Insulation of slopes of plastic windows from the outside is usually done using expanded polystyrene or foam. Another option is to fill the cavities with mounting foam and then install the sandwich panels. A description of the main methods of thermal insulation and step-by-step installation instructions can be found in this material.

The content of the article

- Warming methods

- Preparation for work

- Step-by-step instruction

Warming methods

To protect against cold and drafts, in most cases, heat-insulating materials are used, although plaster can also be used. The main methods are:

- The use of foam - the material is quite light, affordable, practically does not let air through, therefore it effectively retains heat. It is produced in convenient blocks that can be cut to any size. Although it fades in the sun, it is therefore not very durable in the case of windows.

- The most common technology is window decoration from the outside with polystyrene foam. The material is resistant to moisture, sun rays, temperature extremes and decay. It costs more than foam plastic, but it protects better from the cold and is also more durable.

- Insulation of window openings in a simple case can be done using mounting foam. It simply fills all the voids in the space under the window. It is applied in small portions, in several layers, so that the thickness of the insulating layer is 3-3.5 cm.

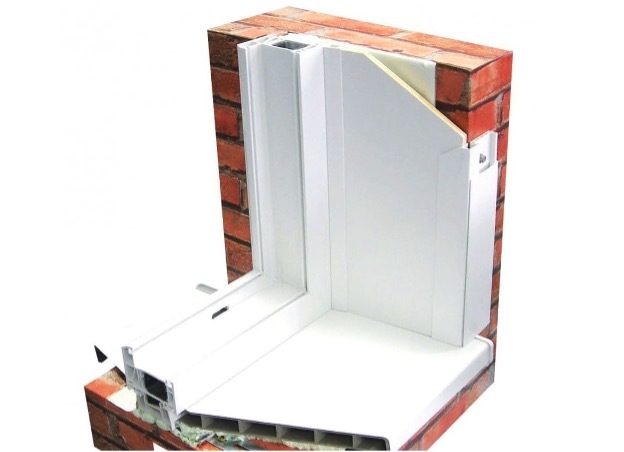

- Insulation of slopes by installing sandwich panels is a more reliable and aesthetic method, and it is suitable for both exterior and interior decoration. You can also install panels after processing with mounting foam - then the effect of thermal insulation will be maximum.

- Insulation of slopes from the outside is sometimes done with basalt wool. It not only protects from the cold, but also passes moisture well, i.e. it is a breathable material. However, its use is possible only with good waterproofing, because due to the ingress of water drops, cotton wool is quickly destroyed.

- Plastering allows you to fill all the voids and form a solid frame. The material is resistant to temperature, sunlight and moisture. As a rule, plaster is covered with paint on top. But if the windows are insulated from the outside with decorative plaster, finishing painting is not required.

- Finally, sometimes fiberglass is used for thermal insulation. It is compact, reliably protects from frost, resistant to moisture and temperature extremes. But the installation of such material is more complicated and requires certain skills.

Preparation for work

Regardless of the material chosen, for example, foam or polystyrene slopes, you first need to carry out preparatory work:

- The places of blowing with a lit candle are determined (they look at where the flame fluctuates with the door tightly closed).

- The surface is cleaned.

- Seal the seams inside and out.

- They are convinced of the quality of sealing - otherwise they close up the cavities with the help of mounting foam.

To proceed to the main stage and make foam slopes, tools are also prepared:

- hacksaw;

- construction roulette;

- brushes;

- spatulas;

- a knife with a sharp blade (can be stationery);

- construction level;

- perforator;

- miter box.

- mask, gloves;

- marker.

Step-by-step instruction

Insulation of window slopes is carried out in several stages:

- The cleaned surface is treated with a prepared cement mixture to obtain a flat plane.

- When the cement dries, measurements are taken and the material is cut into fragments of appropriate sizes.

- Insulation of window slopes from the outside is usually made of expanded polystyrene. The fragments are put on glue (with a layer of 2-3 mm), and then reinforced with dowels.

- Now you need to install the corners so that the surface is even.

- Outside, a special glue is applied to the insulator, on which the reinforcing mesh is fixed.

- Then the layer is leveled with putty composition.

- To make the slopes of polystyrene foam look beautiful, they are painted with water-based paint or other materials are used for cladding.

It is not very difficult to perform slope insulation, but for this it is important to choose the right material. During installation, carefully prepare the surface, cleaning it from dirt, taking measurements and fixing the insulation with glue and dowels. If the installation is done with high quality, the material will last for several years.