The key problem of the classical one-and two-pipe heating system of private houses is the rapid cooling of the coolant. Agree that it is not bad to equip a system devoid of such a flaw.

Do you want to realize heating in your home, where the coolant will be warm as long as possible? We will help you solve this problem - the article discusses the collector heating system, which has been widely popular in recent years. It is she who is able to maintain the desired temperature inside the circuit for a long time.

Also in this material we examined what principles underlie the system and which layout is the most convenient in terms of installation. The article selected schemes and thematic photos, useful tips and videos about the features of the collector system and the nuances of mounting radiators.

The content of the article:

- Device collector system

- Pros and cons of the collector-beam system

- Principles of wiring diagrams

-

Selection of system components

- Pipes for systems of private cottages

- Tubes for apartment buildings

-

Features of the installation system

- Installing the distribution comb

- Laying options for pipeline

- Conclusions and useful video on the topic

Device collector system

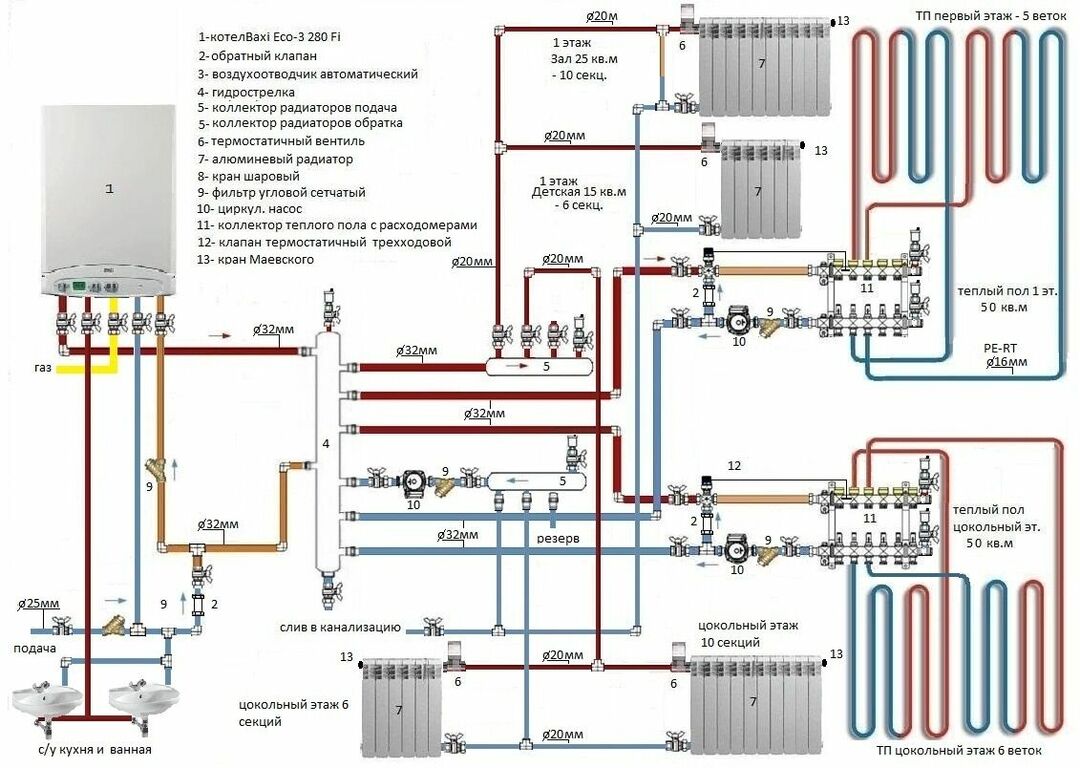

The basis of the scheme of collector heating and the main working body is the distribution node, referred to in common comb system.

This is a special type of sanitary fittings, which is designed to distribute the coolant to independent rings and highways.

The collection group also includes: expansion tank, circulation pump and security group appliances.

Image Gallery

A photo of

The collector heating circuit determines the parallel connection of devices to the distribution node

Due to the parallel principle of connection, a heat carrier that is almost equal in temperature indicators is supplied to heating devices

The coolant from the boiler enters the collector, which is divided into equivalent in quantitative and qualitative indicators flows

The distribution comb, also known as the collector, is installed one per floor. It serves horizontal wiring.

