Types of cutters depend on the area of their use. Tools are divided into several groups, for example, household and professional, for wood, metal and plastic. The main division criteria and parameters that you should pay attention to when choosing a router are described in the article.

The content of the article

- Milling cutter classification

-

Criteria for choosing a router

- Power

- Working stroke of the cutter

- Rotational speed

- Overload protection

- Protection against unintentional start

- Electronic speed control

Milling cutter classification

Types of cutters for wood are classified according to different criteria. The most important parameter is the scope. So, some tools are universal, while others are highly specialized. Most often in practice, the following types are used:

- The submersible (also rod) milling cutter is used everywhere for different types of work. Convenient and practical, it is used by experienced and novice carpenters. Needed to create grooves, rounded areas, also used for chamfering.

- Edging is designed for chamfering. Also with its help, recesses of small depth, a selection of grooves are formed. It is used for working with laminated parts or blanks covered with veneer. This tool is not used in everyday life, more often it is used in woodworking enterprises.

- The planer for jointing with a manual wood router is equipped with several knives for leveling the surface. Used on hard and soft woods.

- Rotary - a tool used in construction for processing edges. It is also used to make holes in wood and other materials, such as plastic.

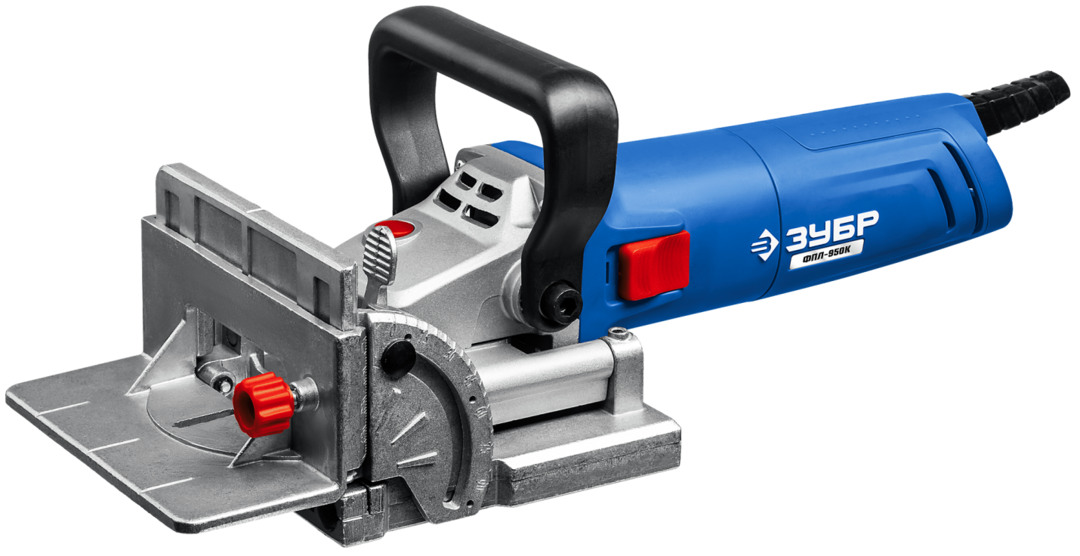

- Filler - a specialized tool for creating paired holes. With their help, the parts are connected to each other. Often used in the manufacture of furniture.

- Lamella - another special purpose cutter. Used to create recesses for grooves.

You can also divide the tools depending on what material they work on. So, there is a metal cutter for a manual router, there are cutters for wood and plastic.

Criteria for choosing a router

Of great importance is which cutters for the router are used. But no less important are the criteria by which the device should be selected. There are several such parameters - they are described in detail below.

Power

It depends on the power how efficiently the equipment will work. The indicator also affects the length of the cutter. According to this criterion, 3 types of router are distinguished:

- Lightweight - power within 750 W, while the tool weighs up to 3 kg.

- Medium - the power increases to 1.5 kW, and the weight is within 5 kg.

- Heavy - can develop power up to 2.3 kW, while weighing more than 6 kg.

For use in everyday life, it is quite enough to purchase a device of a light or medium class. For professional purposes, such as a wood splicer for a hand router, heavy tools are used. With their help, you can cut spikes, process the surface, prepare holes for the grooves. They also allow you to splice wood according to a certain parameter (length, thickness or width).

Important

Beginning carpenters often chase power, believing that the larger this parameter, the better. But for domestic purposes, a device with a power of up to 1.5 kW is suitable. A device with higher performance costs much more, besides, it is noticeably heavier.

Working stroke of the cutter

A wood cutter for leveling the surface is selected taking into account various parameters, including the working stroke. This is an important indicator that characterizes how deeply the tool penetrates the part. For domestic use, from 20 to 50 mm is sufficient. And for professional cutters, the minimum requirement is 50 mm. Often used and tools that penetrate 80 mm or more.

It is impossible to adjust the working stroke for household appliances, but professional ones have such a function. To do this, the tools are equipped with a regulator that allows you to set a step of 0.1 mm. Such accuracy is quite enough even for processing thin details.

Rotational speed

If we talk about what cutters are, it is worth mentioning the speed of rotation. The quality of wood processing depends on this indicator. There are 3 types:

- The standard speed is in the range of 20000-30000 rpm. It is these milling cutters that are most often used in practice.

- Slow is a speed within 20,000 rpm. It is used for plastic parts.

- High - more than 35,000 rpm.

For inexpensive tools used in everyday life, you cannot adjust the speed. A similar option is available for instruments with a higher price. Moreover, if it is supposed to work only with wood, the adjustment function is not needed.

Overload protection

We can say about the cutter that it is a tool with rapidly rotating cutters. In intensive use, they can overheat. This is protected by an automatic shutdown system. It is equipped with only professional equipment.

Protection against unintentional start

This is a fuse that insures against a dangerous situation of accidental start-up of the equipment. Almost all types of wood cutters for a manual router have it.

Electronic speed control

An additional option that is equipped with professional tools. Allows you to maintain the desired number of revolutions, regardless of how dense the wood will be.

Thus, the types of cutters depend on the material with which they work, as well as on the scope. In order for them to work as efficiently as possible, you need to purchase a suitable milling cutter. To do this, the devices are compared according to several indicators and the best option is selected.