The South Korean manufacturer Kyung Dong Navien offers the Russian consumer a wide range of boilers of different power and design variations. The equipment is adapted to the specifics of the work of domestic communication networks and to local weather conditions. Reliable and functional units are quite rightly in demand.

They buy from us mainly wall-mounted models that attract with their compactness and economical consumption of gaseous fuel. The equipment presented for sale is Russified, so that the Navien gas boiler can be set up without any problems. Moreover, it works "perfectly" in various modes.

We will tell you about how to install a home heater for the preparation of coolant and hot water. We will show you how to set it up depending on the period of the year. Here you will find valuable recommendations, following which you can significantly extend the working life of the boiler and prevent malfunctions.

The content of the article:

- Features of the functionality of boilers of the Navien brand

-

Installation and connection procedure

- Providing conditions for installation

- Choosing a location

- Connecting the speaker to communications

- Features of the first launch

- Specificity of the setup

- Recommendations for use

- Conclusions and useful video on the topic

Features of the functionality of boilers of the Navien brand

Boilers of South Korean production with the Navien logo are leading in the ratings based on the opinion of the service technicians for a reason. They work flawlessly, meet the standards of the Russian Federation, and have an impressive list of qualities that ensure comfortable operation.

The benefits that can be enjoyed by owners of gas heating units include:

- Frost protection. A stable operating system that excludes the formation of ice plugs in pipes and the unit. When the temperature in the surrounding space falls below + 10º, the circulation pump is automatically activated, when the temperature drops from + 6º, the burner starts up.

- Surge protection. The safety and continuous operation of the unit is ensured by a device that excludes failures and stops. The SMPS (abbreviation for Switchet Mode Power Supply) chip embedded in the microprocessor is triggered by fluctuations in the mains.

- Low pressure protection in the gas pipeline. The units tolerate the pressure drop in the blue fuel supply systems without malfunctioning. They do not stop working even if the head is only 4 mbar.

- Use with a drop in water pressure. Boilers from a South Korean manufacturer work efficiently if the pressure of cold water at the inlet to the units drops to 0.1 bar.

- Unique heating technology. The equipment is supplied with a remote control panel equipped with a temperature sensor. The readings taken by him are instantly transmitted to the boiler, which turns on and off in accordance with changes in the temperature background within the processed object.

In addition, the boilers of the Navien brand are supplied with an excellent automation and a wide range of security systems that interrupt the heating of the coolant and sanitary water in the event of a ripening or a threatening situation.

Image gallery

Photo from

Gas boilers with the Navien logo have been on the world market for over 30 years. Their reliability and functionality are good reasons for the well-deserved popularity among consumers.

The company that produces gas boilers Navien offers a wide range of wall-mounted and floor-standing models that differ in performance and functionality.

The assortment of gas boilers offered to customers includes single and double-circuit units. The former are intended for the preparation of only the coolant, the latter for heating the coolant and sanitary water

The Navien ATMO line of gas equipment includes models with a capacity of 13 - 24 kW. This is a great option for arranging a city apartment.

Gas boilers of the Navien Deluxe series are produced in a power range of 10 -24 kW. These units are equipped with a turbocharged burner, gas level control system

The range of gas boilers Navien Prime does not differ from other wall-mounted models in terms of power, but it is equipped with weather-dependent automation. Sensitive sensors built into them react to changes in the temperature background and transmit information to devices that start and stop the operation of the boiler

Floor-standing gas processing devices Navien perfectly cope with heating private houses, industrial workshops and commercial premises. Do not interrupt work in the event of a drop in pressure in the water supply network

Trade offers from a Korean firm include condensing equipment - boilers with high efficiency with reduced fuel consumption