Collector circuits are used in the construction of convector and radiator systems, as well as in the device of underfloor heating, in which pipes perform the functions of heating devices

In the device of pipelines supplying the heated coolant and diverting it back to the boiler, they strive to use a minimum of node connections.

When forming branches, only quality fittings are used, since in the event of leakage will have to open the entire floor in the emergency area

The very principle of the device collector scheme dictates the use of pumping equipment. It is recommended to install your own circulation pump on each of the rings.

Principle of the device of collector heating

The advantages of simultaneous supply of coolant

Collector assembly of the heating beam system

Box for installation of the distribution comb

Scope and options of the collector scheme

Rules for laying supply and return pipelines

Pipeline branch formation

Equipment for collector system rings

The collector assembly for a two-pipe heating system consists of two components:

- Input - it is connected to the heating unit through the supply pipe, takes over and distributes the heat carrier heated to the required temperature along the contour.

- Output - it is connected to the return pipes of independent circuits, it is responsible for collecting the cooled “return water” water and redirecting it to the heating boiler.

The main difference between the collector wiring of heating from the traditional serial connection of devices is that each heater in the house has an independent connection.

Such a constructive solution makes it possible to control the temperature of each battery in the house, and, if necessary, turn it off altogether.

Often, when designing a heating system, a mixed type of wiring is used, in which several circuits are connected to the node, each of which is controlled independently. But inside the circuit heating devices are connected in series.

The comb is a section of thick pipe, equipped with one entrance and several outlets, the number of which is determined by the number of connected circuits

Pros and cons of the collector-beam system

Among the indisputable advantages of installing a collector system is to highlight:

- Convenience of operation. Due to the fact that each element is controlled independently, the consumer has the ability to set the temperature at any point in the house. And as required, it is easy to turn off one or a group of heaters in the room. The temperature in other rooms will remain the same.

- Ability to use small-diameter pipes. Since each branch leading from the collector feeds only one device, it is possible to use small diameter pipes for its installation, which can be easily hidden in the screed.

- Maintainability. In case of detection of problems, it will be easy to turn off any part of the pipeline, without interrupting the work of the entire system.

To form several circuits with different parameters, for example: pressure drops or different temperature of the carrier, use distribution combs with the function of hydraulic compensator.

The hydraulic needle is a capacious pipe, to the outlets of which a number of circuits are connected with independent circulation.

Water heated by the boiler inside the arrow. By circulating inside the device, water at different distances from the sidebars is taken and redistributed along the contours.

In the places of tie-in of each circuit, after the arrow, their own values of pressure drop and temperature of the carrier will be set

Due to the fact that the heated coolant with less losses brings heat to the batteries, the efficiency of the system increases. This makes it possible to reduce the power of the boiler and save fuel consumption.

The heating system, the main element of which is the collector, is not without flaws.

These include:

- Pipe flow. When compared with a serial connection, the flow rate of the pipe when laying the collector system is two / three times higher. The difference in costs is determined by the size of the area involved.

- The need to activate circulation pumps. Installation of independent circuits is not complete without the installation of circulating pumps. This entails additional costs.

The weak link of the collector system is its volatility. So even with the boiler running in the event of a power outage, the pipes will remain cold. For this reason, such systems are not recommended for use in areas where power outages are not uncommon.

Circulation pump provides forced movement of the coolant in the system, made of pipes with a small diameter, in which the total hydraulic resistance has a high rate

When laying the contours in the floor screed, it should be borne in mind that any connection is a potential leak. And in the event of a defect for its elimination it is necessary to open solid concrete. And this is a very troublesome and costly event.

Therefore, the network connections of the collector system are located exclusively above the floor level. Most often they are confined to a collector cabinet.

Principles of wiring diagrams

There are no uniform standards for the layout of the layout of the collector system. The equipment is selected for specific tasks.

But experts agree in one authoritative opinion that such a system is in no way suitable for heating apartments. This is due to the complexity of the project due to the fact that two or more risers are usually brought into the living space.

And one of the mandatory conditions for the implementation of the scheme is the need to connect all the batteries to a single riser.

You may also find information about how connect the radiator.

In order to realize the collector layout in the apartment, you will have to leave only one heat channel, pre-brewing the rest - it will take all the load

If we brew all the other water supply channels so that one riser takes up the entire load, a closed hydraulic circuit is formed within the same apartment. All heating devices located higher in the riser will be cut off from the system and will not receive the desired heat.

