Careful attitude to energy resources is dictated primarily by the fact that almost all natural reserves are not endless. Economical consumption of all types of fuel requires the development of new systems or a radical modernization of existing ones.

So, a gas boiler with an electric generator is one of the types of hybrid systems that allow you to reasonably manage blue fuel. We will introduce you to the principle of operation of equipment that generates electrical energy along with thermal energy. Let's imagine typical models of hybrid units.

The content of the article:

- Efficient energy consumption

- Overview of manufacturers of boilers with a generator

- Boiler efficiency comparison

- Profitability of the considered systems

- Conclusions and useful video on the topic

Efficient energy consumption

Even an ordinary layman who has a gas boiler installed for heating his home may wonder about the rationality of using thermal energy. Indeed, when burning gas in a boiler, not all of the heat generated is used.

Always during the operation of the heating system, some part of the heat is irretrievably lost. This usually happens when combustion products are released from the boiler into the atmosphere. In fact, this is the lost energy, which could be used.

What exactly are we talking about? On the possibility of using wasted "ejected" heat in the production of electrical energy.

Assuming that the heating boiler system is already optimized in order to maximize efficiency, then The “ejected” energy still makes up a significant fraction of the energy that is released during combustion fuel

The types of fuel can be different, starting with banal firewood and all kinds of briquettes, ending with the most economical options: main gas with a predominance of methane in the composition, artificial blue fuel and propane-butane liquefied mixtures.

It may seem that this is far from the “discovery of America”, but in fact, the technology developed back in 1943 by Robert Stirling, or rather, the installation exists. Its design features and the basic principle of operation make it possible to classify this system as an internal combustion engine.

Why, then, was this installation not used for such a considerable time? The answer is simple - the theoretical development of technology in the forties of the last century turned out to be very cumbersome in practice.

The technologies and materials that existed at the time of development did not allow to reduce the size of the installation, and the existing methods of generating electrical energy were more cost-effective.

The inclusion in the scheme of a gas boiler of a device that converts uselessly consumed heat into electricity can significantly increase the efficiency of a gas processing plant

What can make us today think about a more careful attitude to resources that are not renewable? Now all over the world there is a common problem - the development of technology inevitably leads to an increase in the consumption of electrical energy.

The increase in consumption is taking place at such a rapid pace that grid companies do not have time to modernize the transmission systems of electrical energy, not to mention production. This situation inevitably leads to the fact that the elements of power supply systems fail, and in some cases this can happen with enviable regularity.

Modern heating boilers are equipped with control systems that are also volatile. The circulation pump, sensors, automation, the panel itself need power. The entire set of devices cannot but cause concern for the preservation of performance during a power outage.

Forced heating systems cannot be started without electricity. A power outage during the heating season is almost catastrophic for them. Not only will this inevitably lead to rapid cooling of the room, but with a long idle heating, the circuit may freeze.

Prolonged lack of operation of the heating system in the cold season leads to freezing of the system heating, to the appearance of ice plugs in it and, as a result, to damage to equipment and heating pipes due to gap

Standard existing solutions to the issue - installation uninterruptible power supplies, generators of various modifications (gas, gasoline, diesel generators or non-traditional sources - wind turbines or mini thermal power plants, hydroelectric power stations).

But this solution path is far from acceptable for everyone, since it is difficult for many to allocate space for installing an autonomous electricity supplier.

If residents of individual houses can still allocate space for a generator, then this is almost impossible for installation in a multi-storey building. Thus, it turns out that residents of apartment buildings with an individual heating system are the first to suffer when the power goes out.

That is why, first of all, companies producing components for assembling heating systems asked themselves the question of the full use of heat that is “thrown out” by the heating system. We thought about how to use the wasted substance in the generation of electricity.

