Not all towns and suburban arrays connected us to a central gas supply. Unfortunately, there are towns and villages, which are actively used bottled gas. For its safe use requires gas reducer - a device that reduces the fuel pressure to a value necessary plates and boilers.

We will tell you all about the choice of benchmarks reducing device. The presented information will help to buy the most suitable gearbox for mounting on a gas cylinder. We have described in detail the types of instruments and criteria according to which preference should be given a particular model.

Those who wish to independently carry out the installation and connection of the pressure reducing device will set out in detail step by step instructions. Here you will find rules that will protect you and prolong the service life of the gas installations. The article is illustrated by photographs, supplemented with video tutorials.

The content of the article:

-

General rules for choosing balloon gear

- Scope devices

- Standards connect to the system

- The order of installation and start-up

- The required pressure and volume

-

Design features and services

- Driving devices forward and reverse action

- Periodic inspection and service work

- Typical faults and repair them

- Conclusions and useful videos on the topic

General rules for choosing balloon gear

Stable operation of the gas system depends on the quality and consistency of all its nodes. When you select the gear you need to take into account the needs of its compliance with the parameters of connected devices through it.

Scope devices

For the gear in the following indices considered as the main characteristics:

- the type of gas that passes through the device;

- a way to connect to the system;

- outlet pressure range;

- maximum performance;

- Operating temperature range.

Cylinders with gearboxes can be installed inside or outside the house.

To a room in which the equipment is installed, make high demands for air exchange with the possibility of rapid ventilation in the event of emergency. Street embodiment saves space inside the building and safer fuel gas leakage.

Pressure reducing device for reducing the gas injected into the pressure cylinder before the working values needed for the normal operation of gas equipment

According to the type of transmitted gas reducers are divided into the following types, each of which is to further identify dyed a certain color:

- Acetylene - white;

- Hydrogen - dark green;

- oxygen - blue;

- propane-butane - red;

- methane - red.

Color coding gearboxes produced outside Russia, may differ.

Reducer, calculated under the balloon with propane-butane mixture, painted in red color. Devices intended for other gases, can not be used for liquefied hydrocarbons

Characteristics of the acquired gear must comply with the parameters and mean gas cylinder and the instrument with which it will be installed. Also important is the correct calibration power outlet gas stream.

When the output pressure value of range of modern equipment gas appliance will make his trip. If he is not equipped with such protection, it may be an emergency situation.

Reducers, as potentially dangerous equipment shall be subject to mandatory certification. If you have any doubts about the origin of the factory purchased the device, you should be required to provide a certificate of conformity.

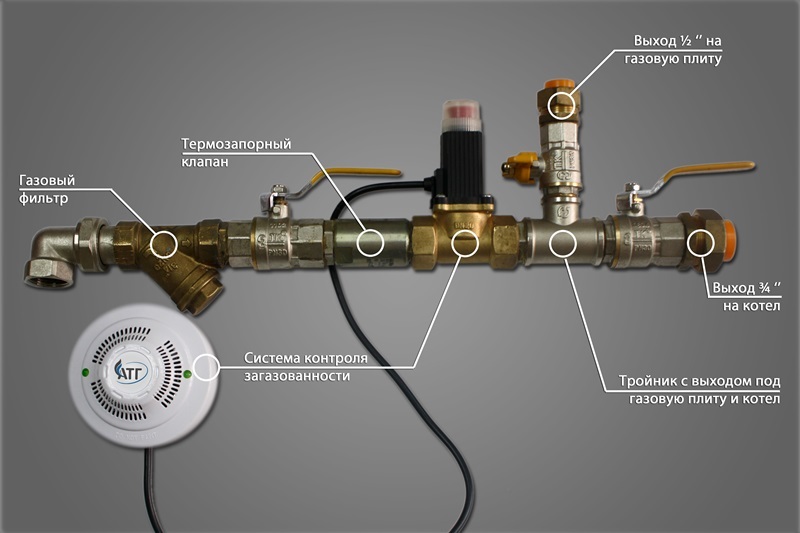

Standards connect to the system

To connect the regulator to the gas cylinder or podvodke typically use 3 standard threaded connections:

- W 21,8 x 1/14 - cylindrical thread to DIN 477 / T1, in Russia, for it is often abbreviated as SP 21.8;

- G - a cylindrical pipe thread where the number following the letter represents the nominal diameter in inches;

- M - metric thread, where the first number after the letters indicates the nominal diameter, and the second - thread pitch in millimeters.

symbols "LH" indicate that the left-hand thread is used.

For different types of gas canisters use different standards threaded connections. This fact must be considered when purchasing gear (+)

Some simple devices equipped with only one compound of this. So popular reducer Type 724B from the Italian manufacturer "Gavana Group S.p. A "equipped with a left-hand thread inlet W 21,8 x 1/14 under standard metal cylinder. At the exit should the right half-inch female thread to connect the bellows liner without any adapters.

