Any appliances periodically break down, and the gas column is no exception. With timely treatment and respect for the rules of operation of such a device is working properly. But if the device is not included, or the flame is extinguished immediately, it may show serious breakage.

To understand why a geyser goes out, let's deal with the peculiarities of its structure and functioning. Also in this paper we consider the causes of extinction of the popular column, and how to restore her health. The material we have added a visual picture and informative videos.

The content of the article:

- Design and operation of the column

-

The reasons for the extinction of the column

- Reason # 1 - no draft in the chimney

- Reason # 2 - regular attenuation burner

- Reason # 3 - significant overheating of the water

- Reason # 4 - Insufficient water pressure

- Reason # 5 - lack of timely TO

-

Typical problems for some models

- Problems with thermocouple from Junkers Bosch

- contact oxidation in columns vector

- Problems with the rod in the Neva models

- Conclusions and useful videos on the topic

Design and operation of the column

Inside the column there are two basic elements: a gas burner and heat exchanger, which appears as a long narrow tube, typically made of copper, or snake coiled helix. Cold water comes from the water supply to the coil is heated above the burner in and out of the device already hot.

Of course, things are not so simple, because the safe and efficient operation of the device provides a number of important sites, such as:

- ignition device or igniter;

- WAG node;

- solenoid valve a set of sensors.

Ignition apparatus often looks like a so-called duty burner: small flame that burns continuously. In this embodiment, the electronic assembly immediately before the column there is a spark, which ignites the igniter. This is a more modern version, allowing even get some gas savings.

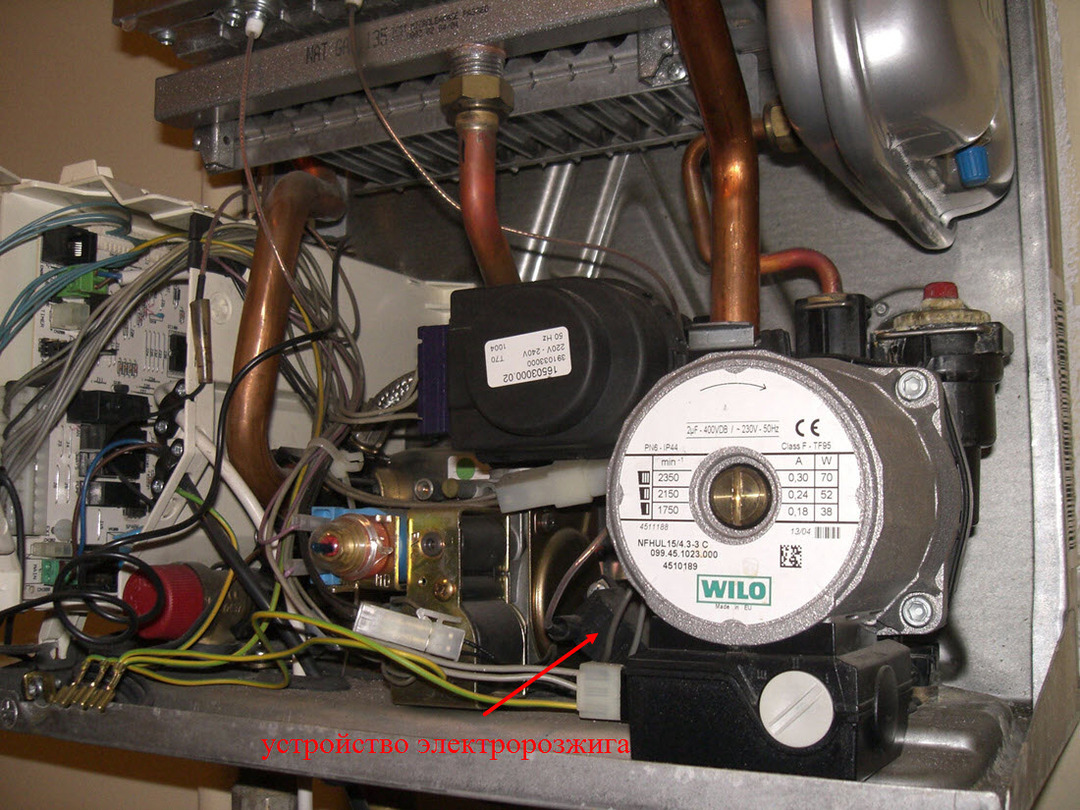

Root repair gas column need to study the structure of the device, the location of the main nodes and the order of their functioning

For the sparks often used a piezoelectric element, which can be run manually. In past years, the models are not defined: a pilot light lit normal match. The gas turned on automatically at start-up water needed water-gas unit. It consists of a membrane which is mounted in the water, and a valve in the gas path.

