As a rule, the door to the bathhouse is made of wood. This is the simplest design that you can actually make yourself. You can choose any wood, but only dry wood. How to make a door to a bathhouse yourself, and what you will need for this, is described in the presented article.

The content of the article

- How to choose a door type

- Step-by-step instruction

How to choose a door type

The door to the bathhouse should be strong, close tightly and retain heat well. Several types of structures meet all these requirements:

- Made from glass – ideal for saunas. Reliable and safe, they look quite aesthetically pleasing. However, it is quite difficult to make them yourself - it is easier to buy a ready-made canvas and hang it with your own hands.

- The double-glazed door has a wooden base and its own small window. To strengthen the frame, it is equipped with aluminum inserts. The glass unit is purchased separately, then it is placed in a structure that you can make yourself.

- A classic wooden door that can be made in just a few hours. They are made from suitable wood, for example, commercial wood, which does not have knots. You can choose almost any material, but it must be dried, with a moisture content of no more than 15%.

Step-by-step instruction

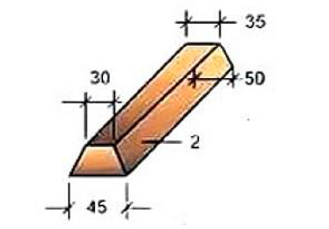

For work, a rectangular beam of 50*45 mm is used. You will also need the following supplies and tools:

- floorboard with grooves and tenons;

- metal loops;

- door handles;

- timber for mounting the box (section 60*80 mm);

- screwdriver;

- self-tapping screws;

- wood saw;

- electric jigsaw;

- clamp;

- construction tape;

- sandpaper;

- level;

- plane;

- chisel.

Now all that remains is to figure out how to properly make a door to a bathhouse.

- The doorway is cut out (if it is intended to be installed in a new location).

- Leave a protruding part of the beam - it will serve as a spike. Using a router, grooves are made in the shape of the letter “p”.

- To properly make bath doors with your own hands, grooves are also made in the threshold. A beam is mounted here - the basis of the jamb. Thanks to this, the structure will withstand even a massive door.

- A door frame is mounted from a wooden beam 60*80 mm. A groove is cut along the width of the side to connect it with the tenon, which is located at the end of the wall. During installation, leave a distance of 10 cm between the opening and the jamb.

- A strip is screwed onto the inside of the box, the thickness of which is approximately 10 mm. This is done so that the door can only open outwards.

- Measure the dimensions of the box on the outside and make the door leaf according to them, leaving gaps of 3-4 mm.

- The canvas itself is made from boards that are cut exactly to size.

- A shield is made from them, first fixed with wood glue. If necessary, tap with a rubber hammer to ensure a tight fit of each board.

- Each board is leveled with a plane, placing the structure on a workbench.

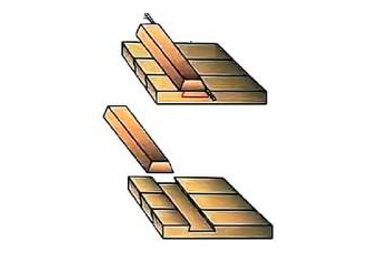

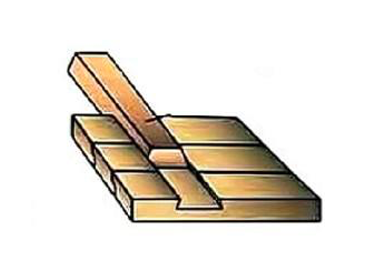

- Dowels are placed on the outer side of the shield, which are also made from timber.

- The dowel is placed on the wide side and nailed to the panel.

- Recesses are first made in the shield itself.

- And the dowels are set on wood glue.

- Next, metal loops are screwed onto the canvas and the structure is suspended.

All that remains is to install the handles, if necessary, treat the door with an antiseptic and paint it. In general, the installation technology is simple, but requires accuracy and precise measurements. At each stage, the correct location is checked with a building level.