An electric sawmill is made on the basis of a ready-made device that needs to be installed on a structure with a countertop. It is assembled from metal pipes or a wooden box covered with laminated plywood. Step-by-step instructions for each method with a detailed description of the actions can be found in the material presented.

The content of the article

- Materials and tools

- Step-by-step instruction

- Sawmill from a manual circular saw

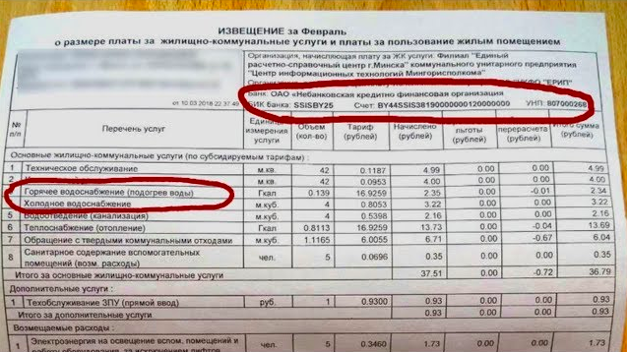

Materials and tools

Before you carefully study the instructions on how to make a sawmill from a circular saw with your own hands, you need to familiarize yourself with the design features, as well as prepare the tools at hand. The sawmill chain (tire) type basically consists of 2 parts:

- Mobile is a carriage that moves with the saw.

- Stationary - a fixed structure on which a beam or a wooden slab is placed for further cutting.

Thus, a do-it-yourself sawmill from a circular saw does not differ from a professional one in terms of device. Moreover, for its manufacture, you will need not only tools and fasteners, but also mechanisms:

- steel plate (length from 60 cm);

- steel channels - 2 units, each 8 m long;

- pipe blanks;

- metal corners;

- metal pipes (minimum diameter 40 mm);

- fasteners - bolts, screws;

- chain mechanism - thanks to it, the circular from the chainsaw moves;

- drill, drills;

- apparatus for welding;

- actual electric chain saw.

Step-by-step instruction

A do-it-yourself sawmill from an electric saw can have a design of various shapes and sizes. You should first draw up a drawing and transfer the dimensions to the channels. The sequence of actions is as follows:

