Solid fuel boilers are used to heat private buildings that are not connected to centralized gas mains. Illiterate installation of units that process solid fuels can be a serious danger to homeowners. Strict compliance with the installation rules will eliminate the threat. Do you agree?

We will describe how the installation of a solid fuel boiler should be carried out in strict accordance with regulatory requirements. The article thoroughly describes the preparatory and installation stages, and describes the rules for arranging mini boiler houses. Taking into account our advice, connecting the unit to heating will not cause difficulties.

The content of the article:

- The choice of premises for placement of the unit

- The ventilation device in the room with the boiler

- Installation work on the arrangement of the chimney

- Preparing the boiler room for the installation of the unit

- The main stages of the installation of the boiler

- Connecting the unit to the heating system

- Recommendations for efficient operation

- Conclusions and useful video on the topic

The choice of premises for placement of the unit

We will understand as detailed as possible, what is a boiler operating on solid fuels? This is a thermal device equipped with an open-type combustion chamber.

The scheme of its connection to the heating system of a private house can be based on the technical requirements for open or closed heating systems. Everything will depend on the operating conditions.

Requirements for open systems are:

- connecting the exhaust system of solid fuel to the chimney, in which the draft will be carried out naturally

- installation at the extreme upper point of the heating circuit of the expansion tank, through which the connection of the heat carrier to the atmosphere will be established;

- constant provision of the heating system with water needed to maintain it in working condition.

Although the owners of private homes often install closed heating systems, rather than open.

All solid fuel boilers are quite impressive dimensions. And therefore they are made exclusively in the performance, providing for floor placement.

Before starting the installation of a solid fuel boiler, it is necessary to clearly define the place, layout and method of its installation.

Installing a solid fuel boiler provides a considerable amount of work:

- determination of the premises for the placement of a solid fuel heat generator;

- preparatory work in the boiler room;

- installation of ventilation system of supply and exhaust type;

- installation of the boiler and chimney system;

- boiler strapping;

- test run of the heating system.

Only by observing such an algorithm of actions can problems be avoided during the installation of a solid-fuel unit, as well as during its further operation.

Ideal arrangement of boiler room when all heavy equipment is installed on the floor

Items 1-3 of the above work order are preparatory work. But this does not mean that their implementation should be approached less scrupulously than directly to the installation work.

In the case of the wrong choice of premises for the installation of the heating unit and errors in the installation of the ventilation system, problems with the operation of the heating system of a private house will not keep you waiting. And the solution will have to be sought at the height of the heating season, during the cold season.

Therefore, it is better to immediately carry out the installation of both heating equipment in a private house, and the most solid fuel boiler. For this, it is necessary to develop in advance a detailed scheme of its installation, given that the installation of some types of solid fuel boilers may provide for power supply from the power grid.

One of the correct variants of the installation scheme of a solid-fuel heating unit involves placing it in the basement, ground floor or basement.

In the matter of installation, one has to be guided by the basic norms of the Construction and Construction Code “Heating and Ventilation” and some provisions of SNiP 31-02-2001 “Single-family houses” (for the Russian Federation).

Burning solid fuels leads to increased dustiness in the room, and during the burning of wood or coal, different amounts of smoke can leak into the room.

Therefore, installing a boiler in close proximity to residential premises is undesirable. Although according to regulatory documents, installation of a solid fuel boiler is allowed in the kitchen, corridor and other non-residential rooms.

The boiler room in the form of an extension can be built near the house. Such a design solution will be quite convenient.

The best places to install the boiler are separate specialized room, preferably separated from the house. As an option, a properly equipped technical room attached to the house will suit.

Also a good option would be to place the heat unit in the basement or in the garage. You can install it in the corridor, but subject to the availability of adequate space and good ventilation of the room.

The ventilation device in the room with the boiler

When fresh air is low, the process of burning fuel will be difficult. If it comes in excess, the process of burning solid fuel becomes difficult to control.

If the flow of fresh air is difficult, it is necessary to build a ventilation system.

Ventilation is necessary in order to:

- provide fresh air at the level required to maintain the combustion process in the boiler furnace;

- remove from the room the products of solid fuel burning, accidentally coming out of the furnace into the boiler room;

- Ensure the supply of adequate fresh air.

Such simple measures will help to safely and effectively operate a solid fuel boiler for a long time.

To ensure complete removal of combustion products, a natural or mechanical type ventilation system should be installed in the boiler room. The ventilation process must be at a sufficient level.