Wall-mounted gas boiler of the Navien brand

Wall and floor gas models

Single and double-circuit gas units

Gas equipment Navien ATMO

Gas boilers of the Navien Deluxe series

Line of gas boilers Navien Prime

Floor-standing South Korean variants of the Navien GA

Condensing equipment Navien NCN

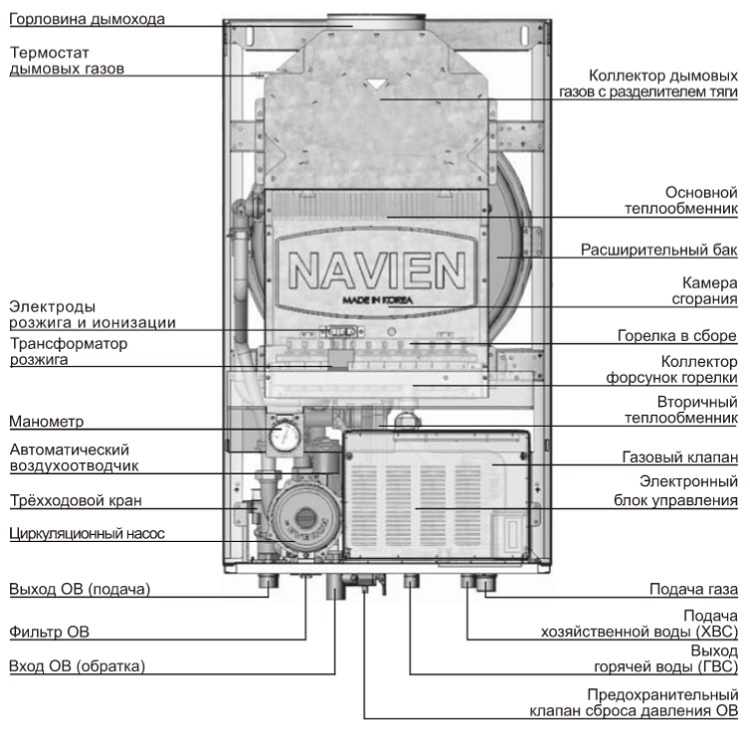

To control the water pressure within the boiler, it is equipped with a pressure gauge. There is a safety valve that allows you to reduce the pressure if it is higher than the manufacturer's standard. To exclude overheating, filters are installed for heating, for water supply, and for gas.

Installation and connection procedure

Immediately, we note that the installation and connection of any model of the Navien gas boiler, as well as its first start-up, must be carried out by a master from an authorized service structure.

Otherwise, the manufacturer will not fulfill the warranty. However, the owner should know how the process is carried out in order to supervise the work of the hired worker.

Providing conditions for installation

South Korean equipment for heating coolant and hot water can process both main gas and liquefied gas mixtures. The blue fuel options available for use are indicated on the plate. It is fixed on the right side of the case.

Information on what type of gas is possible for processing in the Navien boiler can be found in the table on the right panel of the casing. The use of gas that does not correspond to the declared one may lead to failure of the unit or to an accident.

To connect the boiler, you will need to bring the power line to the location. You cannot connect the device to the mains through adapters or extension cords.

Requirements for the power line for the boiler:

- The power supply source for the operation of the boiler of this brand must have the following parameters: 220V, 50Hz. Deviations from these standards may result in either fire or loss of performance.

- It is forbidden to connect any electrical equipment to the source parallel to the boiler. Failure to comply may result in a short circuit.

- The socket must be located 30 cm from the heater body.

- The unit must be at least 60 cm away from electrical appliances of all types.

- Boiler body should be grounded without fail.

In the room intended for the location of gas equipment, a flawlessly functioning exhaust and supply ventilation system must be organized.

The window should have a transom that can be easily opened for ventilation. The door should have a ventilation gap or grill at the bottom.

Image gallery

Photo from

An important characteristic for choosing a boiler is its power, which should be enough to supply the coolant to all circuits connected to the unit. In the case of processing several contours, the kilowatts they need are summed up

The room in which the boiler is to be installed must have everything necessary for ventilation and regular supply of fresh air. It must have an opening window and a closing door with ventilation holes.

