Arrangement of grounding of electrical installations is a prerequisite for the safe operation of any electrical equipment. Properly executed "ground" can prevent serious injury and even save health or life, not to mention damage to expensive equipment.

The content of the article:

-

Classification of grounding systems

- TN-C earthing system

- TN-S earthing system

- Earthing system TN-C-S

- TT earthing system

- IT grounding system

-

Grounding requirements for electrical installations up to 1000 volts

- Natural grounding

- The Importance of Drip Resistance

- Grounding work in case of violation of the protective insulation of live parts

- Protection of electrical equipment in workshops

- Grounding of welding machines

- Protection of mobile installations

- Electrical protection

- Motor Grounding Basics

- Results

Classification of grounding systems

The old (sixth) edition of the PUE provided for 2 options for grounding electrical transformers and consumers. In this case, the classification of grounding schemes looked simple:

- Deaf (dead-earthed) bus-neutral. Connected directly to the ground loop on the distribution transformer. A couple of wires went to consumers. They had their own grounding.

- Remote or isolated neutral. The ground bus was not connected to a circuit dug into the ground, but was carried out with a separate wire in addition to the two power wires already laid.

In theory, the grounding system should have worked like clockwork - it is simple and understandable to any electrician connecting an electrical installation to the network. For the most part, grounding worked properly if the voltage balance and ground wire were properly done.

Problems arose only with an uneven load (usually in rural areas) or with a break in the neutral. An isolated neutral always had an excess potential relative to the "ground zero", which was unsafe.

Even on the simplest lighting devices, refrigerators, not to mention more powerful electrical installations, a potential appeared, the value of which was unsafe for human health and life.

Since 2009 The seventh edition of the PUE (Chapter 1.7) defines new grounding schemes for electrical installations and introduces their classification, letter designation.

In the modern classification, 5 types of grounding of electrical installations are presented:

- TN-C - the old version with a dedicated grounded "deaf" neutral.

- TN-S version with separated neutral and protective (earth) conductor.

- Scheme TN-C-S. The neutral (N) is aligned with the protective conductor PE.

- TT scheme. The protective conductor is connected to the individual earthing of the electrical installation.

- TI version with isolated neutral and own earthing of the electrical installation.

The first and last schemes are the old systems for organizing the grounding of live parts that existed in the sixth and earlier editions of the PUE. They were included in the classification, since all electrical installations, transformers, electrical equipment, wiring in industrial and residential premises were carried out precisely according to these two schemes. Nobody changed anything. No wire colors, no wiring diagram. Therefore, in the seventh edition of the PUE, they simply added 3 additional systems used in imported equipment to the classification.

Now the grounded line relative to the electrical installation was designated "T", and the isolated line - "I". "N" denoted the zero working wire. In the cable, it is always blue and is used for electricity. Mounted on insulated terminals. Regarding the "grounding" on the ground, there will be an excess potential on it.

For grounding the body of electrical installations, connecting to the ground loop (on the ground), a wire with the designation PE (yellow-green, striped) is used. This is a true zero in the wiring.

Until 2009 zero (grounding) in the electrical installation was carried out with a black wire. Therefore, before inspecting or revising the switchboard, it makes sense to first look for the zero yellow-green and black wires. Before starting work, check with an indicator which of them is responsible for grounding the electrical installation.

TN-C earthing system

This is an old earthed neutral circuit for networks with electrical installations up to 1000 V, in some cases up to 6000 V. Here, the working zero and ground are combined in one bus. Despite the "outdated" solution, this option is still used in household appliances, in old power lines.

The TN-C system is considered one of the more effective ways to protect a person from electric shocks. But subject to the correct arrangement of the grounding device in the ground. In order for the grounding part of the wiring to work properly, it is necessary to update and periodically restore the circuit. This is the weakest point in the entire TN-C circuit.