Residents living from above, sooner or later, will identify the cause of this phenomenon, and the scheme will have to be redone by force, laying out a rather large amount.

Heating collector wiring is allowed to be installed in apartment buildings of new construction, provided that even at the construction stage, they installed additional valves for connecting circuits of various configurations.

When arranging the collector system, a number of key points should be taken into account, which are also characteristic of other types of systems.

The collector system is the best suited for private homes.

The main thing is to adhere to the main recommendations of professionals when designing layout:

- Availability of air vent. An automated valve is placed directly on the supply and return manifolds.

- Availability of expansion tank. The indicator of its volume should be at least 3% relative to the total volume of the coolant. But it is allowed to use both devices and with a large volume.

- Location of the expansion tank. It is installed on the "return pipe", placing it in front of the circulation pump along the water. Read more about its installation described in our other article.

- Installation of circulating pumps on each circuit. Their location is not fundamental, but they show maximum efficiency due to the low operating temperature on the return pipe.

If it is necessary to use a comb equipped with a hydraulic compensator, an expansion tank is installed in front of the main pump, designed to ensure the movement of water in a small circuit.

By placing the expansion tank in front of the pump, you can significantly reduce the risk of damage to the device under the action of water turbulence

The circulation pump is fixed in such a way that the shaft is strictly horizontally. Otherwise, the very first airlock will leave the unit without lubrication and cooling.

More information about choosing a circulation pump can be read. in this article.

If there are additional distribution units in the heating system, they should not be communicating.

Selection of system components

When designing heating, it is best to purchase factory-made distribution hubs.

Due to the diversity of the range, the comb will not be difficult to choose for certain heating parameters, thereby ensuring the accuracy and reliability of the system.

On sale you can find ready-made manifold blocks, combining the flow and return nodes, as well as thermostatic valves and automatic air vent

The key parameters when choosing pipes for heating circuits are corrosion resistance, heat resistance and high resistance to breakthrough. In addition, the pipes must have the necessary flexibility so that they can be laid at any angles.

When choosing products, preference should be given to pipes produced in coils. The use of solid products will avoid connections in the wiring, which is especially important when the closed method of installation inside the screed.

Pipes for systems of private cottages

When designing heating in private homes, it is worthwhile to focus on the fact that the pressure in the system is about 1.5 atmospheres, and the temperature of the heat carrier can reach:

- for radiators - 50-70 degrees;

- for warm floors - 30-40 degrees.

For autonomous heating systems with their predictable parameters, it is not at all necessary to purchase stainless corrugated pipes. Many owners are limited to the purchase of pipes made of cross-linked polyethylene marking "REH".

Polyethylene pipes for heating circuits on sale are presented in 200-meter bays; they are able to withstand pressure up to 10 kgf / sq.cm and operate at a temperature within 95 ° С

Connect such pipes using tension fittings, so you can get unbreakable connections.

In addition to high performance parameters, the main advantage of cross-linked polyethylene is the mechanical memory of the material. Therefore, if with an effort to stretch the edge of the pipe, and insert the fitting into the resulting lumen, it will tightly cover it, ensuring a firm connection.

Using metal pipes The connection is performed by means of union fittings with crimp nuts. And this already produces a plug-in connection, which, according to the SNiP, cannot be “monolithic”.

You may also have information on which pipes are best for heating, reviewed here.

Tubes for apartment buildings

If the collector system will be installed in an apartment building, then it is worth considering that the working the pressure in it is 10-15 atmospheres, and the temperature of the coolant can reach about 100-120 ° s It should be remembered that the device of collector heating is possible only on the first floor.

The best option for installing the system in an apartment building is to use corrugated pipes made of stainless steel.

A good example of this is the products of the Korean company Kofulso. Pipes of this brand are capable of operating at a working pressure of 15 atmospheres and withstand temperatures of about 110 ° C. The destruction pressure of Kofulso pipes reaches 210 kgf / sq. Cm.

Due to the excellent flexibility of the pipe, in which the bending radius is equal to its diameter, it is convenient to use the product when laying the “warm floor”

Assembly of pipeline connections using such elements is not difficult. The pipe is simply inserted into the fitting and secured by twisting a nut, which compresses the metal corrugated surface with an elastic silicone seal.

Features of the installation system

Mount the collector heating system of a private house should be at the construction stage. After all, after laying or pouring the finished floor, the installation of such a system will become economically inexpedient. The only way to solve the problem in this case would be an open way of installing wiring.