Floor-standing gas processing equipment is installed in a separate room - in a boiler room organized for it and the boiler

The installation of a wall-mounted model does not require the organization of a separate boiler room. It can be installed in the kitchen or in the hallway equipped with a transom. It is important that the premises are non-residential

Processing multiple contours

Reliable ventilation

Installation of a floor-standing unit in a boiler room

Wall model in the kitchen of a private house

The location of gas equipment in rooms with a characteristic high level of humidity is not allowed: in bathrooms, in swimming pools, in shower and bath facilities. Dampness and insufficient air flow interfere with the normal operation of the boiler. In addition, they reduce its operational time.

Boilers must not be installed in open areas. They are not meant to be in contact with atmospheric negativity. It is forbidden to locate where explosive and flammable substances, as well as bulk building materials are stored.

Choosing a location

In most cases, wall-mounted gas boilers are located in kitchens or hallways, which have a window or only a vent for ventilation.

For installation of floor models equip boiler rooms, separated from residential and functional premises in the house. In either case, provide sufficient space for easy maintenance and repair of the unit.

Image gallery

Photo from

Hanging wall models should be carried out on solid walls with a bearing capacity sufficient for their load.

Direct contact with flammable finishes, building materials capable of burning and spreading fire is unacceptable. It is allowed to hang gas boilers on plastered and tiled walls

Mills made of flammable materials or finished with materials prone to burning must be secured by installing non-combustible protection

It is undesirable to place wall-mounted boilers in cabinet furniture modules. Their casing must be constantly cooled by air currents to prevent overheating.

Wall model on a capital structure

Recommended types of contacting materials

Insulating gasket between the wall and the boiler

Space for blowing off the boiler drum

Consider the rules for choosing a place for a wall-mounted gas appliance as the most common solution for our compatriots:

- Hanging is permitted on a wall made of non-combustible building material. If the wall material is capable of igniting and sustaining combustion, the surface must be revetted with a non-combustible finish.

- The unit must not be located near emergency exits or stairs.

- There must be at least 0.6 m between the opposite wall and the front panel of the gas equipment. A similar distance must be maintained between the boiler and any electrical appliances.

- Leave 0.2 m between the side panel of the case and the nearest structure or piece of furniture.

- There must be 0.8 - 1.1 m between the floor plane and the lower edge of the unit hung on the wall.

For fastening wall model it is advisable to find a place on the load-bearing wall. If the strength of the wall is in doubt, it should be reinforced. The boiler is fixed with anchor bolts.

Image gallery

Photo from

A distance of at least 60 cm must be maintained between the Navien boiler and the heating devices.

It is strictly forbidden to place the boiler next to any type of climatic equipment. Because of this, the combustion process will be disrupted.

Any type of electrical appliance must not be placed next to the boiler, because their body heats up during operation. The minimum distance between them and the unit is 60 cm

The electrical socket must be at least 30 cm away from the boiler casing

Distance between boiler and heating devices

Violation of installation rules

Indent from all kinds of electrical appliances

Socket location rules

If there is a suspicion that the heater will make excessive noise during operation, it is recommended to use buffer substrates on the wall made of non-combustible material.

Connecting the speaker to communications

For gas heater operation coolant and sanitary water, a double-circuit heating device must be connected to communications. We have already talked about laying a separate power line. Everything should be done in accordance with the rules of the PUE.

In order to understand the nuances of connecting a gas boiler, you should carefully study its structural structure. Due to the fact that an inexperienced performer confuses a gas pipe with a water supply branch, a serious emergency can result.