A more complex device with a Type 733 pressure regulating function of the same manufacturer has already input the thread 6 variants: a metallic and composite cylinders under multiventil gasholder and 3 compounds. Also, this model has 3 different output thread.

If the input or output thread in the gearbox does not match the cylinder valve or liner, then use a special adapter. However, it is necessary to minimize the number of such compounds, as they increase the risk of leakage. In the standard gas equipment is easy to find gear with a suitable format to connect.

The order of installation and start-up

First of all make installation Hose gas supply system without connecting it to the cylinder. Then on the cylinder valve mounted gear nut and after that it is connected to hoses.

In this operation, taps gas consuming device, gas heater, Outdoor gas boiler, stove, must be in the "closed" position. Before connecting the reducer to loosen springs must unscrew the adjusting screw against the stop.

Type the adjusting screw in the form of valve is more convenient than the device that you want to twist the screwdriver. However, it is necessary to restrict access to children for such a device

If a common flexible hose, that the simplicity of the procedure for fitting the gear unit can be wetted with water. This connection is necessary to fix the screw clamp. Bellows hose is connected via a threaded adapter, which is instead screwed fitting.

After installation of the system must be checked to pass gas at idle devices. For this it is necessary to tighten the gas flow valve (if any) and release the adjusting screw to loosen the spring is maximum.

If, after the differential pressure gauge needle shows a gradual increase in pressure, the speed reducer can not be used.

After collecting the whole system must ensure delivery of the gas from the container to the gearbox and rotating the adjusting screw to set the required outlet pressure. Then you need to coat with soap compounds from the cylinder space to the consuming device, to check them for gas leaks.

If consumed by the device as a gas stove, you should consistently light the burners. If each of the burner flame is not blue, it is necessary to reduce the pressure on the pressure reducer.

Orange or yellow flame burner is incomplete fuel combustion. This leads to significant emissions of carbon monoxide, which can be dangerous if prolonged use of a stove

When checking the efficiency of the burners on the minimum heat may be a problem with their damping. To solve it, you need a little boost output pressure with the knob on the pressure reducer for gas bottle, or change the flow of the screw position on the plate itself.

If the above problems are not common to all the burners, then on the problem nodes boards need to clean or change nozzles. If a gas leak occurs when the system starts, it is necessary to fully close the shut-off valve. Then you need to ventilate the area and begin to solve the problem.

The required pressure and volume

gearbox capacity should ensure the work of all connected devices in the system at maximum capacity of gas consumption. Some of the problem of determining the necessary parameters is to use different units of measurement.

There are two pressure units for gas appliances: Pascals (Pa) and bars (br). For reducer inlet pressure determined in megapascals (1 MPa = 106 Pa) or bars, and the output - in Pascals or millibars (1 mbr = 10-3 br). Translation between these pressure values measuring units according to the formula:

Br = 1 105 Pa

The volume passed through a pressure regulator and gas consumption devices may also be represented by two values: kilograms and cubic meters.

input and output parameters of pressure most Russian units listed in Pascals. On foreign devices tend to indicate the pressure in bar

Correlate the indicators can be using data on density main balloon gas (kg / m3) At a temperature of 190C and standard atmospheric pressure:

- nitrogen: 1.17;

- Argon: 1.67;

- Acetylene 1.10;

- butane: 2.41;

- hydrogen: 0.08;

- Helium: 0.17;

- oxygen: 1.34;

- propane: 1.88;

- Carbon dioxide: 1.85.

In terms of indicators for household plates it can be a problem associated with the proportion of butane and propane in gas cylinders. Their percentage for different climatic regions regulates GOST 20448-90.

The density of the gas mixture depends on the percentage composition. For example, at the stated ratio of 60% propane and 40% butane, gas density can be calculated as follows:

q = 1,88 * 0,6 + 2,41 * 0,4 = 2,09 kg / m3.

Thus, if the maximum flow rate with four plate is 0.84 m3/ Hour, then pass the same amount should provide and gearbox. Per kilogram, this value will be 2.09 * 0.84 = 1.76 kg / hr.

GOST 20448-90 allows a propane-butane mixture sufficiently large range of percentage values of both gases. This creates a degree of uncertainty in the calculation of its density

For the estimated value of the maximum throughput capacity of the gear you need to add 25%.

This is due to the following reasons:

- the parameters of the gas mixture can vary depending on the region, season, and supplier;

- density of the gas, which is taken in the calculations, depends on its temperature;

- possible loss of elasticity of the spring, which regulates the amount of low-pressure chamber in the gearbox, resulting in a reduction in its maximum capacity.

