Among the various technological and repair equipment, hydraulic presses still look like a curiosity. By force of habit, they are classified as production equipment used in industry. Actually hydraulic press with electric, manual or pneumatic drive — one of the most demanded tools for repairing cars and transport equipment.

The content of the article:

-

What to look for when choosing

- The main criteria for choosing a hydraulic press

-

Overview of the best hydraulic presses

- AE&T T61210T

- HORDBERG N3630L

- AE&T T61110W

- Ombra OHT611M

- GARWIN 021007-30

- WIEDERKRAFT WDK-HP201

- Trommelberg 50

- Stankoimport SD0881

- Torin TY100001

- Results

What to look for when choosing

Using a modern hydraulic press, you can try to press the juice or glue packages of veneer and boards, but most likely the process will be inefficient. The hydraulic press is slow with a relatively short stroke, so it is clearly not suitable for such operations. To do this, there are lighter manual and electric devices.

The main purpose of the hydraulic press is reduced to four operations:

- straightening and bending of car body parts;

- precise bending or upsetting of new parts in the process of fitting to size;

- creation of press connections of two details from different materials;

- draft bushings, rings, couplings, sleeves with adjustable interference.

The best hydraulic presses make it possible to manufacture (stamp from sheet steel) unique tuning elements for bumpers, wheel covers, wheel arch trim parts and motorcycle tanks. But these are rather single copies, even for small-scale production, industrial-type hydraulic presses are needed.

Two main factors distinguish the repair hydraulic press from grape and fruit crushers (juicers). Firstly, a huge force on the rod, on average from 50 tons to 100 tons. Secondly, this force is adjustable. It is created in a hydraulic chamber by a metered supply of liquid. At any time, the load can be reduced or fixed.

The main criteria for choosing a hydraulic press

Before purchasing a hydraulic press, you need to know exactly for what purposes the equipment is purchased. If in the work plans it will be necessary to constantly press out or press in bearings, dismantle small bushings, shafts, couplings, it is quite possible that a small manual hydraulic press with a working force of up to 10 T.

To straighten bodies, frames and frames welded from I-beams, you will need a floor hydraulic press with a force of 30-50 tons and a stroke of up to 20 cm.

Often, a floor hydraulic press with a force of 60-100 tons is purchased for the workshop. Although 50-60 tons are enough during operation. This solution has rational grain, since the wear of seals and cuffs in a hydraulic press is 40-50% less, respectively, the period of trouble-free operation increases operation.

However, the repair of a 100 ton hydraulic press is more expensive, and such equipment also has a low accuracy of force application. If there is no work experience, then you can easily crush or deform the part.

Hydraulic presses are available in vertical and horizontal versions. The latter option takes up less space in the workshop, it is more convenient to put parts under the punch, but there is an error in the direction of the force, plus the stem seal wears out much faster.

This is useful: How to choose a hydraulic pipe bender.

Overview of the best hydraulic presses

The rod drive can be manual, electrohydraulic or pneumohydraulic. The first option is suitable for any workshop, the share of presses with manual injection of hydraulic fluid accounts for up to 30% of all operations.

Electro-hydraulic, as a rule, require an independent connection of a 3-5 kW electric pump, so a 380 V network is required. Electric versions of hydraulic presses should not be chosen if the power supply is unstable in the area.

Pneumohydraulic pressing equipment is ideal for workshops equipped with a receiver and compressor. The air pressure in the injection part of the press, as a rule, does not exceed 8 atm, and with the help of a valve, you can quickly relieve the force on the rod. The review of the best will include all three options.

AE&T T61210T

The classic version of the desktop hydraulic press of the "window" scheme. There are hydraulic presses of this type in any car repair shop. They are mainly used for assembly and disassembly of chassis units, pressure testing of bearings, engine head liners or repair of shock absorbers. Service life of hydraulic presses type T61210T with timely maintenance and replacement of hydraulic fluid is up to 25 years.

