Competently choose boilers for heating a private house is necessary for the device autonomous system. It is heating equipment that will provide housing with heat and hot water. It will create the microclimate necessary for human habitation. In addition, it will work flawlessly. It is so?

We will tell you how to buy a boiler that will meet your requirements and wishes. We have dismantled all the criteria that are worth paying attention to by browsing the catalogs of online stores or an assortment of specialized outlets. Lists problems that can be encountered before and after purchase.

The content of the article:

- The main criteria for the selection of boilers

- Rules for calculating the power of equipment

-

Characteristics of the main types of boilers

- 1. Useful qualities of solid fuel boilers

- 2. The principle of pellet boilers

- 3. Pros and cons of fuel oil boilers

- 4. The expediency of buying electric boilers

- 5. Gas equipment specifications

- 6. How effective are universal boilers?

-

Features of single and double boiler

- The principle of operation of single-circuit equipment

- Specific design of a two-circuit unit

- Selection of space for heating equipment

- The subtleties of using boilers

- Conclusions and useful video on the topic

The main criteria for the selection of boilers

Hundreds of foreign and domestic manufacturers offer thousands of models of heating equipment. It is not easy for an unprepared buyer to navigate in all this variety of goods. I want cheaper and that the quality was on top.

All heating boilers differ in type of fuel and are divided into the following categories:

- solid fuel (processing firewood, peat, pellets, coal);

- liquid fuel (units operating on diesel fuel);

- gas (conventional and condensation);

- electric (requiring electricity supply);

- universal (using either gas or electricity).

Before choosing an option, it will not be superfluous to conduct a small analysis and find out which energy carrier is beneficial to use in your area. After that, you should decide how the boiler should be safe, reliable and comfortable in operation in terms of each penny invested in it.

To choose one or another type of heating equipment you need to first get acquainted with the advantages and disadvantages of each of them.

In order not to be mistaken and not to waste your hard earned money in vain, you need to carefully consider the process of choosing equipment. To do this, it is necessary to take into account a number of nuances that significantly affect the final result.

When choosing a boiler should:

- in every detail to understand the advantages and disadvantages of each type of boiler;

- calculate the optimal heating equipment for your home;

- determine the number of contours;

- choose a place where equipment will be placed later.

The maximum permissible dimensions and weight depend on the location of the future location of the boiler. After all, for a small room it is inappropriate to choose a heavy cast-iron unit.

The choice of heating equipment must be approached responsibly. This is the only way to buy high-quality equipment that will last far from one year.

Rules for calculating the power of equipment

Immediately it is worthwhile to “hack on the nose” that the desire to save on the design of the heating system and the implementation of thermal calculations in most cases goes sideways to the customer. If everything is carefully thought out and trusted to a highly qualified specialist, then the cost of the boiler, radiators and other equipment will be much cheaper.

The power of the heating boiler is selected with a distribution calculation of approximately 0.1 kW per m2 of living space.

For an approximate calculation of the power of the heating equipment necessary to heat the building and provide hot water, you can use special design standards.

Also without fail it is necessary to consider:

- the number of people who will live in the house;

- construction materials used for housing;

- climatic zone;

- number of windows and doors;

- number of storeys and other factors.

The opinion that the power of the boiler is selected with the calculation of 0.1 kW per square meter is quite common. But thanks to modern building materials and innovative engineering equipment, heat loss can be much lower and, accordingly, the performance of heating equipment can be higher.

Characteristics of the main types of boilers

All of the boiler models on the market differ not only in appearance and cost, but also in the fuel used for its operation. They can be divided into separate categories depending on the type of fuel material.

In addition, a large role belongs to the energy carrier, which will be used to heat water in the heating system. It directly affects the efficiency of the boiler, energy efficiency and ease of operation.

1. Useful qualities of solid fuel boilers

In the territory of the CIS countries solid fuel is considered the most affordable and cheap. This explains the popularity of equipment that uses in its work this type of energy source.

It should be remembered that in solid fuel boiler It is impossible to burn all that burns. It is necessary to use only the energy carrier for which the equipment was sharpened.

Boilers designed for solid fuels can only be loaded with firewood, lump peat and coal, but not tires or garbage.

The list of advantages of solid fuel heating equipment should include:

- autonomy;

- good energy efficiency. The efficiency of such boilers is close to the indicators of devices operating on fossil fuels (gas, diesel, etc.);

- low price of energy.

When buying solid fuel units, you need to understand that from time to time you will have to lay firewood in the boiler. That is, every 6-18 hours it is necessary to fill the boiler with wood fuel or waste woodworking production structures.

