Smoking with smoke at low temperatures is a lengthy process, but worth the time. The resulting smoked meats are distinguished by a specific and very tasty aroma. Moreover, they are also stored for a long time, because bacteria during such cooking completely die and do not spoil the finished product.

There are industrial versions of smoke generators on sale. However, you must agree, why pay a lot of money if you can make a smoke generator with your own hands for cold smoking from the means available in your own workshop.

If you have tools with the necessary materials, making and assembling the smokehouse will take several hours. The smoking itself will then last much longer, but the result is guaranteed to exceed all your expectations.

The content of the article:

-

Smoke generator for cold smoking

- Features of the device and principle of operation

- Structural elements of a homemade smokehouse

-

Smoke generator from improvised means

- Option # 1 - from an old fire extinguisher

- Option # 2 - from a bucket or pan

- Option # 3 - passive maze

- Conclusions and useful video on the topic

Smoke generator for cold smoking

There are a huge number of options for making a homemade smoke generator. In the classic ejector version, this is a rather simple apparatus in terms of design, in which there are no complex parts and elements.

It is only necessary to make a chamber from a heat-resistant material, where the wood will smolder, attaching a compressor to it for air injection. And that's it, it couldn't be easier.

If desired, the smoke generating system can be supplemented with a sawdust feeding auger with an electric motor. This automation will simplify the smoking process, but also complicate the generator. If the smokehouse is planned to be used occasionally, then it is better to do without such improvements.

The duration of cold smoking can exceed a day, and one load of sawdust into a small manual smoke generator is usually enough for a couple of hours

If there are a lot of products for processing, then it is recommended to make the smoke generation unit larger and more powerful, or supplement it with an automatic auger.

Cold smoking means long-term fumigation of meat and / or fish with smoke at a temperature of 20-40 °WITH. This is a rather time-consuming heat treatment, but the result is very similar in taste and quality of the product. At the same time, the "cold" option does not require the arrangement of a capacious smokehouse and stove to maintain the fire.

Features of the device and principle of operation

The basis of the cold smoked smoke generator is a bunker filled with wood chips. After ignition, the sawdust inside it smolders and gives smoke to be fed further into the smoking chamber, where the processed products are hung.

On the one hand, wood smoldering in this device should not occur too quickly. On the other hand, the flame must also not be allowed to ignite, and the smoke output must be sufficient.