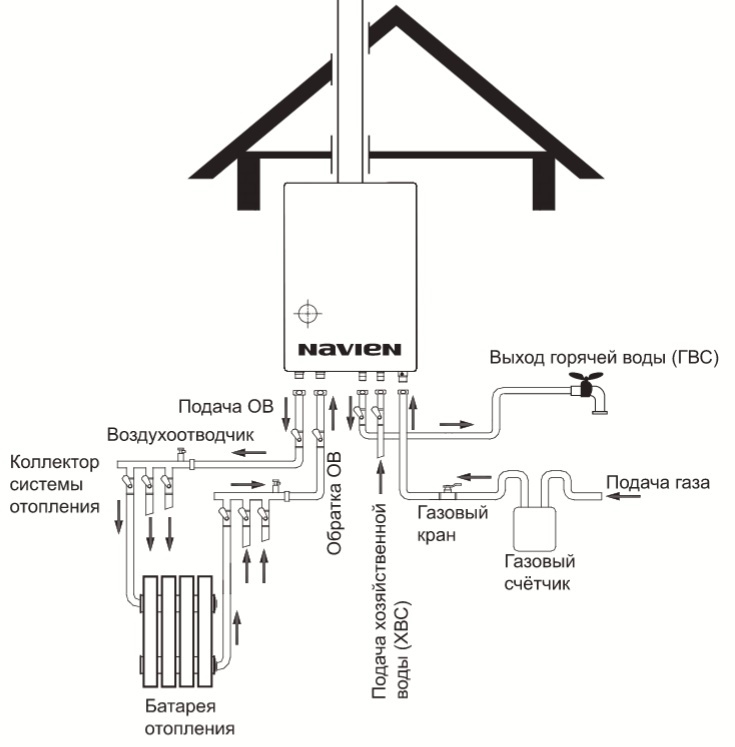

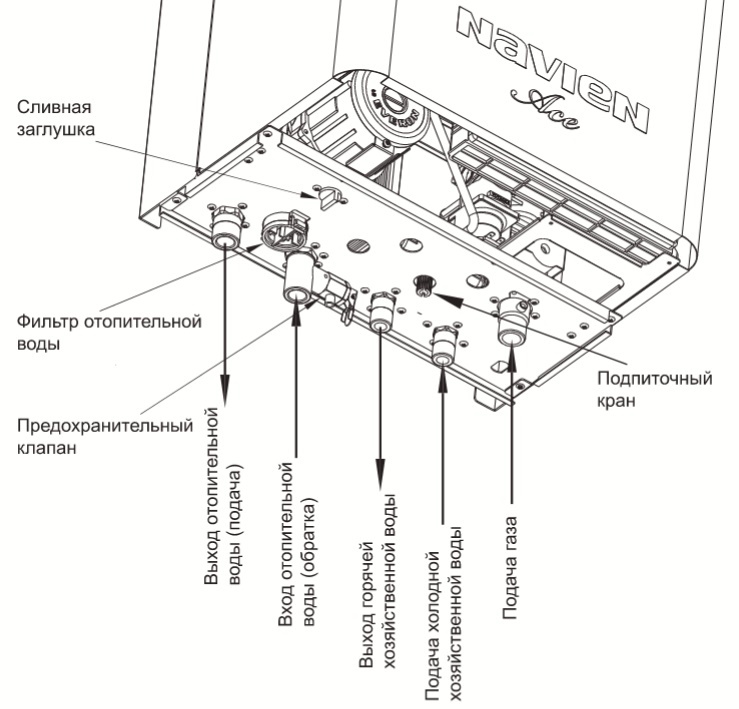

Now it is necessary to bring branches to the boiler from the cold water supply systems, gas supply systems and the heating return pipe. And it is necessary to remove from it the supply line of the heated coolant, the pipe for supplying hot water to the mixers and the chimney.

All stages of connecting a gas boiler of the Navien brand must be performed according to the scheme drawn up in advance by the gas service with which the contract was concluded, and by the plumbers serving the house. It takes into account the technical features of a particular room and the recommendations of the equipment manufacturer.

The connection of the gas boiler to the communications should be handled by a representative of the organization with which signed a contract for the supply of blue fuel, inspection and maintenance of gas-using equipment

After installation, all joints of pipes transporting water must be checked for leaks. You need to test both heating and water supply lines. Gas pipelines also require checks, which are simply covered with soapy water at the connection points to detect leaks.

Pipes that are not involved in the heating process are recommended to be insulated. These are partly heating routes and all water supply branches. As thermal insulation, it is better to use foam insulation that repeats the shape of the pipe.

All pipelines connected to the boiler must be equipped with valves to shut off the device in the event of a threat or breakdown. The boiler should be connected to a liquefied gas source through a reducer, to a group of cylinders - through a gas manifold.

