If you are building a country house or are seriously engaged in repairing an existing one, you should take care of how the space will be heated during the cold season at the planning stage.

Proper design of heating systems in private residential construction is a guarantee of comfort in winter, rational use of resources and efficient operation of equipment.

In this material, we will look at heating systems for a private house, tell you how to choose the best option, and use an example to show how to properly design a heating system.

The content of the article:

-

Step 1 - heating scheme

- What is a single pipe circuit?

- Two-pipe heating model

-

Step 2 - making calculations and the architectural part

- Design of the boiler house in all the rules

- Choose a chimney and determine the size

- Calculation of the required system power

- Is circulation natural or forced?

-

Step 3 - Choosing Energy

- Solid fuel - a proven method for centuries

- What heats diesel boiler?

- Environmentally friendly electric heater

- Use the blue fuel - gas model

-

Step 4 - Other System Components

- Pump - where to embed it?

- Security Unit and Expansion Tank

- Pipeline and radiators - calculation and selection

- What is better - a radiator or a warm floor?

- Features of the choice of the heat carrier

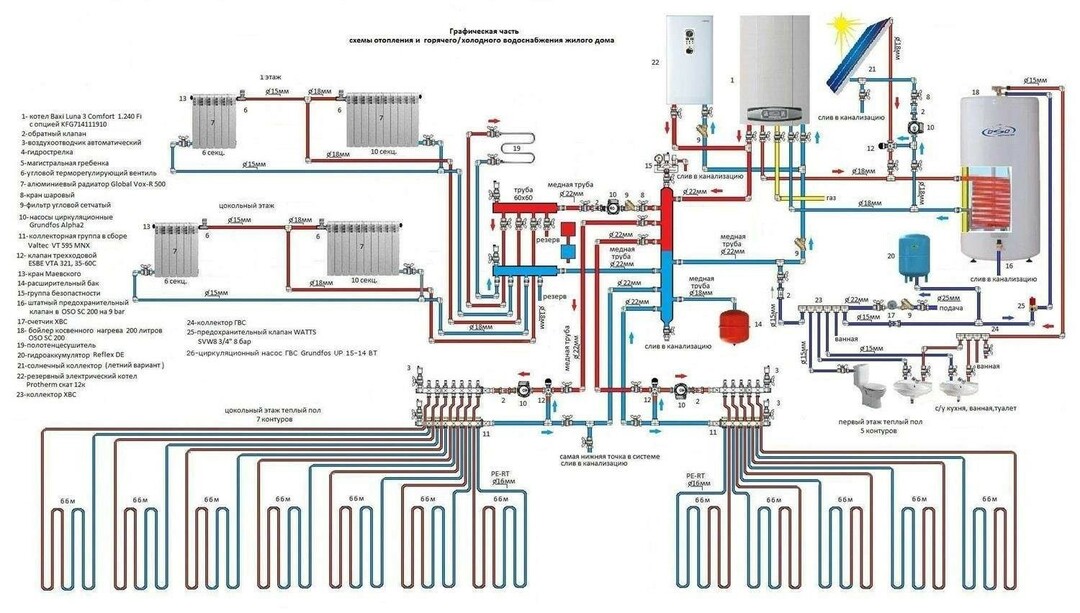

- Step 5 - Layout Design + Examples

- Conclusions and useful video on the topic

Step 1 - heating scheme

The primary task in the design of heating is to determine the heating scheme. Single-tube and two-tube schemes are distinguished. Each of them has its advantages and disadvantages.

Consider what is more important to you: cost savings, uniform heating, or an aesthetic component.

What is a single pipe circuit?

The one-pipe home heating system is a chain of series-connected radiators. The heat carrier of the desired temperature enters from the riser to the heating line.

It moves from one radiator to another, gradually giving off some heat. Thus, the heating may be uneven.

Image Gallery

A photo of

A distinctive feature of the one-pipe system is to connect the heating devices to one main line, which delivers the heat carrier and takes it back to the boiler for heating.