Installing the distribution comb

On the floors of houses with horizontal wiring for heating to accommodate the collector, circulation pump and adjusting equipment you will need to install a closed box - a collector cabinet.

A closed box protects equipment and valves from external mechanical impact and gives the room a more aesthetic appearance.

The collector cabinet is installed in separate niches of the premises protected from moisture. Most often for this allocate space in the hallway, dressing room or pantry.

When designing the heating of a two-story building, it will be necessary to establish two collector groups: on the first and second levels. Additional distribution nodes will provide approximately the same length of the circuit.

As an option, we can take as a basis the scheme in which the first group will be responsible for the distribution heat on individual circuits, and the second - to act as a key component in the arrangement of “warm” floor.

The heated coolant from the room with the boiler enters the main lines to the collectors installed floor by floor.

The number of inlets and outlets of the collector is always equal to the number of heating elements located on the floor: radiators or floor heating rings. For each room, they lay a separate branch, which, combining several heating devices, will embody a passing or dead-end scheme.

To reduce the cost of connecting radiators, apply a "pass-through" scheme.

When the "through" scheme, the thermal valve is installed only on the first circuit of the radiator; whereby the water flow is regulated on all devices connected in series with it

With a “pass-through” system, several series-connected devices will be perceived as one element.

Laying options for pipeline

When collector wiring most often used method of laying pipes in the concrete screed. Its thickness varies in the range of 50-80 mm, which is quite enough for the "monolithing" of the house wiring of the heating system.

But according to the SNiP, only unbroken connections are allowed in concrete.

Connection to the collector of any radiator or convector is made through two pipes: “supply” and “return flow”, therefore the pipes are laid in pairs in the floor screed

To do this, often use metal pipes with a diameter of 16 mm. Due to the fact that they are easy to bend, it is convenient to lay the pipeline under the floor.

Planning to pour metal-plastic pipes with a concrete tie after pressing the system, it is necessary to wrap them with thermal insulation.

This layer will minimize the risk of damage to pipes under the action of thermal expansion, since in this case they will not rub against concrete, but against insulation.

When laying pipes in a coupling, according to the requirements of the SNiP, it is necessary to leave them accessible, placing them for this purpose above the floor level.

On top of the screed is laid plywood, which is covered with a finishing floor covering: linoleum or parquet.

Pipes can also be supplied to radiators on the side or on top, for example: in the space of a hemmed ceiling.

Some craftsmen prefer to lay pipes outside, placing them along the walls and hiding behind decorative plinths. But this method of installation entails an inevitable increase in the length of the pipeline.

The pipeline is not recommended to be laid through doorways. This can lead to the fact that when the threshold of an interior door is set at the time of drilling, the pipe will be damaged.

In case the pipeline needs to be laid through the wall in order to prevent its damage due to shrinkage of the building, the hole in the wall should be equipped with a sleeve.

For each hydraulic chain extending from the distributor comb, a separate stop valve is installed.

To be able to lower the air accumulated in the system, mount:

- at the distribution hub - air vent valves;

- on radiators (accumulates in the highest points) - Mayevsky's cranes.

Due to the fact that the hydraulic circuit that goes after the collectors is a separate system, it is convenient to use it when creating “warm floors”.

The main advantage of the floor-mounted collector system is that heat flows are evenly distributed on the floor

Air circulation in the arrangement of the outdoor version occurs naturally.

When such a system is implemented, metal-plastic pipes are laid on a heat-insulating gasket, forming a snake or spiral pattern. Pipe diameter and pitch is determined by according to calculations. One condition - the length of one circuit should not exceed 90 meters.

The laid contours are connected to the distribution unit, and after checking the tightness of the connections, they are poured with concrete. The height of the screed is 70-90 mm.

According to the same principle, both the collector system of a two-story cottage and a residential building with a large number of floors are mounted.

Conclusions and useful video on the topic

The principle of system design:

How to install:

By installing a collector heating system in your home, you will be able to individually adjust the operation modes of the devices..

And the additional costs of increasing the length of the pipes are compensated by reducing their diameter and simplifying installation of the system.

Do you have a collector heating system at home? Or do you just plan to equip it, but for now you study the information? Maybe you have a question on drawing up the layout of the collector system? Ask your questions, share your personal experience of arranging heating in the house, leaving comments under this article.