A petrol cutter is a tool for cutting metals. Usually runs on gasoline or electricity. The motor transmits the impulse through the drive to the cutting disc (usually diamond-coated). To make high-quality cuts, you need to know how to start the Shtil gas cutter, and what its principle of operation is based on, is described in detail in the article.

The content of the article

- How to start a gas cutter: step by step instructions

- Device and principle of operation

- Additional options

How to start a gas cutter: step by step instructions

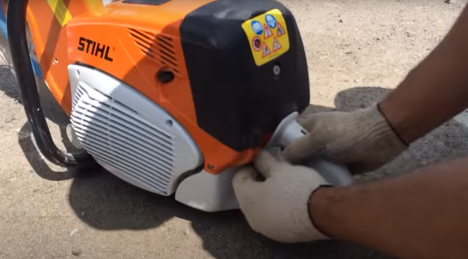

In order for concrete cutting with a chainsaw to be successful, it is necessary to start the chainsaw correctly. To do this, they act like this:

- Click on the button below.

- Move the fork down.

- Pull the cord with force several times.

- Once the engine has started, start cutting.

Device and principle of operation

To work professionally with the device, it is necessary to understand the device of the power cutter. The mechanism consists of several elements, the main ones are:

- cutting element - it can be a diamond disc or ring, an abrasive disc or a diamond chain;

- high torque drive

- clamps and switches;

- pen;

- casing.

The principle of operation of a gas cutter for metal is associated with the operation of the engine, which transfers energy to the drive. He, in turn, reports the torque to the cutting headset, which develops the necessary power and cuts.

Various models are used as an engine:

- two-stroke on petrol and oil - very powerful, but at the same time noisy and gives exhausts, weight and dimensions are small;

- electric - optimally suited for enclosed spaces, not very powerful, but it works with little noise and no exhaust;

- rechargeable – can be used for devices with a disk diameter within 230 mm;

- pneumatic – works only when there is a compressor that supplies compressed air.

The engine is mounted on the frame, and not directly, but through shock-absorbing pads. They dampen vibration, making the machine easier to work with.

Cutting metal with a gasoline cutter can be of 2 types:

- Wet - the disk is cooled with water, it is supplied from an external source. Thanks to this, there is no rapid overheating, and you can work on such equipment much longer. Another plus is that water prevents dust from entering, so diamond-coated discs will last longer.

- Dry - in this case, the cooling of the disk is carried out only by the air flow. And if the abrasive tool works fine, then diamond-coated discs should be used for a maximum of a minute. Then give it 20 seconds to cool down.

Additional options

Modern power cutters have several additional options that improve their performance and extend their service life:

- Easier engine start.

- Double or triple motor filtration for dust protection.

- Possibility of installation on a trolley for the formation of a seam cutter.

- Covers protecting the operator and the diamond blade during operation.

- Special nozzle for fixing to the rail. As a result, it turns out to temporarily construct such an assembly as a rail cutter.

The rules for working with a cutter are quite simple. It is necessary to connect the device to the network or fill in gasoline. Then press the button, move the regulator to the lower position and start the engine. At the same time, it is important to observe safety precautions and work with gasoline devices only in the open air.