Characteristics:

- weight - 45 kg;

- developed pressure-force - 10 tons;

- height - 80 cm, lifting of the support table - 47 cm.

The design of the hydraulic press is such that in the event of a breakdown of the fluid blower, it can be temporarily replaced with a conventional hydraulic or screw jack - five tons. As a rule, this is enough to finalize before replacing a broken node with a new one.

Disadvantages - a complex arrangement of seals on the rod, with constant operation at maximum effort, hydraulic fluid may leak.

Price - 23 thousand rubles. rub., warranty - 6 months.

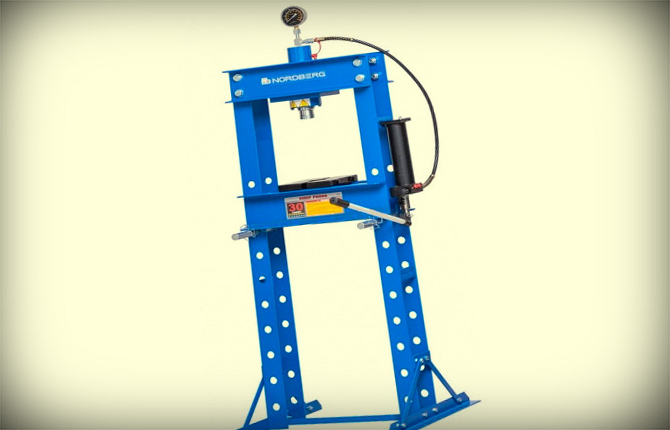

HORDBERG N3630L

Nordberg — not just a position in the ranking of the best models. This is truly one of the best manually pressurized hydraulic floor presses. This is a relatively light equipment, the weight of the hydraulic press — only 150 kg. It can be easily moved within the same room. Developed effort — 30 t, with a stroke of 15 cm. This is quite enough to solve 90% of the problems of repair and restoration of press joints.

Advantages of the N3630L model:

- The convenient location of the manual pump-drive, which supplies hydraulic fluid to the working cylinder. In all other HORDBERG hand presses, as well as in most competitors, the drive is made inconvenient to use.

- Convenient working space under the stem, the support platform can be raised or lowered within 90 cm.

- Easily repaired. You can replace the manual drive and pump the hydraulic fluid within an hour.

- The bed is collapsible on self-centering pins-rods.

This solution is safer to work with. If the rack breaks under load, then the metal of the pin is simply deformed by the shear load. Welded frames and housings are destroyed with the expansion of the weld materials.

The disadvantage is the inconvenient location of the control pressure gauge. It is necessary that the device is in the same field of view as the workpiece and the stem.

The price of a hydraulic press is 65 thousand rubles. rub., guarantee — 12 months

AE&T T61110W

Universal hydraulic press with L-shaped frame. The design was developed in Russia, produced in China. Simple, compact, with a maximum force of up to 10 tons. Weight - 60 kg. The hydraulic press was designed and used primarily for the repair and maintenance of the undercarriage of cars of all models.

Characteristics:

- manual drive with an external high-pressure pump;

- working space (height) - 450 mm;

- stroke of the working rod - 120 mm.

According to users, the force on the drive handle is half that of a conventional hydraulic jack. The only drawback is that a special hydraulic fluid is used in the press injection system. If you work daily, then after a year you will need to change the hydraulics: fluid and seals.

Price - 39 thousand rubles. rub. Warranty - 12 months.

Ombra OHT611M

Garage variant of a desktop type hydraulic press. The frame is welded from structural steel. A jig made of ductile iron is placed directly under the workpiece on the working table. All other parts are made of low alloy steel. The generated force is 10 tons. That is, this is the level of a high-quality hydraulic jack for a truck.

The table can be raised and fixed in three positions. The output of the rod from the cylinder is only 150 mm. In general, the design turned out to be easy to use.

The only disadvantage of the hydraulic press is the small distance between the posts, only 45 cm. This is enough to repair a car, but for any other equipment it is better to choose more powerful presses with a wide working area.