As for the arrangement of the ventilation system for the boiler room itself, the following tips are intended to help correctly. First, the exhaust and inflow openings should be located at different ends of the boiler room.

It is advisable to place the exhausting hole closer to the roof, and the intake duct should be located in the lower part of the room, in close proximity to the solid fuel boiler itself.

Secondly, it is inexpedient to install an exhaust device near the heat generator, in the construction of which a fan (blower) or a smoke exhauster is provided.

In this case, during operation of the turbine, the thrust in the duct will forcibly change the direction air streams, and the air that must go to the hood will be re-inflowed into the room boiler room.

If the entrance to the boiler room is equipped directly through the door from the living room, it will be advisable to install the supply grille in the lower part of the door. The influx of warm air from the dwelling will increase the thermal efficiency of the solid fuel being combusted.

Considering that most of the intake air is directly in the combustion chamber of the boiler, where it reacts with carbon released in resulting from the combustion of solid fuel, after which it comes out in the form of carbon dioxide, the exhaust hole must have a smaller diameter than the hole inflow.

Scheme of the optimal location of the solid fuel boiler in relation to the sources of air flow into the boiler room

The best option is to install the boiler closer to the outer walls. This will avoid the hassle of laying a long horizontal chimney canal, especially in those cases when it is to be removed through the roof.

Common boiler house arrangement schemes and technical room design rules given here.

Installation work on the arrangement of the chimney

The installation of the boiler on a special foundation or on the floor is extremely simple. It consists in simply putting the heat unit in the position in which it will continue to work. Further, its location must be leveled by adjusting the legs, or special pads made of metal.

But the compliance of the axes of the chimney and the corresponding hole in the wall during the installation process does not have to be monitored. Here the alignment can be easily adjusted by adjusting the knees.

In order to avoid possible problems associated with the appearance of condensate during the operation of the boiler, it is advisable to build a solid fuel boiler chimney out of warmed sandwich pipeOr, as an economical option, assemble the construction with your own hands from pipes wrapped with basalt fibers.

The simplest version of the chimney in terms of both the design and installation will be a chimney duct, adjoining the house outside

Installation of this type of chimney is carried out as follows: the pipe is attached to the wall in a vertical position, and the flue from a solid fuel boiler is connected to it by means of a tee.

As for the installation of the chimney in wooden houses, the hole in the outer wall or roof is made in strict accordance with the rules of fire safety.

First, an equilateral opening is cut in the partition, and the dimensions of its sides should exceed the dimensions of the internal chimney by 380 mm. from each side. For example, we have a channel with a diameter of 100 mm and a sandwich pipe, the insulation thickness of which is 500 mm. In this case, the size of the opening will be: 100 + 380 x 2 = 860 mm.

Next, the assembly is made through a node made in the form of a box of steel with zinc coating. A sandwich pipe is pulled through this box, and the voids surrounding it are filled with basalt wool. The final operation will be fixing the lid of the node located outside.

When performing installation work, it is worth remembering that in a brick wall or a wall of a foam block, the easiest way is to install a chimney channel using a gasket and a steel sleeve.

The assembly and connection scheme of the attached chimney from a sandwich is simple and straightforward, and therefore its implementation is within the power of each

However, during the installation of the flue duct it is necessary to observe the following guidelines:

- the pipe should be rotated no more than three times, while its minimum height, calculated from the grate of a solid-fuel unit, should be at least five meters;

- chimney sections should be connected so that rainwater flows along the outer wall, and the condensate moisture - along the inside;

- The horizontal part of the pipe should be installed with a slope towards the boiler.

At the bottom of the chimney it is necessary to install a revision hatch and a tank to collect the accumulated condensate moisture. And in order to avoid the intersection of the chimney with the eaves of the chimney, the latter can be rounded by using two adapters under 30 degrees.

The duct inside the house is best laid on the proposed scheme. In this case, it will perform its direct functions immaculately.

During the installation of the chimney, it is necessary to ensure that the joints of the chimney sections do not coincide with the location of the fasteners of the pipe to the wall. To the top chimney It is advisable to put a protective cap or a rotating vane.

