Specifications electric saws are the same. To select the appropriate, we recommend reading the forums on the topic covered. There, participants share secrets that remain behind the frame of official reviews. Having looked similar, someone decides that it is better to buy a champion than Makit.

. How the

power saw is arranged. The rotation speed is often not indicated. It is clear that inside there is a collector engine, but how fast it is. Pay attention to the parameter of the speed of rotation of the chain. It is expressed in meters per second( 13.5) and shows how fast the links move. It is known that the length of the tire is 14 inches( 35.5 centimeters).For reference: an electric saw tire is called a metal frame, and a chain runs along it.

The total length of links is about 85 centimeters. We take stock on the tension mechanism and the transverse size. This means that in a second the total number of revolutions is N = 13.5 / 0.85 = 16. Per minute, approximately 950 is obtained. This is not the engine frequency, but the number of revolutions of the circuit. But there is information on the drive star, it is written: 6T x 9.53.This means that teeth 6, and the distance between the teeth is 3/8 inch( 9.53 millimeters).It remains to multiply these two figures, to obtain the circumference: 6 x 9.53 = 60 millimeters( rounded).

It turns out that the driving star makes a circle of 85/6 = 15 revolutions, which gives a rotational speed of the shaft of about 14000 rpm. Provided that there is no gearbox inside. Inside there is a high-speed collector motor( you can’t bring asynchronous to this speed), which means there is no choice. Sometimes used gearbox, in other cases, direct drive. In the second case, the electric saw weighs less and there are fewer parts that can break.

Electric Saw

The motor lies transverse to the movement of the plane chain for obvious reasons. The sprocket shaft goes outside and the chain is put on. It stretches around the tire, and then attached to the body. Here are the important mechanisms:

- The tire attachment system should provide for the possibility of tensioning the chain.

To this end, long cuts are made for the spikes on the plane of the steel. Further fastening systems begin to differ. Electric saw manufacturers solve the problem in their own way. For example, the tension is provided by a symmetric spiral screw, like in Champion, or by a single thorn, like in Makit.

is usually delayed by a key. But Makit has a special folding screw. It's good that it is part of the design, but users complain that the elasticity of the springs decreases, and the head begins to dangle. Pay attention to what has been said if you consider it important. Well, if there is a rubber socket on the cord under the said key.

- The star above is covered by the case. It is from him that the tension screw sticks out.

But there is in addition a duty adjustment mechanism. During operation, the chain is loosened, and it would be inconvenient to constantly remove the cover, turning off the screw. The duty mechanism is implemented in different ways. For example, in the case of the Champion he must be tightened with a screwdriver, and the nest is located on the side of the canvas.

Sparky is missing a screw, but there is a large diameter plastic trimmer wheel. It is convenient, located on the side. In standby mode, tighten the chain does not take much time. The wheel looks fragile, there are fears that the mechanism is prone to breakage. When choosing a power saw, pay attention to the duty means of maintaining the tension of the chain.

Sparky

- Chain Saw To prevent the chain and tire from getting warm, a special pump feeds oil into the area of the pinion gear.

So the coefficient of friction decreases, and the generation of heat decreases. Users complain that Makita's pumps easily fail, and the oil either stops flowing or is injected too quickly. To control the level on the side of the electric saw there is a viewing window. The type of oil is indicated in the instructions. If during sawing the log smoke appeared from the saw blade, it is recommended to stop work immediately.

At a power saw usually two handles. The first is located in front of the case on the left. Arcuate and durable. In this place there is a shield that serves both to protect against flying chips, and as a spare switch. In many cases, when working with an electric saw, a so-called back kick occurs: a tire with a moving chain rebounds towards the woodcutter. As a result, the shield hits the hands and flips a switch, interrupting the power supply to the engine. Power saw immediately stops, blocking the possibility of an accident.

In this sense, all devices are designed in the same way, but the part has additional protection against chain jams. In practice, the electric saw refuses to cut thick wet logs. In the case of a fatal blocking the motor will be saved from inevitable death. The chance that the chain is stuck on the tire is minimal, but it is present. If stuck, the gearbox may be damaged. Products of this type are not recommended without additional measures.

The rear handle is for the right hand. Taking a power saw in hand, try to see whether it is well balanced. Modern 2 kW models weigh a little more than 2 kg, which facilitates the work. The saw should be free to lie in the hands for easy cutting. The technical data gives the maximum log diameters. Size is limited by tire length.

Do not touch the objects with the end of a working electric saw, in this case the chain in an arc bounces toward the head of the master. What can end sadly. Similarly, you do not need to try to cut logs whose diameter exceeds that specified in the instructions.