All communications entering and leaving the boiler must be equipped with taps that are required for shutting off the flow of the medium in the event of repair or replacement of equipment, as well as in the event of a threatening situations

Upon completion of the installation operations, the boiler is first started up, which must be performed by a representative of the organization supplying you gas. Then the setting is made according to your personal preferences and requirements for the indoor microclimate, as well as in accordance with the season.

Features of the first launch

The first start-up and commissioning operations are carried out by representatives of the service center, who installed the boiler and connected it to communications. All actions are documented.

The owner of the equipment needs to keep these papers, because they are written confirmation for the subsequent fulfillment of the warranty obligations.

Before performing installation work, a diagram must be drawn up. The contractor must provide the customer with an estimate with the materials that he has to purchase

For the first launch you need:

- Fill the boiler and the circuits connected to it with water. This is done through a make-up unit located on the bottom of the boiler, equipped with its own tap. They also use it if for some reason the pressure in the gas boiler drops during operation.

- Observe the pressure during filling. When the pressure gauge shows 2 atm, the valve should be closed.

- Remove air pockets manually. Further, excess air from the unit will be removed automatically, but for the first time after filling the circuit heating with a coolant, they must be eliminated using the Mayevsky crane from each device, starting from the very far.

- Top up the water in the heating circuitso that the coolant occupies the space that was previously occupied by non-removed air.

- Bleed air from the circulation pumpinstalled in the boiler.

After the above steps, you need to start the equipment by pressing the "Power" button. Then you need to start setting the temperature regime that is priority for the owners.

If error code 02 appears on the display after filling the communication systems and bleeding air, you must use the make-up tap to replenish the water. It is also needed to relieve water pressure in the circuits.

Specificity of the setup

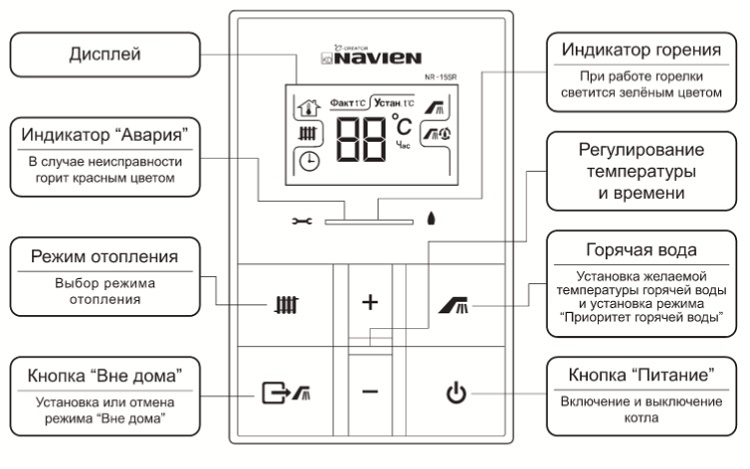

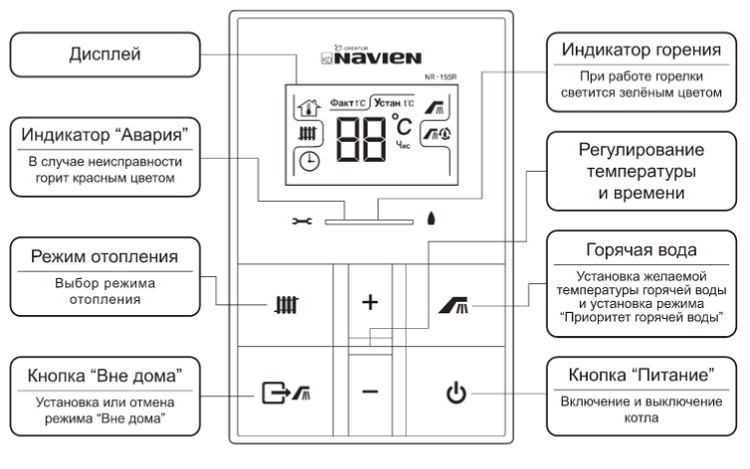

The Navien boilers are equipped with a remote control panel. It is with its help that the setting is made. All commands and modes on the panel are spelled out in Russian, the buttons of all functions are accompanied by extremely understandable graphic icons.