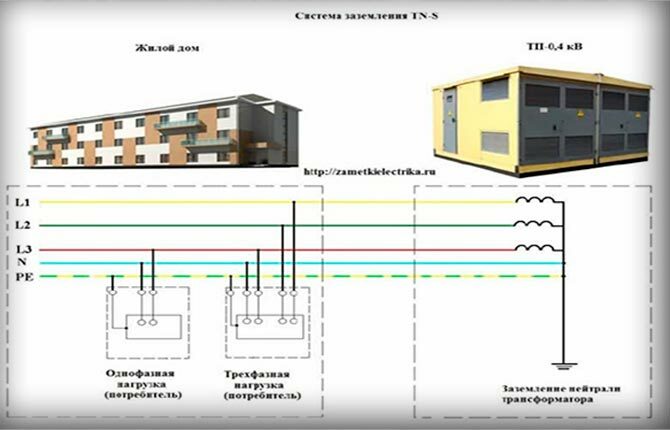

TN-S earthing system

The scheme appeared in Europe 60-70 years ago, and it turned out to be very reliable, safe, but more expensive to maintain. It was not popular in the USSR.

The isolated neutral version is only used in electrical installations up to 1000 V. The TN-S scheme is used in conditions where it is not possible to equip effective grounding using a dissipative metal circuit in the ground. Sometimes used on mobile power generating installations.

Imported household appliances, brought from the same Eastern Europe, surprised by the presence of an additional ground terminal on the plug. TN-S is often referred to as euro grounding, although this is not entirely true. A single-phase network with an operating voltage of 220 V is supplied to the apartment with 3 wires (phase, neutral and earth). For a three-phase power supply of electrical installations, 5 conductors were required, respectively.

The TN-S system means that zero protective and "neutral" are separated along the entire line.

In this case, PN is a neutral (blue wire), PE is a clean zero "ground" (yellow-green striped conductor).

The TN-S system has a number of advantages:

- there is no need to bury the metal circuit in the ground;

- no interference from high frequency radiation;

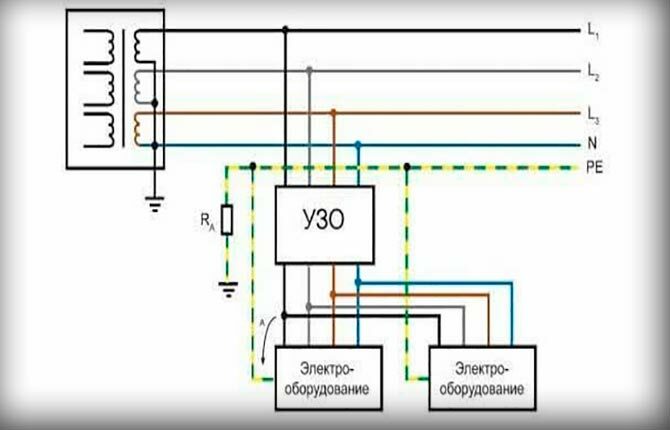

- It is possible to install an RCD.

Apparatus or protection devices operate on the principle of measuring the leakage current in a humid environment. As soon as the leakage current from the phase to the ground (wet floor, walls or any other surface) or to the neutral exceeds the safe threshold of 30 mA, the machine will disconnect the line from the power supply.