Sometimes, complete with modern facilities offering a certified Specify reducer with pressure regulator on the case of using a gas cylinder with propane. This variant is optimal fire safety position and the system is working.

Design features and services

Trouble-free operation of the system is impossible without regular maintenance and removal of small gear malfunctions. To do this, you must know the structure of the device and the typical signs of problems.

Driving devices forward and reverse action

By design type gearboxes are divided into instruments of direct and reverse action. In the first case, the valve opening is directed overpressure incoming gas in the second - the missing pressure in the working chamber of the apparatus.

The design of the forward and reverse actions of simple single-chamber gear. The absence of complex parts is causing long life without failure, if the product is made qualitatively

The main elements of both types of gear designs are the same:

- choke through which the gas flow;

- High pressure gauge indicating the pressure value supplied to the gas appliance;

- reverse spring working on the valve closing;

- a high pressure chamber;

- valve whose position controls the amount of transmitted gas;

- a relief valve which is triggered upon reaching unacceptable pressures in the working chamber;

- low pressure manometer defining a working gas pressure value;

- a working chamber (low-pressure);

- adjusting screw determining the position of the membrane;

- main spring;

- membrane processing chamber;

- pin between the mainspring and the jet valve.

reverse acting reducers got more popular, as they are more reliable.

Existing models equipped with pneumatic pressure sensor, where instead of the main spring on the diaphragm is exposed to gas, providing a balance system.

As a rule, the adjusting screw is tight turn. This is due to the nonacceptance of spontaneous change of position under the action of forces directed to the membrane. When it rotates in the clockwise direction decreases the volume of the working chamber and the exhaust gas pressure rise.

The common output gear units uneven pressure depends on the input and usually reaches 15-20%. Two-stage (or dual chamber) model used in the case of the need to maintain an accurate pressure of the exhaust gases.

This oxygen reducer well illustrates the construction of two-stage type: inherently - two separate devices coupled together

These gearboxes have a more complex device and slightly larger dimensions. They are more expensive than their single-stage counterparts. Therefore, without the need for their use impractical.

Periodic inspection and service work

For long-term and proper operation of the gear necessary to conduct with him simple procedures. Once a week you need to record the gauge. By reducing the elasticity of the springs may slow but steady decrease or increase in pressure.

Once a quarter, you must do the following:

- Check gasket sealing interface, Relief valve and pressure gauge with the device housing. This procedure can be performed, causing suds to the field of possible gas leak.

- To carry out a purge of the safety valvebut to exclude it from sticking. For this reducer to the compressed air source is necessary to pressurize and attach to the resistance of the protective mechanism at the closed outlet.

It is impossible to carry out repair and maintenance work related to the physical impact on the housing (including the tightening of threaded connections) when the gearbox is under pressure.

It is dangerous to release and ignition of flammable gases. Furthermore abrupt depressurization of the device may occur with the possible application of physical damage to people being in the room.

Gas service specialists are required to conduct an annual technical inspection equipment to detect non-compliance with safety and issue orders to the algorithm to eliminate them

Typical faults and repair them

Gas leakage and pressure deviation values beyond the regulatory range can be eliminated independently. The first problem can be caused by the following reasons:

- depressurization of the body;

- damage to the membrane.

gas pass through loose connection housing elements can be eliminated by replacing the insert or by applying silicone sealant. The damaged diaphragm must be replaced in a similar element of repair kit.

Causes of deviation of pressure values may be:

- A problem with a spring. It is necessary to disassemble the gearbox and determine the cause of the fault. In the case of a spring bias is necessary to correct it in case of damage - replace. If there was a loss of elasticity, it is sufficient to enclose under it a solid gasket.

- Leakage of compressed gas in devices with pneumatic pressure to the diaphragm principle. Independently it is very difficult to eliminate the problem. Necessary to replace the gearbox.

- The problem with the membrane. If there was a break, it is necessary to replace the unit of the device, and in case of loss of tightness in the joints and washers - troubleshoot this problem by pulling the edges.

- The problem with the bypass valve. If there was a deterioration of the rubber pads, you should replace it. In case of violation of the beam movement is necessary to replace the hinges.

Given the low cost of gear it is advisable to carry out repairs only in case of impossibility of quick replacement. If the actions of the device its analysis was carried out, then for safety reasons it must be checked for leaks when you first start.

Conclusions and useful videos on the topic

Video # 1. The design of a simple gear for the five-liter bottles:

Video # 2. Example repair common gear GER series:

Selecting the gear for the system on the basis of liquefied gas must be made considering the desired pressure information and the transmitted volume. Simple operation and timely elimination of minor faults will allow the device for a long time and efficiently carry out its functions.

Please write comments in the box located below. Tell us about the choice of the gear that you have put on a gas cylinder, write about the rules of operation of the device. Ask questions, share opinions and photographs on the theme of the article.