Houses made from SIP panels are gaining popularity due to their energy efficiency and speed of construction. However, when choosing a heating system in such houses, it is necessary to take into account the characteristics of the material. Warm floors in a house made from sip panels are the optimal solution, combining comfort and efficiency.

The content of the article

- Warm water floor: the ideal solution for SIP houses

- Step-by-step instructions for installing water heated floors

- Important Operation and Maintenance Aspects

- Mistakes when laying heated floors in a SIP house with your own hands

- Conclusion

Warm water floor: the ideal solution for SIP houses

A water heated floor in a vulture house is a system in which the coolant circulates through pipes laid under the floor covering. This heating method is ideal for houses made of SIP panels, as it ensures uniform heat distribution and minimizes heat loss.

Advantages and nuances of installation:

- SIP panels have excellent thermal insulation properties, which reduces heat loss in a house made from SIP panels and increases the efficiency of the underfloor heating system.

- Uniform heat distribution ensures a high level of comfort in living spaces.

- Compatible with various types of heating. Can be used both with traditional heating systems (for example, heating a house made of sip panels with electricity), and with alternative sources, such as a fireplace in a house made of sip panels.

Step-by-step instructions for installing water heated floors

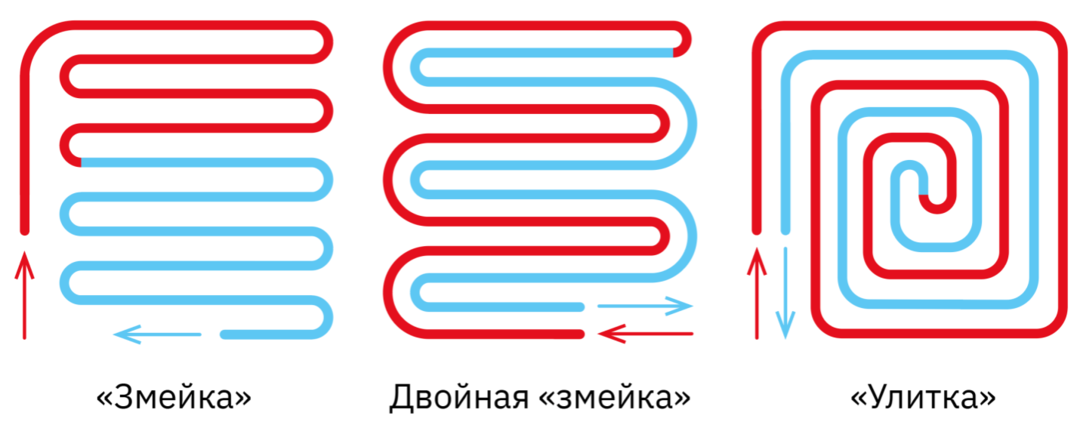

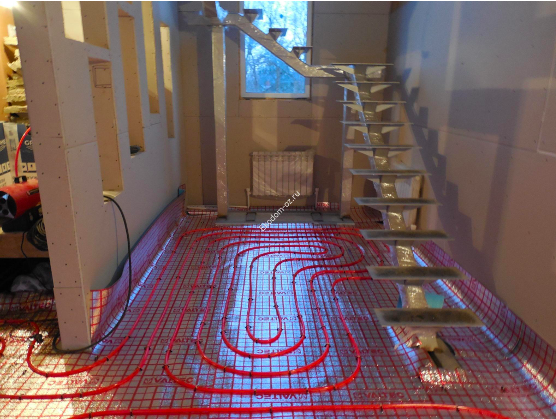

Before starting installation, it is necessary to carefully plan the system and draw up a diagram of the water-heated floor in the vulture house. Key steps include:

- Make sure the floor surface is level and clean.

- Laying the insulating layer.

- Pipe installation.

- The pipes are connected to a boiler or other heat source.

- The pipes must be completely covered with screed to ensure even heat distribution.

- Installation of thermostatic equipment to control room temperature.

Important Operation and Maintenance Aspects

One of the key aspects of operating a heated floor in a house made of sip panels is regular maintenance and monitoring of work. This includes checking for leaks and inspecting connections and pipes for damage or wear. Such actions help prevent possible accidents and extend the life of the system. It is also important to monitor the performance of all system elements, including pumps and thermostats.

Maintaining optimal pressure in the underfloor heating system is critical to its efficient operation. Pressure that is too low can result in insufficient coolant circulation, while pressure that is too high can cause leaks or damage to system components. It is also important to maintain the optimal temperature of the coolant to ensure comfortable warmth in the room and avoid overheating.

Regular maintenance of your boiler and other key heating system components is essential to keep them operating efficiently. This includes cleaning, checking for corrosion, replacing worn parts and checking connections for leaks. Such measures help prevent system failures and ensure safe operation.

An important aspect of using a heated floor is also the correct arrangement of furniture and other interior items. It is necessary to avoid prolonged covering of radiators and thermal zones with furniture or carpets, as this can lead to overheating of the system and poor heat circulation. Proper placement of furniture promotes uniform heat distribution and increases the efficiency of the heating system.

Mistakes when laying heated floors in a SIP house with your own hands

When laying heated floors in a house using SIP panels with your own hands, it is important to avoid a number of common mistakes to ensure the efficiency and safety of the system:

- Incorrect power calculation. An error in calculating the power of the system can lead to insufficient or excessive heating of the premises. It is important to take into account the area of the heated space and the thermal insulation properties of SIP panels.

- Ignoring the insulating layer. Missing or insufficient thickness of the insulating layer under the heated floor can lead to increased heat loss. It will also lead to a decrease in the efficiency of the heating system.

- Incorrect pipe installation. Improperly laid pipes can cause uneven heating of the floor. It is important to follow the recommended installation spacing and ensure that the pipes are evenly distributed over the entire floor area.

- Failure to take into account the thermal expansion of materials. Underestimating the effect of thermal expansion may result in floor deformation or system damage. Expansion gaps must be provided to prevent such problems.

- Failure to comply with screed requirements. The wrong choice of material for the screed or its insufficient thickness can lead to cracks and damage. A high-quality screed ensures pipe protection and uniform heat distribution.

- Ignoring the control and regulation system. Lack of thermostats or underfloor heating controls can lead to inefficient use of energy and overheating.

- Failure to comply with safety regulations. When installing it yourself, it is important to follow safety precautions, especially when working with the electrical components of the system.

- Insufficient testing of the system before pouring the screed. It is necessary to conduct a complete leak test of the system. Next, you need to check the functionality and only then fill the screed.

By avoiding these mistakes, you can ensure the durability and efficiency of the heated floor in a house made from SIP panels.

Conclusion

Installing heated floors in a semi-detached house yourself is a realistic task for a homeowner with basic construction and plumbing skills. Such a heating system not only increases living comfort, but also helps reduce heating costs in a house made of SIP panels. Careful planning, careful installation and regular maintenance will ensure an efficient and long-lasting hydronic floor heating system.