The heating private houses or country cottages are often used combination boilers for heating the house - they will allow provide a comfortable temperature in all rooms, regardless of the presence or absence of a centralized gas or firewood.

Significant advantage of such units - adjustment of cost estimates not only for heating the building, but also on the supply of hot water. It is also very convenient to be able to use different types of fuel, right?

Efficiency combined boiler in the absence of access to the central system supply of energy resources is confirmed by numerous references of their respective owners. The main task - to find the optimal type of heating unit.

We will help you make the right choice. The article describes the features of the work, operation and maintenance of different types of combined boiler. We have identified the main criteria for evaluating equipment and brought practical advice on the choice of the heating unit.

The content of the article:

- The main types of combined boilers

- Features aggregates the combined type

-

Popular variants fuel combination

- Option # 1 - combination gas / electricity

- Option # 2 - a combination wood / gas

- Option # 3 - a combination wood / electricity

- Option # 4 - multifuel installations

- What you need to know to choose the right?

- Conclusions and useful videos on the topic

The main types of combined boilers

Heating equipment combined type is focused on downloading and processing of two or more types of fuels.

Over 70% of the models presented on the market, equipped with special electric heaters, contributing partial or complete failure of engagement of the main heating elements for heating the water in summer season.

Kind of fuel material used allows equipment be divided into 2 main groups:

- standard - use no more than two different types of fuel;

- universal - capable of operating in three or more embodiments of fuel.

In most cases, it appears possible to replace the burner to change the fuel supply function. On sale there are also models equipped with hobs and even two burners with electronic or electromechanical type control.

The catch here is one - the more extended the functionality of the unit, the more difficult it will be the process of installation.

Boiler for pellets refers to solid fuel installations. It burned pellets pellet made of wood waste (+)

Features aggregates the combined type

The owners of country houses, in which heating is provided a combined boiler, in one voice declare its indisputable advantages. Especially if the house is located far from major population centers, and the lack of gas supply and frequent power outages are the norm in this area.

In addition, the combi boiler, which is also called a universal, has many other advantages.

They allow you to compete with the most popular kinds of one-component systems:

- able to connect several circuits;

- a wide range of resources for technical modernization - replacement of burners, installation of the boiler;

- the current level of program management;

- no interruption in the heating system - at the time of outage of one of the fuels is possible to apply the alternative option;

- economical consumption of resources to ensure the heating system.

Models with electromechanical control will be simply irreplaceable in the houses located in areas frequently experiencing electricity shortages.

Such an embodiment allows, if necessary translate boiler system in the manual mode, without losing the efficiency of its operation.

The boiler output is becoming a major when choosing a boiler from a comprehensive range

Popular variants fuel combination

Different variations of the combined heating units make it possible to solve all sorts of problems - from large-scale to less global problems. For example, they can provide hot water as a single family of 3-5 people, as well as heating of an office building or block of flats.

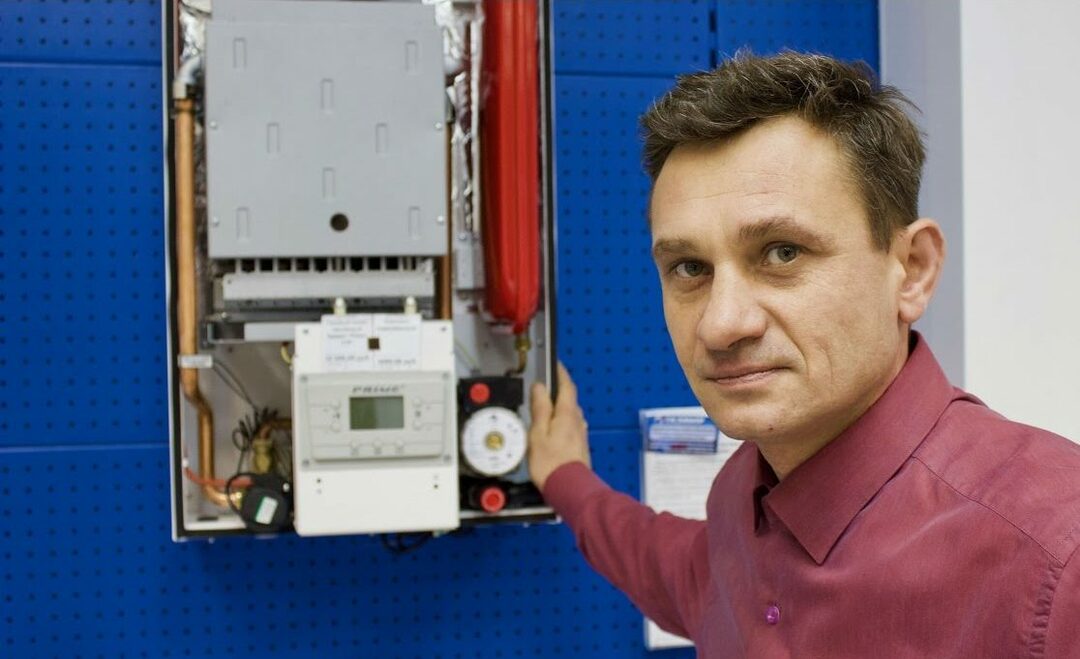

Option # 1 - combination gas / electricity

For the most efficient heating of water is electricity. The rapid increase in temperature produced by the action of the coolant on at least the delay fraction.

