To create a comfortable microclimate inside the steam room, even at the construction planning stage, you need to choose the right way to insulate the ceiling in the bath. With proper implementation of all stages, not only good thermal insulation, but also safety will be ensured.

The content of the article:

- Warming the ceiling of the bath - what is the need?

-

Insulation options - their pros and cons

- Cement and sawdust

- Ecowool

- Foil insulation

- Penoizol

- Expanded clay

- Styrofoam and extruded polystyrene foam

- Mineral wool

-

Mounting options depending on the type of ceiling

- panel ceiling

- false ceiling

- Decking ceiling

Bath ceiling insulation — what is the need?

In the steam room, a comfortable microclimate is established when the air temperature reaches +70–90 °C, and the humidity index is approximately 70%. Under such conditions, the surfaces are systematically exposed to the negative influence of humid hot air.

If good insulation of the ceiling in the bath is not ensured, the following processes are observed:

- the air in the bath cools quickly, as the rising hot air escapes into the external environment through the attic;

- you have to constantly add fuel to the stove, which reduces its life;

- washing in a bath that does not warm up enough is not a pleasure.

Condensation accumulates on the ceiling, which they did not try to insulate. It flows in cold drops on people in the steam room, causing discomfort. From excessive dampness, wooden structures quickly collapse. Mold and rot appear on them.

To avoid such unpleasant consequences and maintain the integrity of the surfaces in the bath, you need to decide how to insulate the ceiling.

Properly installed ceiling insulation requires compliance with the following factors:

- steam from the stove remains in the interior of the bath;

- the roof receives protection from moisture penetrating through the ceiling;

- condensate does not accumulate on ceiling structures.

Reading: Ceiling insulation in a house with a cold roof.

Insulation options — their pros and cons

It will be possible to properly insulate the ceiling in the bath with your own hands, provided that a suitable heat-insulating material is used. When choosing, they study all the characteristics, which will eliminate negative consequences.

Cement and sawdust

Take lime, cement, sawdust and water. Component ratio: 1: 1: 10: 1.5. After mixing, the elastic mass is distributed in a uniform layer (15–20 cm) in the bath over the surface of the ceiling, which needs to be insulated.

Pros:

- low cost;

- no harmful emissions;

- high vapor permeability.

Minuses:

- the complexity of preparation and application;

- after drying, cracks often form that need to be covered;

- in terms of heat-insulating characteristics, sawdust is inferior to other types of heaters;

- when exposed to fire, this material begins to smolder.

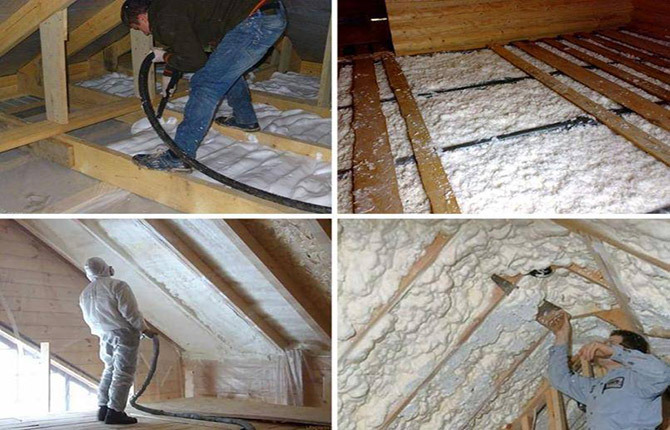

Ecowool

This popular fibrous insulation is made from cellulose with special impregnations.

Advantages:

- ecological cleanliness;

- low thermal conductivity;

- low weight;

- resistance to temperature fluctuations;

- durability;

- due to impregnation with sodium tetraborate and boric acid, a rare damage to ecowool by mold and insects is observed;

- availability.

Flaws:

- If the dry laying method is practiced, then the ecowool gradually becomes caked, which reduces the thermal insulation characteristics.

- In a situation where it is decided to insulate a cold ceiling in a bathhouse using the method of wet application of ecowool, efficiency is lost. This is due to the use of special equipment.