Moving from one device to another, the coolant cools down, which explains the differences in the heat output of the first from the boiler and the far radiator

Heating systems of private houses are arranged with both the upper and lower wiring. In the first case, the pipe extending from the boiler is laid under the ceiling or within the insulated attic

In most cases, single-tube contours are constructed with horizontal wiring. They are no longer than 30 m in length.

One-pipe systems are built according to dead-end and passing diagrams. In a dead-end, the heated and cooled coolant moves in different directions.

To stimulate the movement of the coolant in dead-end circuits and in systems with lower wiring use a circulation pump

The overwhelming majority of one-pipe heating systems are assembled according to the tee-principle. Pipes are connected by angles and tees, installed around the perimeter of the premises

Monotube heating circuits are easy to assemble and maintain. The minus is the lack of adjustment of the thermal mode of individual devices. To reduce or increase heat transfer is possible only for the entire circuit.

The principle of the one-pipe system

Disadvantages of monotube contours

Heating option with top wiring

Horizontal monotube wiring

Dead-end version of the movement of the coolant

The use of a circulation pump

Tee scheme for assembling pipes of a heating network

Typical heat engineering features

When implementing a one-pipe circuit with top wiring, the trunk pipe is laid along the perimeter of the entire heated circuit above the appliances and window openings. The radiators in this case are connected at the top, which in itself is not very aesthetically pleasing.

Both at the inlet and at the outlet the radiator is equipped with shut-off valves. At the entrance can be placed thermostatic head.

In schemes with the lower wiring pipeline passes below the heaters. This option looks much better, but it requires mandatory installation of Mayevsky cranes on each battery.

They are needed to remove excess air from the top of the batteries formed as a result of the supply coolant from the bottom without first passing through the open expansion tank for outgassing

Advantages of single-pipe heating of a country house:

- saving on materials;

- simplicity of design and installation.

A relatively small number of pipes significantly affects the appearance of the heating system, which in most cases is laid in an open way.

In the two-storey and large in size cottages it is better not to use such a scheme.

Disadvantages:

- the complexity of temperature control;

- the operation of each radiator depends on the state of the entire system;

- limited length, the ability to process a contour with a length of no more than 30 m.

To ensure the possibility of temporary or permanent shutdown of one or several radiators without stopping the system, a bypass is laid under each of them - a bypass pipe with a valve system.

Improvement Leningradka schemes connecting the battery by installing two or three shut-off valves allows you to turn off a separate instrument for repair without stopping the operation of the system and draining the coolant from it. More about the arrangement of a single pipe heating system in a private house Further.

Two-pipe heating model

A much more perfect scheme is the two-pipe one. The principle of its operation consists in the presence of two pipes - supply and return, to which radiators are connected in parallel.

When laying the heating in a two-pipe circuit, the radiator is connected to the supply and return pipes, equipped with shut-off valves on both sides

The coolant flows through the supply pipe to each device with the same temperature. After passing through the radiator, water enters the return pipe. Such a scheme can ensure uniform heating of the entire cottage.

Advantages of a two-pipe heating scheme for a country house:

- independence of devices from each other;

- uniform heating;

- The ability to control the heat output of each radiator with the help of thermostats installed on the devices.

In addition to the relatively high consumption of materials materials and cost of design, two-pipe system heating has almost no flaws.

Image Gallery

A photo of

In two-pipe heating circuits, the supply of heated coolant is carried out through one pipe, and in the cooled form it is discharged to the boiler through another

In all devices of two-pipe heating networks, the coolant is supplied almost simultaneously. It is possible to regulate the heat transfer in each individual device

The layout of two-pipe networks is carried out according to the horizontal and vertical scheme. In horizontal air vent for each device is required.

In vertically oriented heating schemes, air vents are installed on risers, which significantly reduces the number of devices for exhausting excess air.

For the construction of two-pipe systems there are no restrictions on the length and number of devices

To connect the devices, they use both the T-joint version and the collector version, according to which the coolant to the devices is supplied through parallel pipes

According to the type of coolant movement, two-pipe heating circuits are divided into gravity and pump circuits. The first ones are easier to build and operate.

When using polymer pipes in two-pipe heating schemes, concealed installation is possible, which has a very positive effect on the interior.