In the off state, the chain of saws is hidden in the casing removed during operation. The front body of the electric saw is equipped with plastic or steel teeth. They need to rest against the workpiece, and then swing the blade up and down. So it is easier to cut, and the teeth serve as a limiter on this side. The last thing we want to say applies to food:

- The cord is short. This is done for reasons that the washer connector does not drag on the ground: there is a high probability of a short circuit due to moisture that has penetrated inside, which is at ground level.

- The second reason: the lack of drag factor. Probably, it was often noticed that the device was inconvenient to use, as the plug with the socket always touched something. The power cord of an electric saw with a length of less than half a meter leaves no chance for such incidents.

- The design of electric saws has double or equivalent insulation( electrical safety class II).But, most of the devices work in the rain is strictly prohibited. And this is understandable - the electric brushes are open for short circuits along a wet path that stretches along the surface of the collector drum.

- Most electric saws on the power cord have a small grip for the extension cord. This ensures the strength of the mechanical connection. As a result, we work and freely move the saw.

Working with an

electric saw How to use an

electric saw It has already been written above that the end of a working electric saw should be kept away from objects. But the power saw is suitable for cutting trees in the forest. You will need an electric generator of at least 6 kW, because the considered instrument is single-phase. It is better if three woodcutters are engaged at the same time. This will ensure a uniform load on the three phases of the engine, which will create a gentle mode of operation.

A powerful electric saw is good, but often it is noisy, heavy and rough. For a thin, even cut, take a weak motor. He does not like the speed, but the quality is higher.

On a damp tree the power saw goes badly, and a number of models will stop because of the built-in protection. As the process progresses, constantly monitor whether there is a waste near the leading star. Part of the power saws is sinned by the fact that the lumps are carried in the direction of the body, and they remain inside. For greater speed, try to take the motor more powerful, but remember about the working cycle. This means that the power saw must periodically rest. For example, it can work 15 minutes, then rest is laid. Depending on your needs, choose the correct working cycle of the electric saw, carefully read the operating manual for this topic( see the example in the figure).

Cut from instructions

It is important to work properly with an electric saw. Do not lift it above the elbows, stand with the unit on the stairs. Look carefully at your feet to stand on a flat, hard surface. Without the ability to slip. Most electric saws, despite the complicated switching mechanism, have the ability to lock the state. But the engine will continue to work until you stop it. And if the power saw fails out of the hands, it can happen irreparable. All types of electric saws should be kept away from combustible and explosive materials.

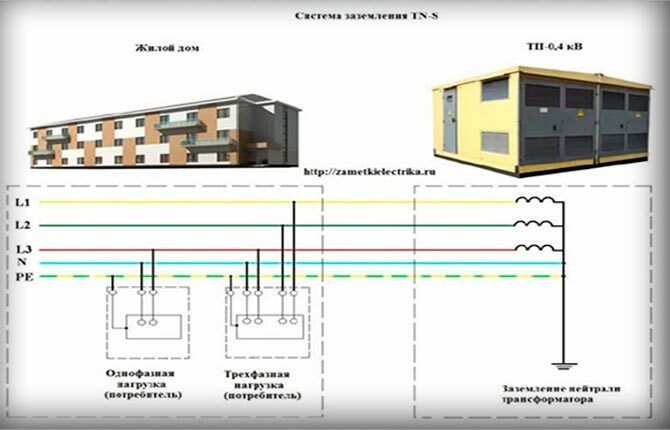

Carefully select an extension cord for an electric saw with a high degree of protection on IPX4 or IPX5.These are jet-proof and splash-proof sockets, they will withstand all the tests for 100%.Electric saws often lack grounding, and the presence or absence of a side coil does not matter. But the socket must be connected through a differential machine. And, if it happens in nature, such protection is obligatory. Please note that the generator must be grounded, and for the outlet it does not matter.

In the course of the story about electric saws, we did not say three-phase variants: it is difficult to find them. The collector motor is usually powered by a single phase, and the voltage of 380 V is used primarily for asynchronous. It is clear that such saws, if they occur, are in the form of machines in the industry to reduce noise. As for domestic options, they are designed to power 220 V. This is inconvenient, because most generators are three-phase.

Add that differential machine is needed to protect the saw and the worker from the danger of the circuit. The considered class of devices is connected simultaneously to the phase and the neutral wire. According to the rules of PUE, sockets for equipment operating in outdoor conditions are supplied with a differential circuit breaker with a current threshold not higher than 30 mA.