It should also be borne in mind that fibrous insulation easily absorbs moisture. This leads to a decrease in thermal insulation properties. If you want to insulate the ceiling plane of the bath, this type of material should be discarded.

Foil insulation

When deciding how best to insulate a cold ceiling in a bath, they analyze different types of thermal insulation with a foil coating.

Advantages:

- due to metallized spraying, such material retains heat well;

- provides a high rate of thermal insulation;

- saves fuel.

Manufacturers offer different types of insulation with a surface foil layer:

- Basalt wool mats laminated with aluminum foil. For example, you can buy Ecoroll 35 FA insulation 50 mm thick. This non-combustible material with high thermal insulation performance is well suited to insulate the ceiling plane in the bath.

- Metallized polyethylene foam. This material with a protective aluminum film will not only insulate the ceiling, but also ensure noise reduction and prevent moisture from penetrating. Differs in resistance to temperature drops characteristic of a bath, simplicity of installation, flexibility. It cuts easily. Withstands atmospheric humidity up to 100% and temperature -40…+100 °C. The disadvantages include the need to provide protection from direct exposure to sunlight.

Foil insulation is a good option if you decide to insulate the ceiling with this material. It is not necessary to finish all surfaces in the bath with vapor-tight insulation, as in this situation competently executed ventilation will be required.

Penoizol

This popular heat insulating material is also known as carbamide cellular modified foam. More often it is used to insulate various surfaces in the bath, including the ceiling, in liquid form. Suitable for conditions with temperatures -50…+100 °C.

Advantages:

- Low thermal conductivity.

- Elasticity, elasticity. Lush foam easily penetrates into all the cracks. The result is a smooth surface without cold bridges.

- Resistant to mechanical stress. After solidification, the material is crushed under the influence of gravity, but then, after the pressure stops, it returns to its original shape.

- Resistant to changes in humidity and temperature.

- High vapor permeability. Due to this characteristic, condensation will not appear on the ceiling of the bath.

- Good adhesion, providing reliable adhesion to various types of ceiling substrates.

- Penoizol coating is not affected by mold, rodents and insects.

- Durability. If the ceiling is properly insulated with liquid foam insulation, its insulating characteristics will be preserved for 50 years or more.

- Environmental friendliness. Penoizol does not emit harmful compounds during operation.

- Fire safety. The heater is non-combustible. Does not emit toxic compounds in direct contact with the flame.

Flaws:

- Liquid foam is not suitable for surfaces that are exposed to frequent intense moisture. This is taken into account if you need to insulate the steam room.

- Sun protection required. The material is capable of being destroyed if it is exposed to ultraviolet radiation.

- Application requires specialized equipment.

You can buy penoizol in the form of sheets. Dowels are used to fix them. The cladding is attached to the top.

Producers also offer granulated penoizol. The size of fractions does not exceed 15 mm.

Expanded clay

Popular expanded clay is a porous granules with good thermal insulation performance. The raw material for firing is low-melting clay.

Advantages:

- expanded clay does not ignite, which is important if it is decided to insulate the ceiling plane in the bath with clay granules;

- belongs to the group of environmentally friendly materials, as it does not contain toxic impurities;

- has low thermal conductivity;

- has a long service life;

- not subject to the appearance of rot, mold;

- frost resistant material.

Flaws:

- despite the low weight, expanded clay insulation involves pouring a layer 20–25 cm thick on the ceiling, which increases the load on the walls of the bath;

- if the vapor barrier film is damaged, expanded clay is able to absorb a large amount of moisture, which worsens its characteristics.

Styrofoam and extruded polystyrene foam

Polyfoam belongs to the group of porous materials with good thermal insulation properties. The base is foamed plastics.

Pros of foam:

- low weight, which allows not only to insulate the ceiling by laying sheets in the attic, but also fixing them to the surface from the inside;

- good indicator of strength;

- high moisture resistance.