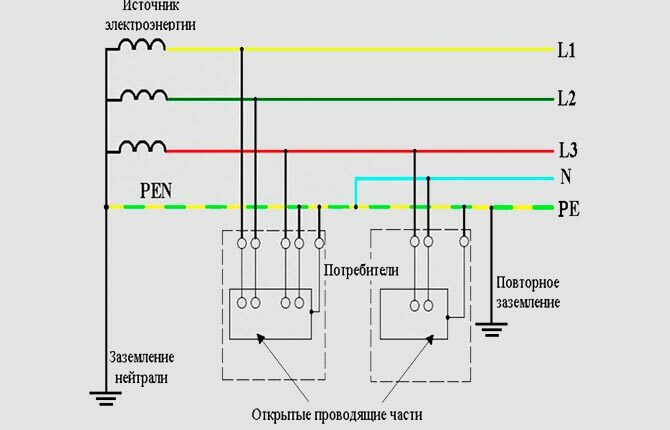

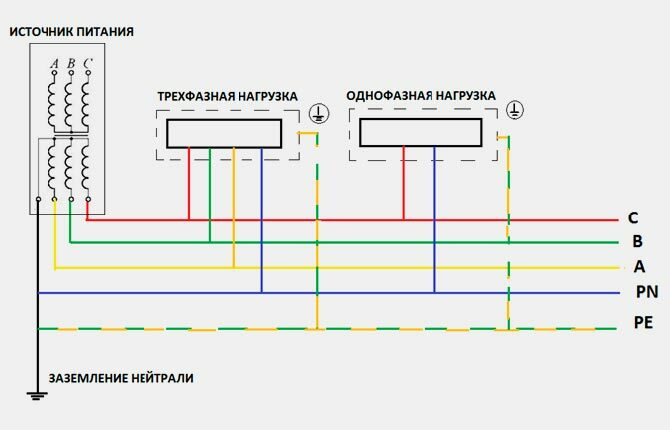

Earthing system TN-C-S

This option can be considered an intermediate solution or a way to eliminate the problem of old TN-C and more modern TN-S in the housing stock. The issue is more than relevant due to the mass construction of new housing stock, as well as the overhaul of old apartments.

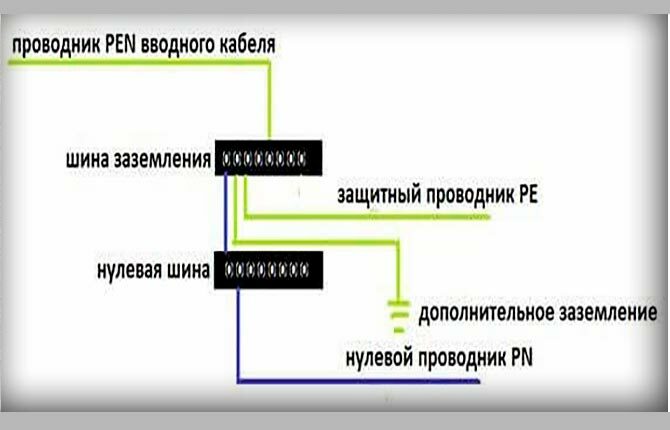

TN-C-S combines elements of previous earthing systems. In the most advanced grounding system for electrical installations TN-S, the cable to the apartment on the switchboard came with a divided neutral and a protective line. Moreover, the entire beam stretched from the transformer substation. Now, a cable was supplied to a private house (in the entrance of a high-rise building), in which one common PE-N or PEN cable was used for protection and grounding (as well as neutral).

On the input shield PEN, 3 wires are switched:

- neutral, blue wire (N);

- protective, yellow-green wire PE;

- outlet to the ground bus of the local ground loop.

As a result, it turns out that it is possible to connect imported electrical installations, since there is a protective and neutral line. On the other hand, the wiring in the house or apartment is equipped with local grounding on the ground, which increases the level of security.

The system, as it were, combined the advantages of TN-C and TN-S, but at the same time inherited their disadvantages. For example, in the event of a break in the PEN line or if the outlet to the additional ground loop is rotten (often happens), then an increased potential will come through the neutral to the electrical installation case. This is already fraught with electric shock.

TT earthing system

At first glance, a slightly unusual, but actually very practical double-grounded CT circuit for a long time and massively used in the suburbs, in the countryside, summer cottages and cottage settlements.

In accordance with the seventh edition of the PUE (clause 1.7.3), a TT system is a circuit in which the neutral is deafly grounded to transformer substation (or distribution transformer), and also equipped with grounding circuit of open parts electrical installations. In this case, both grounds are electrically independent.

The system is simple and reliable, although before the appearance of the PUE in the 2009 edition, considered risky and formally banned. Today, the use of electrical installations in private homes for grounding is permitted only if the following conditions are met:

- Arrangement of a full-fledged ground loop in the ground.

- Installation of a potential equalization system on all metal elements in the house.

- Use of RCD (residual current device).

Paragraph 1.7.59 of the PUE determines the scheme by which RCD devices should be turned on.

The most difficult will be the manufacture of a ground loop. It is not enough to dig a trench and weld the perimeter from an old metal corner. The metal-ground contact surface must be large enough so that the ground resistance measured by a special device does not exceed the calculated value in Ohms. It (R) should not exceed the quotient of 50 divided by the maximum value of the tripping current of the RCD. From several devices, the one that has the maximum current is selected.

The potential neutralization system is a (copper) conductor, which is used to connect the main metal objects to the ground, on which excess potential may appear. It could be:

- electrical installation housing;

- Appliances;

- steel frames;

- ventilation;

- water and sewer pipes.