Although today there are systems that can boast of automated laying of logs or wood chips, but this kind of the equipment is mostly intended for woodworking enterprises, and not for private houses and cottages.

Solid fuel boilers - although it is an outdated design, but today many manufacturers offer decent equipment, the design of which was carried out using modern materials

2. The principle of pellet boilers

Pellet or wood pellet is a woodworking waste that is pressed into a small cylinder. For example, it may be shavings or sawdust softwood.

The product is formed without any additional additives or glue, only a pressure of about 300 atmospheres is applied. The diameter of the granules is usually 6-10 mm, and length - 10-30 mm.

The main advantage pellet boilers lies in their offline mode of operation. Now you can easily find a technique with a small bunker, where there is auger supply of fuel pellets. On average, stocks last for several days.

Often, in order to increase the autonomy of the equipment, another small bunker will be organized for a couple of cubic meters in the basement or in any outside room. From such rooms fuel pellets are delivered to the bunker, and then directly to the boiler.

The period of operation of such a system can reach one month. With regard to efficiency, the pellet boilers can boast a much greater efficiency than conventional and even pyrolysis devices.

The pellet boiler is characterized by relatively high efficiency and low consumption of fuel wood pellets. Moreover, this technique is also environmentally friendly.

The disadvantage of such heating equipment is the constructive complexity of technology. Because of this, the pellet boiler is sensitive to the quality of the fuel. In order for the unit to serve for a long time and not have any problems during its operation, it is necessary to use class A or B fuel granules, which were made by foreign manufacturers.

Another disadvantage of pellet boilers, which prevents their popularization in the domestic market, is their high cost. On average, the price of such devices starts from $ 2,200.

3. Pros and cons of fuel oil boilers

Fuel oil boilers are considered simple and reliable equipment that, with proper care, will serve for decades. They are bought for installation in cottages and in private homes.

The main advantages of this category of boilers:

- lack of dependence of the equipment on the gas main;

- ease of installation;

- no need to obtain any permits for the installation of the boiler;

- fairly high energy efficiency;

- Some models of diesel boilers can be adapted to work on gas.

In addition to such obvious advantages, the equipment has certain disadvantages, one of which is the need to winter period to heat the fuel line so that the temperature of the energy source does not fall below +5 degrees Celsius

Fuel oil boiler the best solution after the gas heating equipment, if the connection to the centralized highways is not planned yet, and there is no place for the installation of a gas-holder. For the installation and operation of the unit on liquid fuel does not need any coordination

Also disadvantages of liquid fuel heating equipment include:

- mandatory storage compartment for fuel:

- equipment due to the constantly working burner creates a lot of noise;

- the need to periodically bring high-quality liquid fuel;

- unpleasant smell from the fuel bunker;

- rather large operating costs.

Even in spite of the large list of drawbacks, liquid fuel equipment is in demand from the owners of summer cottages. Especially if access to other energy resources in the area is limited.

4. The expediency of buying electric boilers

Electricity boilers are often installed when the village under construction is not yet equipped with a full-fledged gas network. But subsequently, such units are replaced by gas. This option of using heating equipment is about a quarter of all sales. electric boilers.

The most common models, whose power is 5-10 kW, can maintain a temperature of about 6 degrees Celsius, when outside the window -20. This is quite enough to continue the finishing work in the newly built house.

Electric boiler worth buying only as a last resort. Due to the high cost of electricity, this type of heating equipment is unprofitable.

Distinctive features of electric boilers are low cost of equipment, simplicity of its installation, small dimensions, lightness, the absence of an open flame, unpretentiousness of care and the absence of the need to organize a separate room for unit.

When buying such heating equipment, you need to remember about the high cost of electricity, the need connect high power devices to a three-phase network and the sensitivity of the device to interruptions with electricity.

5. Gas equipment specifications

If we compare gas boilers with all other types of heating equipment, then this type is the best choice for most consumers.

After all, gas units are more economical and easy to operate. Such equipment does not require special care, and the process of their work is fully automated. Yes, and do not need to store fuel.

Going to put floor or wall gas boiler, you need to know that before installing such equipment you need to obtain the appropriate permits. The certificate is issued by the state regulatory authority.

Gas boiler is the most efficient and economical type of heating equipment, if it is connected to the system of centralized supply of blue fuel. In the case of gas-cylinder or bottled gas, the economic efficiency is lower

The disadvantages of this type of heating floor type equipment It should include the need to install automation, which will block the pipeline in case of leakage of energy or in case of insufficient ventilation. Also, due to seasonal pressure surges, equipment may fail and need to be repaired.