In the lower right corner of the remote panel there is a button that is used to turn on / off the unit. One press activates the operation of the boiler in the mode set by the owner. Pressing it again will stop the heater.

To control the boiler and select a suitable operating program, gas processing equipment from Navien is supplied with remote controls

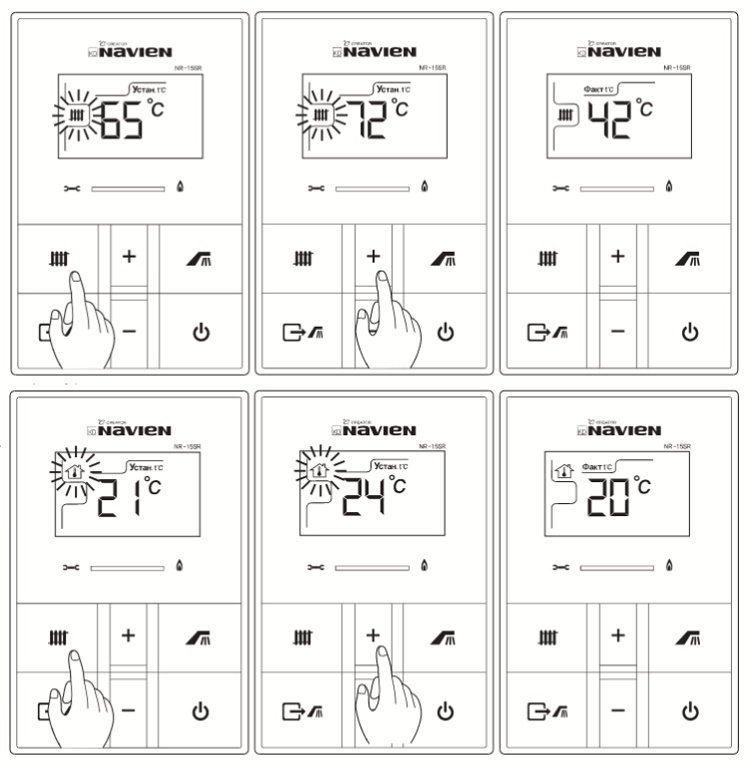

You can turn on heating with temperature control of the coolant as follows:

- We find on the panel a button with an icon resembling a battery. We press until a similar symbol appears on the display.

- We select the priority temperature for us, using the buttons with the "+" and "-", located in the center of the lower part of the panel. We increase and decrease from 40 ° to 80 ° C in the most usual way.

- Similarly, we designate the period during which the coolant will be heated.

Everything is extremely simple. If the "battery" icon on the display pulses, then it shows the parameters that we have just set. If it stops flashing, it means that it displays the actual temperature at the moment.

In order to set the heating mode with the optimal temperature, you need to find the desired function on the remote control and set the priority temperature

To set the mode in accordance with which the boiler will start / stop, focusing on the temperature background in the room, perform the following actions:

- We find on the panel a button with an icon resembling a battery. However, now we are waiting until an exaggerated image of a house with a "thermometer" appears inside.

- We return again to the "+" and "-" buttons to select the temperature background in the room that is priority for us. It varies in the range from 10º to 40ºС.

- The flashing house will show us the selected temperature, the unblinking one - the real temperature parameter at that moment.

Upon completion of all the actions performed, you do not need to press any buttons to save, the settings we have selected are automatically saved.

To select the desired water temperature, you need to find the function indicated by the shower head on the remote control and set the desired value. Note! Changing the temperature while taking hygiene procedures by another person is prohibited.