Minuses:

- when the material is heated, toxic compounds are released into the atmosphere;

- polystyrene is easily damaged by rodents;

- the heater is characterized by a low operational period.

When choosing, you can analyze another type of insulation similar in characteristics - extruded (extrusive) polystyrene foam, which is often sold under the Penoplex brand. Despite the same type of raw material, it differs from the foam created by the action of steam by the extrusion method of production.

Advantages of extruded polystyrene foam:

- If you need to insulate the ceiling with polystyrene foam, its thickness will be lower than that of polystyrene. This is due to the lower thermal conductivity.

- Penoplex is distinguished by the ability to maintain operational properties at -50... + 70 ° C.

- It is not subject to colonization by fungal colonies.

- It has an operating life of medium (30–50 years) duration, which is higher compared to polystyrene.

- Extruded polystyrene foam is characterized by a high compressive strength and minimal water absorption.

Minuses:

- The porous structure of the insulation attracts rodents. Mice and rats can equip holes in it.

- When heated, it releases styrene, which is harmful to health.

- Belongs to the group of combustible materials.

If you choose a material to insulate the bath from the side of the ceiling, then foam plastic, extruded polystyrene foam, as well as any other type of polystyrene, cannot be used for such specific conditions. This is due to the ability of materials, when heated, to release toxic fumes into the surrounding atmosphere.

Mineral wool

Frequent use mineral wool in the role of a heater is explained by the availability and easy installation of this material, represented by three types: glass wool, slag and stone (basalt) wool.

slag wool

The raw material is the molten slag remaining during blast furnace production.

Advantages:

- Slag insulation belongs to the group of non-combustible materials. Melts when the temperature reaches over 300 °C.

- Demonstrates high rates of thermal insulation and sound absorption.

- Light weight for easy installation.

- Not damaged by rodents and insects.

Flaws:

- With the systematic exposure to moisture, slag wool loses its characteristics. As a result, the service life is reduced.

- At hit directly on a heater of water aggressive acids are formed.

- When heated, vapors of phenol-formaldehyde resins are released.

glass wool

The raw material for this type of insulation is glass melt.

Advantages:

- Glass wool is characterized by high strength and elasticity.

- The material, consisting mainly of fibrous inclusions, demonstrates high vibration resistance.

- Thanks to its flexibility, it is suitable for laying on uneven surfaces.

- Glass wool does not burn. If the temperature reaches +250…450 °C, performance characteristics are lost due to the burning out of the binder resins. Sintered at +500…+550 °C.

- Microorganisms do not settle on the insulation.

Flaws:

- The danger is brittle fibers that form prickly dust. On the skin, it causes itching and irritation. When inhaled, lung damage is observed in the form of asthma, bronchitis, and oncological diseases. Contact with glass wool in the eyes provokes pain, pain, tearing.

- With periodic moistening, glass wool shrinks.

- Due to the use of phenol formaldehyde as a binder, toxic compounds are released into the air.

stone wool

The raw material for this type of insulation is the melt of mountain (mainly gabbro-basalt) rocks.

Advantages:

- Due to the porosity, basalt wool, which can be used to insulate a steam room, has a high vapor permeability. Demonstrates good heat and sound insulation properties.

- The material is incombustible. It starts to decompose with the formation of hot dust at +600…700 °C.

- Differs in durability. Does not lose technical properties for 50 years and longer.

- Refers to the positive aspects of biological stability, environmental friendliness, easy installation, low weight.

In order to safely insulate the ceiling from this group of heat-insulating materials in the bath, stone wool must be used. In any season, it will provide good heat retention inside the steam room in the bath, it will not be covered with mold.

