistant to channel contamination. On the one hand, fewer adjustment points significantly reduce the ability to fine-tune the chainsaw. On the other hand, when working with Stihl, it is better to turn one adjustment screw than two, even to the detriment of accuracy. Although in reality, the point is probably to make the engine work more stable.

Nozzle

Responsible for spraying fuel in the carburetor diffuser. Equipped with a non-return valve to prevent accidental leakage of gasoline back into the chamber.

When assembling Stihl, before installation, the check valve is tested for gasoline leakage, sometimes adjusted according to the flow area. During long-term storage of Stihl, the mixture of gasoline and oil often turns sour in the valve, therefore, before adjusting, it is necessary to blow or flush the channels with clean gasoline.

In addition to the nozzle, an idle jet (sometimes jets) “looks” into the air channel. It works with the throttle closed (the gas on the chainsaw is completely removed) in idle mode. The working section is smaller than that of the nozzle, so it practically does not affect the main mode. Adjusting the idle speed screw on Calm is considered one of the main ones and will require tremendous patience.

throttle valve

It is installed in the flow part. It looks like a round plate on a rotary axis. Needed to adjust the flow of gasoline through the nozzle. With partial blocking of the channel by the throttle valve, the air speed increases sharply, the rarefaction and the amount of gasoline sprayed in the diffuser by the nozzle increase.

It is allowed to adjust the damper position screw at a minimum and maximum.

air damper

Used to quickly lean the fuel mixture after the start of Calm. The adjustment of the damper position is such that at the time the chainsaw is started, the channel section is blocked. The amount of air at the start must be reduced to enrich the mixture with gasoline vapor.

After starting, the damper rotates parallel to the movement of the air flow, without creating resistance. The same damper adjustment scheme is used if you need to purge the Stihl engine after an unsuccessful start attempt.

There is no other way to remove excess gasoline from the chainsaw cylinder.

Main types of faults

Most of the difficulties in working with Stihl are related to basic problems:

- difficult starting chainsaw;

- unstable operation at idle and in operating mode;

- gasoline is lost or fuel is clearly insufficient.

Sometimes, after a dozen manipulations with the adjustment screws, the Stihl carburetor begins to overflow. You may need to remove the fuel pump.

Chainsaw won't start

Even a rather worn-out Calm, with already reduced compression, should start without additional adjustments. On a cold engine, you need to pull the starter cord a couple of times to blow out everything that is left in the cylinder. Next, close the damper, turn on the power to the candle and spin the flywheel strongly. Calm always starts confidently, without intermediate jerks.

If the Calm does not start, then either the mixture does not enter the cylinder from the carburetor, or the candle is filled with gasoline. In the first case, the membrane or the nozzle valve is to blame. Disassembly is required, the membrane must be changed, the valve must be flushed from engine oil residues. After assembly, you will have to adjust the carburetor for idle speed.

Sometimes, due to dirty gasoline, the filter mesh just sticks, no adjustments are needed, just unscrew the screw, rinse the mesh, put it back in place and try to start Calm again.

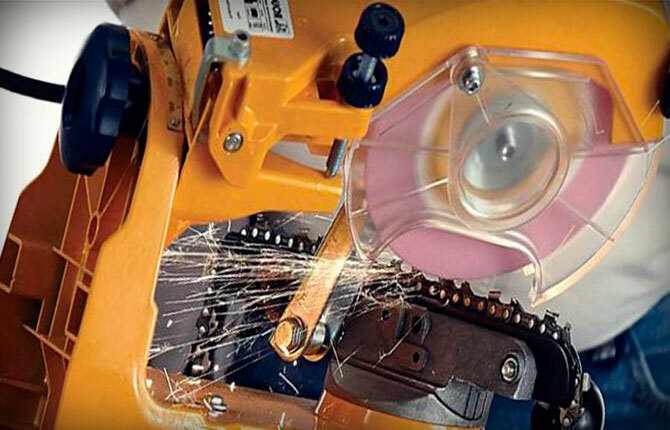

As per video:

RPMs fluctuate at idle

Even on a cold Calm it starts up and works quite steadily at first at high speeds, then it goes to idle. Turnovers can float if the engine has not warmed up enough. The problem is usually with the feed - it is clearly not enough for stable operation.