The principle of operation of two-pipe heating systems

Advantages of two-pipe heating schemes

Horizontal wiring of the heating circuit

Vertical layout of the heating network

Enhanced Arrangements

Ways to build heating networks

Options for the movement of coolant

Heating pipe laying in constructions

Step 2 - making calculations and the architectural part

The architectural part of the design of heating involves the arrangement or construction of a room for equipment - a boiler house in a country house, as well as the selection and calculation of the chimney. To correctly design the equipment capacity, pipe diameter, coolant volume and other parameters, it is necessary to make calculations.

The computational part does not require deep knowledge from the field of higher mathematics, it is enough to substitute the necessary coefficients in the formulas and use the calculator.

Design of the boiler house in all the rules

Before proceeding with the design of wiring and the purchase of materials, you need to choose a suitable location for the location of the heat generator. This may be a separate room in the house - boiler room. If there is no extra room, you can build an extension.

For a gas boiler that will operate from the central gas pipeline, you need to organize a boiler room according to all the rules, because gas services strictly monitor the implementation of standards for the operation of gas equipment. When placing the boiler in the wrong place or with violations, the project will not be signed and use of the boiler will be prohibited until the comments are eliminated.

High-quality boiler room strapping provides unhindered access to all system components.

Basic requirements for boiler rooms in cottages:

- ceiling height from 2.5 m;

- room volume from 15 m3;

- the enclosing structures of the boiler house must have a fire resistance of 0.75 h;

- natural lighting should be provided;

- ventilation is required.

The location of the boiler depends on its capacity. So, if the power of the unit is 151-350 kW, it can be located only in a separate room of the basement or ground floor, as well as in the annex. Boilers with a capacity of 61-150 kW can be placed on the second or subsequent floors.

Devices up to 60 kW can be even in the kitchen of a country house, subject to the availability of windows with a window. We also recommend reading the material on how to correctly to equip the boiler room in a country house.

Choose a chimney and determine the size

Another important detail in the design - chimney. It will remove combustion products to the outside. The main requirements that apply to the chimney:

- fire resistance of the material should not be less than 1 hour;

- all joints and joints must be treated with flame retardant materials;

- the chimney must be completely gas-tight;

The chimney cross section is determined according to the requirements of SNiP 2.04.05-91. The size of the chimney channel depends on the power of the heat generator.

According to the materials of manufacture chimneys can be:

- brick;

- metal;

- ceramic.

The brick version is usually designed at the stage of the construction of a country house. pipes are wall, mounted and indigenous. The device wall option is possible only during the construction of the walls of the building. The root and mounted type can be built both after the erection of the walls and after the construction of the roof.

Disassembled chimneys have the form of meter sections. Connections must be sealed with flame retardant material.

Metal chimney is now used everywhere. Stainless steel is a reliable, durable material, which is not afraid of hot products of combustion. Modern chimneys are designed in the form of so-called sandwich systems. Stainless steel pipe is placed in the same, but larger diameter. The free space between them is filled with insulation, as a rule - with basalt wool.

Ceramic chimney pipe is used less frequently. Its main advantage is high heat resistance, and the main drawback is brittleness. In addition, the ceramic chimney is quite heavy.

Designing the chimney is a crucial step. Hole size is one of the most important parameters. It depends on the performance and power of the boiler.

Average diameters of round chimneys:

- for boilers with a capacity of up to 3.5 kW - 16 cm;

- up to 5.2 kW - 19 cm;

- up to 7.2 - 22 cm.

When calculating the height of the chimney, the height of the roof and the distance from the chimney to the ridge are taken into account. If the pipe is located close to the top of the roof (up to 1.5 m), the height of the chimney height will be 0.5 above the roof m. If the distance between them is greater (from 1.5 to 3 m), the chimney should be at least on the same level with the ridge.

Calculation of the required system power

In order to calculate the heating system of a country house, you need to take into account several factors at once, these are:

- climatic zone in which the cottage is located;

- power source of thermal energy;

- sources and amount of heat loss;

- area and volume of heated premises;

- the number of radiators and their size;

- the presence of insulation fencing structures.