Mounting options depending on the type of ceiling

In order to properly insulate the ceiling in the bath, you need to take into account the design features.

panel ceiling

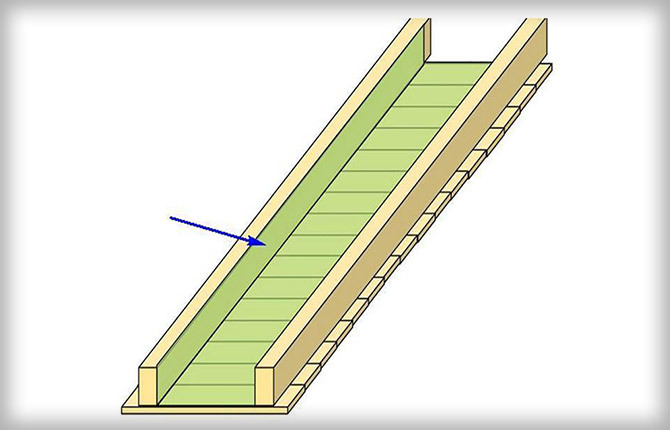

A bath built with a cold roof allows the panels used to mount the ceiling to be well insulated. They represent modules with insulation inside. It is easier to buy ready-made panels, although you can make them yourself if you wish.

Sequencing.

- Two beams with a diameter of 50 x 100 mm are laid on a flat surface parallel to each other. The interval between their outer sides is 500 mm. They nail, using nails, pieces of the board. Their length is 600 mm, which allows them to protrude beyond the timber by 50 mm on both sides. A suitable board thickness is 25–30 mm.

- When all the dies are nailed, the structure is turned over. Using a construction stapler, a vapor barrier film is fixed inside. Leave the upper planes of the bars open.

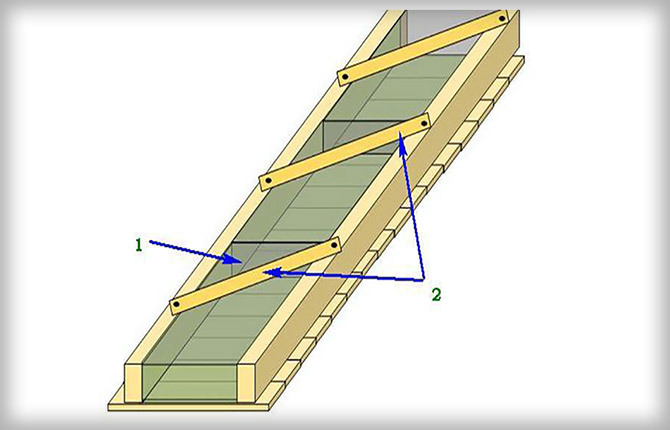

- If it is decided to insulate the future ceiling with basalt wool, then continue assembling the panel on the ground. For heavier insulation, it is advisable to first move the structures to the attic of the bath, since the weight of the finished module can be significant. The mats (1) are placed tightly between the bars. To preserve the integrity of the insulation during lifting, temporary wooden lintels (2) are nailed.

- In this form, the panels are lifted, laying on the crown. You can first prepare a stepped special groove for them on the upper edge of the wall or attach a beam. Under the panels, in advance, in places of contact with the wall of the bath, an insulating layer (2), for example, a felt tape, is laid. When installed between the panels (3) with the temporary bridges removed, a gap of 100 mm is left, which is necessary to insulate the joints. In each such narrow opening, a vapor barrier film is spread on the sides and bottom, and then a strip (4) of basalt wool is laid. The insulation will reliably close the bridges of cold.

After these operations, a diffuse membrane is spread on the panels, which is attached to the bars with brackets. Lay on both sides and in the center of the board (5) with a thickness of at least 30 mm. Their length should be such as to fasten all the panels. Boards are nailed to each bar. It remains to perform outside flooring for the attic floor.

The panel ceiling, if desired, from the inside of the bathhouse can be sheathed with clapboard.

false ceiling

This type of ceiling is chosen if it is planned to make an attic above the bath. The beams are made from the same material as the frame, providing them with the necessary strength.

Subsequence:

- Before insulating the ceiling, a crate is made, providing a hole for the pipe.

- From the bottom side, a vapor barrier film is attached with a 20 cm approach to the walls. The foil layer is turned inside the bathhouse. It will keep you warm. The strips are overlapped. The joints are glued with waterproof aluminized tape. Nailed for fixing several rails. At the same time, they will serve as a frame for the subsequent lining of the ceiling, which needs to be insulated, with clapboard.