Price — 30 thousand rub., guarantee — 6 months

GARWIN 021007-30

The brand is German, the tool is made in China. Hydraulic press for 30 tons, positioned as a professional. The bed is welded from low-alloy steel. Table material — cast iron with a stainless steel insert. Frame dimensions: height — 210 cm, post spacing — almost a metre. Weight — up to 180 kg.

Externally, in design and shape, the GARWIN 021007-30 hydraulic press practically does not differ from most press equipment with the same characteristics. Many users note that Garmin has a lot of “pleasant” little things, such as convenient table height adjustment, hardened mounting pins, and a fairly fast hydraulic rod stroke. All this makes working on a hydraulic press more comfortable and safer.

The cost is 85 thousand rubles. rub. with 12 months warranty.

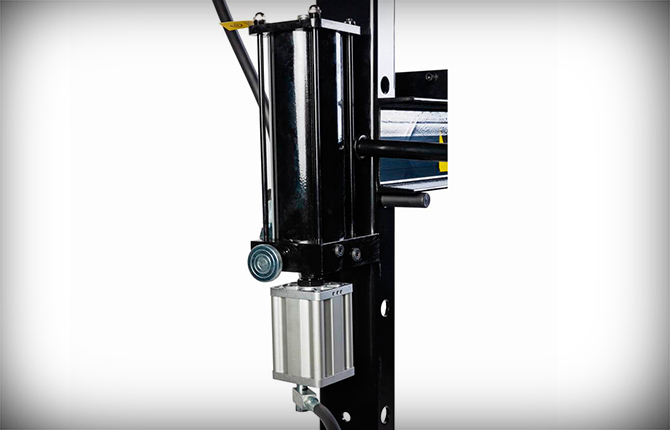

WIEDERKRAFT WDK-HP201

Popular model of a hydraulic press with the pneumatic booster. Designed in Germany but manufactured in China. The use of a pneumohydraulic drive makes it possible to significantly accelerate the rod during lowering onto a pressed part or surface. For a hydraulic press, you only need to connect an external compressed air source. It can be a conventional compressor with an 8 atm receiver.

Model Benefits WIEDERKRAFT WDK-HP201:

- relatively small weight - 90 kg, for manual hydraulic presses, the total weight of the structure is 120-130 kg;

- fast lifting of the piston and rod, it takes 2-3 times less time to remove the part from the press table than on a simple hydraulic machine.

There is an automatic safety valve. Fluid will be released into the return chamber if there is a sudden pressure drop in the cavity above the piston. Type models WIEDERKRAFT WDK-HP201 can be used for inline machining of parts. Such a scheme is often used in large car repair shops, where the number of the same type of pressing-pressing operations can reach several hundred per shift.

The disadvantage is the rapid contamination of the hydraulic fluid with dust and water vapor from the air. Therefore, it is recommended to connect the air line through an oil/water separator.

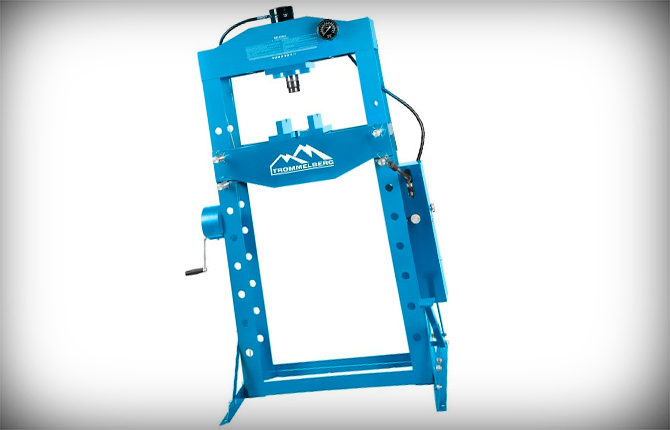

Trommelberg 50

The design of a well-known manufacturer of power equipment. In this case, a model with a manual drive and a huge (as for a simple scheme) pressing force — 50 tons

Equipment characteristics:

- weight — 264 kg;

- limit force on the rod - 50 tons;

- limit output of the working rod - 120 mm;

- the position of the desktop on the frame can be adjusted from 8 cm to 106 cm.