Although the cost of gas now is not too high, the energy carrier is fossil fuel. This means that over time, its value can probably increase. Therefore, manufacturers are trying to adapt the gas type of boilers to operate on biogas fuel.

For example, in the modern market there are models of equipment that work without problems on a mixture, where about 15% is occupied by biogas.

6. How effective are universal boilers?

The main advantage of universal heating systems is their convenience. Most often they are installed in those cottage villages where there is no stationary gas supply. People are forced to somehow get out, so they use a gasholder method, the essence of which is to heat a house with liquefied gas.

After the settlement will be supplied with a sufficient amount of this energy carrier, the boilers switch to its use.

Combined units are impractical in areas with characteristic periodic power outages or gas interruptions

The market of heating equipment offers a variety of boiler modelsusing several types of fuel in their work. A prime example is a system that can burn both gas and liquid fuel.

Its advantage lies in the fact that regardless of the type of energy carrier currently used, the heat output of the boiler remains practically unchanged.

Features of single and double boiler

Thinking about how to choose the right heating boiler for your home, special attention should be paid to such characteristics as the number of circuits. Single-circuit equipment is intended solely to heat the coolant circulating through the heating pipes.

Single-boiler is designed to serve only one system: either hot water or heating. If it is not possible to install a double-circuit unit, it is permissible to use no more than two boilers in one boiler-house, regardless of their floor or wall version

In this case, to preheat the tap water will have to additionally install a boiler. Yes, a single-circuit boiler is convenient, but the disadvantage of such a solution lies in its high cost - you will have to buy not only heating equipment, but also a boiler. Moreover, both devices will take a lot of space.

Concerning double boiler, here the heating equipment and water heater are assembled into a single structure. Thanks to this structure, you can solve two problems at once, while buying only one unit.

In addition, in the absence of hot water, the heat carrier can be redirected to the second circuit and used alternately to heat the house and to provide hot water.

The principle of operation of single-circuit equipment

Single-circuit heating equipment is most often used by owners of luxury country houses. In fact, a single-circuit boiler is the same water heater, but supplying water to the heating system.

The principle of operation of this type of equipment is based on burning fuel in a special compartment and heating the liquid. The heat line is connected to the outlet where the hot coolant enters. Further, the water begins to circulate through the pipes and heat the room.

The final stage of circulation is the flow of waste heat carrier back to the boiler through the inlet pipe.

If you do not need to provide hot water, it is better to give preference to single-circuit boilers.

The cost of a single-circuit boiler can be more than a two-circuit system. Even with less functionality, this type of equipment is less expensive to install, easier to use and more economical to use energy carrier.

Single-circuit equipment is suitable for those buyers who want to spend money once and buy reliable equipment that does not require special care. This type of boiler will be ideal and the only right choice when the house does not need hot water.

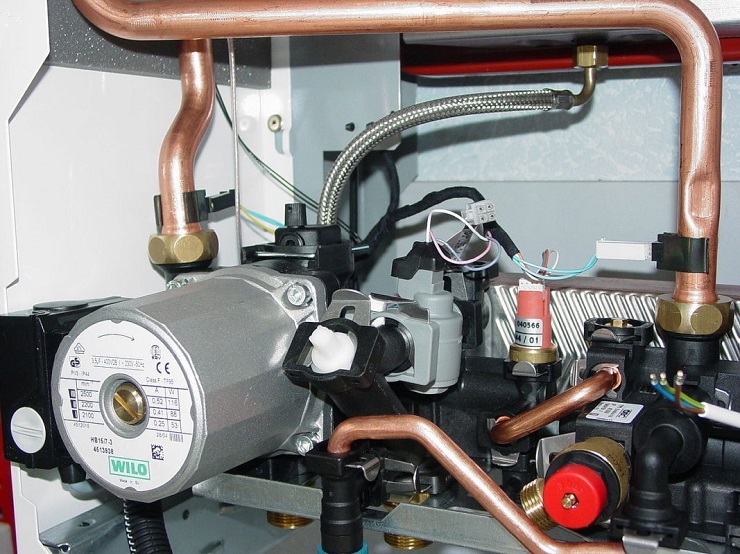

Specific design of a two-circuit unit

The double-circuit boiler is a system where, in addition to the primary heat exchanger, there is an additional one designed to heat water and then feed it to the water supply system. The movement of thermal media is controlled by a three-way valve. It directs the heated water either to the DHW circuit or to the heating system.