When the faucet is opened, water starts to move, changes the position of the membrane under the influence of the flow and transmits a signal to the valve. It opens and lets gas stream to the burner, which is ignited. When turning off the water membrane returns to its original position, the valve closes the gas flow, the burner is extinguished.

If the main burner does not speakers piped gas, most likely, it is covered by one of the security elements, to react to some fault

Due to the water-gas assembly is not necessary each time to manually open the gas when you turn on the water. Solenoid valve also regulates the flow of gas according to the readings of different sensors, fixing a flame rod, dangerous overheating and the like

This node is required to increase the security of the system. The sensors respond to system failures, and valve blocks flow of gas when there are serious problems in the operation of the device.

In addition to the sensors connected to the valve thermocouple. This element is responsive to the presence or absence of the pilot burner flame. If the fire is not entering the column gas lights, and will accumulate, which is very dangerous.

If the column must parse, you must first determine the places of water and gas connections to cover these pipe respective valves

The reasons for the extinction of the column

Any of the nodes described above can cause attenuation column. Flame goes out if the safety system detects a violation of normal operation. To start the unit, you will need to identify and eliminate the cause of such disorders.

Here are the most common variants of possible problems:

- a chimney offline Rod;

- extinguished main burner;

- there is a dangerous rise in temperature of the water in the heat exchanger;

- the individual elements are worn out and require replacement.

If the column does not fire, it is necessary to start to make sure that not violated the conditions of its operation, and check the manufacturer's warranty terms. The required information is contained in the product data sheet and instructions for its use.

Reason # 1 - no draft in the chimney

traction test - the easiest way to diagnose the condition of the device. It is necessary simply to bring the viewing aperture columns thin strip of paper or flame lighters, matches and etc. But if there is even a slight suspicion of gas leakage, the use of open flames is better refuse.

Contact Rod - dangerous phenomenon, it can blow out the flame of the pilot burner, whereupon flow of gas to the device is terminated

If the paper or flame draws inside, all right, there is a craving. No change in their position indicates the absence of traction, and the deviation in the opposite direction - that is observed back draft.

make sure the causes of the problem, you need to remove the column and check in the same way only traction in the chimney. After that, it will be clear whether there is a fault in the flue duct or inside the column, too.

When the chimney design in order "to blame" lack of traction becomes heat rather zabivshie his soot particles, which impair the air. Must be removed from the column protective cover and clean the heat exchanger with a stiff brush.

Improper installation of the gas flue columns can lead to a reduction or absence of traction, rapid clogging with soot and the soot, as well as other problems of dangerous

If the chimney is dirty, it is easy to clean and re-connect with the device. In the absence of a positive response you need to make sure that the chimney structure is assembled correctly from suitable materials. Sometimes the reason for the lack of traction could be flaws in the installation of the system area.

Often, the problems of this type arise due to external reasons, such as lack of adequate ventilation of the room. Plastic windows and closed doors almost sealed room in which the heater. Inflow of fresh air flows is missing, so there is no movement in the flue-gas channel.

It never hurts to check the ventilation system throughout the house or apartment.

traction testing - an important point security in the use of the gas column. This procedure should be done regularly, not waiting when problems arise

It is necessary to ensure that a sufficient amount of fresh air into the room. If a natural way to organize the ventilation fails, you can install the air inlet window or wall.

Then it must be ensured that the air flow does not only come into the house, but also to move freely on the premises. To do this, you must install the ventilation grilles on doors or make a small gap at the bottom.

Reason # 2 - regular attenuation burner

Absence of the pilot burner flame sensor is fixed, whereupon the gas flow is blocked immediately. This situation can occur if a small flame was hit by a strong gust of wind. It is not necessary to arrange the room drafts while working, especially if the outside is very windy.

Strong air flows can penetrate not only through the windows and doors, but also on the flue duct. The result can be the same - the burner is extinguished, automatic stops gas flow.

To restore the normal operation of the appliance, switch off a column, check the status of the pilot burner (here should appear flame), and turn on the unit again.

Reason # 3 - significant overheating of the water

This occurs when the pressure of the water stream passing through the heat exchanger is reduced, and the heating intensity remains unchanged. In some cases, there may be even boiling water, which is dangerous for the integrity of the device.

