If there is no gas pipeline nearby, then modern pellet heating boilers will be the most efficient and economical option for heating residential or non-residential buildings. In addition, such units are durable, battery life and safety.

In order for the operation of the boiler not to cause trouble, and the purchase did not disappoint, it is necessary to approach carefully the choice of equipment.

We will help you in this matter. The article presents the pros and cons of pellet boilers, specifies the features of their work and maintenance, and also describes in detail the characteristics and parameters that should be considered when buying.

The content of the article:

- Main characteristics of pellet boilers

- The advantages of pellet equipment

- Types of equipment for pellets

- What you need to know about pellets?

-

How to choose the right equipment

- What to look for before buying

- Take care of the fuel in advance

- Pellet boiler selection rules

- How to choose the right model of equipment

- Conclusions and useful video on the topic

Main characteristics of pellet boilers

All pellet boilers are designed for heating buildings. In addition, these products can provide hot water. True, such a function is optional, therefore it is not provided in every product.

The main feature of such solid fuel boilers is high automation. They use compressed wood pellets called pellets as fuel.

For the equipment to work, the owner has enough:

- with a periodicity of several days, or even weeks, months (it all depends on the size of the bunker), to ensure the supply of fuel;

- perform simple maintenance - basically it consists of cleaning from ash and takes only a few minutes.

The boilers that receive energy from burning pellets are used to heat private and apartment buildings, cottages, hotels, office, industrial buildings, shops. If you want to heat a separate room, you can use pellet stoves with the lowest performance.

Each pellet boiler has two bodies (internal, external), and between them there is heat insulating material, which eliminates the possibility of burns (+)

The advantages of pellet equipment

At present, the advantages of pellet boilers are significant, which makes them in demand. One of the most important advantages is high efficiency, it reaches 80-97%. It is comparable to the most recognized equipment for heating - gas boilers.

It is important that efficiency is provided by cheap fuel - pellets are made from wood waste (chips, pressed sawdust various hardwood or softwood), thanks to this, their cost is second only to gas.

Reasonable fuel prices paired with high efficiency provide equipment efficiency. In Russia, it is the cheapest type of heating after gas, in some post-Soviet countries (for example, Ukraine) and is the most affordable.

For example, the use of pellet boiler will cost 1.5 times cheaper than similar equipment operating on coal. And heating the building with electric boiler 2-3 times more expensive.

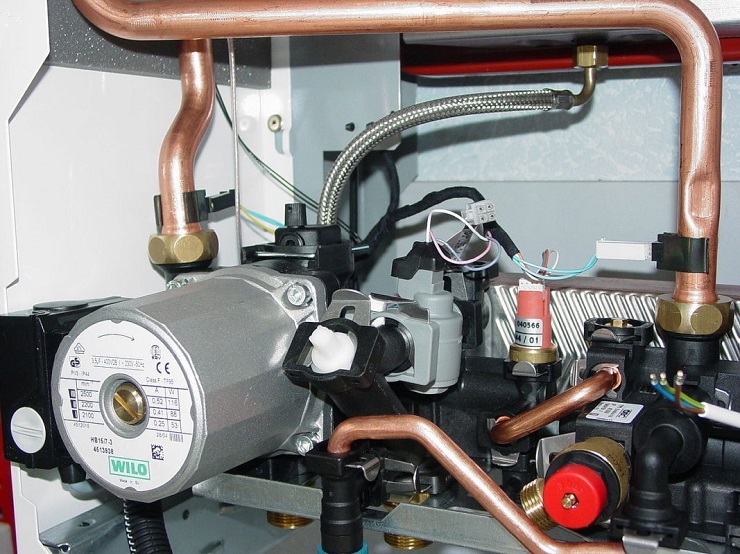

Pellet boiler is different from any other solid fuel only by the presence of a special burner

An important advantage is the autonomy in the work - it is achieved by a high level of automation. For example, the boiler itself is able to supply the right amount of pellets to the furnace, control the temperature set by the owner, stop and start work. Often the equipment can even clean itself of ash.

Autonomy is within 2-15 days, and if an automated boiler is provided with an uninterrupted supply of fuel, then it is able to work without the intervention of a person during the entire cold season. Also, these units are independent of the availability of centralized heating, gas pipeline.

We must not forget about environmental friendliness - pellets are compressed sawdust, they do not contain glue or other binders. This guarantees the absence of harmful substances in the granules (for example, sulfur), their ash content is ten times lower than that of firewood, as is the release of carbon dioxide.