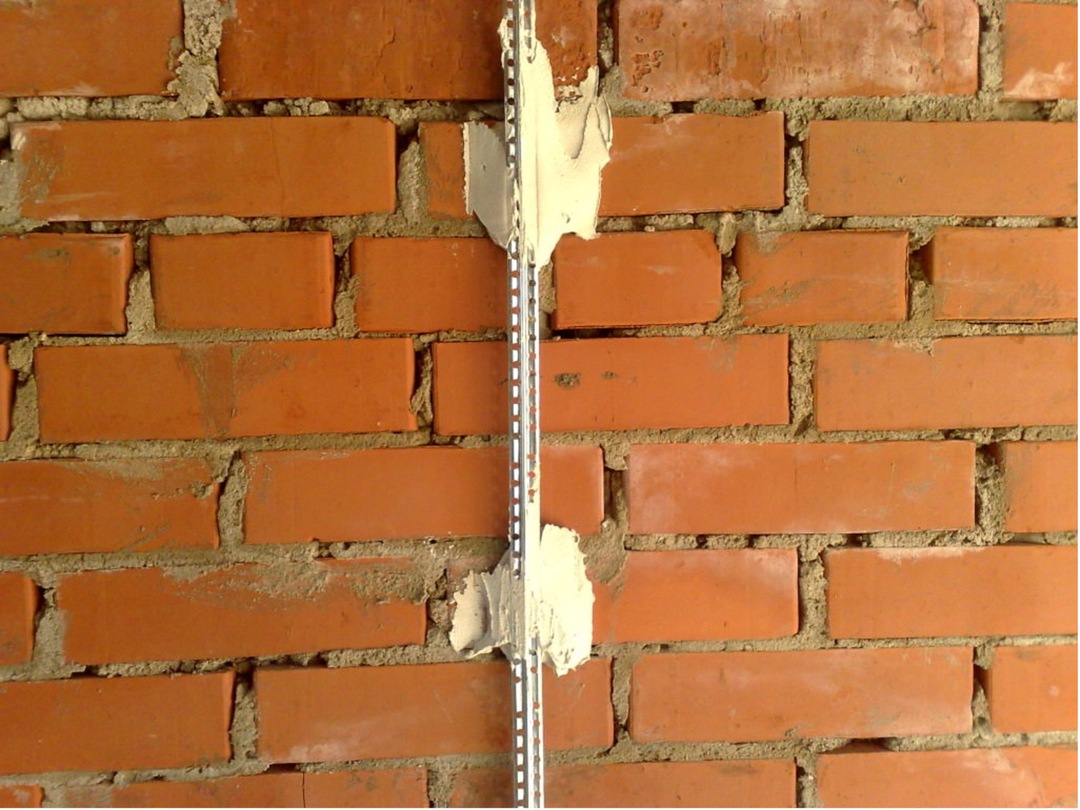

- From 2 channels 8 m long, each makes 4 racks, welded together or fastened with bolts. It is clear that welding is the most reliable way, so it is better to use the machine.

- Do-it-yourself chainsaw circular consists of a movable cart, which is made of steel sheet. Moreover, its thickness should be at least 5 mm. Each clamping plate is equipped with gaskets, with which they are bolted together.

- A homemade chain saw should be equipped with fasteners based on metal corners. They are placed in the upper and lower parts of the carriage, while the upper corner is again better to be welded.

- Now the parquet sawmill is almost ready, it remains only to make a fixed support, for example, from metal pipes with a diameter of 40-50 mm or more. They are threaded with movable rods, which are fixed at a certain height.

Sawmill from a manual circular saw

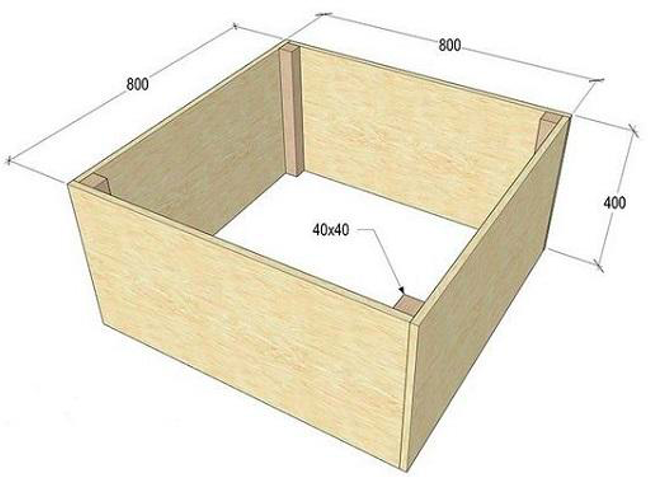

There is also a way to make a sawmill from a hand-held circular saw. This is a simpler option, which can also be implemented independently. In this case, they take a ready-made saw and make a table for it from wooden bars with a section of 40 * 40 mm and plywood.

The main steps are:

- Assemble a square box 80 * 80 cm.

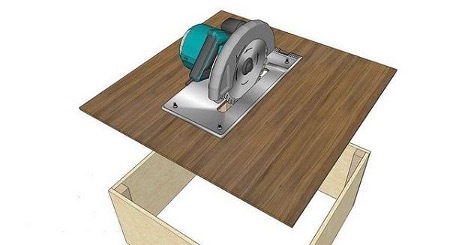

- Fix the tabletop from a square sheet of dense plywood of the appropriate size. It is best to take plywood with a laminated or varnished coating. This is one of the best ways to make a do-it-yourself electric saw, the carriage of which will slide freely over the surface.

- A cut is made in the center of the tabletop, corresponding to the size of the disk (should ensure free rotation).

- From below, a circular hand saw is attached to the structure, they do it with the help of bolts, sinking their hats.

When the device for the electric saw is ready, you can test its operation. As a rule, if the gap has the correct dimensions and shape, the disc rotates properly, and a smooth surface ensures a smooth ride. With the help of such a device, you can solve almost all household tasks.