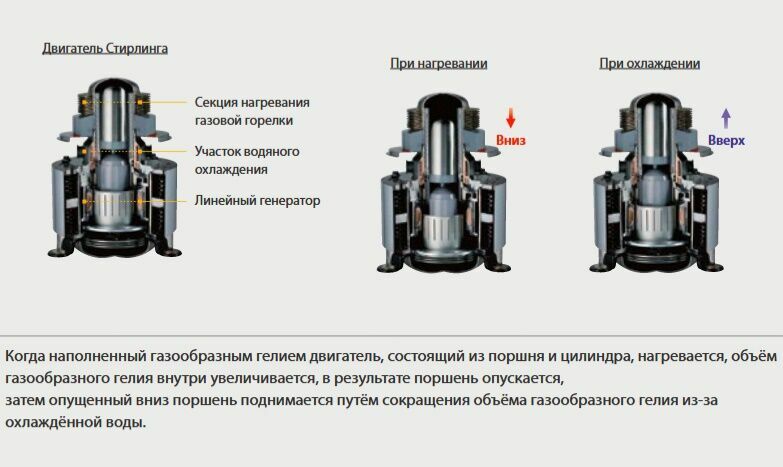

Of the well-known technologies, the developers have chosen the “well-forgotten” Stirling installation, modern technologies make it possible to increase its efficiency while maintaining its compact size.

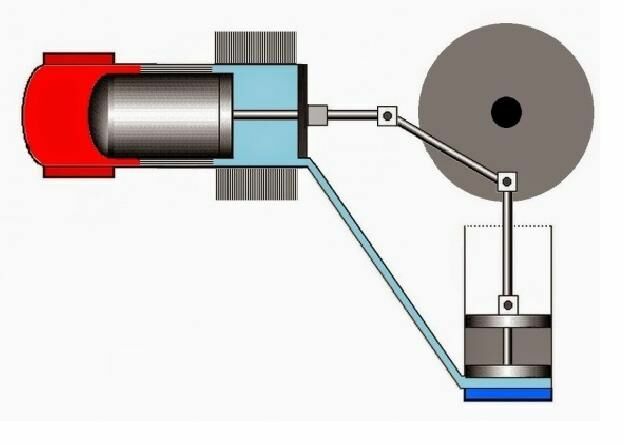

The principle of operation of the Stirling engine is the movement of the engine piston up and down. The motor runs almost silently and does not cause machine vibrations.

The principle of operation of the Stirling plant is based on the use of heating and cooling of the working fluid, which in turn drives a mechanism that generates electrical energy.

The injected gas is located inside the (closed) piston; when heated, the gaseous medium expands and moves the piston in one direction, after cooling in the cooler, it contracts and moves the piston in the other direction side.