The first step is to unscrew the screw on the cover and check the filter between the fuel pump and the needle valve. It is possible to blow air through the channel, but be careful not to damage the pump diaphragm.

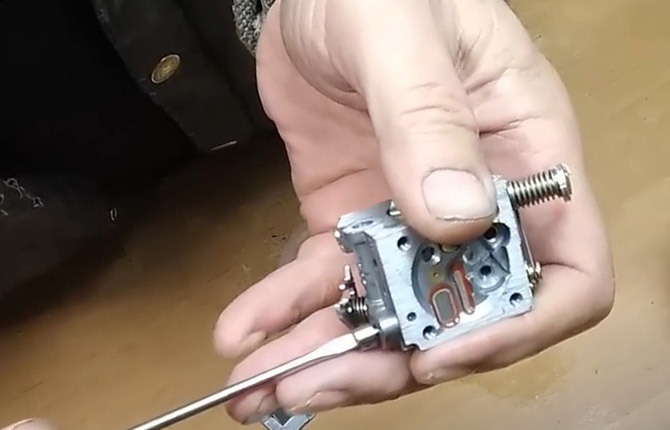

The next step is to check the jet. At idle, you can turn the adjustment screw. The motor should respond with a change in speed. If nothing happens, there is no reaction to the rotation of the screw, then the jet will need to be cleaned.

The scheme is something like this:

- Unscrew the screws and get to the jet.

- It is blown with compressed air from the compressor.

- For a day, the jet is placed in a jar of acetone. Alcohol, gasoline, kerosene, solvents are not suitable.

- After 24 hours, the jet is taken out, and a hole is punched with a sharpened wooden toothpick. Metal cannot be used otherwise the saw carburetor will go for repair.

You can put on a carburetor. After cleaning, you will have to work with the idle screw to adjust the lower speed level on Stihl.

Loss of power, high gas mileage

Another problem is that the carburetor overflows, despite the fact that the adjustment screw is completely wrapped. As a result, fuel consumption almost doubles, in addition, Calm gets very hot and loses power. Even with the choke fully open.

It is impossible to operate a chainsaw in this mode. Despite the protective coating, the piston may burn out. The resource of the candle is almost halved. In addition, overheating often causes deformation of the gaskets and the bearing surface of the carburetor. There is a lateral air leak through the gasket. Now, even if you adjust the increase in speed with the screw, the power of the chainsaw cannot be increased.

The cause is usually a damaged pump diaphragm. If the carburetor is Chinese (with the inscription “China” on the body), then you need to change it unambiguously. After a year or two of operation, it will still become sour under the influence of fuel. We need to look for the owners of the original Calm. The repair kit usually has a spare membrane, so it should be installed instead of the Chinese one. At the same time check for air leaks through the gasket.

The candle will need to be cleaned of soot in the same way as the jets. Cleaning of the electrodes is allowed after soaking in acetone (nail polish remover) only with a wooden chip. Can't be burned.

Also, after overheating, you need to check the operation of the adjustment screws. Sometimes they burn in the thread to the body material.

Stihl 180 chainsaw carburetor adjustment

On the case you can find three screws - "L", "S" and "H". This is not difficult, since all the adjusting screws on the carburetor are marked. The upper and lower speed ceilings are set first and last, their position directly affects the operation of the jet. The "S" screw is used when adjusting the carburetor to adjust the idle.

Next, with a flat-head screwdriver, you need to wrap all three until they stop, but with a minimum tightening force. To start the chainsaw, turn out one and a half to two turns "L", "S" and "H".

Important! The saw can only be adjusted after the engine has warmed up.

After starting, at least 5 minutes must pass, after which the idle speed can be adjusted. First, turning the “S” screw with a screwdriver half a turn left and right, find its position at which the idle speed will be maximum. It must be remembered that the mixture formation system does not immediately respond to a change in flow rate, so turning with a screwdriver must be done slowly enough.

After determining the maximum, it remains only to tighten the screw "S" by ¼ turn.

After adjustment, it is necessary to work with the saw under a load of full heating and once again check the operation at idle.

Adjusting the carburetor of the Stihl chainsaw using the adjustment screws is not as difficult as it can be read in the instructions. The only condition is that you need to use high-quality fuel - A92 with the addition of 5% branded Stihl oil for two-stroke engines.

Tell us about your experience in operating and setting up Stihl chain saws - what features should you pay attention to when setting up a carburetor?