- Then, already under the roof, they continue to insulate the bath from the side of the attic. If heat-insulating mats are used, they are laid between the bars with a layer of about 10 cm. Leave a distance from the insulation to the upper edge of the beams of about 3 cm. This gap allows you to insulate the bath more reliably, as it will provide air circulation.

-

Sheets of a waterproofing membrane are spread from above. The overlap is about 10-15 cm. To glue the joints, use construction tape. Then they sheathe the frame ceiling with boards, performing the floor of the attic.

Given the strength of the false ceiling, you can insulate it with other materials. For example, dried garden soil or a solution of clay mixed with chopped straw will be cheap.

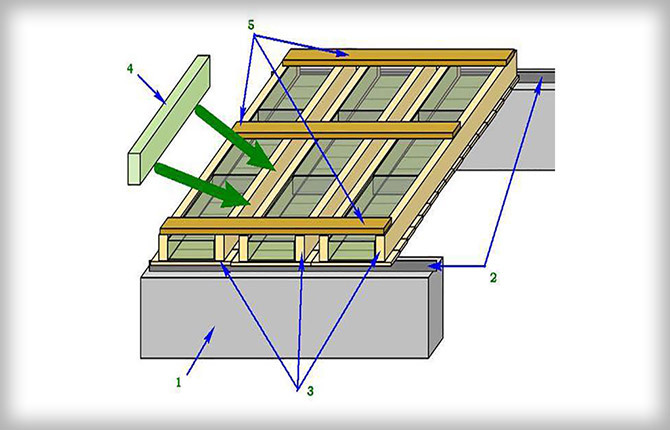

Decking ceiling

They use an easy-to-install floor ceiling with a small area of \u200b\u200bthe bath. Since the boards are laid directly on the walls without supporting beams, it will not be possible to equip the attic in this situation. To insulate the bath from above, you will need a light heat-insulating material. The thickness of the boards must be at least 50 mm.

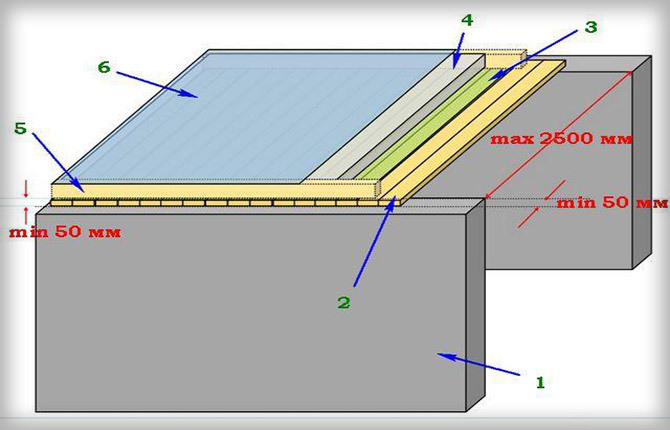

In accordance with the diagram, which shows a section of the structure, the following sequence of operations is practiced when creating a floor ceiling:

- The boards (2) are laid on the walls (1) so that they go over them by at least 50 mm. There should be no gaps between the boards, so well-crafted lumber is chosen.

- Spread the vapor barrier film (3).

- Lay insulating material (4). To insulate the structure, they often take varieties in rolls or mats. For bulk insulation, it will be necessary to mount partitions from bars (5).

- To insulate the ceiling more reliably, spread a diffuse membrane (6) to provide waterproofing. Close the plane with plywood or boards, fixing them with self-tapping screws.

Sometimes the top is left without boarding, as the attic space will not be used.

Choosing options for how to insulate the ceiling in the bath, they analyze different methods. This will allow you to competently perform the necessary actions, providing a comfortable safe microclimate. If you are interested in the information presented in the article, share it with your friends and bookmark it. Maybe you have already done the insulation in the ceiling bath with your own hands? Tell us about your experience in the comments, please.