House by definition should be warm. Ensure that it is possible in many different ways. However, a prudent owner strives to make it as efficiently and cost-effectively. Such options include the installation of wall-mounted gas boiler. And rightly so, because the gas heating is very profitable, and the equipment is fairly simple to use and install.

If you too have started to think about the purchase of the wall of the boiler, be sure to read our material. In it, we try to tell as much detail about the principles of operation of such equipment and the types of wall-mounted devices. Also, consider all the nuances of such a system connection.

The content of the article:

- The principle of operation of the gas boiler wall type

-

Varieties of wall units

- Group # 1 - the device with open combustion chamber

- Group # 2 - appliances with closed combustion chamber

- Whether self-installation possible?

- How to start the installation?

- Environmental requirements for the boiler

-

Step by step installation of equipment

- Step # 1 - Preparing the Wall Mount

- Step # 2 - Connect heating pipes

- Step # 3 - the connection to the water circuit

- Step # 4 - Connection to mains gas

- Step # 5 - connection to the mains

- Step # 6 - O arrangement chimney

- Step # 7 - Preparation for the first start-up

- Conclusions and useful videos on the topic

The principle of operation of the gas boiler wall type

Installation and connection of the radiator depends on its type. So you need to understand exactly how the device works and how of its varieties will have to deal.

Any wall type gas boiler It is a compact device, whose maximum power is limited to 42 kW.

Wall gas boilers - powerful compact devices providing space heating and hot water

The main elements of the system include:

- gas burner. Delivers gas into a chamber, where the combustion process. By means of fuel nozzles distributed as uniformly as possible. Modern modulated burner can maintain a predetermined temperature and adjust the force of the flame.

- heat exchangerThrough which coolant moves. Best performance in a copper device. In condensing boilers such elements may be two.

- Expansion tank. It is intended to compensate for the excess water appearing as a result of heating.

- Circulation pump. In high-power models can be two such elements.

- boiler automation device or system whose task it is to maintain a predetermined temperature in a heated room. May include devices running on electricity or volatile.

- The devices controlling and regulating boiler operation.

- Fan. It can only be used in turbocharged models.

- security system. Shuts down the boiler in emergency.

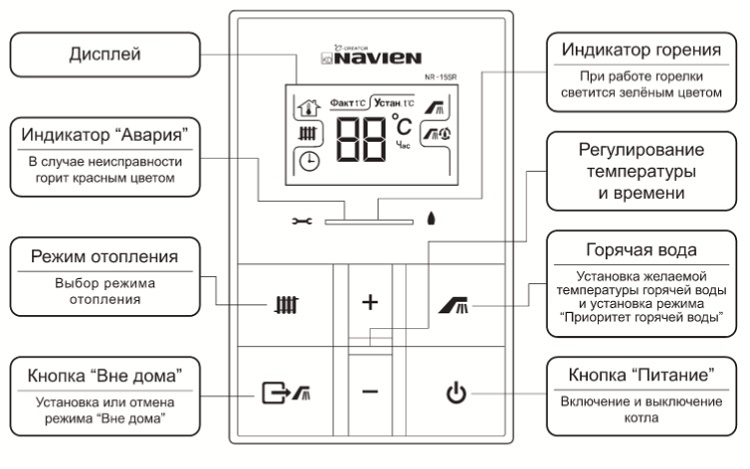

Current models are additionally equipped with self-diagnostic systems that are able to identify about 90% of the boiler malfunctions. The display shows the number of diagnosed damage, which quickly corrected the master of the service.

The figure is a diagram of a bypass wall gas boiler with the combustion chamber closed type

Varieties of wall units

According to their functional purpose gas heating units are divided into two groups:

- Single loop. Designed for heating only. Connected to the heating circuit and heat the heat transfer fluid. Organization of hot water supply in such a case, by setting the electric or gas heater of any type.

- Combi. Heated room and provide a supply of hot water. The additional integrated circuit boiler for heating water. The technological feature of the device lies in the impossibility of the simultaneous heating of water and space heating.

priority actions combi units Water is heated, the heating operation at this time is terminated. Given that the water can be heated quickly, the boiler quite efficiently heats the building.

If the gas unit is expected to include tasks as heating the coolant, and the supply of hot water, it is better to buy double-boiler. They come with one or two heat exchangers. When equipped with two may simultaneously serve two circuit

By the combustion method all the devices are divided into two groups.

Group # 1 - the device with open combustion chamber

Such devices are also called heaters with natural draft. Oxygen required for combustion, they are removed from the room in which the device is located.

they need to discharge combustion products chimney conventional type. Thus a requirement for the installation of the boiler arrangement is a good ventilation.

If the heater is installed in the living room, there should be a high-performance ventilation is undeveloped.

Optimal variant for installation of the heater with an open combustion chamber is considered a separate room, the so-called furnace where it and place.

