Installing a stove in a bathhouse on a wooden floor is only possible if it is not a heavy structure. Classic brick structures are not suitable, since they require the installation of an individual foundation. Therefore, you can consider options with a cast iron, steel or electric stove. Step-by-step installation instructions taking into account fire safety requirements can be found below.

The content of the article

- Types of furnaces and load calculation

- How to determine the installation location

- Step-by-step instruction

Types of furnaces and load calculation

You can also place the stove on a wooden floor if you correctly calculate the load on the base. It largely depends on the type of structure:

- The heaviest and at the same time the largest are brick kilns. Their weight reaches 500-600 kg or more. Therefore, masonry is placed only on a separate monolithic foundation - wooden beams are not suitable in this case.

- Cast iron stoves not as large, so despite the massiveness of the material, they are not as heavy as brick ones. The unit can also be placed on a wooden floor by strengthening the corners in advance.

- Steel - even lighter, portable structures that can be placed on a wooden surface. The material is not as durable as cast iron, but it heats up quickly and transfers heat to the bathhouse.

- Finally, for small spaces you can consider electric ovens, which do not require fuel. Their weight is usually in the range of 10-30 kg, but you need to add the total mass of the stone to it - about 50-80 kg. Even taking this into account, installing a sauna stove on a wooden floor is quite possible.

Regardless of the choice of one type or another, you first need to calculate the load, since the durability of the structure depends on this. To do this, proceed as follows:

- Measure the gap between the load-bearing walls.

- Calculate the total load in kg per square meter of area.

- Based on this, the optimal cross-sectional size of the beams and the step between them are determined.

As a rule, the bathhouse is small. If the walls are located at a distance of within 5 m, you can use beams made of pure solid wood, for example, coniferous or deciduous. If the interval exceeds 5 m, you should use laminated timber, which can withstand maximum loads.

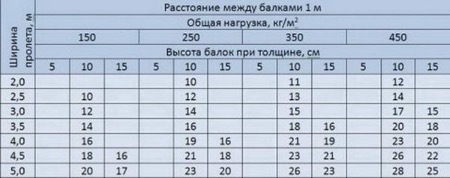

If you take a step of 1 m as a basis, you can determine the height of the beams using the following table.

You also need to take into account the cross-section dimensions.

How to determine the installation location

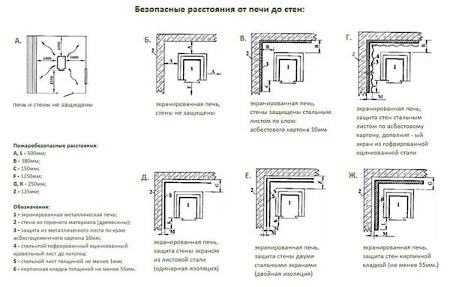

Before installation, you will also need to determine the installation location taking into account fire safety requirements:

- The minimum distance between the front side of the stove with firebox and the nearest wall is 150 cm.

- If this is not possible, it is permissible to leave a distance of 100 cm, but the wall must be protected with a sheet of metal (height from 120 cm) or laid with brickwork, the thickness of which will be at least 12 cm.

- The distance to other walls is from 70 cm.

- When using heat-insulating boards, the distance from them to the stove should be at least 50 cm.

- Exactly the same distance should separate the shield and the wall or partition.

- Finally, the top of the stove and the ceiling should be separated by an interval of 120 cm. If the ceiling surface is also protected by thermal insulation, 100 cm is allowed.

Step-by-step instruction

The stove in the bathhouse is installed on a wooden floor in several stages:

- Measure the stove and transfer the markings to the wall between the bathhouse itself and the dressing room.

- A small opening is cut out.

- Knock out the wall material.

- The base is prepared - a steel sheet is placed on the floor, which is covered with a special material (minerite). They can simply be laid on the floor without fixing anything.

- A layer of refractory bricks is formed on the sheet in 2 rows. It is not necessary to use a cement-sand mixture, although it will not be superfluous for the strength of the structure.

- A second steel sheet is mounted on top of it.

- The result is a finished base on which the stove can be installed.

- Pre-heat the oven with dry wood for 1-1.5 hours.

- They put it in place, checking the correct position according to the level. Masonry in the opening is made from fireclay or refractory bricks.

- An overlap is formed.

- And they complete the laying.

- Installing a chimney.

At the last stage, it is necessary to protect the walls (and, if necessary, the ceiling) with steel sheets or thermal insulation materials. Then the structure is carefully inspected to ensure its tightness. After this, the stove is lit and care is taken to ensure that no smoke comes out of it anywhere.