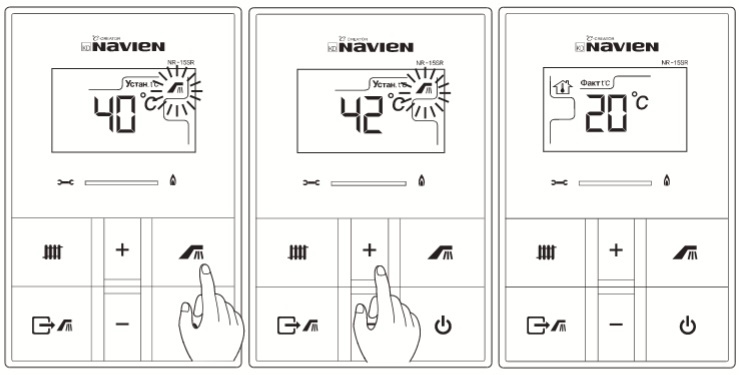

You need to choose the temperature that is optimal for the preparation of sanitary water as follows:

- We find the button to control the "Hot water" mode. We press it and wait for a pulsating image of a working shower head to appear in the upper right corner of the display.

- Again we use the "+" and "-" buttons in order to find the optimal temperature for us. It can be set in the range of +30 - (+60) ºС.

- We are waiting for the darling to finish flashing. This means that the boiler has automatically saved the preset level and switched to the operating mode in accordance with it.

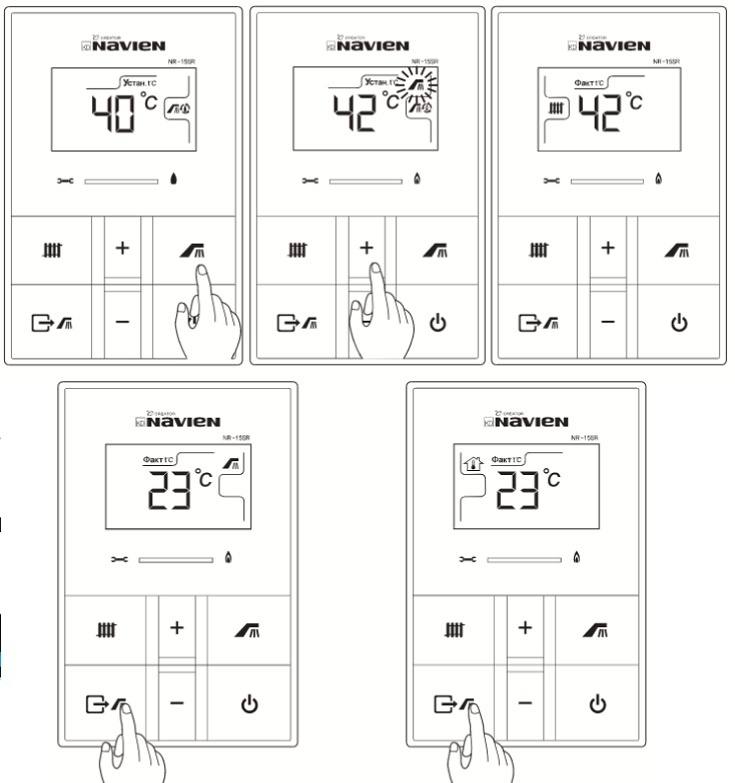

If the unit is to be used only in the summer, or if it was purchased at all for preparing hot water, the function "Hot water priority" comes into play. The procedure for its selection is slightly different from the above-described method. The difference is that a double symbol will appear: a shower and a circle of three arrows.

Selecting this mode will force the boiler to heat sanitary water even when it is not being used. Those. the heater is activated and prepares water, and after 10 minutes it turns off if no one has opened the taps during this period.

If the heated water is consumed, as indicated by an open tap and a drop in pressure, then the boiler will always prepare water at a given temperature. It works to heat water only when there is a need for it. If you switch the equipment to a different mode, then this automatically stops working.

Navien boilers can only work for heating hot water. To do this, they need to be switched to the “Hot water priority” mode (a diagram of 3 points above) or “Out of the house” (a diagram of two points below)

You can transfer the Navien boiler to a mode that only warms up water using another function. Our compatriots know it under the name "Winter-Summer". However, it is correct to call her "Out of the House". The button for its selection is located in the lower left corner.

A timer is available to set the period of constant operation of the gas unit and shutdown when it is not particularly necessary. They control it according to the absolutely simple scheme described above. The range of capabilities of the timer device is designed for an interval from 0 to 12 hours.