System with natural ventilation are quite popular due to low cost and non-volatility.

The figure schematically shows boilers with burners open and closed

Group # 2 - appliances with closed combustion chamber

Turbocharged device equipped with closed combustion chamber. Air, which is not possible without the combustion process, they take the street. For this purpose devices are equipped with a chimney coaxial type.

Such a chimney is formed as a structure of two tubes, one of which is embedded in the other. As the inner tube of the combustion products are discharged to the outside.

Simultaneously, in the reverse direction across the gap between the two tubes comes outside air. It is clear that the boilers with a furnace of closed type do not affect the composition of the air inside the room, which makes possible their arrangement, even in the living rooms.

Thus it is necessary to arrange a system of coaxial chimney, which has a higher cost and a more complex installation as compared with the separate conventional chimneys.

Whether self-installation possible?

can be carried out installation of wall gas boiler is the simplest modifications of their own hands. Such for example as single-circuit devices with an open combustion chamber.

For their installation is required to connect the heating system to bring gas chimney and organize. However, some manufacturers of boilers in the technical documentation to indicate their products, the installation must be carried out only by specialists.

Installation and connection of a gas boiler - a responsible and rather complicated work. Many manufacturers of heating equipment required to fulfill its professionals

In this case, self-assembly of even simple models is prohibited. Thus, if it is planned that the equipment will be installed on their own, make sure that the manufacturer authorizes it before buying it.

Check the correctness of the installation and connection of the device to the gas line should only be a specialist with special clearance.

In addition, the representative of the gas service must issue and authorization to operate the equipment installed. Without this, the owner of your own and set the running instrument will face serious penalties.

Thus, without the invitation of experts can only be made to connect the device to the heating system and water supply. It is desirable to do so only if there is some experience.

Wall-mounted gas-fired boilers in autonomous heating circuits forced type with natural circulation of coolant

How to start the installation?

First, you need to prepare the documentation required for installation. We must start with an initialization gasification facilities. It can be started only if it is brought to the pipeline.

Then the owner shall submit to the appropriate service statement, which indicates the desired him in a month or a year, gas consumption. If a satisfactory response to the statement of the pipeline, suitable to be placed necessarily equipped with a counter.

Before proceeding to the installation of equipment, it is necessary to develop and approve the installation project. All of the items that should do exactly

The owner gets his hands on the permits and technical conditions under which the equipment must be designed to connect the project.

Last includes the layout of the system of gas pipes from the heater to the point of connection with the highway and all the conditions of equipment installation. Designed project must undergo harmonization in gas service.

Together with the project owner of the premises where the boiler is installed, provide a certificate of conformity and the log purchased equipment, the conclusion of the expert service of its compliance with all safety requirements and instructions use.

Only after the project is approved, you can begin installing the heater. It should be clearly perform all items of project documentation.

image gallery

Photo of

On the tube, the feed gas to the equipment, the stopcock must be set overlapping stream blue fuel after stopping unit

Before each tube, part of the wall gas boiler must be installed shutoff valve required to disconnect the water supply

Gas unit wall type can be installed in the boiler in which the temperature should not be below 5º

Adjacent to the walls of the unit must be made of non-combustible materials. The boiler is hung on the brackets so that between a wall of the housing, including side was not less than 2 cm

Allowed direct contact with the boiler wall combustible walls. If there is no alternative, the wall of the boiler should be equipped non-flammable panel

Between the gas cooker and installed equipment wall flow type should be at least 10 cm

The distance between the sink and the wall flow type gas boiler can not be less than 30 cm. Distance to the mixer from the exit from the boiler through the pipe not less than 1 m

In the room with the mounted gas boiler has to work effectively with natural or artificial ventilation

The stopcock on the gas supply tube

Valves on the pipes outside the boiler

Location of the gas in the boiler room

Cmezhnaya with wall boiler wall

Wall-mounted boiler is installed in a wooden house

Regulate the location relative to the plate

The specifics regarding cleaning installation

Ventilation grille in the room

Environmental requirements for the boiler

Gas equipment belongs to the category of explosion and fire. Therefore, to the room in which it is installed, there are special requirements.

First of all, it must have natural lighting. Thus on each cubic meter room should account for at least 0.03 square meters. m window opening without a frame, that is, only the glazing. Window have to be equipped with windows.

A wall, on which is installed a gas boiler, must be finished non-combustible materials

Another necessary condition - the presence of ventilationWhich can provide air volume change rooms within 3 times in one hour. Thus fumes in the room will be able to minimize.