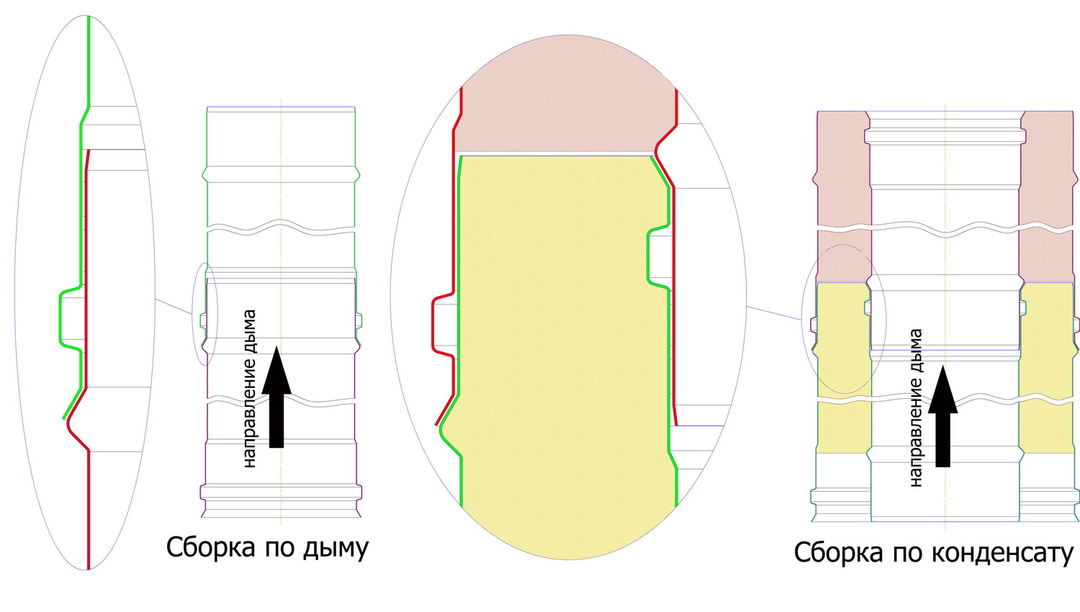

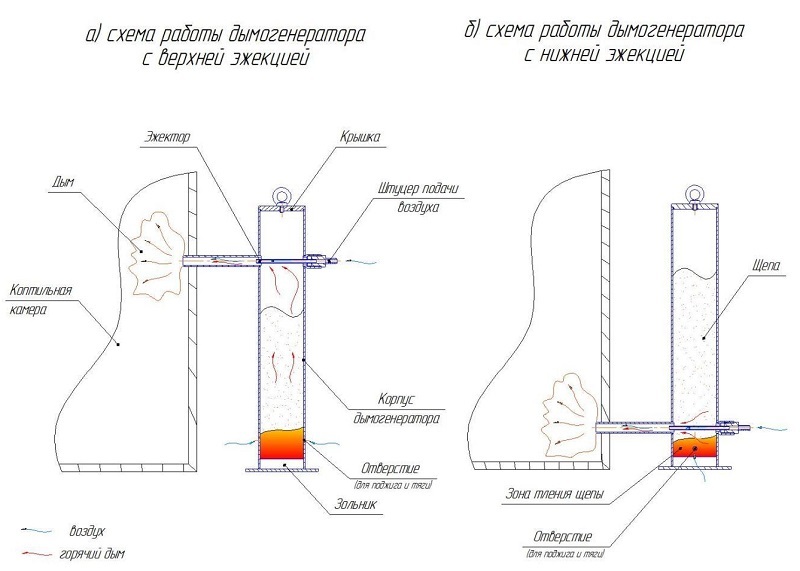

The ejector at the smoke generator can be located in the upper or lower part of the bunker - the first option requires a more powerful compressor, but also produces more smoke

If the ejector is made from below, then the chips burn out much more completely, without "sticking" inside on the walls of the bunker. It's all about the condensate formed during smoldering. When the smoke is emitted from above, condensate drops run down the inner surface of the generator and wet the sawdust. As a result, some of them do not burn out and remain inside.

The following are used as fuel for the smoke generator:

- chips;

- sawdust;

- braces;

- branches.

Usually it is the wood of fruit trees, which, when burned, gives a “tasty” smoke, giving additional flavor to the finished product at the exit.

Most often, when cold smoking is used:

- alder;

- bird cherry;

- juniper;

- birch;

- oak;

- maple;

- apple, pear and cherry.

Alder bark gives bitterness to smoked meats, so it must be carefully peeled off before placing fuel in the bunker. Juniper gives a pleasant taste and aroma. However, it will have to be diluted with other wood, otherwise the final product will have an unnecessarily harsh taste.

It is also recommended to remove the birch bark from the birch so that the meat and fish do not taste bitter later.

Structural elements of a homemade smokehouse

The classic ejector cold smoked smoke generator consists of the following elements:

- Compressor or fan.

- Fuel combustion chamber-bunker (smoldering chips and sawdust).

- Ejector (unit for supplying smoke from the generator to the smoking chamber).

- Ash-pan with grates.

- Condensate collector.

It is also possible to use an electric stove and a pan on it with chips inside. All these elements are installed in a barrel, at the top of which meat (or fish) is suspended. In this case, the ash pan, fan, condensate trap and ejector are missing.

Smoldering occurs due to the heating of the pan, the ash remains in it, and the smoke naturally rises and smokes the products located at the top.

If the ejector is located on top, then it lasts longer, since, in comparison with the analogue placed below, it is farther from the smoldering wood and is less susceptible to high temperatures

If the ejector is placed underneath, chips and / or ash can enter it. As a result, it will have to be closely monitored during smoking so that the smoke passes through the pipe without obstruction. Plus, it will need to be cleaned more often and more thoroughly.

Smoke generator from improvised means

The main working elements of a smoke generator for cold smoking are a fuel combustion chamber and an ejector. The more durable and resistant to high temperatures materials are made, the longer the smoke-generating unit will last. Everything else in its essence is additions and improvements to this device.

A homemade cold smoking smoke generator can be made from:

- tin cans;

- a fire extinguisher or iron pipe of similar size;

- stainless steel can;

- sheet iron (you will definitely need welding machine);

- pots or buckets;

- perforated metal or fine mesh.

The diameter of the combustion chamber (wood fuel bin) should be between 10-15 cm. With a lower value of fuel, very little will be included in one tab, it will have to be changed more often. And with dimensions over 15 cm, the fuel will produce too much smoke.

