“A snow blower is an indispensable thing in winter,” every private trader will confirm this. It will clear the area of snow and ice several times faster and more efficiently. In this case, the user will need to make much less effort than when using manual equipment.

There are many types of snow blowers according to different criteria - cheap, middle class, expensive, professional, wheeled, tracked, self-propelled, non-self-propelled, with a steel auger, with a plastic auger, with different distances of snow spread, electric, gasoline, etc. Further.

Prices for their species also fluctuate greatly - from 10,000 to 150,000 thousand rubles. Not everyone can afford such an expensive device, so the topic of how to make a snowplow on your own has become popular. They take a classic trimmer as a basis, preferably gasoline, as it is more powerful than an electric one.

If you decide to save money, don’t want to buy, or you have nothing to do, but want to make things, then read on - how to make a snow blower from a grass trimmer.

First you need to say that not every trimmer is suitable. The main reasons are power and shaft. If you have an electric trimmer, then most likely it will not work. Electric models are less powerful, so it will be more difficult for homemade snowplows from them to clean the area. They will not be able to do anything with ice or if there is a lot of snow, plus the engine will often overheat. Regarding the shaft, the trimmer shaft/tube should be straight and level, with no kinks near the nozzle. The fact is that in trimmers with such a bend, a flexible shaft is used - a special cable that transmits torque from the engine to the coil. The cable is not designed for heavy loads, so they put the appropriate engines in them. If you make a snow blower out of it, then its power will not be enough even for a small amount of snow. The engine will constantly be overloaded, it will overheat and shut down. The cable/shaft may also break.

If you have one of the listed models, do not even try to make a snowplow out of them.

Preliminary work on the creation of a homemade snow blower. To make a snow blower from a trimmer, you will need:

- Trimmer

- Tin, thin sheet metal (thickness from 2 millimeters, 1-2 sheets measuring meter per meter)

- The bottom of a metal barrel or cylinder

- Profile pipe (standard thickness, length 2.5 meters)

Tools:

- Spanners

- Welding machine

- Bulgarian and / or drill with bolts and screws

- Hammer, marker, ruler, tape measure

First of all, prepare all the elements and the workplace. Also at this stage, you need to disassemble the trimmer coil - remove the protective cover and nozzle with fishing line from the coil. They will not be needed, but leave all the fixing elements.

How to make a snowplow from a trimmer. The process of making a homemade snow blower

If you have a beer barrel bottom, this will make the job much easier. If it is not there, take its dimensions as a basis, cut out a circle from thin sheet metal, which will need to be surrounded by a tape of the same metal. Its length should be equal to the circumference, and the height should be 20-25 cm. Next, make a hole in the center of the circle and weld the elements together. As a result, you should get a cylinder without one bottom and with a hole in the second bottom - a drum / working chamber.

Cut two lengths of 60 cm each from the profile pipe - this will be the basis of the structure. Attach them to the made drum, they should fit snugly against each other. Cut a piece from the prepared pipe as long as the distance between the ends of the pipes. Weld it with two other pieces. You have made the foundation.

Now take care of the support for the trimmer - you will need two pieces of the same profile pipe 60 cm long, two smaller ones (their length depends on what slope the trimmer will be located at, choose it yourself) and the rod (longer than the width drum). At one end of each long piece, you need to make a hole for the rod. The short sides of small segments need to be cut off with a grinder. The depth of the cutouts also depends on how much you want to tilt the trimmer while you work. At this stage, you can try on by leaning the trimmer on the rod. Choose a suitable slope and weld all the pipes together. As a result, you should get a base with a support that resembles an inclined swing.

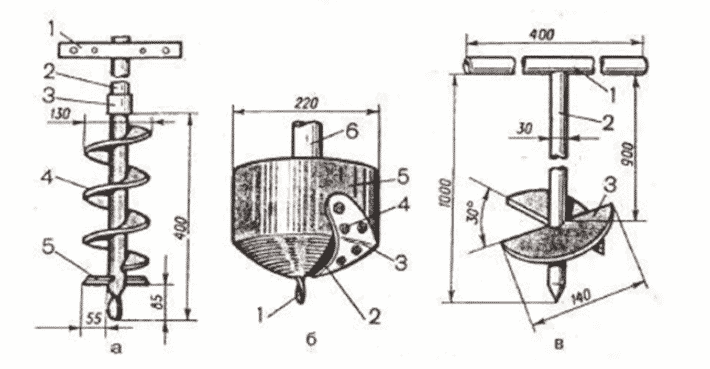

Cut out a sheet metal circle that is the same as the one inside your drum, but a few millimeters smaller. In the center of this circle, make a hole for the trimmer coil. Next, cut out the blades from the same sheet. The length of the blades must be less than the radius of the circle. The hole must not be blocked by blades. The blades can be curved, straight, straight at an angle, rectangular or triangular (right triangle) shape, there can be 5, 6, 7 of them. Here everything depends on your desire. Weld the finished blades to the circle. The distance between the blades on the circle should be the same. It is recommended to make 6 triangular blades and install them at an angle.

Cut a hole in the wall of the drum for a pipe to eject snow. Choose the size and diameter of the pipe yourself, based on your situation. After that, weld the drum to the base of the profile pipe structure and check how the nozzle made earlier sits in it.

Cut out an isosceles trapezoid from sheet metal. Choose its height yourself in the range of 15-30 cm. The length of the larger base is within 30-46 cm. You will also need two rectangular trapezoids, the length of each of their larger bases should be equal to the length of the isosceles lateral edge. Height 15 cm. You will also need a rectangle as long as the smaller isosceles base and 15 cm high.

Weld these elements together to form a bucket. Attach it to the drum. Note where the rectangle is blocking the drum. Trim the rectangle along this line. Weld the bucket with the drum. You can weld a piece of a rectangle to the top of the drum so that when the blades grind and throw out the snow, it does not spill back.

Thread the trimmer spool into the drum. The drum itself must be fixed instead of a protective casing, and a nozzle from the blades instead of a nozzle with a fishing line. A plastic sewer corner of the same size must be put on the pipe in the drum.

How does a homemade snow blower work? The user is pushing the car. Snow gets into the bucket. The blades rotate from the shaft, which rotates the trimmer motor. They crush the snow, after which it flies out through the outlet pipe. A sewer corner is installed on the pipe, which can be rotated to change the direction of snow ejection. The basis of the design allows you not to hold the trimmer in your hands, but to push it like a cart or sled.