The pumping of hydraulic fluid into the working cylinder is carried out by a hand pump SD200850 Dual Speed: dFor fast feed and precise stem movement. A manometer is installed on the cross member, closer to the right column on the pump drive side. When the master works with the pump handle, pumping liquid into the press chamber, the pressure gauge is in front of his eyes. It is impossible to make a mistake in the applied effort.

For most automotive repair tasks, this is more than enough, so the model Trommelberg 50 may seem too expensive, heavy and inefficient. In fact, this is a press with increased accuracy of the upsetting of the parts to be joined.

By manual feed, you can adjust the force and accuracy of movement with an accuracy of 0.5 mm. As a result, the quality of pressing in critical parts is perfect. Therefore, when assembling engines, it is usually recommended to use a press Trommelberg 50, although in terms of the amount of force applied, it was possible to use a 20 ton hydraulic pump with an air drive.

Price - 160 thousand rubles. rub., warranty - 6 months.

Stankoimport SD0881

Hydraulic press of the Russian brand "Stankoimport ”, designs for more than two decades, and during this time the popularity of the hydraulic press has only increased. Not least due to the fact that the main production of equipment was located in Taiwan.

This model is a classic version of a hydraulic press with an electric pump that supplies the working fluid to the chamber with a rod. For the drive, an electric motor with 3500 W to 380 V is used. That is, such a drive provides a very fast lowering and raising of the rod. The press is designed for high productivity.

Characteristics:

- weight - 360 kg;

- force - 50 tons;

- piston-rod stroke is 200 mm;

- table 70 cm wide.

The increased working space allows you to place blocks of motors or even continuous axles from SUVs and trucks on the press. In general, the accuracy and reliability of the mechanism is enough to work in a garage or car repair shop.

High price - 350 thousand rubles. rub., the warranty for the press can be extended by the manufacturer up to a lifetime under a separate agreement.

Torin TY100001

The press is completely designed and manufactured in China by TORIN. It is clear that the company's engineers did not develop or optimize anything, but only borrowed the best solutions from the most popular models of European brands. Nevertheless, the press turned out to be quite reliable.

Characteristics:

- the force developed on the rod is 50 tons. This is enough for a small car repair shop that repairs the chassis and engines of cars and trucks;

- stroke - 200 mm;

- manual pneumohydraulic drive;

- the press weighs 293 kg.

The bed can be raised by 90 cm. The increased distance between the posts and a wide range of table positioning heights makes it possible to work with almost any components and mechanisms of modern cars.

Stainless steel hydraulic cylinder, nickel plated piston and 0.8mm thick zinc plated rod. In addition, the mechanism uses a double seal of the stem and air chamber with rings made of wear-resistant polyurethane.

It is actuated by a handle, but not liquid, but air is injected into the cylinder. You have to do an additional amount of “pumping” with the handle, but the rod comes out and returns to its place much faster than with conventional hydraulic models. You can not connect the press to the pneumatic line.

You can also note a convenient dial gauge with a white scale. It is larger than traditional instruments that show effort in tons. There are smaller divisions, so the press is easier to control by the force on the rod.

Price - 175 thousand rubles. rub. Warranty - 1 year.

This is useful: Press tongs for metal-plastic pipes.

Results

Choosing the best press is not difficult if you know exactly what tasks the equipment is purchased for. Most of the models from the top of the most popular are similar to each other and differ only in the drive scheme, force and frame dimensions. Therefore, it is almost impossible to get confused in different models.

Tell us about your experience with hydraulic presses. Which of them, in your opinion, turned out to be the most convenient to work with? Write comments, bookmark the article and share it on social networks.