The height of the chimney, rising above the roof, depends on the distance between the chimney and ridge. The diagram gives minimum height guidelines, the magnitude of which may be affected by local conditions, for example, a tall tree near the house on the leeward side

When working on the creation of a smoke ventilation system, it is worth remembering that the top of the chimney pipe should not be located in the zone of the wind backwater of any of the houses (both its own and neighboring). And in order to always be consistently good chimney pipe must be installed at the level shown in the above scheme.

For the convenience of maintenance and cleaning of the heat exchanger of the solid-fuel unit from all sides, from where these activities are planned, it is necessary to create access to the boiler. The ideal option would be to create a meter gap in front and from the side and rear walls of 60 cm. Minimally these indents should be 25 cm.

Installing solid fuel boiler, it should be remembered that it is strictly forbidden to connect the flue gas duct of the heating unit with the brick wells of the ventilation ducts of the house passing through the inner space of the walls.

On the eve of the purchase and installation of a solid fuel boiler, it is necessary to carefully check its height with the height of the future boiler house. It is also worthwhile to pre-calculate the placement of other equipment of large sizes, such as a heat accumulator, a buffer tank and a boiler of indirect heating.

Preparing the boiler room for the installation of the unit

Solid fuel boilers with an open combustion chamber must be placed in separate special rooms - boiler rooms. Such rooms are set up in the basement or in the basement, equipping them with an intensive ventilation system to ensure the normal operation of the solid fuel unit.

If necessary, fill the special foundation in the place of the intended installation of the heating unit.

Boilers that consume solid fuels can be installed by hand, and without any coordination with the relevant services. However, in the process of installing a solid fuel boiler, you must follow a set of rules.

So, the floor at the installation site of a solid fuel boiler should be made perfectly flat and durable. In most cases, boilers are installed on special plates made of non-combustible materials.

In some cases, the boiler is placed on a flat base of concrete screed, with a thickness of 50 mm.

Install the boiler at some distance from the walls. The gap between the rear wall of the boiler and the wall of the room must be at least 60 cm, while the distance between the wall of the boiler room and the front surface of the boiler must be at least 25 cm.

Before installing the heating unit, the walls and floor of the boiler room must be covered with fire-fighting material with a minimum fire resistance of 0.75 hours. For these purposes can be used: sheets of metal, basalt cardboard, minerite or asbestos cement.

Also, the boiler room should be equipped with a low-ventilation system. This can be a regular window, or a hole made in the wall. At the same time, its area is calculated on the basis of the power of the boiler: 8 square centimeters of ventilation opening should fall to 1 kilowatt of boiler power.

In the case when the room of the boiler room is equipped only with lighting, it is worthwhile to install sockets with power supply from the electrical network of 220 V.

If the boiler is placed at a distance of less than 38 centimeters from the wall, it is sufficient to isolate this wall with a sheet of fire-resistant material.

The heat resistant sheet should cover the floor directly at the installation site of the boiler so that the protective material protrudes 80 cm from the front wall of the boiler. This measure will help to avoid the occurrence of fire in case of loss of heat from the furnace.

All manufacturers of thermal units in the instructions for installing their products recommend building a foundation for installing a boiler on it. So, if the boiler is of small capacity, the weight of which does not exceed 200 kg, it can be installed with a calm soul on the basis of cement screed. In the case of the right arrangement, it can withstand this kind of load without problems.

But for the installation of the unit, whose weight exceeds 300 kg, it is advisable to build a foundation of reinforced concrete screed. Moreover, its thickness should be from 10 to 12 cm. If the weight of the boiler exceeds 300 kg, then it must be installed exclusively on the foundation consisting of a separate base plate.

The installation of pellet boilers with an electric motor and a pellet auger is made on a specially poured foundation in order to minimize the effect of the vibration load on the base below.

Solid fuel boilers are allowed to be installed on the floor of wood. However, to begin with, the installation site will have to be prepared personally, having previously strengthened it with bar-shaped lags, the cross section of which is at least 100x50 mm.

If in the boiler room it is planned to install additional heavy equipment, then it is not advisable to fill the foundation for each of its units. In this case, it is much easier to pour the so-called industrial floors, that is, to make a screed of concrete to a height of 12 cm.

At the same time, its filling should be fittings with a diameter of 8 to 14 mm. Then you need to make a dense pillow of rubble, and put a grid with a window size of 20x20 cm on top.

The area of the room allotted for the equipment of the boiler room must be at least 15 square meters, with a ceiling height of 2.5 meters

Based on how the boiler is connected to the chimney: through the roof or through the wall, it is necessary to design the placement of the hole through which the chimney pipe will be led out and run through it. At the same time, its internal diameter should coincide with the diameter of the outlet neck of a solid-fuel unit or slightly larger.

