sovet-ingenera.com

In this article we will try to give as much information as possible on how to make an indirect boiler with your own hands, why it is used in houses and apartments, and the basics of its work. Get comfortable, because the next 5 minutes will be very interesting!

The content of the article

- The principle of operation of a homemade indirect boiler

- Do-it-yourself indirect heating boiler based on an electric heater: myth or reality?

- What materials do you need to prepare for an indirect water heater with your own hands

- How to make an indirect heating boiler with your own hands - assembly steps

The principle of operation of a homemade indirect boiler

Since the purchase of a store heater will cost a lot of money, craftsmen have long come up with a way to make equipment from improvised means. Everyone can cope with this, because on the Internet there are a lot of do-it-yourself drawings of indirect heating boilers.

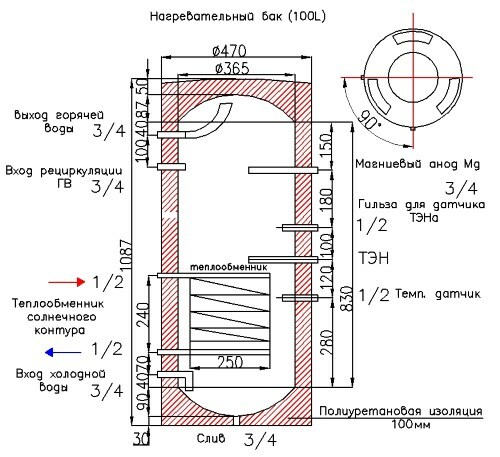

This type of water heater is characterized by simplicity of design and a minimum of parts, so it can be assembled independently. What no boiler can do without:

- Heating element - a cylinder or spiral piece installed inside a reservoir through which heat from a general heating system passes. In universal models, instead of the usual heater, there is a heating element (tubular).

- Tank - getting from the mixer, cold water under the action of the coil is heated inside the device. Then the hot liquid is transferred further through the water supply system.

- Thermal insulation - it is necessary in order to increase the heat capacity of our tank, since a simple metal shell gives off too much heat to the outside without its intended use. Steep thermal insulation in factory devices with a thickness of at least 50 mm.

The heating of the water in the system occurs because we either connect the system to our heating, or have an electric tubular heater installed. The heat carrier is one or more heating elements. When in contact with water, its temperature rises to 60-70 degrees, after which it can be used for domestic purposes.

Do-it-yourself indirect heating boiler based on an electric heater: myth or reality?

In fact, there is always such a possibility. The elements are freely removed from the inside of the tank, and a simple coil is put in its place. The whole scheme is carried out through home heating.

The advantages of this solution is that we already get a tank with full thermal insulation. All that is needed for a do-it-yourself indirect heating tank is just to disconnect the heating element and insert a spiral.

However, this assembly method also has disadvantages:

- Low circuit power - the heater will have a huge place for contact with water, due to which the warm-up time and heat loss will increase.

- The speed of obtaining at least warm water is several times lower than a conventional do-it-yourself indirect boiler.

This option is almost never made in "artisanal" conditions. It is easier to make an indirect heating boiler yourself by selecting the necessary parameters of the tank, heat-insulating elements and temperature increase elements.

What materials do you need to prepare for an indirect water heater with your own hands

kotly.org.ua

The first thing to start with is to find a good tank. Regarding the material - you can't imagine anything better than stainless steel. To do this, either look for a barrel of the appropriate diameter and height, or buy an empty gas cylinder - it quite enough in size and wall density to make an indirect heating water heater your own hands.

Another option is to make a tank from heat-resistant plastic. Two holes are made in the tank, necessary for the supply of cold liquid and the exit of the heated one. Holes are made vertically on opposite sides (future bottom and top). Additionally, you need to make two more holes for the coil, which will be connected to the heating system.

The material for the coil is brass or copper. These materials are easy to shape and conduct heat well. For manufacturing, we need a metal tube or a piece of wood, sharpened under a cylinder. It will be necessary to wind a copper pipe around it to get a kind of spring. Life hack: in order not to damage the copper tube during bending, fill the entire container with sand - this will increase the density and nothing will crack. The coil will turn out to be the correct size, diameter and shape.

How to calculate the parameters of the spiral for a homemade indirect heating boiler? To do this, you need to adhere to just a few points: the volume of the tank, the material and the heat capacity. It is generally accepted that for every 10 liters you need 1.5 kW of heat.

And to calculate the dimensions, a special formula is used: for a 200-liter cylinder with a copper tube diameter of 1 cm, the length is about 15 meters. With the help of simple mathematical operations, based on the obtained indicators, you can find out the length of the pipe for your tank.

Prior to the assembly of the indirect heating boiler, you need to take care of future thermal insulation. If you want to save money and not install it at all, then such frauds will only increase your subsequent spending on utilities - the efficiency of the boiler will be extremely low.

The ideal homemade method is to find a tank of a larger diameter, immerse the heater in it and fill the gaps with foam.

Well, for the subsequent assembly, we need fittings, adapters, mixers and other plumbing elements - a little bit of everything.

How to calculate the dimensions of the tank for the manufacture of an indirect heating boiler with your own hands

Approximate calculations show that for a family of 4, the average water consumption per day is around 200-250 liters. If the water is used only for taking a bath or shower, 100-150 liters will suffice.

For greater clarity, we present several examples of how much water is consumed in a particular procedure:

- Kitchen sink - about 20 liters of water per day are spent, of which 5-10 are from the heater;

- Washing - from 1 to 3 liters from the boiler;

- Shower - up to 30 liters of water per day.

Also, if you plan to install the system in a suspended way (with brackets on the wall), then there are restrictions on the weight of the entire structure - a tank of more than 150 liters cannot be used. If you need a larger size - look for a place on the floor.

How to make an indirect heating boiler with your own hands - assembly steps

You can start assembling the heater when you have found all the main elements and made the coil.

- We make 2 through holes in the tank: for a cold source and an outlet for hot water.

- If we install a tubular heater, then a separate hole is also needed for it.

- We put a coil in the tank, and to its edges we bring tubes that are pre-welded to the tank. You can attach it in any other way, just do not forget about the tightness of the structure.

- Racks are welded to the bottom (for floor), or a panel for anchors or brackets is welded to the side.

- Then the spiral is connected to the heating in the house.

- We install the passage of cold and hot water through the pipes.

- For convenience, we can immediately make several water intake points for different rooms (for example, a bathroom and a kitchen).

- We pre-dress the body of the boiler in a heat-insulating layer - from foil wool or polyurethane foam (which is simpler and cheaper).

Thus, we made an indirect heating boiler with our own hands in just a couple of hours, while spending no more than 5 thousand rubles. We assure you that no heater is worth such a small amount of money.