IT grounding system

The old version, widely used in the expanses of the former USSR during the mass construction of "Khrushchev". The IT grounding scheme is a classic with an isolated neutral.

The housing of the consumer electrical installation receives only 3 wires (three-phase current) and 2 - with a single-phase network. Zero on the consumer's network is grounded into the ground according to the existing grounding rules.

Benefits of the scheme:

- Accidentally touching a live but uninsulated wire with your hand results in a slight tingle instead of a full electric shock.

- Low leakage current when zero is shorted in the wiring to a grounded case.

- A wire falling to the ground (a break on a pole) does not lead to the appearance of a step voltage.

Among the shortcomings, the impossibility of using RCDs can be noted. In addition, when a powerful low-resistance load is switched on between zero and one of the phases, an excess potential of a significant magnitude appears on the third wire.

Grounding requirements for electrical installations up to 1000 volts

The equipment of grounding and protective devices on the side of the transformer or generator is of little interest to consumers. For those who operate electrical installations, use household appliances, it is more important to properly ground.

The requirements apply to the grounding of electrical installations up to 1000 W:

- Ensure a reliable connection with minimal current resistance between the body of the electrical installation and the ground.

- Ensure the normal dissipation of the excess potential that has fallen on the body of the electrical installation due to an emergency.

- Avoid step voltage.

On a properly equipped grounding, in the event of an insulation breakdown, the current will follow the path of least resistance - through the metal parts of the case to the grounding bus into the ground. Since at the substation or at the intermediate section, zero is also grounded into the ground, the current will go through the ground masses in the direction of the transformer. Due to the resistance of the ground masses, the electric current will dissipate, losing potential.

In this case, touching the grounded body of the electrical installation with a dry hand will be absolutely safe, even if the increased voltage partially breaks through it. Normal ground resistance rarely exceeds a few ohms. For dry human skin, this figure is several thousand ohms, for wet (but not wet) - from 500 ohms to 1000 ohms.

Basic requirements for the arrangement of protective earthing for voltages of 42-380 V for alternating current and 110-440 V for direct in special conditions (presence of media with high conductivity) are described in GOST 12.1.013-78. In other cases, grounding of electrical installations over 380 V AC and 440 V DC is carried out on the basis of GOST 12.1.030-81.

Natural grounding

These are objects and environments that contribute to the draining of the voltage potential into the earth mass dissipating the current. Grounding conductors can be artificial and natural. The former include specially manufactured scattering masses and devices with specified characteristics. To the second - any metal objects on the surface of the soil, laid in the near-surface soil layer. It can be:

- steel water pipes;

- powerful cables with a metal (lead) protective sheath;

- wall and foundation reinforcement;

- cast iron sewer communications;

- racks;

- elements of vertical holders.

All this one way or another is in contact with the soil and, in the presence of a conductive medium (humidification), can act as a natural ground. In addition to the ability to transfer potential to the ground, natural grounding conductors are characterized by the ability to dissipate current, partially extinguish and transfer its energy into heat.

Natural grounding conductors can help dissipate excess potential, and can cause electric shock if the grounding is faulty. For example, if the socket in the bathroom or the electrical installation housing is not grounded or the ground bus is faulty. Plus, the floor is on a reinforced concrete slab.

Concrete easily absorbs water and moisture seeps through to steel reinforcement (one of the types of natural grounding). Excessive potential from the phase in the socket can flow down the wet surface to the water mixer. If you stand barefoot on the floor and touch the faucet, you can get a strong electric shock. Therefore, the floor in the bathroom or in the kitchen must be covered with waterproofing.

The Importance of Drip Resistance

The most important characteristic of grounding is the value of the excess potential dissipation resistance. The operation of the ground loop can be represented as a closed circuit, in which the current from the phase line enters the electrical installation housing, then goes to the ground along the path of least resistance.

The electric current flowing into the ground loop must be effectively extinguished. Therefore, the ground loop is made not just from massive steel profiles or pipes with a relatively large surface area. The perimeter should be large - this improves the "spread" of the current in the conductive mass.

Therefore, the grounding of powerful electrical installations with an operating voltage of 380–660 V is made in the form of a rectangular circuit with a long perimeter. The larger the rectangle, the better the current dissipation and the lower the resistance.