The main stages of the installation of the boiler

In order to mount a heating system based on the use of a solid fuel boiler, you will need the heating unit itself, pipes and heating radiators, expansion tank, circulation pump, heat accumulator, components of the automatic boiler control system.

The latter include:

- safety valve;

- air valve;

- pressure gauge;

- Temperature regulator.

All manipulations associated with the installation of a solid fuel boiler and the connection of peripheral systems and devices are carried out in accordance with a strict step-by-step algorithm. So, on the eve of the boiler installation, a specialized foundation is being erected at the site of its planned location.

At the same time, it is imperative to withstand all the necessary dimensions of indents and correctly position the body of the heating unit both vertically and horizontally.

Next, electric heating elements are installed in the event that they are included in the boiler package. As a rule, solid fuel boilers are equipped with fixtures for the installation of heating elements, next to which a temperature controller is installed.

The next stage involves the installation and connection heating system pipes. It is important to close all connections by means of intermediate shut-off valves, and seal the butt joints with sanitary tape or with a material consisting of flax fibers. This will simplify access for future repairs.

Installation of thermal communications make it so that during the operation of the heating system it is possible to easily carry out maintenance and repair

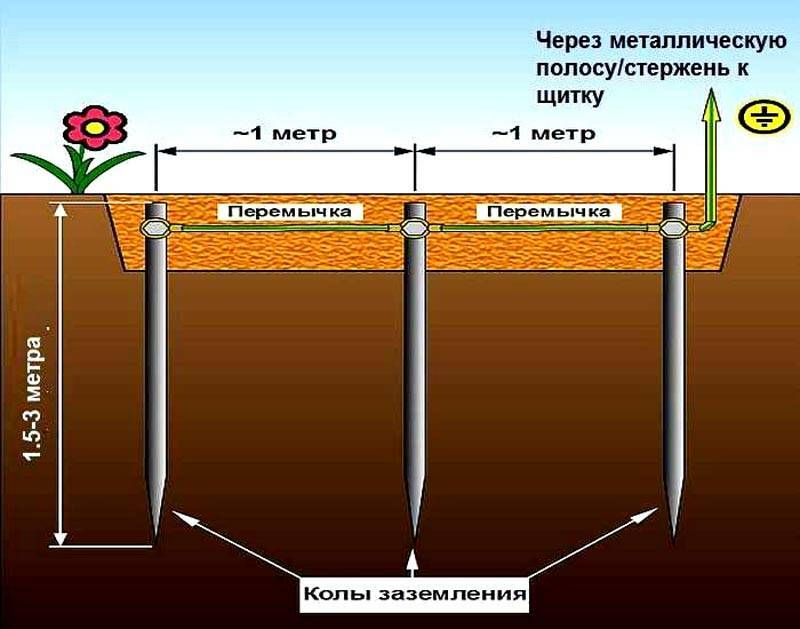

In the case when the work of the heating system provides for the use of electrical connections at home, at this stage it is necessary to make all the necessary wiring connections, their insulation and grounding.

Next is the installation security groups. Its equipment depends on the model of a solid fuel boiler, but, as a rule, it consists of: safety valve, air valve, temperature controller, thrust sensor, pressure gauge and other devices. All these devices are installed before all locking devices.

The next step will be the installation of the chimney pipe. In places where the elements of the system are connected to smoke extraction, they are sealed with a sealing substance that is resistant to high temperatures.

The method of installation, the height of the chimney channel, as well as the cross-sectional area are calculated so as to further ensure at the proper level the process of natural draft. And for this it is necessary to strictly comply with all the requirements of the instruction manual for the installed boiler model.

Next, the water is filled thermal circuit of the solid fuel boiler. At first, the water pressure level should be slightly higher than the worker. This stage involves testing the system for leaks.

Then it is necessary to check all the internal elements of the furnace of a solid fuel boiler: plugs for cleaning, kindling dampers, fireclay stones, grates, etc.

And finally, one should discharge the pressure in the boiler to the performance indicators, put the valves in the furnace and the chimney in the position prescribed by the instruction, and lay solid fuel in the boiler.

After completing all of the above manipulations, you can proceed to start-up of a heating system based on the use of a solid fuel boiler

To start the heating process, it is enough to load fuel into the boiler and set fire to it. Then after 10-15 minutes, it is necessary to close the valve tightly for kindling.