Overview of manufacturers of boilers with a generator

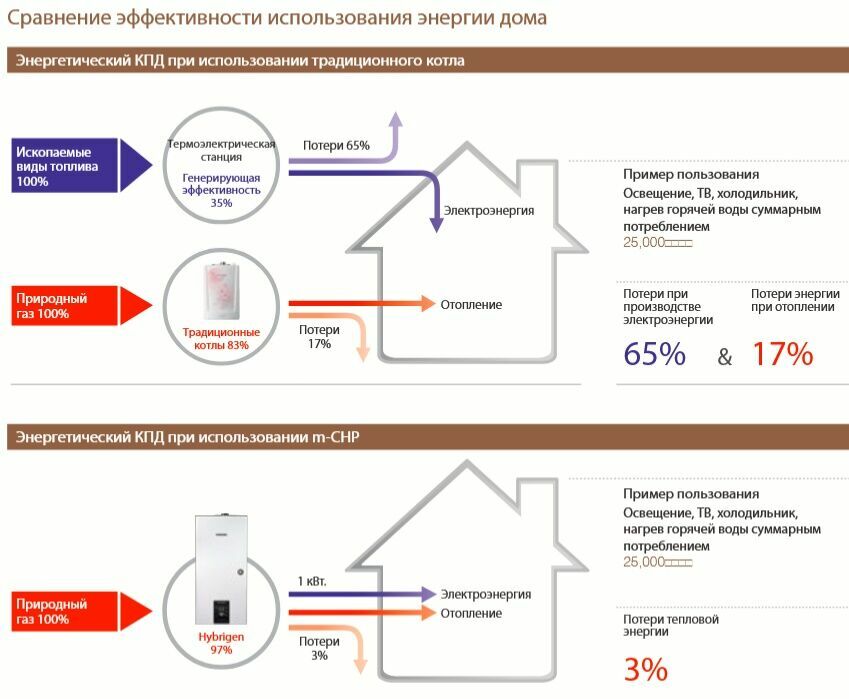

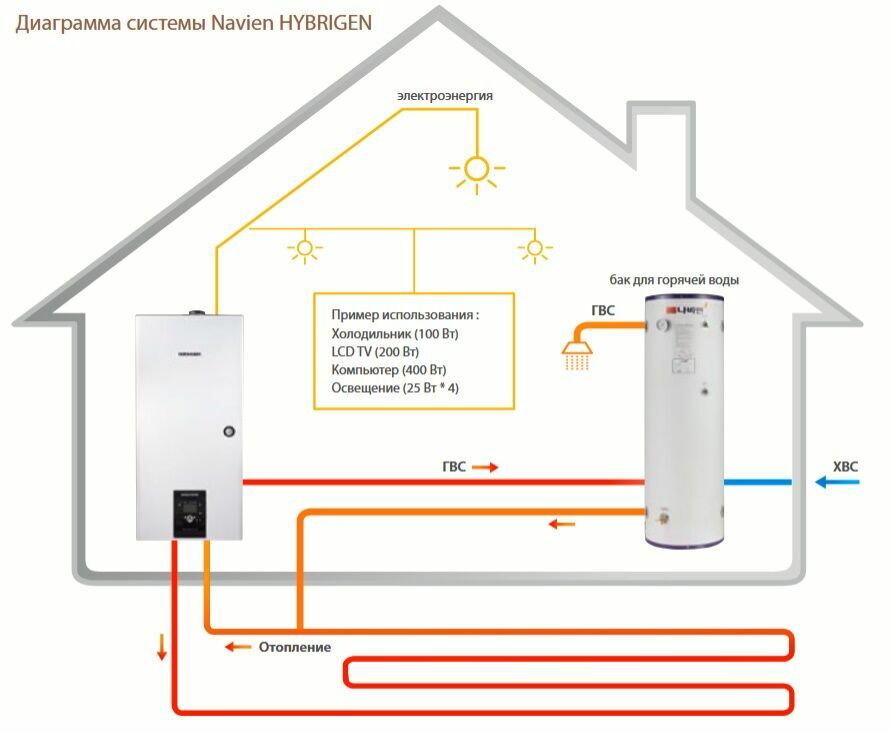

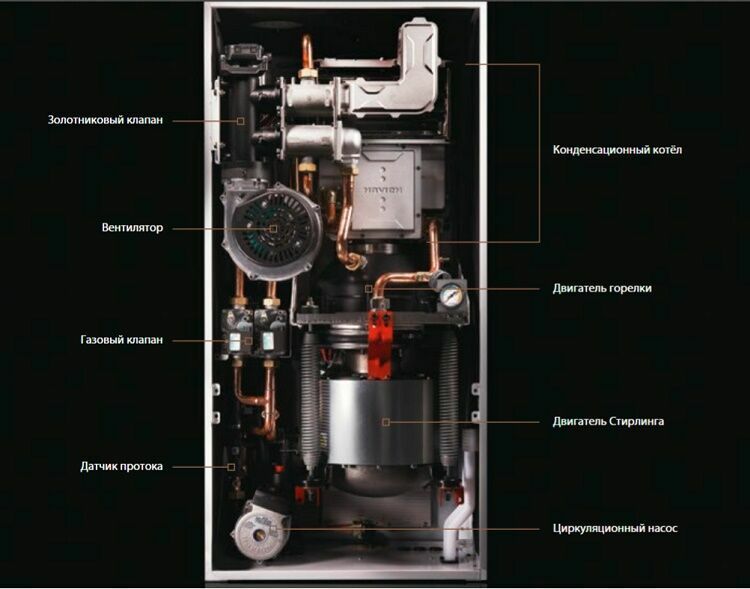

Let us consider specific examples of the system of household boilers that exist today, in which the principle of using exhaust gases (combustion products) to generate electricity has been successfully implemented. The South Korean company NAVIEN has successfully implemented the above technology in a HYBRIGEN SE boiler.