It is also not recommended to strongly reduce the resistance of the grounding device. The amount of current dissipation must comply with the recommendations of the PUE and GOST, and most importantly, be relatively constant at any time of the year.

This is especially important in cases where a substation or transformer with a grounded neutral is located near the house. For example, if a private house is in an urban area with numerous underground utilities, then it is quite possible that steel water pipes can drastically reduce the resistance of the "earth" and lead to an accident on electrical installation.

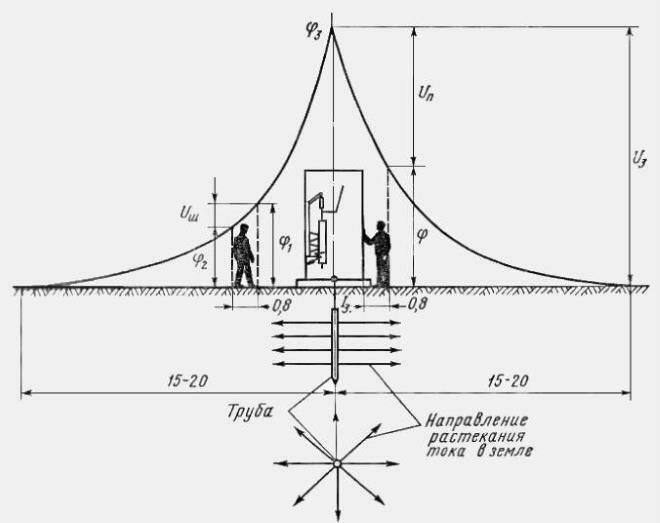

Sometimes owners are limited to conventional pin grounding. This is simpler and cheaper than a circuit, and for small household electrical installations it is quite enough. But in this case, a second problem arises. The electric current that enters the soil from the body of the electrical installation along the ground bus itself creates an additional potential on the ground. The higher the line voltage, the higher the drain potential. Especially if the details of the ground loop are dug to a shallow depth.

Since the contact area of the metal rod with the ground is small, the resistance of the ground loop is large. The excess potential spreads radially from the rod, decreasing on the surface as the installation point moves away. Step voltage appears.

This means that in rain, fog, or sleet, anyone who chooses to walk in wet shoes near the ground spike will receive a painful electric shock to their feet.

If you get into such a zone, then you can only leave it by jumping, firmly pressing your feet to each other.

Typically, such zones occur near high-voltage electrical installations.

Grounding work in case of violation of the protective insulation of live parts

The situation when the insulating sheath of the cable on the line was broken is not considered. The network has its own grounding and if an insulation breakdown occurs, the machine will turn off the line.

At home or at the workplace, phase insulation damage is possible:

- In a TN-S system (which is ubiquitous in modern living spaces), excess potential will fall on case, respectively, the current will go through the protective conductor PE to the ground loop connected to switchboard.

- If the phase insulation is not broken, and the wiring burns in small pulses. In humid rooms, when touching metal parts or live parts, slight tingling sensations (potential shocks) can be felt. There will be no problem if there is an RCD on the line with damaged wiring - it will simply turn off the wiring on the shield.

Approximately the same picture will be in the case of grounding home electrical installations according to the TN-C-S scheme. Only excess potential will go to the ground loop of the entrance. The only negative is that the common grounding device connected to the switchboard of an apartment building can be broken or damaged. In this case, you can get an electric shock, since the protective conductor PE, which must be grounded, is also connected to the neutral leading to the substation.

TT and IT systems are not used in domestic conditions.

In the T-C scheme, if the insulation is damaged, the current will partially go to the zero line and partially to the ground loop buried in the courtyard of the house. If it is correct, then nothing will happen. Just in the event of a short circuit, the automatic bagger will de-energize the line. It is safe to touch the case, but without touching other metal objects.

Sometimes a light, barely noticeable blow does occur. But this phenomenon is due to the fact that the human body has its own capacity.

Protection of electrical equipment in workshops

In industrial premises, as a rule, a significant amount of main and auxiliary equipment is installed. In addition, the workshop must have ventilation and lighting systems that are connected to a separate line.

Lighting must be independent according to fire safety rules, Ventilation is additional equipped with a whole grid of auxiliary (insulated) conductors with arresters and artificial ground electrodes. With their help, the high-voltage potential of static electricity that accumulates on the ventilation ducts during air movement is removed.