The main priority of quality equipment with a combination of gas / electricity is its flexibility, manifested in the possibility of connecting several heating systems, as well as multiple assembly embodiment contours]

Features combined heaters that provide significant advantages:

- small size. The device has an oversized combustion chamber for the combustion gases, the heat exchanger with built TAN or other type of heating device;

- Low electricity consumption. The boiler operates in a gas heater and a start operation only on request - for quick heating of the water or in the absence of access to the gas supply;

- Low price category. It is achieved due to the absence of separate combustion chamber - a heater installed within the heat exchanger. In equipment where no secondary circuit connecting the heater is planned embodiment;

- with a small capacity of the heating elements - many presented on the model of the market, it is only designed to support the specified temperature.

Although the gas belongs to the economical type of fuel, an electric power is impossible to say. Therefore, for the houses located in areas with poorly developed gas supply network, should keep an eye on another version of the boiler running on other fuels.

Option # 2 - a combination wood / gas

More economical fuels and wood gas are considered. The dimensions of the heating device running on such fuel, impressive - he has for each of the fuel types are separate combustion chambers.

Design features of boilers with a combination type gas \ cleaved determine the placement of one or two heat exchangers. For the first case it is a common element for all combustors.

After all, with interruptions of gas supply equipment will move to electricity - a month of such heating will come round in the payment for electricity

AT two-circuit boiler Only one type of fuel is used to provide hot water. This type of combined boiler requires preliminary resolution to issue documentation for installation.

In addition, these boilers are separated for two subspecies: the general and separate combustion chamber. The first option refers to the installation, create your own. They are used to minimize the total cost estimates for the maintenance of the heating system of a country house.

The hands produced gas burner assembly in the classical model of the boiler, if the solid fuel is used, it is dismantled. This embodiment creates unacceptable for heat exchanger operating conditions - exposure to high temperature during operation of the burner. It was she who is a frequent cause of violations of the boiler efficiency.

When registering permission to install the combination type gas boiler / wood main aspects are performance solid-zones, which should not affect the gas

The construction with separate chambers of the furnace is equipped with two circuits, one of which is used to heat water for heating and the other - to provide hot water.

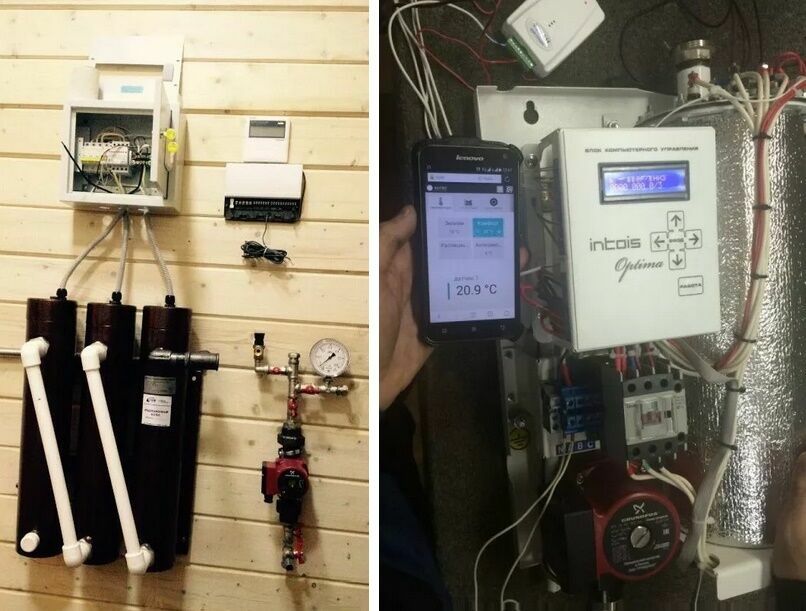

Option # 3 - a combination wood / electricity

If it is impossible to connect the main gas or maintenance of heating arrangement bottles most often used solid fuel boilers. They have more power and are nonvolatile.

Structurally, the type of combination boilers wood / electricity are quite similar to the gas model. Also available, and independent production of this type of device. the required capacity will be sufficient to determine, choose the heater and mount it in the heat exchanger.

The factory model of universal heating boilers wood / electricity are fully equipped with the necessary elements. In their capacity and location of PETN properly designed, which leads to a high level of safety in the operation period

In addition to these characteristics it is necessary to note the following features of the combined boilers working with wood and electricity:

- support capabilities - heating element connection unit via a contact area with a temperature controller or a special programming unit providing remote control operation of the boiler;

- increased resistance to breakages - factory provide heating by operating the heating elements (heating elements), which can withstand high thermal effect during operation of furnace chamber;

- repairability - upon failure of the electrical part of the boiler, it can be easily replaced. In many models, the gas heat-generating installations such feature is not available.

Power solid fuel boiler is regulated relatively slowly. In connection with such a feature for quick adjustment of heating level manufacturers recommend use electronic part teploustanovki.