To choose the power of the boiler and radiators, use the following formulas:

Mto= Spom x umto/10 + 30%where:

Mto - boiler power;

Spom - area of the room;

MINDto - specific power of the boiler per 10 square meters. m. heated area.

MINDto depends on the region. For Moscow and the Moscow region take the value of 1.2-1.5 kW. A margin of 30% will be sufficient for a single-circuit boiler. If a two-circuit scheme is assumed, it is necessary to add another 20% to water heating.

Thus, the house 9 × 9 in the suburbs can be heated with a single-boiler with a capacity of: Mto= 81 x 1.5 / 10 + 30% = 16 kW.

Knowing the power of the equipment, you can calculate the minimum amount of water in the heating system of the cottage using the formula:

V = Mto x 15.

For the same house in the Moscow region, it will be necessary to fill the system with V = 16 kW x 15 = 240 l of heat carrier.

Is circulation natural or forced?

When designing a heating for a country house, you need to decide how the coolant will circulate in the system: under the influence of gravity or with the help of a pump.

Due to the small slope of the pipeline, warm water from the boiler rises up and moves through the pipes, and cooled down - goes down. Thus, the system becomes completely autonomous.

The natural way is good because the system does not require electricity. Circulation is carried out due to the physical properties of the fluid with temperature.

Disadvantages of a system based on this principle:

- need more coolant;

- pipes must be of a larger diameter;

- need to comply with a bias of 2%.

In addition, to balance the temperature in the network with natural circulation It is necessary to increase the number of sections in batteries located farthest from the boiler.

If you are planning a system with forced circulation, the boiler room must be supplied with power for the pump at the exact point where it will be located according to the project.

Forced circulation works with a much smaller amount of liquid and the diameter of the pipeline, a slope is not required, and the choice of radiators expands significantly.

However, for full operation, it will be necessary to equip the system not only with a pump, but also with measuring instruments and an expansion tank. All this should be taken into account when designing the system. with forced circulation.

Image Gallery

A photo of

When a circulating pump is included in the heating circuit, the open expansion tank is most often changed to closed

The use of a closed tank eliminates evaporation of the coolant, slows down the cooling, which reduces the load on the boiler. However, for normal operation, the system is complemented by technical devices that ensure safety.

In order for the heating circuit to function in trouble-free mode, an automatic air vent, pressure relief valve and pressure gauge are installed.

Components of security groups can be installed together on a common case or separately from each other. The main thing that the safety valve was installed on the flow behind the boiler

Expansion tank closed

Technical devices for system operation

Security group components

Assign Security Group

Step 3 - Choosing Energy

The basis of the entire heating system is the boiler. Depending on the type of fuel used for heating, there are 4 categories of boilers:

- solid fuel;

- diesel;

- gas;

- electric.

Having learned the main characteristics of all types of thermal energy generators for a cottage, you will not go wrong in choosing the right option.

Image Gallery

A photo of

The most common heat generator for the autonomous heating system is the gas boiler. The outdoor version usually complements the water heater.

The most efficient gas-fired boilers are their condensation variants, the high performance of which is due to the use of steam energy emitted during the combustion of gas.

For the arrangement of apartments and private houses with an area of up to 150 m², wall-mounted gas units are more often used, equipped with their own security group and compact expansion tank

As previously popular solid fuel boilers, the demand for which is explained by the availability of fuel. The downside is that the storage of firewood / peat / coal requires a place, besides it will have to be heated

Combined models of boilers capable of processing two or even three types of fuel are currently enjoying the highest consumer demand.

Due to partial automation and convenient fuel supply scheme, solid fuel pellet boilers are in rather high demand.

The use of liquid fuel will increase costs by 3 times compared with gas. However, in areas not connected to centralized power grids and gas supply, this, along with solid fuel boilers, is the only way

Installation of an electric boiler will be cheaper, it does not need a boiler room, a chimney and a warehouse for fuel. However, the payment of electricity is much higher than the cost of other types of fuel

Gas equipment in the autonomous heating

Condensate floor unit

Wall mounted gas version

Traditional solid fuel boiler

Combined equipment type

Solid fuel pellet boiler

Pros and cons of liquid fuel

Convenient in operation electric type

Solid fuel - a proven method for centuries

For country cottages often choose exactly solid fuel models boilers. This is due primarily to the availability of raw materials.