Another important advantage is security. To ensure it, a multi-level fire-fighting system is used, which includes control sensors, electronics providing interruption of the supply of pellets, automatic shutdown, a number of boilers are equipped with systems alarms.

Low-cost service will also please you - this is a guaranteed fact, due to the fact that there is little work and any person who does not have special skills can handle them.

An important advantage is simple installation - the owner of the boiler does not need to get any permission, to draft. The current rules allow you to mount such equipment in the back rooms, basements, corridors, kitchens. Besides, Pellet boiler harness can do it yourself.

Types of equipment for pellets

Any pellet boiler is solid, therefore it has all the features of such products. That is, steel, cast iron are used for its manufacture, and the design consists of traditional elements: the body, the firebox, the heat exchanger, the chimney has not gone anywhere.

But there is also its own “zest” - the burner, which works together with the electronics and the fuel feed mechanism into the furnace. This structural element significantly affects the characteristics of any boiler, therefore, according to their characteristics, boilers are divided into types.

There will be no particular difficulties with choosing the type of burner - there are only three options:

- flare;

- volume;

- chimney.

Flare burners differ in such advantages: compactness, durability, unpretentiousness. Also, these products have a relatively low productivity, so they are used only for installation in household boilers of moderate power.

It is recommended to choose them if the equipment will turn on / off frequently (for example, in summer houses where people do not live permanently). It is also the best option for universal boilers, that is, using different types of fuel.

It looks like a flare burner. It is unpretentious, reliable, but has a significant drawback: due to the horizontal location, a local overheating of the furnace body occurs

Another important feature of all torch burners is sensitivity to the quality of pellet fuel. Such equipment is capable of working effectively and for a long time only on moderately wet pellets, which retain their shape before entering the burner with a low content of sand and other impurities.

Volumetric burners - it is the most productive and efficient among other types. Therefore, they are installed in powerful domestic and industrial boilers. Usually have a greater mass than the flare counterparts. Also, such equipment is insensitive to the quality of fuel.

The burner of volume burning for today is the most demanded in the market of equipment for heating boilers

Fireplace burners - designed to be installed only in the smallest boilers (stoves). They are sensitive to fuel quality.

Also, this type of burner is characterized by moderate performance, but due to the simplicity of its design, the highest reliability.

All pellet boilers are divided into groups by purpose.

To understand this question is simple, since there are only two types:

- heating boilers;

- fireplaces.

Heating boilers - serve to heat and provide hot water. Typically, their power starts at 13-15 kW, the maximum performance of 2 megawatts. Differ massiveness, unpretentious appearance. Such equipment is installed in the basements of houses, individual buildings.

Fireplace stoves - serve to heat the room in which they are installed. They are compact, feature quiet operation, have an attractive appearance.

Additionally, all the pellet boilers are divided by the level of automation into the following types:

- automatic;

- semi-automatic;

- mechanized.

Automatic boilers. The uninterrupted operation of such products will have to be made extremely rarely, usually it is required to start the boiler in the fall, turn it off in the spring. Everything else is controlled by the processor - fuel supply, ignition, heat exchanger cleaning and even ash removal.

But such equipment will not be available to all because of its high cost, complexity of design, expensive installation, as it requires a lot of precise electronics settings.

In addition, automatic products will show their qualities to the maximum if the fuel supply is large, that is, a warehouse of at least a few cubic meters is needed. And if the bunker will have to be loaded frequently, then the sense of paying impressive money for such equipment is lost.

An automated boiler needs a bulk bunker or warehouse so that the fuel supply can be maintained at a sufficient level.

Semi-automatic products Usually, they differ from automatic boilers only in that they must be cleaned manually. But this procedure does not cause difficulties even among strangers with such equipment.

In addition, the cleaning procedure is short, takes a few minutes (no more than 15-20). Yes, and it is rarely done - usually no more than once a week).

Mechanized boilers - the most common group. There are several reasons for this, for example, they are distinguished by compactness, the most affordable cost, simplicity of design, which increases reliability.

Since the level of automation is somewhat lower than in other cases, a person will have to clean the heat exchanger and ash pan independently, but this is not critical at all. This procedure is usually simple, takes a little time, and the frequency depends on the quality of the pellets, the intensity of use of the boiler.

Since the bunker of a mechanized product has relatively small dimensions, it will have to be loaded manually after a few days. The exact frequency depends on the mode of operation (in the cold more often, in the offseason an order of magnitude less often).

All equipment that uses pellets for its work is characterized by versatility - this applies to the type of fuel used.

There are boilers of the following types:

- pellet

- conditionally combined;

- combined.