Recommendations for use

In order for the heating agent and sanitary water heater not to get lost during operation and fail prematurely, the operating rules must be strictly observed. You just need to remember them and try not to violate the instructions specified by the manufacturer.

If you do not need the heating system to work in the next two or three days, do not disconnect the equipment from the power supply. Together with the interruption of the power supply, the anti-icing system will stop. Ice must not grow in the boiler or in the pipes connected to it at this time.

However, if the ice plug has managed to form, do not despair. You probably have an effective and quite affordable tool for eliminating it. Use a home hairdryer and warm up the pipes. And if he didn’t help either, call the gas workers.

If a long "downtime" of the boiler is planned without work in winter, all the water from it and from the systems processed by it need to drain. It is not necessary to create the slightest prerequisites for the freezing of the contours. Believe me, the consequences can be not only dire, but also extremely dangerous.

The control panel of the gas processing unit must not be installed near air conditioners, electrical appliances, heaters. Otherwise, its built-in sensor will record distorted data, and the boiler will not work correctly.

Before switching on, try to constantly check whether the taps for the water supply and outlet of the heated coolant, as well as the supply of blue fuel, are open. Do not forget that working on heating without a medium that the unit is obliged to process, it can burn out.

Never wipe the body of an electrical appliance while it is running with a damp cloth. If you want to tidy up the Navien gas boiler, see how to turn it off. To do this, first interrupt the work with the activation button on the remote panel, then disconnect it from the power supply line.

Remember that the faceplate must not be positioned to cause unintentional external heating. It does not need to be installed in an intensely sunlit corner or near a heating appliance. So all the temperature settings will get lost due to the fact that the sensors record an unrealistic temperature.

Filters installed for the heating system must be cleaned regularly to maintain the performance of the boiler at altitude.

Clean the heating and cold water filters regularly. Clogging them will force the unit to unnecessarily increase the heating power in an attempt to maintain performance. As a result, overheating and failure of important functional systems of equipment will occur.

If there is a need for translation of the boiler Navien on the use of liquefied gas, invite an employee of the gas service. He will change the gas injector module and reconfigure the boiler. Note that translation work can be done on your own, if you do not doubt that you will be able to carry out them efficiently.

Image gallery

Photo from

To transfer Navien to the consumption of a liquefied gas mixture, a priori configured and equipped for operation on main gas, we buy a manifold with gas nozzles of the boiler recommended by the manufacturer diameter

We remove the front panel of the boiler body in order to "get" to the installation site of the standard manifold with nozzles

We detach the connectors connecting the ignition device with the gas boiler transformer

To open the combustion chamber, first remove the horizontally installed gas supply pipe, then the sensor of the overheating protection system

Remove the outer cover of the closed combustion chamber. We dismantle carefully, trying not to deform

Having unscrewed two fastening bolts on the sides of the standard manifold, we remove it. We put in place a new one with smaller nozzles and fix

Before installing a new manifold with gas injectors designed to supply a mixture of liquefied gases, remove the O-ring from the former device and transfer it to the new manifold

On the control board, we find a microswitch responsible for the use of a certain type of gas. He is usually the fifth from the bottom. We switch it to the right position

Step 1: Purchase a manifold with LPG injectors

Step 2: Removing the casing bezel

Step 3: Detaching the connectors of the ignition device

Step 4: Removing the gas line and overheating sensor

Step 5: Removing the combustion chamber cover

Step 6: Replacing the manifold with gas injectors

Step 7: Install the O-ring

Step 8: Switching the processor on the control board

Do not use yourself and make sure that the invited technician does not use used pipes to connect gas processing equipment. This is fraught with serious poisoning and damage to property for a very impressive amount.

Conclusions and useful video on the topic

Detailed instructions for connecting and commissioning a wall-mounted version of a gas boiler:

Knowing the specifics of installing, connecting and setting up a gas boiler is useful as an independent for home craftsmen and owners who invite plumbers with gas workers to perform the above work.

Possession of information will ensure correct execution and decent control of all actions. Then the boiler will work perfectly, will not create problems and will last an extremely long time.