A solid fuel boiler can work not only on coal or wood, but also on wood processing production waste, pellets, briquettes, peat, even on organic fuel from manure. The main thing is to have where to store the entire stock of fuel. As for the efficiency of solid fuel systems, it is quite low - about 75% on average.

Modern solid fuel boilers have a compact size and a presentable appearance, but require the organization of a boiler room in accordance with the standards of safe operation.

Another advantage of this boiler is ease of use. In addition, when using solid fuel, the system heats up very quickly, which is important for country cottages. But with such a heating rate it is necessary to constantly add fuel to the furnace, otherwise the system will soon cool down.

When buying a solid fuel model, be prepared to load it every 4-5 hours. With the same frequency will have to clean the ash from soot and ash.

What heats diesel boiler?

Diesel boilers are powered by bright heating oil - a type of diesel fuel. It differs from automobile diesel engines in that the requirements for its quality are not so high, but this fuel is cheaper due to the lack of road tax.

To use a diesel boiler, you need to install a tank for diesel fuel of at least 750 liters. You can imagine how much space it will occupy in the boiler room.

Diesel boilers are relatively bulky and noisy, but in a separate boiler room they will not cause inconvenience.

Of the advantages of this type of heating emit low cost equipment, automatic on and off. But to leave such a system unattended for a long time is undesirable. Another disadvantage of this device is the noise during operation.

Environmentally friendly electric heater

It would seem that using electricity to heat a country house is a simple and profitable solution. But here everything is not so simple. The fact is that the total power of electrical equipment that you can install in your cottage is limited to the energy supplier.

Look at the switchboard. For example, a current of 16 A is indicated. Knowing the mains voltage (220 V), it is possible to calculate the allowable power.

16A x 220V = 3520W.

3520 W - the maximum allowable power. This means that a boiler with a capacity of over 3.5 kW is not suitable for your country house. It remains only to write an application for permission to install machines of greater power. The electric boiler can be connected to an ordinary outlet, and can operate from a three-phase current (380 V).

Electric boiler does not create noise and does not pollute the environment at all. This is the only type of heat generator that does not need a chimney and a separate room.

The advantages of the electric heating source:

- autonomy (does not require constant monitoring);

- automatic temperature support;

- I do not need a chimney;

- environmental friendliness - no combustion products;

- ease of use.

Of the disadvantages emit a high power consumption. We also recommend reading our other article, which describes in detail the system electric heating.

Use the blue fuel - gas model

Gas boiler - one of the most common and widely represented on the market. It runs on natural gas, can be connected to a gas pipeline or cylinder, if the gas is imported.

For liquefied bottled gas, this type of boiler is not the most convenient. One 50-liter bottle will be enough for 1-2 days to heat a country cottage.

A modern gas boiler can be an ornament to the boiler room - the design of some models is pleasing to the eye

There are single circuit and dual gas boilers. Single-boiler is designed specifically for space heating. In the double circuit there is also the function of preparing hot water - it acts as a gas column. If you plan to periodically live in your country house in the winter, then it makes sense to install a double boiler.

But if in the cold season you will be absent for a long time and turn off the boiler, it is better to purchase a single circuit. The experience of many users shows that draining water from the system for temporary preservation in double-circuit models difficult, some water can remain in the system, which is very dangerous and threatens to freeze and crack pipes.

Step 4 - Other System Components

In addition to the heart of the heating system of the cottage - the boiler, it also includes other equipment. Properly designed circulation pump, expansion tank, radiators or floor heating coils and pipe material is no less important than the choice of the boiler itself.

Therefore, do not neglect the detailed study of the characteristics of additional equipment and the subtleties of its choice.

Pump - where to embed it?

Heating design with forced circulation requires a pump. For country houses use, as a rule, circulation pumps of the wet type.

When choosing a pump should consider the following parameters:

- pressure;

- performance;

- operating conditions (area of the room, selected coolant, connection type, diameter of pipes);

- additional aspects (noise level during operation, the size of the unit).

