A circular grinder is made independently using improvised tools and materials. To do this, you don’t even need a welding machine - you can make a wooden table and install a bracket with a grinder. Then it is gradually raised (with the tool turned on) and a gap is obtained in the countertop. It will become the main work surface. How to make such a device in 1-2 hours is described step by step in this article.

The content of the article

- Materials and tools

- Step-by-step instruction

- How to use the tool correctly

Materials and tools

A do-it-yourself circular made from a grinder has quite a few advantages. The main plus is significant savings due to the fact that you do not need to purchase an additional tool. At the same time, you can make it yourself, and it will not take much time.

To correctly understand how to make a circular from a grinder, you need to prepare improvised tools and materials:

- actual grinder or grinder angle grinder;

- drill - it is used to form holes into which fasteners will be inserted to fix the brackets;

- several chipboard boards;

- clamp and other fasteners;

- a special disc designed for cutting wood;

- construction roulette;

- pencil.

The grinder saw is made on the basis of the corresponding tool. Moreover, it must have sufficient power, because the quality of sawing depends on this parameter. Another point - the grinder should be medium or large in size. If it is too small, it will be possible to work with such a device only with thin materials.

It is also worth considering that the circular saw from the grinder is equipped with its own disk. It will not work to use the nozzle from the circular, because it does not match the size of the mounting hole. In addition, protrusions in the form of teeth should be located along the outer diameter. Their number varies depending on the specific model.

Step-by-step instruction

Do-it-yourself saw from a grinder is made in just 2 hours. The main task is to make a work surface in the form of a small table with a notch (slot), as well as fix the tool on a pre-installed bracket. The sequence of actions is as follows:

- On chipboard, make markings for 4 legs and the central part.

- Drill 4 holes with a drill for the legs.

- Drill a hole in the center, put a bolt with a nut and circle it clearly along the contour. Using a chisel, expand the hole along the intended boundaries.

- Insert a nut with a bolt into it and check how it is twisted.

- Attach the chipboard to the larger slab, make a basting and drill holes.

- Similarly - and with the second plate.

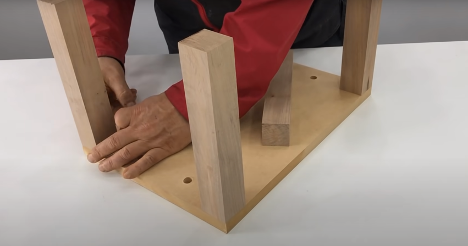

- To make a circular saw from a grinder with your own hands reliable, you need to make 4 legs from a bar. It is sawn into identical parts and mounted at the corners of the workpiece.

- Self-tapping screws are screwed with a drill - it turns out a small table.

- Another plate is fixed with metal pins, as shown in the photo.

- Place a second plate on top.

- They take the workpiece made in the first stage (it will be located in the middle of the table) and screw the bracket.

- There comes the main stage of the instruction on how to make a circular from a grinder with your own hands. Using a clamp, fix the tool, as shown in the photo.

- Finally fix the bracket on all sides.

- Fix the disc for sawing.

- Finally install the top surface.

- Mount a wooden handle with a wheel - bracket height adjuster.

- Turn on the grinder and, gradually raising the bracket, drill a slot.

- The result is such a miter saw from a grinder.

How to use the tool correctly

If you make the device correctly, in terms of quality and reliability of the design, it will be no worse than a store-bought one. But at the same time you need to understand how to use it correctly. There are no specific rules, in general they are simple and intuitive:

- Sawing can be started when the trimming from the grinder with your own hands gains the necessary power, that is, the rotation speed.

- In one cycle, you can work continuously for a maximum of 20 minutes to protect the engine from overheating.

- If the speed drops during sawing, the wooden part must be removed immediately to deal with the cause. Otherwise, you can ruin the whole mechanism.

- If the number of revolutions, on the contrary, is too large (from 10,000), you need to reduce the voltage by rotating the spindle. Otherwise, wood smoke may occur.

You can make a circular grinder if you wish, even without special experience. This is a fairly simple and at the same time very useful device. And it will cost much cheaper than a store tool. Suitable for most household tasks.