It should be noted that in the first case the coolant will be supplied only if the hot water tap was opened. The feature of such heating equipment is that while the tap responsible for the supply of hot water is open, the system does not work.

If you have a big family and some of its members like to take a shower for a long time, then the rooms can become cool. Manufacturers solve this problem by installing a storage water heater in their boilers.

The disadvantages of the design of a double-circuit boiler should include the need for careful and attentive maintenance. This is due to the fact that the secondary heat exchanger can overgrow due to the use of water containing organic and mineral particles suspended in it, and the small diameter of the pipes.

If active flow of hot water is planned, installing a double-circuit boiler is not the best solution. After all, then the house will be heated badly. On the installation of this system is worth thinking only in a small house or apartment, where there is not enough space for organizing a full-fledged boiler room.

Selection of space for heating equipment

All types of heating boilers are produced mainly in the floor version, electric in the wall version, and gas both in the wall and in the floor form. The last variation is better to install in a spacious separate room. Such heating equipment is very powerful and massive.

Wall mounted boiler will be the ideal solution for small houses, where every square meter counts

And due to the fact that the weight of floor boilers is not limited by anything, manufacturers install a cast iron heat exchanger in it, which is much more reliable than steel.

Wall-mounted heating equipment is compact in size and fairly light in weight. But this type of boiler is limited in power. This minus is especially relevant for dual-circuit systems - the performance of the heating circuits will be quite low.

It is worth choosing wall boilers only in the case when the heated area does not exceed 200 m2and the consumption of hot water is not more than 14 l / min. If there is more need, it is better to give preference to floor variation of heating equipment.

It should be noted that many customers, regardless of the size of the living space, prefer to use floor systems that are equipped with a cast iron heat exchanger. After all, such devices are less demanding on the quality of power supply.

The subtleties of using boilers

For the normal functioning of the vast majority of models of boilers requires electricity. The only exception is solid fuel heating equipment that burns coal or wood. Such devices can work autonomously.

Why do you need electricity? Current is required for the automation of the boiler system and its pumps. Therefore, a good solution would be to order an electric generator together with heating equipment. This decision is especially important for those regions where the light is often turned off.

When organizing a boiler room, special attention should be paid to the chimney to ensure proper operation of the equipment and safety when using it.

Regardless of the type of boiler used, the manufacturer is doing everything possible to ensure that the operation of its equipment is as safe as possible.

Therefore, almost any modern model of heating equipment is supplied with the following protection systems:

- a sensor that detects the presence or absence of a flame;

- traction control sensor;

- a device that will stop the operation of the boiler in the event of a decrease in pressure in the pipeline below the permissible level;

- a device that turns off the boiler in the absence of electricity;

- system that protects equipment from overheating;

- sensor stopping the operation of heating equipment in the event of a decrease in the volume of thermal media.

All the above details are the necessary minimum that will save the boiler from damage, and the housing itself from fire.

As for the location of the equipment, certain models of boilers, the boiler power does not exceed 100 kW, can be installed directly in the kitchen.

Other types of heating equipment must necessarily be placed in specially equipped room a certain cubic capacity, with a well-thought-out and well-designed ventilation system, with fire safety devices, etc.

It is necessary to approach the organization of a boiler room with all responsibility and to follow all recommendations of experts, and also standards of fire safety

The most used boilers in the territory of the CIS countries are currently gas. This demand is due to the low cost of this energy source, as well as the reliability and durability of boilers of this type. But due to regional peculiarities, gas heating equipment is not always the most optimal and profitable solution.

It is necessary to choose heating equipment depending on personal wishes and needs, sizes of living space and availability of energy

Economical fuel consumption and reduction of equipment maintenance costs is an important component in choosing the optimal unit for an independent heating system. Organization Rules energy-saving heating given in our recommended article.

Conclusions and useful video on the topic

Features of the choice of boilers are discussed in the video clip:

The most common mistakes in the choice of boilers for heating are given in the video:

A video clip tells about the long burning furnaces:

In order to decide which boiler is best for a private house, you need to consider in detail all the positive and negative sides of each type of heating equipment.

If you spend a little time, carry out a simple analysis of the availability of fuel, correctly calculate the power and Responsible approach to the installation of the system, you can not only make your home warm, but also save on its heating.

Want to tell interesting facts about the choice of boilers for independent heating devices? Any questions during the review of the information we have provided? Please write comments in the block below and post subject pictures.