When designing the heating in your own country house, it is important to find the most suitable place in the circuit for the pump inset. By and large, a properly selected pump will do its job equally well on any part of the system.

The reason why it is recommended to install it in front of the heat generator — on the return pipe — is to reduce equipment wear when pumping water at a relatively low temperature.

The wet-type pump does not need to be lubricated - during operation, the impeller and bearings are lubricated with coolant. Cooling function on it too

For reliable operation of the pump in the design it is important to take care of the filter. A coarse filter is installed directly in front of the pump. It picks up particles that have fallen into the water in the heating circuit. If you ignore the installation of the filter, the pump can quickly fail.

Security Unit and Expansion Tank

Since the heating circuit is a closed system, and water tends to increase in volume when heated, an expansion tank should be designed into the heating system of a country house. When the pressure in the pipes increases, the excess coolant enters the tank, thereby lowering the dangerous pressure.

The security unit is a set of three devices that ensure reliable and safe operation of the entire heating system of a cottage.

These include:

- pressure gauge - to measure pressure;

- safety valve;

- air vent.

There are no questions with a pressure gauge - it should be designed to measure the pressure of 2-3 atmospheres. That is, the pressure gauge at 4 atm. will be just right. The safety valve has the same function as the expansion tank, but in case of emergency, when the tank did not work for some reason.

In case of a critical increase in pressure, the excess is discharged from the system through the drain hole of the valve.

The pipe branch in the form of a trident on the left is the security group. A red tank on top - expansion tank

Air vent should protect the boiler from accidentally fallen into the air heating circuit. Since air bubbles in the water rise up, devices for removing excess air are installed at the top of the riser or each battery.

Pipeline and radiators - calculation and selection

The next stage is to determine the material of the pipes for the heating circuit. Options may be:

- steel;

- polypropylene;

- metal plastic;

- polyethylene.

Steel tubes previously used for the device of heating of country houses. They are durable and not afraid of high pressure. Their main drawback - susceptibility to corrosion. Rust can pass through steel, fistulas appear in the pipes and the entire system becomes unusable.

Due to corrosion deposits on the inner surface of steel pipes, the clearance decreases over time. And for their installation you will need at least a qualified welder.

The weak point of any pipeline - connections. When designing a heating circuit made of polypropylene, do not worry about this. Pipes are connected by welding - a special soldering iron. Joints are monolithic.

Polypropylene pipes are not subject to corrosion, they practically do not pollute from within, durable, light and inexpensive.

Fittings for polypropylene pipes can also be made without the use of metal. This makes them cheaper, and is well reflected in the quality of the connection.

Metal pipe sold in coils of great lengths - up to 500 m. Thus, you can generally avoid connecting pipeline from individual parts, building metal-plastic pipes along the entire heated perimeter cottage. They also do not rust, nothing is deposited in them, they are durable. But you need to protect plastic pipes from UV rays and damage during installation.

Polyethylene pipes use for hot water supply, heating and the device of a warm water floor. They have the same advantages as others, and their main drawback is the high cost of the pipes and fittings themselves.

What is better - a radiator or a warm floor?

In a country house, sectional, lamellar or panel radiators are used as heat emitters.

Such batteries can be:

- cast iron;

- aluminum;

- steel;

- bimetallic.

Cast iron batteries very heavy and fragile, but they give off warm well. Aluminum models are light and inexpensive, but chemically unstable, subject to corrosion and are afraid of pressure surges. Steel batteries also suffer from corrosion, but are chemically resistant.

Bimetallic type of batteries combines the advantages of aluminum and steel radiators. The coolant moves in a steel pipe and does not come into contact with the aluminum body. This option is suitable when using antifreeze, not water in the circuit.

In this case, the radiator is connected to horizontal wiring. Underground polypropylene pipes are used. Pipes are warmed

Batteries are placed under window openings - in places where the wall is cooled the most. As a result, it is possible to avoid glass misting and condensation on the walls. Number of radiators depends on the number of openings, but not less than 1 second in the heated room. Read more about the calculation of radiators read here.

When building a cottage, it is important to design a heated floor for heating a room. Water floor heating is a pipe laid under the floor covering, which are part of the heating circuit. This design is very effective.

