Diamond blades are produced by different manufacturers - Russian, Belarusian, European. When choosing for professional purposes, pay attention to durability, number of teeth, price and other parameters. Below is a ranking of diamond blades for concrete based on customer reviews from independent sources. The main features, pros and cons of each brand are described.

The content of the article

- Husqvarna

- Bosch

- GRAFF GDD

Husqvarna

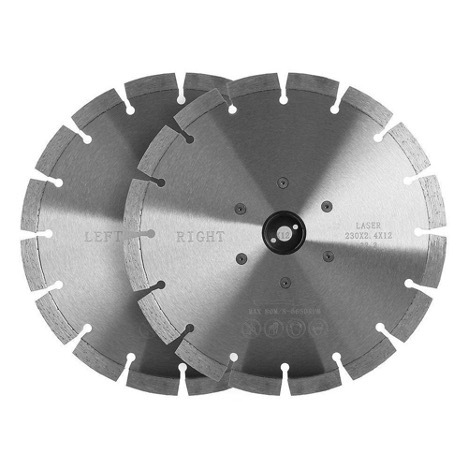

This is a Swedish brand that produces discs for professional tools on a gasoline engine. It produces various types of cutting elements based on high-strength steel. Equipped with 15 teeth with diamond coating. The diameter of 230 mm ensures comfortable operation. With the help of such equipment, you can quickly cut through materials of high strength, including brick and concrete surfaces.

Among the advantages are the following points:

- reliable tool;

- very long service life;

- 15 teeth;

- there are grooves of great depth, allowing to remove dust and reduce heat;

- 2 disks are included in the set;

- there are 2 holes for the pins, so the disk does not rotate on the shaft.

At the same time, such a tool is quite expensive. There are other downsides:

- if there is continuous work, then every 15 minutes you need to stop to cool;

- the device cannot be used on a grinder;

- water cooling is required.

Bosch

This is a German brand of construction and household appliances. Diamond blades are produced in a set of 10 pcs. They can be used on a grinder with a 22 mm landing shaft. The cutting wheels have a diameter of 15 cm, are equipped with 9 teeth, and have a turbocharged cutting technology. This allows you to quickly remove heat through the grooves. The spraying goes in 3 layers, so these are the best diamond blades for concrete. They are distinguished by reliability and durability.

The cutting speed and heat dissipation is very high. Therefore, you can work even at very high frequencies - the manufacturer claims 10200 revolutions per 1 minute. Other advantages include the following:

- equipment - 10 discs at once;

- no need to use a water cooling system;

- universal purpose - suitable for any type of work;

- thickness 2 mm - increased resistance to fracture.

Although these discs are more expensive than many others, they will last at least 10 years. At the same time, it is not always possible to purchase the goods by the piece - usually it comes in a kit.

GRAFF GDD

If we talk about which diamond blade is best for cutting concrete from the budget segment, it is worth taking a closer look at the GRAFF GDD. A company from Belarus that sells discs, the price of which is lower compared to European ones.

They reach 35 cm in diameter, while the devices are equipped with teeth in the amount of 24 pcs. Each of them is coated with a diamond coating. The section size of the cutting part is 3.4 mm. This allows you to work with brick-based material, paving slabs and even curb blocks.

The discs cut at high speed and efficiently, they are quite strong and durable, the purpose is universal. Such devices can be put on manual cutting and professional machines. Judging by the reviews and technical specifications, the main advantages include:

- the disk stands confidently, “walks” during operation;

- you can gain speed up to 5400 rpm;

- suitable for all types of cuts;

- you can work with hand tools and on machine tools and stone cutters;

- affordable.

But there are downsides too. The device is quite heavy, weighs 700 g. It will not work to cut thin strips with it, because the edge crumbles. The size of the device is 2.54 cm, which is not suitable for the shafts of all machines.