After the temperature has reached the level of 80-85 degrees, you will need to set the temperature controller to the desired heat supply mode. Subsequently, it will be necessary to simply supply the boiler with solid fuel, if necessary.

Connecting the unit to the heating system

After completion of the installation of a solid fuel boiler and a smoke exhaust system, the next stage of work will be the so-called piping. When performing it, one rule should be strictly observed: during operation of the heating unit, under no circumstances should cold water enter it. Especially the one in which the heat exchanger is made of cast iron.

If this happens, the walls of the boiler will immediately be covered with condensation moisture. The reason for this will be a sharp temperature drop. This liquid is dangerous because when it comes into contact with carbon deposits deposited on the sides of the boiler, it turns into a viscous and dense layer of plaque.

Sticky coating is quite difficult to remove from the surface of the walls of the boiler, moreover, it significantly reduces the efficiency of the thermal unit. Minimize the process of condensate, when burning solid fuel in the boiler, you can perform a typical scheme strapping with a three-way valve and bypass when setting the coolant to a stable temperature of 50-55 degrees

Thus, the water in the system will move in a circle until it reaches the above temperature. And after that the valve will start to let cold water into the system.

In the process of tying a solid-fuel unit, it is important to take into account the particular model's features, having studied the manufacturer's instructions. So, it is important to carefully connect the control unit and the burner. Sometimes an automatic fire-fighting system is installed in the boilers of European brands, which is connected to the central water supply system.

In order not to be mistaken in the process boiler installation on pellets it is necessary to obtain technical advice from the official representatives of the manufacturer of the boiler. It is important to install all components of a solid fuel system as prescribed by the appropriate instructions.

After installing the system, it must be tested by filling it with water so as to create a pressure of 1 Bar. And then test the boiler operation by kindling

Recommendations for efficient operation

During operation of the boiler that consumes solid fuels, slag deposits remain in its furnace. As they accumulate, they must be periodically deleted. In addition, to maintain the energy efficiency of such a boiler, certain actions should be taken periodically.

First, from time to time the walls of the boiler must be cleaned of accumulated ash and soot. Due to the millimeter layer of soot on the walls, the energy efficiency of a solid fuel boiler is reduced by 3%. Clean it at least every seven days. In this case, the boiler must be turned off, and its walls cooled down.

Secondly, as the grid of grates is clogged with ash, the boiler will also gradually lose its power output. If such a phenomenon has been noticed, it can be eliminated quite simply by slightly moving the contents of the firebox.

Modern models of solid fuel boilers are equipped with a special lever for turning the coal, moreover, if necessary, it will help to reset the coal.

Thirdly, in order to improve the circulation of water along the thermal contour of the boiler, it is possible to use circulation pump. This will greatly improve the energy efficiency of the thermal unit, since heat carrier in the system will occur much faster, and it will return to the boiler with a higher temperature

And this means that for its reheating will take less heat energy, therefore, the energy efficiency of such a boiler will be much more.

The circulation pump can be positioned before entering the boiler in the return water supply pipe.

Fourthly, it is necessary to control the state of thrust in the smoke exhaust channel. And to keep it in optimal condition, chimney must be cleaned at least once a year. Segments of the chimney canal running through the premises without heating must be warmed.

This should be done to prevent the formation of condensation vapors. They, in turn, are harmful because they accumulate, interfere with the normal release of combustion products.

And in order to use the fuel most efficiently, it is necessary to set the temperature regulator to minimum performance, but only when the house is well warmed up, and on the street warmed up.

The owner of a private house can always choose the way to perform the whole complex of works: with his own hands or through specialists from companies involved in installing boilers

Conclusions and useful video on the topic

The nuances of heating a private house with a solid fuel unit are discussed in the video:

Video about the installation features of one of the popular models of solid fuel boiler:

Installation work on the installation of a heating boiler that consumes solid fuel is not particularly difficult. There are no impracticable requirements for their implementation. Yes, and state permits do not need to receive.

Although from the point of view of implementation in practice this complex of works is very laborious and can cause a lot of trouble, since it consists of many nuances.

Please write comments in the box below. Ask questions on controversial points, share your own opinions, useful information and photos on the topic of the article. Perhaps you want to talk about how to install and connect a solid fuel boiler in your country house or in the country?