The boiler uses a Stirling engine, which, according to the passport data, generates electricity with a power of 1000W (or 1kW) and a voltage of 12V during operation. The developers claim that the generated electricity can be used to power household appliances.

This power should be enough to power a household refrigerator (about 0.1 kW), a personal computer (about 0.4kW), LCD TV (about 0.2kW) and up to 12 LED bulbs with a power of 25W each each.

Navien hybrigen se boiler with built-in generator and Stirling engine. During the operation of the boiler, in addition to the main functions, electricity is generated of the order of 1000 W of power

Of the European manufacturers, Viessmann is engaged in developments in this direction. Viessmann has the opportunity to offer two models of boilers of the Vitotwin 300W and Vitotwin 350F series to the customer's choice.

The Vitotwin 300W was the first development in this direction. It has a fairly compact design and looks very similar to the usual wall mounted gas boiler. True, it was during the operation of the first model that the “weak” points in the operation of the Stirling system engine were identified.

The biggest problem turned out to be heat dissipation, the basis of the operation of the device is heating and cooling. Those. developers faced the same problem that Stirling faced in the forties of the last century - effective cooling, which can only be achieved with significant sizes cooler.

That is why the Vitotwin 350F boiler model appeared, which included not only a gas boiler with an electricity generator, but also a built-in 175l boiler.

The storage tank for hot water is made in the floor version due to the large weight of both the equipment itself and the liquid prepared for sanitary purposes

In this case, the problem of cooling the piston of the Stirling plant due to water in boiler. However, the decision led to the fact that the overall dimensions and weight of the installation increased. Such a system can no longer be mounted on the wall like a conventional gas boiler and can only be floor-standing.

Viessmann boilers provide for the possibility of feeding the boiler operation systems from an external source, i.e. from the central power supply networks. Viessmann positioned the equipment as a device that provides for its own needs (the operation of boiler units) without the possibility of extracting excess electricity for domestic consumption.

The Vitotwin F350 system is a boiler with a 175l water heating boiler. The system allows you to heat the room, provides hot water and generates electricity

In order to compare the efficiency of using generators built into the heating system. It is worth considering the boiler, which was developed by the TERMOFOR companies (Republic of Belarus) and the Krioterm company (Russia, Minsk). Saint Petersburg).

It is worth considering them not because they can somehow compete with the above systems, but to compare the principles of operation and the efficiency of generating electrical energy. These boilers use only wood as fuel, pressed sawdust or wood-based briquettes, so they cannot be put on a par with models from NAVIEN and Viessmann.

The boiler, named "Indigirka Heating Stove", is oriented to long-term heating with wood, etc., but is equipped with two thermal electricity generators of the TEG 30-12 type. They are located on the side wall of the unit. The power of the generators is small, i.e. in total they are only able to generate 50-60W at 12V.

The fundamental device of the Indigirka stove allows not only to heat the room, but also to cook food on the burner. The addition of the system is two 12V heat generators with a power of 50-60W.

In this boiler, the Zebek method, based on the formation of an EMF in a closed electrical circuit, has found application. It consists of two dissimilar types of material and maintains contact points at different temperatures. Those. developers also use the heat generated by the boiler to generate electrical energy.

Boiler efficiency comparison

Comparing the presented types of boilers, which not only heat the room (heat coolant), but also generate electricity by using the generated heat, you should pay attention to important aspects during operation.

Both NAVIEN and Viessmann position their boilers pointing to undeniable advantages - full automation process, no need for service repairs and, in general, the complete absence of intervention after commissioning by buyer.

For the operation of these boilers, only the stable operation of the system is needed, the stable availability of gas (whether it be main supplies, a bottled installation with liquefied gas or gas tank). Accordingly, household gas is used for the operation of boilers, which, after combustion, does not pose any harm to the environment.

In principle, almost the same can be said about the Indigirka heating stove, only the type of fuel here is not gas, but firewood, pellets or pressed sawdust.

Complete absence automationwhich requires electricity. The system for generating electrical energy and the boiler itself do not affect each other's operation, i.e. if the power generation system fails, the boiler continues to perform its functions.

