Gas equipment of the boiler + water heater type is a suitable solution for owners of apartments and private houses: heat is provided, hot water is available, economically. And the connection of a double-circuit gas boiler to the heating system is not as difficult as it seems. But before embarking on the implementation of such a project, it will not be superfluous to get acquainted with the theory, do you agree?

In this publication, we will talk about the features of the connection process: what are the requirements of service organizations it is necessary to take into account and what technical nuances of installation of wall and floor models should be paid special Attention. We will supplement the presented material with visual photos and videos, which will help to complete all the work as quickly and without errors.

The content of the article:

-

Equipment installation rules

- General requirements at the design stage

- Documentation preparation process

-

Features of the strapping of the wall model

- Stage # 1 - connection to the heating system

- Stage # 2 - connecting the boiler to the power grid

- Stage # 3 - connecting the unit to the chimney

- Installation of the floor-standing appliance

- Options for schemes with a boiler

- Additional installation guidelines

- Conclusions and useful video on the topic

Equipment installation rules

The installation and connection of the boiler to the system should be started after passing the design stage, when a place in the house has been prepared for the unit. If installed in violation of the requirements, the specialists of the gas distribution company will not connect the equipment to the gas main.

General requirements at the design stage

The main norms for the installation of gas equipment are spelled out in SNiP 42-01-2002. Supporting information is also contained in the already invalid but useful SNiP 2.04.08-87.

Usually, all the rules are taken into account by the design engineer, but it is also useful to know them for yourself. The room for the location of the boiler can be a kitchen if the power of the device fluctuates in the range of up to 60 kW. A separate or attached furnace is relevant for units with a power rating of up to 150 kW.

Additional standards for the installation of gas equipment are given in SNiP on boiler installations, as well as on heating, ventilation, air conditioning

The room requirements are as follows:

- The minimum value of the height of the room is 2 m, the volume is 7.5 m3. If there are two or more gas appliances, the parameters change by 2.5 m and 13.5 m3 respectively.

- Not suitable for installation: basements, balconies, bathrooms, corridors, rooms without vents.

- The walls of the premises must be covered with non-combustible materials or protected with special panels.

- Lighting: at 10 m3 the room has a minimum of 0.3 m2 window. In the event of a gas explosion, the windows are an easily resettable structure, which increases safety of equipment operation.

- Be sure to have grounding, cold water pipelines.

- The chimney section corresponds to the capacity of the installed equipment.

- The space around the device is left: in front - from 1.25 m, on the sides (if maintenance is necessary) - from 0.7 m.

- The distance from the vertical chimney to the unit was observed - no more than 3 m.

Ventilation should also be provided. Natural is calculated in the amount of 3 room volumes per hour. When organizing the supply air, combustion air is added to this value (the parameter is indicated in the boiler passport).

The requirements are not limited to the premises. The distance from the mounted device to the nearest structures is also regulated. This information is indicated by the manufacturer in the instructions for the equipment.

If the double-circuit boiler is installed on a wooden wall, a sheet of roofing steel (0.8 - 1 mm) or a minerite slab is attached to it. Provided that the equipment is located outside the kitchen, asbestos is also possible.

Floor-standing models of boilers are installed on non-combustible bases. If the surface is wooden, a metal backing is required.

It is recommended to place the appliance as close to the gas pipe as possible. The use of special hoses is permissible, but they should not be too long. Bellows hoses up to 5 m are on sale, they are allowed for installation, but according to European standards, the length is limited to two meters.

Documentation preparation process

After a general acquaintance with how to technically correctly connect double-circuit gas boilers, you can start preparing the documentation. First step - obtaining technical specifications. It is necessary to contact the regional gas service with a statement, which indicates the estimated volume of consumption of blue fuel per hour.

Specifications are issued in 1-2 weeks. The document is a permit to connect housing to the gas main.

The second stage - according to TU is being developed equipment installation project. Third - statement prepared documentation by the engineers of the service gas distribution company.

The project includes both the installation diagram of the boiler itself and the laying of the gas pipeline from the connection point to the main. If we are talking about a private house, a drawing of communications on the site is added

The boiler's technical passport, operating instructions, certificates, an expert opinion on the compliance of the device with all standards are submitted to the controlling organization. The required papers are provided by the manufacturer of the double-circuit boiler.