The distance from the ash pan (the bottom of the smoke generator, the place of ignition) to the point of smoke exit should not exceed 1 meter - if you do more, the smoke will lose temperature and speed

The use of aluminum housings is not recommended due to their fragility. There is no open combustion in the smoke generator. However, the smoldering temperature also turns out to be quite high - the aluminum walls of the combustion chamber will not last long.

The situation is similar with cans. This is actually a one-time use of the generator. Smoke fish with such a device will be enough for a couple of times. But for regular use, it's better to do something more reliable and secure.

Option # 1 - from an old fire extinguisher

The smoke generator is manufactured as follows:

- The fire extinguisher is cleaned of contents and rust.

- A “lid” 4–5 cm high is cut off from the top of the balloon.

- A hole is made in the “cover” from above and a tee (ejector) is inserted.

- On one side of the tee, a compressor is connected, and on the other, a branch into the smoking chamber.

- At the bottom of the fire extinguisher, holes are made in the side walls for setting fire to chips and supplying air.

A grate stand is installed inside the cylinder, separating the fuel from the bottom. Plus, in the middle of the chamber, a spiral is inserted around an iron bar.

A spiral inside the hopper is needed to provide air flow from below for thrust and smoke rise to the ejector - otherwise it will not rise through the compacted sawdust and drown out the smoldering

The ejector is made so that the supplied air does not fall on the smoldering fuel and does not ignite it by blowing oxygen.

The task of this element is to create an air flow that will draw smoke into itself, directing it into the smokehouse with products.

The air supply pipe on the inner diameter is selected in 6–8 mm, and the smoke outlet pipe should be 18–20 mm. These are optimal values that do not require the installation of a powerful compressor and produce sufficient smoke.

A compressor for a smoke generator can be taken from an aquarium or a small radial fan can be purchased. You can also adapt a cooler from a computer to pump air.

Option # 2 - from a bucket or pan

To create this version of the smoke generator you will need:

- Barrel.

- Electric single-burner cooker.

- A saucepan or bucket as a fuel hopper.

- Mesh or rods with hooks.

- Cover (iron sheet).

In this case, wood fuel smoldering without igniting it with fire. After switching on, the electric stove heats up the hopper with sawdust and chips, as a result of which the latter begin to smolder from the heat from below.

Then smoke is formed and naturally rises, fumigating the food at the top of the barrel.

If you need to smoke several fish, you can do without a barrel and an electric stove - a large bucket on the fire, it is enough to pour sawdust inside it, and install a grill for food on top

One load of such a smoke generator is enough for about 5 hours. At the same time, you will have to constantly control the smoldering process and regulate the temperature of the burner, without leaving the smokehouse for a long time. Moreover, the barrel will need to be lifted regularly to reach the power switch.

Labor-intensive in the smoking process. But it is easier than ever to manufacture and prepare.

Option # 3 - passive maze

A smoke generator in the form of a labyrinth or a spiral involves the creation of an extended path from rammed sawdust, which are ignited on one side and gradually smolder from edge to center.

This generator has no fans or compressors. The whole process of smoldering and the formation of smoke occurs with natural draft.

The dimensions of the labyrinth smoke generator depend on the dimensions of the smokehouse - however, the longer the wood path (snake), the longer the fuel smolders on one load

A smoke generator in the form of a square with a side of 30–40 cm, a height of 5 cm and paths about 5 cm wide is usually enough for 8–10 hours of smoldering. Such an apparatus is made of metal with fine perforations or a mesh with a fine mesh. The existing holes provide air access to the smoldering sawdust, but do not allow the fire to ignite.

The passive smoke generator is placed directly in the smokehouse under the meat (fish). Sawdust smolders, smoke naturally rises and smokes food. At the same time, the wood fuel does not ignite, since there is not enough oxygen inside the smoking chamber due to smoke.

If you are interested in this topic, we recommend that you also read the article on how to make potbelly stove for a garage from a gas cylinder.

Conclusions and useful video on the topic

Iron pipe smoke generator:

The principle of operation of the smoke generator for cold smoking:

Smoke cleaning in the right smoke generator:

It is not difficult to make a cold smoked smoke generator yourself. There are several simple designs, which are made with their own hands from improvised means in two to three hours.

If you have any clarifying questions about the device or the principle of operation of the smoke generator, write them below in the block with comments. Your ideas or experience in the manufacture of such devices will also be interesting. Write - share your knowledge or ask questions.