Boilers belonging to the category of pellet, can only work on wood pellets. More universal conventionally combined products allow the use of alternative fuels, for example: briquettes, firewood.

But there is an important condition - any type of fuel, except pellets, should be used only in exceptional cases and for a short time. The reason for this is the design of the boiler.

The form of its furnace is designed to use only pellets, and firewood, coal can cause local overheating, which will lead to equipment breakdown.

Usually the ability to use alternative fuels is provided by additional structural elements for example, often a grate is included in the kit, which is mounted in the firebox if it has run out pellets.

The combined type of equipment allows you to use several types of fuel on an ongoing basis. This feature is achieved due to the presence of several fireboxes. This solution allows you to make the boiler as versatile as possible, but also makes it more cumbersome and expensive.

Pellet boilers are durable, they are ready to serve for more than 20 years, provided proper operation

The important point is the characteristics of the pellets themselves and their quality. The fact is that the automation of the presented equipment is designed only for granules of a certain type and quality. Therefore, before buying you need to learn to choose the right fuel.

What you need to know about pellets?

Wood pellets used as fuel come in different sizes, they depend on the standards adopted in the state. Thus, pellets produced in the European Union reach a length of 30-60 mm. In Russia, where the rules have not yet been established, the granules may be longer.

Therefore, if you use such a product for a boiler produced in Europe, it will be hard to set up the automation to the desired mode. As a result, overruns are possible, incorrect work in the owner-defined modes, and so on.

The bunker may be located at a substantial distance (up to 10 m) from the boiler itself.

Also all boilers for heating, operating on pellets, require that they be of sufficient quality. That is, the granules must retain their shape until it enters the furnace. Otherwise, no overruns are possible.

The strength of the pellets depends on workmanship, humidity. It is important that it does not exceed 12%. If the rate is not observed, then the calorific value will decrease, and in severe cases, the granules will become completely unusable.

This type of fuel is:

- household (ash content up to 1%) - they are made from waste of hardwood with minimal addition of bark;

- industrial (ash content up to 3%) - it is made from softwood waste with the addition of bark (up to 10%);

- from agricultural waste (ash more than 3%) - make them from biomass of different origin (sunflower husks, straw).

Granules for domestic use have the highest calorific value, as they contain a small amount of dust and have low humidity. They are always white.

Cheaper - granules for industrial use. Low cost is a significant advantage. Their disadvantage is not the highest calorific value. In addition, the boiler will have to be cleaned much more often and this procedure will be more labor-intensive.

You can identify industrial granules by color - they are dark brown. They are undesirable for domestic use due to low calorific value.

There is another type of pellet made from agricultural waste. But you should not use them - they have an extremely low calorific value, high ash content. This means that the boiler will clog frequently, and cleaning it, in this case, is quite difficult, especially the frozen ash.

You can set up production of pellets yourself, for more details on the manufacture of a special press, see this article.

How to choose the right equipment

Before making a decision on the purchase of a pellet boiler, it is necessary to sort out a number of points in order to avoid substantial financial losses. It so happens that, rushing to purchase, the owner can not install the purchased equipment or fully exploit it.

What to look for before buying

So, before buying, you should deal with a few nuances.

First of all, make sure whether it is possible to place the necessary equipment in the building. It is usually installed on the first floor, in the basement.

It is necessary to take into account not only the estimated dimensions of a particular product, but also the requirements for its installation, for example, there should be gaps from 700 mm between the components of the boiler.

Secondly, you need to figure out whether it is possible to store fuel in the right quantity. It is also necessary to pay attention to the convenience of delivering it to the boiler (transportation from the supplier, moving from storage to the bunker). Yes, and fuel should be stored only in a dry room.

It should be borne in mind that the pellets will be quite a lot. For example, for home heating, a relatively small area (100 square meters. m) when it is cold, you need 25 kg of pellets per day

ThirdlyIs there sufficient power grid? Since the control unit, together with the sensors, the ignition system is powered by electricity, for normal operation, for a short period, they can create a significant load.

This happens during the boiler ignition procedure, when a special heating element raises the temperature in the combustion chamber to an impressive 1000 ° C in order for the pellets to catch fire.

Take care of the fuel in advance

Also, before buying a boiler, you should find out if there are any organizations that supply pellets nearby. There should be several sellers - if he is alone and suddenly ceases to exist, then exploitation problems will begin.

It is also necessary to pay attention to the fact that it is usually cheaper to buy fuel from a manufacturer. To prevent any accidents to the potential buyer of the granules, even before the purchase, you should familiarize yourself with the offers of the sellers.