Documentation approval can take place in a week or take up to 3 months, it all depends on the complexity of the project. In case of refusal, the inspectorate is obliged to provide a list of corrections to eliminate deficiencies. If all the requirements are met, seals are affixed and you can start connecting the equipment.

Features of the strapping of the wall model

First, you need to make connections to the heating system, water supply and power supply, if the device has control and regulation elements. The connection to the gas main is carried out by an employee of the relevant service or a licensed company. The homeowner only needs buy counter and a gas filter.

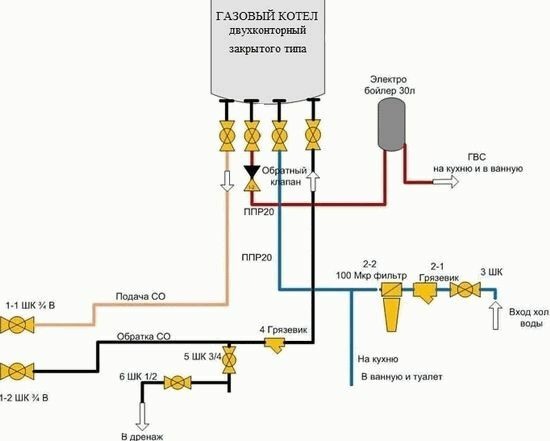

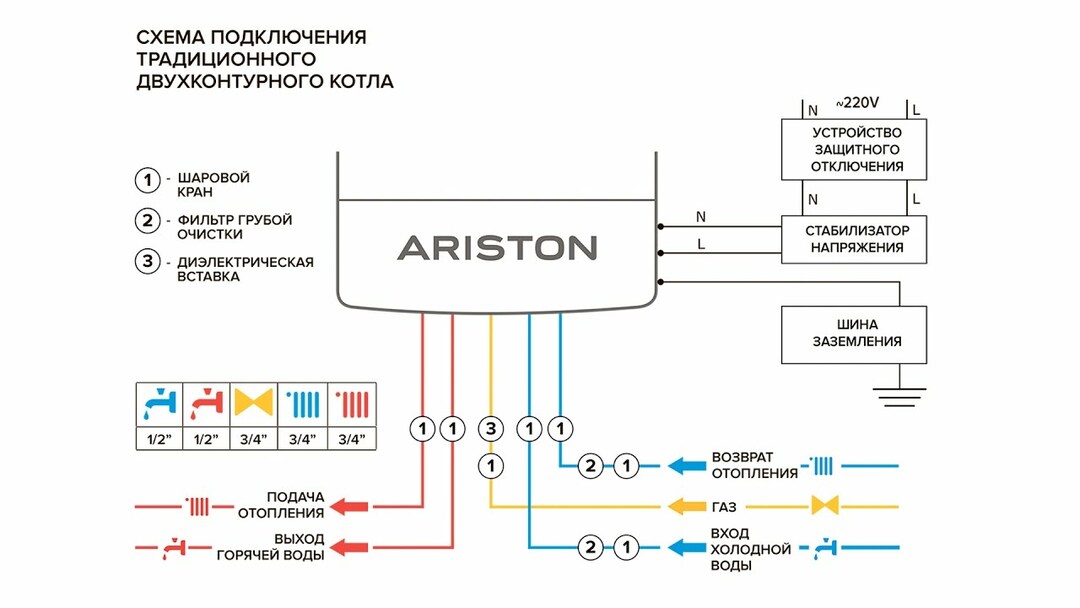

The device has 5 connection pipes: supply and return of the heating system, cold water inlet and hot water outlet plus gas supply. It is convenient to screw all the fittings before hanging the device on the wall. Handles that interfere with rotation can be removed by unscrewing the nut on the stem. Installing a gas valve will not do without a dielectric gasket

What products and materials will be needed in the process of work:

- 3 ball valves with American size 1/2 "and 4 of the same size 3/4";

- 2 mud collectors (mechanical or self-cleaning) - installed on the cold water supply and return pipe of the heating pipe;

- gas filter;

- expansion tank (if its volume is not enough for a large pipeline network, a membrane tank is also needed);

- pipe fittings - elbows, tees;

- three-core cable (VVG brand, cross-section 2.5 mm2);

- automatic two-pole switch 20 A.

This list is suitable for heat generators with a simple design with an open combustion chamber. Expensive models are equipped with an expansion tank and a gas filter.

If the water pressure is less than 1 atm, it is worth setting pressure boosting station. It is useless under the condition of constant water pressure within 2-3 atm.