The pressure is reduced when the open cold water to dilute the stream to a comfortable temperature, and cold water displaces the hot. Heating is better adjusted by the speaker settings.

Another cause of such a phenomenon - lime sludge accumulated inside the narrow heat exchanger tubes. To restore normal pressure, it is necessary to regularly clean the unit from the scale, as well as ensure that the water was not too hot. For domestic use water sufficiently warm up to 45-50 degrees.

This mode reduces the formation of a solid precipitate. If the water in the system is too rigid, and often have to clean the heat exchanger, it makes sense to think about setting up a special filter that will output from a salt flux. Purification of the heat exchanger is performed by means of special tools or household chemicals: soda, vinegar, etc.

Since the column will stay in a protective casing, as well as to turn off gas and water. Then the heat exchanger is disconnected from the water and disassembled. Inside the pipe coil cleaning composition is poured and allowed to stand for some time. After this heat exchanger are washed, put in place and perform reassembly column.

Inside the water-gas unit has a flexible membrane, which wears out with time. In this case, it must be replaced, even though sometimes it helps and easy washing

Periodically impurities clogged strainer mounted on the tap water inlet to the heat exchanger. It also needs to be cleaned. To eliminate conventional pollutants simply wash the mesh in the water, but sometimes you have to use chemicals. If damage is found on the filter, it is better to replace it immediately.

Reason # 4 - Insufficient water pressure

The lack of normal Water pressure in the system without overheating and can result in the valve block the gas stream and the burner is damped.

In this situation, you should check the condition of the water system, it is possible, you just need to put circulation pump. Even when buying speakers should ask minimal pressure values for a particular model.

To get a spark and ignite the pilot burner, on most models need to press the electric or pezorozzhigom. If the flame dies out at once, you should check the status of the pilot

Reason # 5 - lack of timely TO

Following the recommendations of the manufacturer should be regularly clean column. Delays in maintenance does not improve the situation. Consider the main problems for this reason.

Grounded battery power

If the column is provided an electric ignition, it is carried out by means of batteries. Grounded batteries need to be replaced, and the problem will be solved.

And when the spark for a piezoelectric element is used with the turbine, it will not run in low water pressure, this time need to be considered.

If the spark is in the pilot light is not formed, it is necessary immediately to check and replace the batteries, as well as clean contacts, if they are oxidized

Significant blockage igniter

No flame pilot burner often occurs when the clogged igniter. Gas just does not enter in sufficient quantity to ignite the burner. Igniter need to clean the metal wire to the column began to work.

Cleaning is best done in advance, instead of waiting until the hole is clogged. Clogging accumulate gradually.

If the igniter in the gas column is clogged, the burner receives enough gas to appeared flame tongue will have to be cleaned

If a tongue of flame diminished considerably, it is time to check the status of the pilot. Another sign of the emergence of such problems - cotton, which can be heard when the burner is turned on. Poor flame is unable to immediately ignite gas supplied to the device. It gradually accumulates and turns with cotton, like a small explosion.

Pollution or deterioration of the membrane

As previously mentioned, there is in the water-gas membrane assembly. This polymer element which, when a permanent contact with the water gradually loses elasticity. Sometimes it even cracks, limescale is deposited, etc. The membrane ceases to respond to the flow of water, and the resulting gas is not supplied to the burner.

WAG need to disassemble the unit, remove the worn elements and replaced by a new membrane.

If during the inspection it turns out that pollution is not too large, and the element is elastic, you can simply rinse the membrane and set it in its place.

In modern models with a large number of electronics control board may burn, and then the column, of course, will not light up.