Option # 4 - multifuel installations

Design features multi-fuel heating equipment for residential use are based on the use of several alternative fuels. Such heating systems include a combination of model beads pellet / gas / wood / electricity.

In most variations pellet heating boilers of the combined type burner is shown as a detachable element, so its combustion chamber can be used for other fuels

The most important structural feature of the composite pellet boilers - equipment multiple combustion chambers, adapted for engaging one of the fuel types - rigid or liquid.

In addition the functional possible assembling of the electric heating element, located in the chamber of the heat exchanger.

Due to the easily removable pellet burner becomes possible to use other fuels, such as diesel or gas.

For application of this kind of energy needed to create the conditions forced draft pressure and certain structural features of the heat exchanger. All these characteristics are peculiar pellet boilers type.

Multi-fuel heating system can be installed only after such requests:

- Uninterrupted power supply - a prerequisite for the revitalization of pellet boiler, diesel and gas burners (use of solid fuel material is excluded);

- Organized supply of fuel materials to the boiler - this is the most acute problem in the design of the installation of boilers with a combination gas / wood / electricity;

- Providing energy storage locations - to use a balloon mounted external heating boxes of steel or allocate a separate room, and in some cases the building; diesel is saved in tanks connected to the pump unit.

Before purchasing a universal heating equipment, it is necessary to analyze the main factors influencing the choice of a particular model.

So, should assess the appropriateness of the use of each type of energy sourceBecause the cost of such devices is significantly higher mono-fuel systems.

Also required diameter of the chimney must be calculated as traction coefficient is required to meet at least the minimum requirements for each of the fuel material

What you need to know to choose the right?

The only objective criterion for the selection of the combined boiler for your home - the necessary power for the operation of the heating system. Moreover, this measure should not affect the number of connected loops.

It makes no sense to pay more for a powerful pot in hopes of adjusting its work automation. This approach helps to "idle" the instrument, which leads to more rapid failure. In addition, a similar operation to accelerate the condensation process.

With regard to the calculation of power, theoretically for heating an area of 10 m2 will need to use 1 kW of heat energy.

But this is a fairly conventional index, which is adjusted on the basis of these parameters:

- ceiling height in the house;

- the number of floors;

- the degree of insulation of the building.

It is therefore advisable to use in their calculations bonder ratio, ie calculations increase margin of 0.5 kW. Power multiloop heating system is calculated with allowance of 25-30%.

For example, to heat the building, the area of which is equal to 100 m2 will require capacity of 10-15 kW with single-circuit heating coolant and 15-20 kW - for a bypass.

To select a gas burner in a solid fuel boiler is necessary to accurately measure the dimensions of the combustion chamber. That these proportions will match the size of the gas burner

No less important criterion when choosing a combination boiler - this price category. The price of the device depends on the capacity, the number of features and manufacturer.

For users not less important, and other characteristics:

- DHW;

- manufacturing material;

- easy to manage;

- dimensions;

- accessories;

- weight and mounting features;

- other.

Immediately have to solve the problem with hot water: to provide hot water to the boiler, or for good electric water heater.

In the case of determining the first embodiment, selects a more preferred method - or rollup flow, and the parameters of the water reservoir according to needs (calculated from the quantity living).

As for the size of the equipment, they are only meaningful in the case of indoor installation with a small area.

Material for the manufacture of a wide range of boilers. But the most popular options - steel or cast iron. Also, such a boiler capable of withstanding high and continuous thermal stress, has a higher service life.

It should be noted that cast iron boilers, however have thicker walls than those of the steel product

Automation of management affects the usability and security of the system depends on how automated the process of combustion energy. Most models can be operated using the convenient remote control panels or panels.

Most models of different additional equipment. These include the presence of a cooking surface for cooking, injectors, traction controllers, burners, a sound enclosure etc.

Choosing the boiler for this parameter should be based on personal preferences and the amount appropriated for the purchase.

When choosing a boiler with a combination wood / electric power is necessary to calculate the required power PETN. It is recommended to choose the model, with the index of at least 60% of the required ratio for home heating

But the weight of the equipment and the complexity of its installation should immediately pay attention.

Installation of a residential building in the majority of floor models combined boilers for heating systems, equipped with several flue cameras require additional devices concrete pedestal, because a standard floor covering will not be able to withstand such load. Optimal solution - to equip a separate boiler.

Knowing the basic parameters affecting the choice of combi boilers, we can choose the most appropriate model.

Additional recommendations for selection, as well as a comparative review of the different heating units for private homes are given in this article.

Conclusions and useful videos on the topic

The operating principle of universal heating equipment in the video:

Rules for the choice of the combined boiler in the video:

Example of operation of the combined boiler pellet:

Regardless of the type of equipment to purchase it is necessary to design a future heating system. These include: pipes, chimney channel and safety measures for the operation of the heater.

This will ensure full functioningsystemheatingatminimumcostsonenergy resources.

Look for an efficient combi boiler for the house? Or have experience in the use of such facilities? Leave, please, comment on the article, participate in discussions and share experiences on the use of heating units.