It is not always possible to say unequivocally which is better - metal-plastic or polypropylene, since each material has its pros and cons. In general, metal-plastic is more reliable, but it costs significantly more. A visual comparison of the advantages and disadvantages can be seen below.

The content of the article

- Comparison table

- Metal-plastic: advantages and disadvantages

- Polypropylene: types, advantages and disadvantages

Comparison table

When choosing a metal-plastic or polypropylene for water supply, it is initially recommended to study the technical characteristics of each material. A visual comparison of the most important parameters is presented in the table.

| Characteristic | metal-plastic | Polypropylene |

| pressure resistance | 10 atmospheres | |

| Maximum allowable toC of water | +95оС | +75оС |

| Permissible increase in toC* | +110оС | +95оС |

| Operational period in cold water | over 50 years | 50 years |

| Service life in hot water supply | 50 years | 25 years |

| Price | expensive | cheaper |

| Ease of installation | less convenient | More comfortable |

*only for a short time

Metal-plastic: advantages and disadvantages

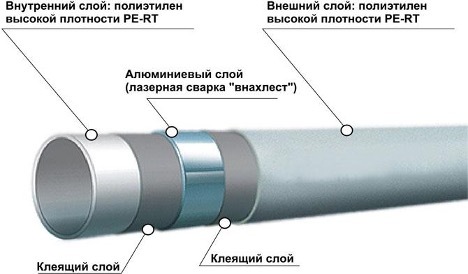

In order to understand in detail what is better - metal-plastic or polypropylene, you must also take into account the features of the products, their real pros and cons. So, metal-plastic, in fact, is also polypropylene. But unlike it, it is reinforced with a special aluminum layer sewn with the rest of the special glue, as shown in the diagram.

Thanks to the aluminum insert, such a pipe acquires several important advantages:

- Strong thermal expansion during heating is compensated, the risks of deformation are reduced. In this regard, it is easy to understand which is better - polypropylene or metal-plastic pipes. The latter option is more practical, since it can withstand even high temperatures up to + 95 ° C - almost boiling water.

- A diffusion barrier is formed that prevents the penetration of oxygen into the heating circuit. As a result, the service life of both pipes and radiators is increased - they suffer less from corrosion.

- The appearance of stray currents is excluded. But in this sense there is no difference between metal-plastic pipes or polypropylene pipes. Both types of products have this advantage.

- The internal surfaces are 100% smooth, which eliminates the accumulation of blockages. Considering which is better - metal-plastic or polypropylene for heating, by this criterion, again, you can choose both options.

- Since the material is multi-layered, it ensures quiet operation. Water flows are almost inaudible, even if there is a fairly powerful stream.

- If you choose a metal-plastic or polypropylene purely for the price, you should keep in mind that the first option is much more expensive. On the other hand, it is also more durable.

When studying which pipes are better - polypropylene or metal-plastic, one should not forget the shortcomings of the metal. In fact, it has its drawbacks, some of which can become very noticeable:

- It is impossible to operate such pipes at negative temperatures, because under these conditions the material quickly collapses, an emergency situation is possible.

- If you use a threaded connection, the cross-sectional area decreases - accordingly, the volume of passing water per unit time also decreases.

- Assessing which is better - metal-plastic or polypropylene for plumbing, you need to take into account that the polymer is badly affected by direct sunlight. On the other hand, this disadvantage is inherent in both materials.

- In rare cases, even metal-plastic can be deformed due to temperature effects. But this minus is easy to compensate for by tightening the fittings.

Polypropylene: types, advantages and disadvantages

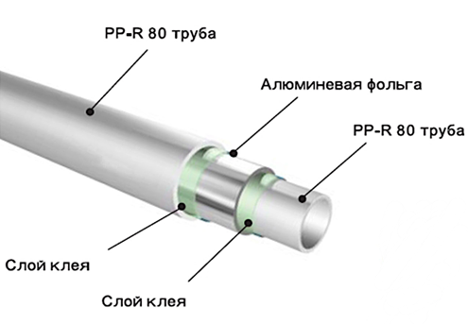

If you choose metal-plastic pipes or polypropylene pipes for plumbing, you need to study the features of each material. Unlike metal, polypropylene is a monolithic pipe. It does not have layers as such, but sometimes the product is reinforced with foil, which is directly soldered into the plastic.

If we consider plastic or metal-plastic for plumbing, you will also need to study the types of pipes. The main classification is related to the conditions under which pipes can be used, that is, how much they can withstand certain temperatures and pressures. Depending on this, they are assigned the appropriate marking:

- PN10 - operate at a pressure within 1 MPa, are intended only for supplying cold water or for underfloor heating. A comparison of metal-plastic and polypropylene pipes shows that this option is of limited use.

- PN16 - limitation on working pressure up to 1.6 MPa. Such pipes can be used to supply cold water, as well as hot, but with a temperature limit of up to + 60 ° C. In this regard, it is clear what to install - plastic pipes or metal-plastic ones. Metal is more practical, because it can withstand even boiling water.

- PN20 – can cope with pressure within 2 MPa. At the same time, they are more resistant to hot water - the upper limit is + 80 ° C. Therefore, such products can also be used both for cold liquid and for coolant when supplied to batteries.

-

P25 - work at a pressure within 2.5 MPa. The most resistant type of pipes, since it is designed for temperatures up to + 95 ° C. The reason is that these pipes have an aluminum layer that is closer to the outer surface. In this case, there is no doubt that it is more reliable - metal-plastic or polypropylene: products from both are quite durable.

When studying what is better for heating - metal-plastic or polypropylene, it is advisable to consider the positive and negative characteristics of the latter. Of the obvious advantages, the following can be distinguished:

- Durability, minimal risk of corrosion.

- Resistance to pressure drops, mechanical stress - metal-plastic or polypropylene in this sense are approximately the same.

- The smooth surface on the inside prevents clogging. According to this criterion, there are also no differences, which is better - propylene or metal-plastic.

- Even if the water is flowing intensively (for example, an apartment on the ground floor), the noise is almost inaudible.

- The joints are completely sealed, leaks are excluded (subject to proper installation).

- Low thermal conductivity - low heat loss.

- If necessary, you can perform hidden installation.

- The material is rigid, but even if deformation occurs, it is quite maintainable.

But if you carefully study which is better - metal-plastic or polypropylene for water supply, one cannot fail to mention the disadvantages of the latter:

- Not all types of pipes can withstand high temperatures close to + 100 ° C.

- Installation is rather complicated, although in the case of metal-plastic it is even less convenient due to the less flexibility of the pipes.

- The material is combustible.

- All polymers are sensitive to sunlight.

From this review it is clear which is better - metal-plastic or polypropylene for water supply. We can say that both materials are quite good and durable. But metal-plastic still wins due to the reinforcing layer of aluminum. Although it costs more, the investment will pay off due to the long service life.