In addition, by selected power boiler It depends on the volume of the room in which it is installed. The equipment capacity of 30 kW or below can be taken in a 7.5 cu. m boiler.

image gallery

Photo of

Gas boilers for wall mounting with a private security group, a circulating pump and a small expansion tank

Due to the security group, interrupting the flow of gas in violation of the normal mode of operation for this type of equipment not necessary to arrange a separate room

Wall-mounted gas boilers varieties accepted mounted in bathrooms, bathrooms with toilets, kitchens, halls of country houses, etc.

Note, however, that the room should be aired freely. The apartments chimney must be connected to a collective flue, and in a private house evacuated outside the building

Wall gas unit in the kitchen

A separate room for the location of the unit

Wall mounted gas boiler in the bathroom

A properly installed unit

For heating devices whose power varies from 30 to 60 kW, the furnace volume required 13.5 cu. m and above. If the heater will be placed in the apartment, it is usually installed in the kitchen.

This is possible if kept all the requirements of SNIP. An important caveat: in this case, the total heat capacity of all located in the kitchen heaters should not be higher than 150 kW.

According to the norms install wall-mounted gas boilers to improve ventilation in the kitchen door you need to make a hole area of not less than 0.02 m and close the grille.

Experts recommend to be installed in an apartment house only equipment with a closed combustion chamber, equipped with coaxial chimney. The kitchens volume of 7.5 cubic meters. m or less is prohibited to set more than one heating appliance.

for the installation of gas heating equipment requirements are regulated by the SP-41-104-2000 and SNiP 42-01-2002. Observance of installation standards ensures safe operation

In private homes for gas boilers it is recommended to allocate space, separated from the living rooms refractory strong walls.

Optimally, the materials which decorated room had fire resistance time limit for at least 45 minutes. It is advisable to lay the premises prevented the rapid spread of flames in the living room.

Securing gas boiler can be performed only on a solid foundation. Partitions made of plywood or drywall is not suitable for this purpose. The wall on which the heater is housed, must be trimmed refractory materials.

If it does not, under the boiler is installed non-combustible substrate. The minimum distance from the device to the supporting structure is 0.5 m to the ceiling or wall and to the floor of 0.8 meters.

In the photo one of the following connection wall gas boiler

Step by step installation of equipment

Before installation, you need to unpack a brand new boiler and to do Checking the contents. Parts availability is checked for operational instructions that must be attached to the device.

In the absence of any element should immediately contact the supplier. Another nuance. The boiler must have a perfect appearance without dents, chips and signs to carry out repairs. If not, you need to call sellers.

It is important to make sure that the technical data specified in the data sheet heater, exactly the same as those that applied to the unit itself. In addition, they must comply with the figures specified in the device's operating instructions.

Immediately prior to the installation of the boiler tube must be washed, which can be different debris caught inside the device during its manufacture and transportation.

Installation of gas boiler involves connecting heating pipes, water and gas lines, as well as the arrangement of the chimney

It is also desirable to wash out and line heating system. After the training is over, you are ready to install.

Specificity and the procedure of determining characteristics of the equipment: the number of circuits involved and the type of combustion chamber.

Most often in houses put combi devices with a closed combustion chamber. We consider in detail the installation is of such a modification.

Step # 1 - Preparing the Wall Mount

To fix the gas boiler uses a special bracket, which must be included with the device. For mounting on the wall reliable fasteners are used. They should be selected for the material from which the wall is made.

It is possible that those who packed the manufacturer together with the heater, do not fit. Then you need to choose and buy the other.

bracket challenge is to sustain the weight of the boiler and auxiliary equipment, as well as provide it with a smooth well-tuned position, without distortions.

For accurate marking the walls, you can use the paper stencil, which usually comes with the boiler. With it, you can easily mark the holes for fasteners.

Once this is done, the bracket is secured in place and it is hung boiler.

Heating pipes are connected to respective nozzles of gas equipment. You can determine their location on the picture

Step # 2 - Connect heating pipes

Depending on the variety of the heating system, and it can be single pipe or two-pipe, Connectable to the boiler tubes can vary. In any case, starting with the removal of the plugs from the device nozzles.

To protect the boiler from the dirt particles from the heating pipe is recommended to put to the input of the return strainer.

If the water in the system of rigid or other parameters does not meet the manufacturer heaters requirements need to be concerned about installing additional cleaning equipment.

It can be, for example, polyphosphate dispensers. If this is not done, the unit breaks down quickly. All connections must be made in compliance with all rules and regulations.

Sealing is required. For this purpose, special sealants: traditional paint or tow any modern sealing thread. In addition, experts recommend mandatory installation of shut-off valves in the flow and return.

This is necessary to facilitate the repair of the boiler, if it fails. In addition, the fittings will prevent the possibility of airing radiators.

Water filter - element, which is necessarily set when connected to a gas boiler water circuit

Step # 3 - the connection to the water circuit

These works are almost similar to the connection of heating pipes. The main difference is in the used cranes and pipe diameter.