Additionally, the system may include: a third cartridge fine filter, pressure gauges for monitoring of pressure in different places of the circuit, automatic air vent, circulation pump, stabilizer stresses

In the case of a separate boiler room, a heating radiator will be needed, which will provide a normal temperature regime for the operation of the boiler and protect it from condensation

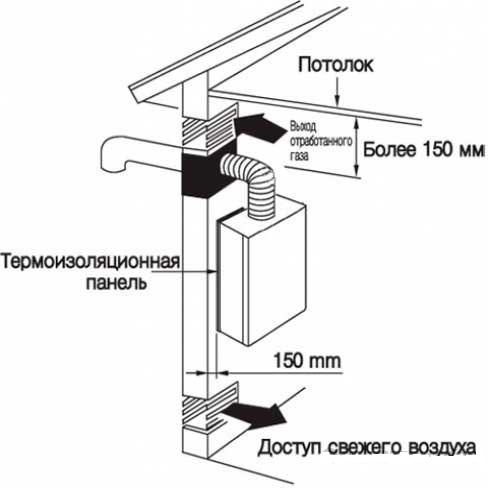

Next, we hang the boiler on the wall, having determined the optimal height. It is not worth hanging under the ceiling - ease of use is important. The minimum distance from the ceiling to the outlet is 15 cm, from the floor - 80 cm, from the wall - 20 cm.

To mount the device, you will need two special brackets that are supplied in the kit. They are attached to the wall with plastic dowels and self-tapping screws. To position them correctly, it is recommended to use a level and a plumb line.

Stage # 1 - connection to the heating system

Everything Ball Valves to shut off the pipeline, they are installed more for servicing the system than taking into account its possible cutting off and dismantling during operation. Heating equipment is characterized by reliability. Example: a shut-off valve on the heating return is designed to clean the filter without draining the heating medium.

The standard connection diagram is in the passport of any double-circuit boiler. It is worth navigating along it when tying the device

Connection recommendations:

- Half-inch taps are installed on water connections and gas supply. And DN20 are mounted on nozzles with a coolant.

- The fittings must be screwed down with the branch pipes.

- Filters are connected horizontally, "spouts" are turned to the floor. In this position, it is convenient to clean them.

- An external expansion tank is connected to the return line using additional fittings.

- The drain connection is installed at the lowest point of the system.

If you plan to fill in the system as coolant non-freezing antifreeze, for reinsurance, additional supply and return valves should be added to the circuit. This makes it possible to dismantle the boiler without draining the antifreeze.

Stage # 2 - connecting the boiler to the power grid

There are usually no difficulties with the supply of electricity - it is enough to plug the device into an outlet. But there are also rules and safety requirements here.

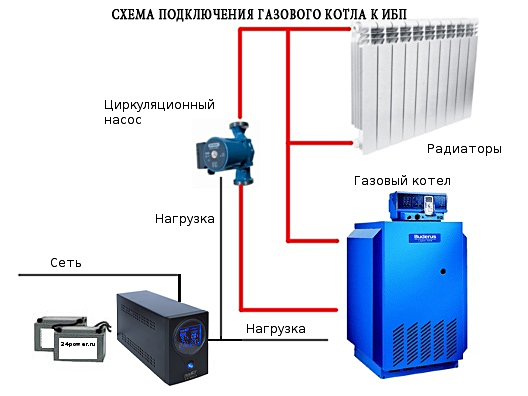

If the boiler is highly dependent on electricity and its supply is often cut off in the installation region, the scheme is supplemented with an uninterruptible power supply

The main requirement for connecting the device to the network is grounding and the presence of a circuit breaker. The latter is located so that in the event of an emergency, water does not get on it.

Primary requirements:

- You need a wire connected to the ground loop. If such a cord was not included in the kit, the conductor is connected to the body of the device itself.

- It is forbidden to use steel pipes of the hot water system as grounding conductors.

- The cable is laid in a protective "corrugation".

When connecting turbocharged boilers from European manufacturers it is important not to confuse phase with zero. Otherwise, the electronic unit will not start the system.

Stage # 3 - connecting the unit to the chimney

In 95% of modern houses, wall-mounted boilers with closed-type combustion chambers and coaxial chimney. It is discharged horizontally through a wall with a slope of 3-5% towards the street for condensation drainage.