Both grounding systems must be galvanically independent from the main electrical equipment protection system. TN-C and TN-S can be used in small isolated rooms with a maximum voltage of electrical installations up to 380 V.

To protect electrical installations in workshops, 2 grounding systems are used - TT and TI. In addition, all communications and metal parts with which workers and maintenance workers are in contact are grounded. The secondary grounding system provides for the connection to additional grounding of the reinforcement of reinforced concrete floor slabs, walls, flights of stairs with railings.

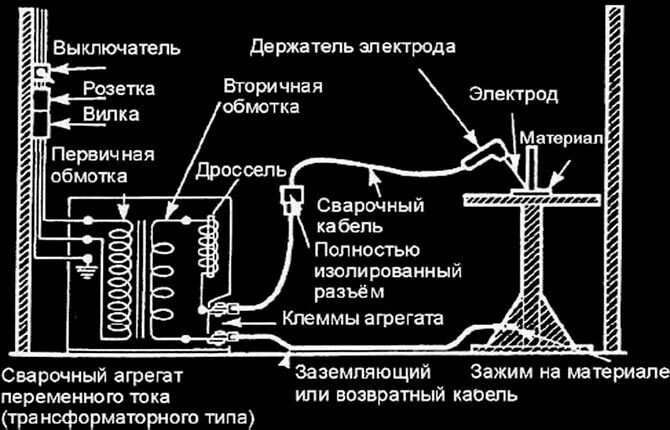

Grounding of welding machines

This type of electrical machine falls out of a number of electrical installations for many reasons. First of all, because of the huge currents, due to which secondary pickups are formed on the cables of the welding machine. If in conventional electrical appliances on the case from a running engine or power supply a potential difference of a few volts was induced, then the welder's pickup can be several tens of volts.

The second important point is the inductive and periodic nature of the load. In addition, significant currents fall on the zero of the welding machine, and the overshoot of the potential at the moment of switching on can briefly reach more than a hundred volts.

Features of grounding welding machines:

- Each electrical installation must have its own individual ground loop.

- Connection of several devices to one grounding is not allowed.

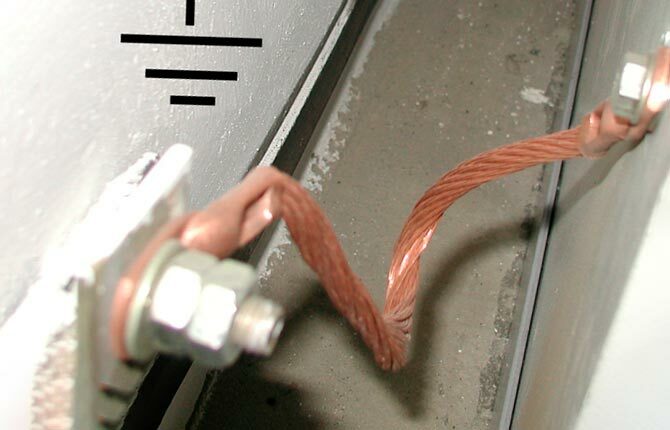

- A terminal for a screw - a nut (wing nut) or a clamp must be welded on the body of the electric welding, the contact from the bus to the "ground" must be clamped mechanically.

According to PUE-7 (clauses 1.7.112-1.7.226), the grounding wire for a stationary electrical installation must be with a cross section of at least 10 mm2 for copper, 16 mm2 for aluminium, 75 mm2 for steel.

Welding inverters and all similar types of electrical installations can be grounded according to the isolated neutral scheme, provided that an RCD is installed on a dedicated line.

Protection of mobile installations

As a rule, we are talking about electrical installations located on the basis of vehicles. For repair shops, mobile welding machinesinstalled on unequipped sites for a relatively long time (up to 2 weeks), grounding according to the TT scheme can be used.

For mobile measurement laboratories, radio stations, equipment with a small current load, the TN-S scheme is used. In both cases, earthing is provided using a standard aluminum earthing stake with screw nozzle. It must be wrapped in the ground to a depth of at least 80 cm, if there is a grass cover on the site. This indicates that the soil is wet. For dry sites for grounding electrical installations, a contour of 3 steel pins is used, hammered to a depth of 100-120 cm.