It is advisable to contact them directly and find out all the details - the cost of delivery, whether the organization will be able to carry out shipments regularly etc. And with industrial expenses, it is best to sign an agreement with the supplier before the purchase. supply

The bunker can be installed on either side of the boiler - the main thing is that it is convenient to use the equipment

Pellet boiler selection rules

If there is no doubt about the possibility of installing and providing fuel, then you can proceed to the choice of the boiler. This should be started with power calculation.

Theoretically, it is easy to calculate - all manufacturers indicate this characteristic in their passports, and for simplicity they add how many square meters they are ready to heat the boiler.

For example, if the description says that the power is 30 kW, the manufacturer will indicate that his boiler is able to heat 200-300 square meters. m rooms. But all these are average values that are not very suitable for determining exact values.

Also, any person is able to perform the calculation himself, since it is considered that 1 kW of power is required for each square meter. The formula is relevant only for buildings with low heat loss. In their decoration used effective insulating materials, and doors and windows, too, to match them.

Otherwise, it is necessary to calculate the heat loss that only a specialist can do. It will cost money, but will guarantee that the building will be warm and not overpay for it.

Without the necessary calculations, the purchase will be made on the “random”, which is unacceptable, given the cost of purchase and installation

In addition to the rated power, it is necessary to take into account such a moment as its modulation. Although it does not sound clear, but everything is simple here - this is the possibility of a pellet boiler to work on modes below its maximum performance.

This is true for regions in which the cold season is not the most part of the season. Therefore, the heating equipment does not need to work at full capacity, and it is enough to use only 30-40% of it.

If the boiler does not have such an opportunity, then, at first glance, it does not matter - having reached the maximum temperature specified by the user, it will turn off. When it decreases to the minimum set level, it will turn on again. But during such on / off, wear occurs, which significantly reduces equipment life.

Heat exchangers make steel or cast iron. The first give off better heat, less massive, the second are more resistant to corrosion

You should also pay attention to the dynamic power. The owner may rarely encounter such a characteristic, but in unpleasant moments (if the boiler is chosen incorrectly).

To understand the dynamic power, it suffices to disassemble an example: a sharp decrease in temperature occurred and the boiler began to not cope with heating.

If he has enough opportunities for a short time, but significantly, to increase his performance and quickly bring the temperature to the set point - it means the boiler has sufficient dynamic power.

If this does not happen, then the indicated characteristic is insufficient and it is better not to buy the boiler - it will sometimes make the owners freeze.

How to choose the right model of equipment

When power is determined, you can proceed to the choice of model. At this point, the potential buyer will understand that there are many manufacturers, as well as models. In order not to get entangled in this diversity, it is necessary to decide which manufacturer’s boiler to take - known domestic or foreign.

It is worth buying equipment only from a seller well-known in the country or region who is servicing, updating all software, repairing a sold boiler.

The larger the bunker, the greater the autonomy of the equipment. This will allow no longer add fuel.

Also, when choosing, you should pay attention to the type of model you like, advantages, versatility, and so on.

But in any case, you need to check:

- Is the boiler certified by Rostechnadzor;

- whether there are conclusions of independent specialized institutions confirming the high efficiency of the selected equipment, the size of harmful emissions;

- whether there is a fire extinguishing system and whether the boiler automation can prevent “reverse fire” when, for some reason, the flame began to move from the burner to the bunker;

- what methods are used to prevent overheating of the working boiler.

Since the boiler will operate in different modes, it is worth checking the information on the efficiency, the amount of emissions on all of them. Also, do not be amiss to find out the noise of work and worry about security.

In addition, you should see how simple the equipment is being programmed, controlled, whether there is an automatic ignition so that all households can handle it. Should be simple and cleaning products from ash.

Since the boiler will be connected to other heating equipment, it is always necessary to find out the standards, the wiring diagram, the requirements of the manufacturer in this case, the diameter of the pipes. The last moment is especially relevant if they are already installed or purchased.

Conclusions and useful video on the topic

The advantages and disadvantages of heating pellets in the video clip:

The video provides an overview of the pellet equipment market:

What is a pellet boiler and its comparison with an electric one in a video clip:

Choosing a pellet boiler is a responsible procedure. To do this, you need to pay some attention to studying the features of this equipment. And it is also important not to save, but to give preference to a product made in Europe.

Since, the durability of boilers strongly depends on the quality of materials, sufficient thickness of its body, and compliance with all standards is guaranteed only by manufacturers from the European Union.

Looking for a reliable and efficient pellet boiler? Or have experience using such heating units? Please leave comments on the article, ask questions and participate in discussions. Contact form is located below.