Liner cold water it is necessary to equip the filter, which would eliminate the possibility of entering the heater particle pollution. Otherwise deteriorate equipment.

Used to cut off the water supply valves on the boiler must be a plug connection.

Such models are called "American women". They greatly simplify the installation, and in the case of unforeseen situations provide an opportunity as soon as possible to replace the worn out valve.

It must be remembered that the pipes, lead-cold water, are located at the heater from the left side relative to the center, the hot lead-in - on the right.

Step # 4 - Connection to mains gas

This part of the work should only be a person with a tolerance because the cost of failure can be very high. In any case, at the end of the connection that it is correct is to check the gas service representative. He will first start the equipment.

All operations at independent conduct of works must be carried out very carefully. Beginning with compound gas branch line with a corresponding nozzle in the boiler.

Only tow, otherwise not be able to achieve the desired tightness may be used for all connections to the boiler gas line threaded connection seal

In the crane, which cuts off the flow of gas from the pipeline must be equipped with a special filter. Experts strongly recommend not skimp on this part.

Cheap low quality filter will last long, which can cause failure of the gas boiler. At arrangement of the connection, special attention should be paid to its sealing.

It should be understood that the weight of the gas is much less than that of air, and inadequate sealing engagement will ooze out of the pipeline. The consequences can be dire. Therefore, carefully sealing is required.

The main materials for the threaded connection and seals are paint tow, the use of sealants fum-type tape unacceptable.

After filtration element mounted particular flexible connection. We need to know what to use for his arrangement of rubber hoses is strictly prohibited.

This is because over time the material of which the item is made, and covered with dry cracks through which gas begins to leak. Therefore, the best choice for arranging such a compound is the corrugated hose.

Bellows - a good choice for connecting the appliance to the gas pipeline. He is strong enough, it is durable and is not destroyed by the gas

For its production is taken quality durable stainless steel. It is very strong and durable material, wherein particularly resistant to moisture and adverse effects of gas.

By the nozzle heater hose is secured with a union nut. Thus necessarily used asbestos fabric laying, which provides the necessary sealing compound.

Step # 5 - connection to the mains

This operation is only required for devices with a closed combustion chamber, which need electricity. It feeds a fan which directs the combustion products, and automation that controls the system.

Normally, the standard three-wire connection scheme. Experts recommend you to connect the boiler to the network only via a stabilizer that will make it possible to avoid power surges and thereby extend the life of the boiler.

If you live in areas that are prone to power outages, it is further

it is desirable to purchase an uninterruptible power supply - this will protect your equipment from sudden surges

voltage

Step # 6 - O arrangement chimney

The easiest way to connect to the heater chimney with a closed combustion chamber. For them, using special coaxial tubes. In apartment buildings, the boiler must be connected to a collective flue.

The individual buildings coaxial chimney is displayed on the outside through the wall. The height of the suspension pipe in this case does not matter, since the necessary thrust creates built-in fan.

Instruments with an open combustion chamber compulsorily connected to an individual chimney. The boiler is connected to pipe them the desired section.

The material for its manufacture is chosen so that the item had been resistant to the products of combustion, high temperature and mechanical wear.

Checking the tightness of gas pipe connections can use the soap solution. Gas leak will show itself the appearance of bubbles

Before starting work, make sure that no residues of soot in the chimney, the mounting garbage, etc. When installing the chimney pipe it should be placed with a slight slope in the direction of the gas boiler.

At the outlet of the device is set vertical length of pipe, its length should be equal to the rotation at least two pipe diameters. The total length of the section connecting to the chimney should be minimal.

Step # 7 - Preparation for the first start-up

Before test start heating system is filled with water. Fluid is pumped in until a pressure of 2 atmospheres. Injecting water is carried out slowly as possible to remove the maximum amount of assembled inside air.

In addition, the system check is carried out for leaks. All leaking connections to be sealed immediately.

To identify compounds insufficiently dense gas line should be diluted soap solution and lubricate them all connections. Then watch.

On the low-quality sites will be air bubbles. All faults found must be removed and re-check. The first launch of the equipment should be carried out only in the presence of gas service.

Conclusions and useful videos on the topic

The video examines in detail the regulatory requirements for the installation of gas boilers wall type:

Video tells of the wiring diagram of the boiler wall:

Video shows the installation process of the wall of the boiler:

Installation of gas heating unit - a responsible and rather complicated operation, the quality of the implementation of which depends the safety of all who live in the house. Therefore, representatives of gas services strongly do not recommend to deal with it on their own.

And the heaters manufacturers insist on it. Therefore, even an experienced handyman is best to seek professional help, which ensures long-term, and most importantly a safe operation of the device.

Please leave your comments if you have any questions on the subject of the article. Or maybe you yourself had to deal with the installation of the gas fired equipment and you have something to suggest to our readers?