All these gas-processing heating units, with Stirling engines under the burners, produce electrical energy that can be used for various purposes.

Boilers of NAVIEN and Viessmann companies will not be able to "boast" of this, since the Stirling system engine is built directly into the design of the boiler. But how profitable are such systems and how long will such a boiler pay off? This issue needs to be dealt with in detail.

Profitability of the considered systems

At first glance, the boilers of NAVIEN and Viessmann are practically mini-CHPs in a private house or even an apartment.

Even despite the large overall dimensions, the ability to produce electrical energy simply by using boiler for heating a boiler or space heating should encourage the buyer to install such a “miracle” without hesitation technology."

But upon closer examination of the NAVIEN boiler, questions arise that need to be answered. With a declared power of 1 kW (free power that can be used at your discretion), the boiler consumes quite a lot of electricity during system operation.

What is meant? At a minimum, the operation of automation, even if a small amount of power is needed, but it is needed in order for the fan and circulation pump to function. The listed devices in total can not only successfully consume this kilowatt of energy, but it may not be enough when “overclocking” the system.

Schematic diagram of the Vissmann Vitotwin 350F heating system with a 175l floor standing boiler. The system allows both the use of electricity from an external source and the transfer of excess electricity generated to the general grid.

Exactly the same questions arise regarding Viessmann's boilers, but here at least the possibility of extracting electricity for their own needs was not declared. Only the possibility of autonomous operation of the system in the absence of external supply was stipulated.

Although the developers immediately indicate that "the system may require additional electrical power at peak loads." Against the background of the declared 3500 kWh of electricity produced per year, this nuance is already in doubt, and by simple and simple calculations we get the following:

3500:6 (months of the standard heating season): 30 (30 calendar days on average): 24 (24 hours per day) = 0.81 kWh.

Those. the boiler produces about 800W during stable (constant) operation, but how much does the system itself consume during operation? Perhaps the same, produced by 800W, and possibly more.

In addition, electricity is generated only during the operation of the burner. Those. either constant operation of the system is required, or everything is a little different, as the system developers say.

What were these calculations? The wood-burning boiler system really gives out its 50Wh (or 0.05kWh), which can be used to recharge a tablet, phone, etc. even for the banal “duty LED light bulb”. As opposed to the development of two world-famous companies, but the described developments clearly look more like a good marketing ploy, and nothing more.

As for the pricing policy for these systems, it's generally difficult to evaluate something. Since even the manufacturers Viessmann and NAVIEN immediately stipulate that the equipment "does not require maintenance." Translated into simple language - it broke, which means that the unit needs to be completely replaced.

This may not apply to the entire system, but to individual components: Stirling engine, gas burner system, etc. The result will be quite an impressive amount. Based on the fact that the average price for these systems is about 12 thousand rubles. euro or 13.5 thousand. $. The scheme of operation of a boiler with a generator, then only the manufacturer of the systems can win in such a situation.

The Indigirka stove cannot participate in the comparison at all, not only because the type of fuel is not gas, but the price is not comparable (15 times less), but because the stove is positioned not for domestic use, but more for travel, expeditions and etc.

If in Europe the situation with energy carriers significantly affects the choice of the consumer (when choosing heating systems or energy supply) in terms of economy and environmental friendliness, the EU states stimulate this by subsidizing the introduction such systems.

For a domestic consumer in Russia, such systems are likely to be too expensive both initially “system + installation” and during operation.

Conclusions and useful video on the topic

The principle of operation of the Stirling engine that equips the gas boiler:

Demonstration of the operation of a gas boiler with an electricity generator:

An example of a wood stove with an electricity generator for comparison with a gas unit:

Do not forget that European energy generating companies are quite loyal to the "manufacturers" of energy-saving equipment.

In Russia, the possibility of generating and transmitting electrical energy to the grid by a household consumer is not only not fixed by law, but is also not welcomed by grid companies. Therefore, the presented systems are unlikely to have serious chances for application in the conditions of the Russian Federation today.

Please comment on the article submitted for consideration in the block form below, ask questions, post photos on the topic. Tell us about whether you are familiar with boilers with power generating systems. Share useful information that will be useful to site visitors.