Pipe sections of several elements are mounted into each other in the direction of the flow of combustion products. In the vertical channel, the joints are necessarily sealed

For a high-power floor-standing unit, only a vertical structure is suitable, which is able to cope with a large volume of combustion products. It should have as few turns as possible and protrude beyond the boundaries of the roof at a distance of 0.5 m.

Installation of the floor-standing appliance

If a two-circuit heat generator requires power supply, then it is connected in the same way as a wall-mounted "colleague". The non-volatile appliance has a built-in copper or stainless steel coil for heating water. In addition to the burner, automation and heat exchanger, nothing is supplied in the complete set for such equipment.

To install a non-volatile unit, you will need a set from the previous list plus the following system elements:

- security group, the safety valve of which is designed for the operating pressure of the boiler (the data is in the passport);

- expansion tank with a volume of 10% of the total amount of coolant;

- circulation pump.

The safety group is always installed on the supply pipe next to the heater in order to protect the most expensive part of the system from being destroyed by a sudden pressure surge.

The distance from the boiler to the device should be no more than 50 cm. On the section of the pipe between the heater and the element, it is impossible to install taps, tees, the line is left clean

If the floor-standing appliance is connected to a gravity system, only an open-type expansion vessel with overflow is installed. The pump and safety group are excluded from the diagram.

In this situation, pipes with a diameter of 40 mm or more are needed, which are laid at a slope of 5 mm for each running meter of the line. The heat generator remains at the lowest point, the tank is placed at the highest.

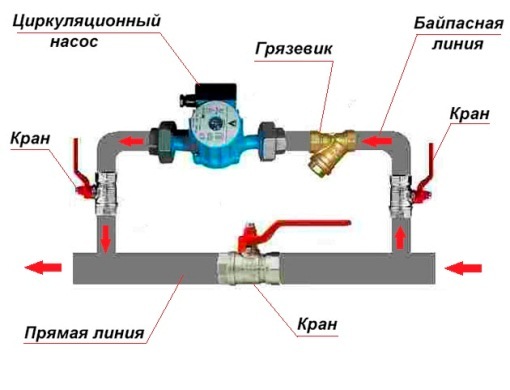

If electricity is connected, it is permissible to organize forced circulation using a pump. In this case, its installation is carried out through the bypass.

Most modern systems include circulation pump, which is efficient, but dependent on electricity. When the light is turned off, heating and water heating are turned off. It is prudent to arrange for an alternative natural circulation method for force majeure.

Options for schemes with a boiler

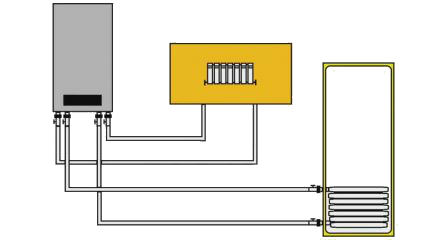

When the standard capacity of the device of 9-13 liters is not enough to meet the needs of the residents (for example: there is a bathtub in the bathroom), the system is supplemented with a boiler. If selected indirect heating boiler, then it is impossible to simulate the flow with an additional circulation pump, which is turned on and off by a thermostat signal.

An incorrect circuit entails a problem in the form of prolonged heating of the boiler. During this time (up to 2 hours), the house is not heated, the premises cool down. Plus, the resource of the boiler is reduced due to the "clock" effect and the flow of hot water into the second circuit, and not cold water. In the boiler itself, bacteria multiply.

The correct scheme is to connect an indirect boiler to the heating circuit. The thermostat is connected to the boiler automation. DHW outlet pipes are simply plugged

In such a scheme, heating between the circuits is provided by a three-way valve. The boiler is loaded in 20-25 minutes. The plugs do not affect the resource of the heat generator.

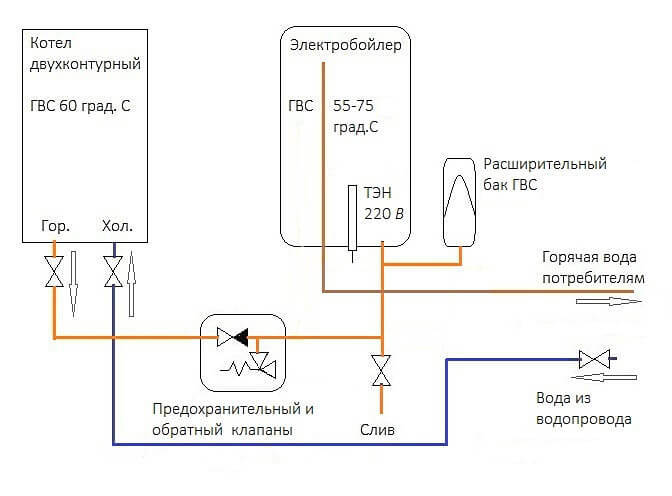

More practical options are the installation of a layer-by-layer heating boiler (there are models for double-circuit) or an electric storage. The former does not have a heat exchanger, which reduces the cost of the system. The second significantly improves the comfort of using hot water.