Clogging strainer

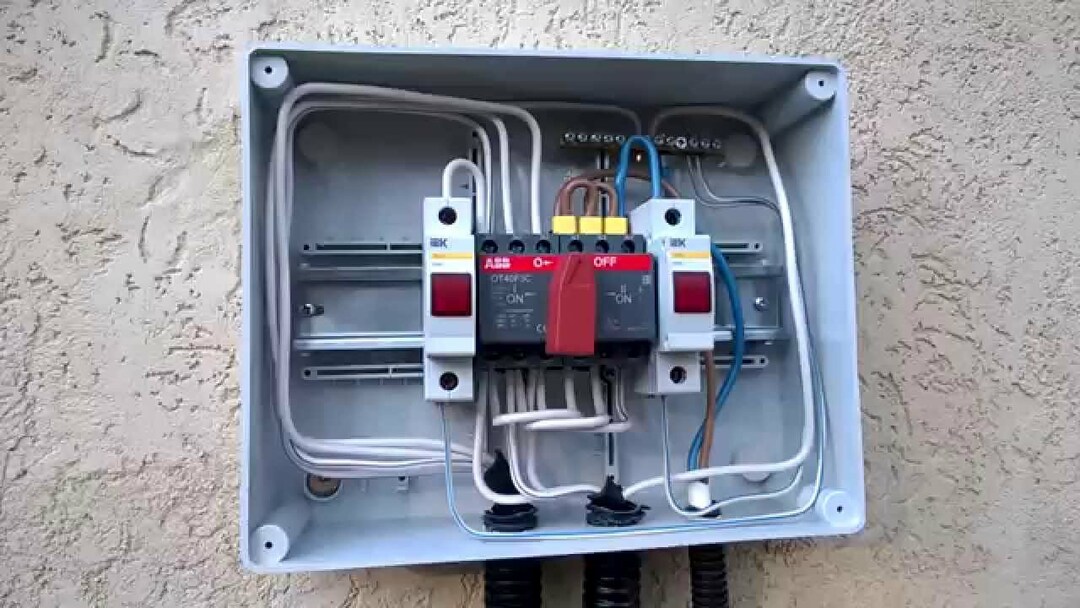

The reason for this failure - poor quality of power supply, to which foreign devices not designed. In addition, some models with electronic control should not turn off at night, they need to be on all the time. To solve the problem of power failure, it is possible to use a stabilizer.

Clogging coarse filter could lead to a dangerous reduction in water pressure flowing to the gas column. This element should be regularly cleaned and replaced if necessary

Typical problems for some models

Even well-known firms speakers over time can break for a variety of reasons. In the operation of the devices owners noticed damage that occur in specific patterns often.

Problems with thermocouple from Junkers Bosch

For example, a weak spot device Junkers WR 13-P production Bosch - thermocouple.

After two or three years after the start of operation it stops normally react to heat from the pilot burner. As a result, the flame igniter constantly fades over time, it will simply cease normal light.

Sometimes it helps trim trimming thermocouple with fine sandpaper, but when this method will no longer bring the desired effect, the element will have to be replaced.

In some models, gas columns eventually fails thermocouple, which is easy to replace with a new element

The displacement of the igniter tube, which is fastened too tightly in such models, can also lead to similar problems. The tube can be pushed accidentally, even just touching her match during ignition. Between the nozzle of the gas lance and the burner has a slot through which air flows.

By moving this gap is reduced, the air required for proper combustion becomes insufficient. Language flame does not reach the thermocouple is not heated, gas does not flow to the main burner. If you restore the normal position of the tube, the column will work properly again.

Practical recommendations on cleansing and elimination of breakages JUNKERS column:

contact oxidation in columns vector

Speaker "Vector" is considered to be a characteristic problem oxidation of the contacts in the power supply. If so, then the replacement battery shrunken on the new elements will not give the desired result, the spark will not appear until the contacts will not be cleaned. Sometimes in these columns there zakisaniya rod microswitch on the water valve.

If the column is at work a little hiss or whistle, perhaps, is loose coil tubes, they need to test and solder

After cleaning the normal operation of the device is restored normally. If shortly after the column appears characteristic whistle, please check the flue pipe connections, they may need to be re-sealing.

Problems with the rod in the Neva models

In columns mark "Neva" jamming sometimes occurs in the gas valve stem. As a result, the element stops functioning properly.

To eliminate this defect, it is necessary to remove and disassemble water-gas unit, and then move the rod ordinary screwdriver. If the item is not amenable to mechanical stress, it completely replace the item.

This video demonstrates Troubleshooting for column NEVA:

Conclusions and useful videos on the topic

Search for Causes and Remedies column decay problems can be found here:

Attenuation column - it's a symptom of an internal failure or breach of the device operation. It is necessary to correctly determine the cause of the problem, after which a significant portion of the described failures can be fixed by yourself. But for the solution of complex problems will have to contact the service center.

You have when searching for the causes of the decay column Questions? Ask them under this article - our experts and visitors will try to help you.

Or maybe you want to tell other users about the problems that have arisen from your column during the operation and success of their decision? Share your experience, leave your recommendations in box below.