It is necessary to design a warm floor with the entire system and take into account its presence when calculating the boiler power and the number of radiators.

Image Gallery

A photo of

Cast iron heating devices are resistant to corrosion, impressive weight and heat engineering inertness. Designed to operate at 6 - 9 bar, resistant to hydraulic shocks

Aluminum radiators are lighter and more graceful than cast-iron ones, with a working pressure of 16–25 bar. Heat up and cool down faster, react to thermostatic devices

Bimetallic type of radiators is an improved modification of the aluminum radiator, disadvantages which are eliminated by installing inside the case either a steel backing shell or only collectors

Steel panel heating devices quickly heat up and cool down as well. Delight at an affordable price, but designed only for 10 - 12 bar of working pressure. Adjustable

Habitual cast iron radiator

Elegant aluminum radiators

Bimetallic solution

Low cost steel panels

Features of the choice of the heat carrier

As the heat carrier clear water or antifreeze acts. Water, of course, cheaper and more affordable. It has a high heat capacity and copes well with its function. However, what is especially important for country houses, when the boiler stops, there is a risk of water freezing inside the system and damage to the pipeline.

For such cases, you can design a system with antifreeze as the coolant. It does not freeze, has good fluidity and heat capacity. However, it is an environmentally unsafe substance. Drain it into the sewer is prohibited. Most boilers are not designed to work with antifreeze. And besides all the above, antifreeze is also much more expensive than water.

Use heat transfer medium specifically designed for this purpose. It is unacceptable to pour a non-freezing car into the system, you can run into a fake and pour an unknown aggressive substance, such as acid, into the heating circuit.

Step 5 - Layout Design + Examples

Pipeline assembly can be performed in several ways:

- tee type assembly;

- collector.

The second name of the collector connection - beam. A collector is connected to the boiler, and pipes to each of the radiators diverge from it under the floor.

For heating a single-storey house there will be enough collector for 6 entrances. If the cottage has two floors, it is better to install a collector twice as large.

The collector scheme is implemented using flexible metal-plastic pipes. After laying the flooring materials all the heating pipes are completely hidden and do not spoil the appearance of the room. Entrances and exits to each radiator are brought from below directly from under the floor.

The tee connection is made via the connection of all heating devices to the feed pipe and return pipe with a tee cable. It is easier to carry out such a scheme, you do not need to spend money on collectors and look for a place to install them, which is usually done in the center of the building to equalize the lengths of the rings connected to the comb.

In order not to reinvent the wheel, you can use one of the standard heating wiring for a country house, which are successfully used in construction. The traditional one-tube model is well shown in the following drawing.

The drawing shows a small country house in which a one-pipe system would be sufficient.

For a typical cottage is often used a combination of one-and two-pipe scheme. In this case, the wiring diagram looks like this.

The first part of the pipeline has the form of a single pipe and only before the first radiator it is divided into two

The same house can be heated using a collector circuit.

In this case, the collector is enough for 4 rings connected to one heat generator

In this scheme, a separate branch leaves the boiler and leaves on the porch of the house. It is heated steps to prevent the formation of ice.

The main part of the circuit is a two-pipe system, while the additional branch is a single-pipe one.

In this case, the system provides a separate pump, tank and safety unit for one-pipe branch to the warm floor in the area of steps

In the following scheme, the heat pipe has branches to each of the rooms. That is, each room is heated by a separate circuit.

The pipes will need several times more, but the valves and thermostats on each branch allow you to adjust the temperature in each room individually

Conclusions and useful video on the topic

The video shows the main methods of connecting radiators, describes the advantages of each of them:

This video describes in detail all the nuances that should be considered when choosing heating pipes:

But a good example of designing a combined system for heating a two-story cottage:

Since the heating system of a country house should be first and foremost reliable and efficient, the development of the project should be given maximum attention. Any unaccounted detail may adversely affect the performance of the heating. It is better to entrust the design to a professional, in order to avoid mistakes.

If you already had to independently design and equip the heating system for the house, and you know subtleties that need to be paid attention, please share your knowledge and experience with our by the readers. Leave a comment in the box below.