In the circuit with an electric boiler, check and safety valves are mounted on the supply pipe. Water sometimes flows out of the latter, which must be disposed of. Safety valve requires manual check 2 times a month

In the case of an electric boiler, it is recommended to additionally install an expansion tank. And if the pressure in the system is more than 6-8 bar, a pressure reducing valve will be needed to reduce it.

Additional installation guidelines

Categorically the diameter of the inner section of the pipes to be connected must not be reduced. The optimum value for a boiler up to 28 kW is at least 20 mm for heating and at least 15 mm for water supply.

If the boiler is not included in the circuit, it is wiser to install the device closer to the hot water tap, which is often used.

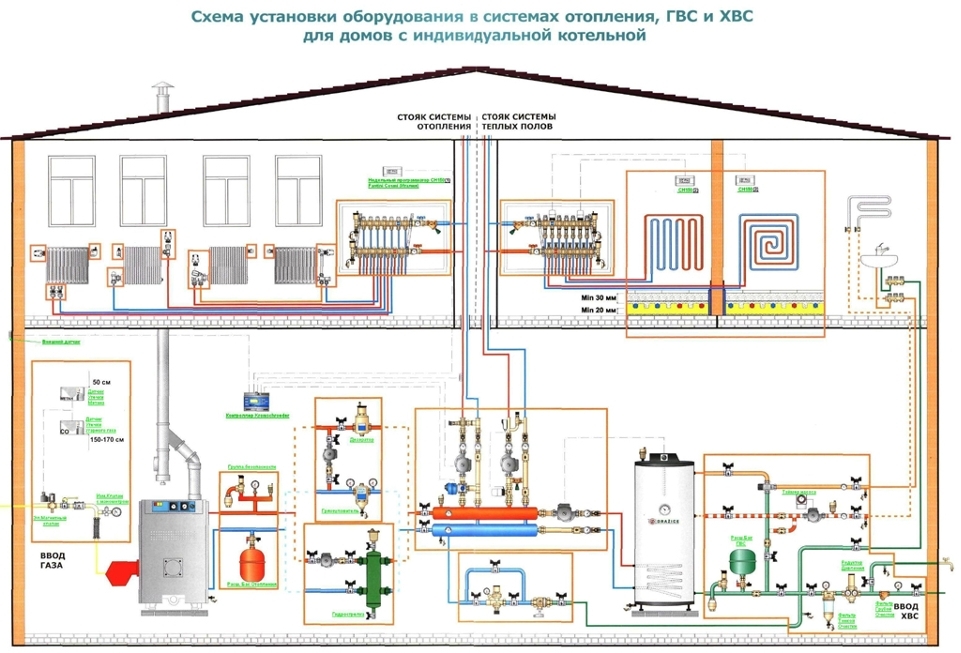

In case of connection warm floors, the system is complemented by a separate branch with a manifold and a circulation pump.

Conclusions and useful video on the topic

The principle of operation of a double-circuit boiler. Advantages and limitations of the model.

Analysis of the connection diagram for a double-circuit heat generator with recommendations for the nuances of the installation.

Connecting the boiler to the system - the consequences of incorrect installation.

After collecting and preparing the documentation, it is necessary to connect the double-circuit boiler to heating, electricity and a chimney. The devices are different, but the requirements for their installation are the same. The features of a particular model are indicated in the instruction manual.

It is wiser to entrust the first start-up of the unit to a gas service specialist. He will pressurize the double-circuit, check all the units, set the modes and instruct the owner on the operation of the equipment.

Do you want to share your own experience in installing and connecting a household double-circuit boiler? Tell us about the difficulties you encountered in the process - leave your comments in the block below the article.

If you have questions about the rules for connection or installation, ask our experts and other site visitors - the feedback form is located below.