You can use portable earthing switches. They are used by electricians for the repair and maintenance of outdoor electrical installations of all types. Any station generator, the transformer has its own capacitance, and the presence of overhead lines (wires) suspended on poles above the ground only increases the value of C. Therefore, after a blackout, the second step is to install the "ground" (portable grounding) on all lines. They can also be used for temporary grounding of mobile electrical installations.

Electrical protection

Protective grounding schemes for industrial electrical installations and devices are described in detail in the technical documentation. But household appliances, even relatively complex ones, such as a boiler or a washing machine, are not equipped with a grounding device circuit. It is believed that representatives of the company will install the electrical installation - they will make the grounding.

You need to ground any household electrical appliance with an operating voltage of 42 V AC or DC - 110 V and above. This is a requirement of clause 1.7.33 of the PUE. An electrical exception is usually made for lighting systems with which there is no constant contact. Everything else that we take with our hands and has a connection to a 220 V network is unambiguously grounded.

Typically, for domestic electrical installations, the TN-C-S or TN-C scheme is used. A protective PE is used in the socket. It also goes to the switchboard and common ground.

If the apartment has powerful electrical installations (boiler, washing machine, heating boiler), then it is better to make an individual grounding with a circuit in the ground. Moreover, it is not a fact that the common “land” on the introductory shield of a high-rise building, on which 20-25 apartments hang, will work 100% in case of force majeure.

It is also necessary to ground electrical installations equipped with switching power supplies. This will remove high-frequency pickups and eliminate the risk of a phase entering the case through the line filter leakage current.

Be sure to ground the refrigerator, this is the second statistically (after electric boilers) cause of electric shocks.

Motor Grounding Basics

Approximately half of all electrical installations are equipped with electric motors, most often these are AC motors. A feature of the compressor motor is a large number of wires laid in the stator or rotor winding. Moreover, the wires are in very thin, easily damaged varnish or enamel insulation.

Therefore, a malfunction of the electric motor most often causes electric shocks:

- Insulation is minimal, strong heating of the windings.

- The wire may be in contact with the body.

- The rotor rotates even after the electrical installation is turned off and can deliver the stored energy both to the line and to the housing.

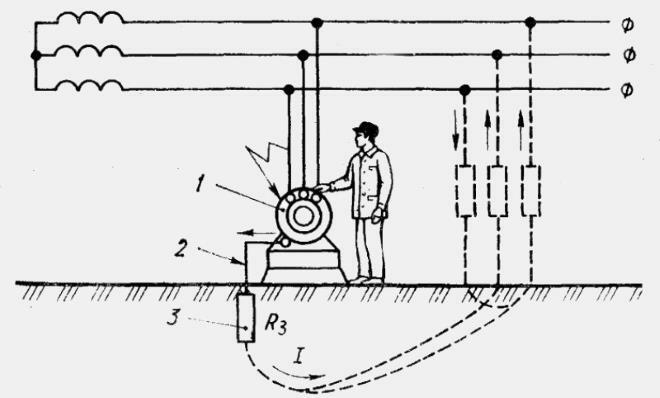

For grounding of electric motors, a dissipating circuit is used, connected by a wire or bus through a terminal on the housing. The supply wiring is connected to the motor via the TT system. If several electric motors are installed in the room, then all of them are connected to the current-carrying bus with an independent wire parallel to the bus - no serial connections are allowed.

For low-power 220 V electric motors, an exception is sometimes made with a protective wire, but only if the motor mounted on a metal base, fixed with crutch studs driven into the ground to a depth of at least 60 cm.

But even in this version of the “ground”, the maintenance of the electric motor must be started with a complete de-energization and connection of an additional external ground to the housing. First, a ground loop is installed, only then they are attached to the motor housing. This is a universal rule for connecting all types of grounds.

Results

Grounding an electrical installation is the only way to protect against current surges, both from the side of the supply transformer and from the residual potential left on the line. Despite the fact that some practical points are not detailed in the PUE, when working with electrical equipment, it is necessary to use the rules, only then the manufacturer's instructions.

Tell us about your experience of grounding installations - what problems you had to face and how they were solved. Bookmark the article so that useful information is not lost.