What problems do apartment building residents often face in winter? First of all, it is low-quality heat supply. It is also saddened by the hopelessness while waiting for the start of turning on the heating systems. A gas boiler room for an apartment building will help maintain a constant temperature in each apartment and save on bills.

Residents are forced to freeze from the cold before the start date of the heating season. The need to pay a lump sum monthly to pay for heating finishes the most persistent.

Installing a gas boiler room on the roof will solve heating problems once and for all. The main obstacles to resolving the issue of installing a gas boiler house are related to obtaining permits from the administration and purchasing suitable equipment.

The content of the article:

- The advantages of an autonomous gas boiler room

- Disadvantages of modern heating systems

-

Classification and features of roof boiler rooms

- Block-modular boiler rooms

- Built-in boiler room on the roof of the house

-

Autonomous boiler room device

- Key components of the boiler room

- What needs to be considered?

- Conclusions and useful video on the topic

The advantages of an autonomous gas boiler room

Usually, an autonomous gas boiler room is equipped in apartment buildings in separate rooms. For these purposes, separate rooms on the roof are suitable.

They house all the necessary equipment for the continuous operation of the heating system. The capacity of the installed equipment should be sufficient for heating radiators and heating water in the apartments of the whole house.

The first appearance of roof-top boiler houses in Russia in the 90s was due to the desire of construction investors. They wanted to install high-quality and uninterrupted heat supply in houses under construction. Centralized systems could not meet exaggerated demands

Such mini-boiler rooms are equipped with a variety of modern appliances and a variety of devices. The autonomous systems use the most modern heating technologies. This allows one boiler room to be used even for several houses, which increases the profitability for residents several times.

There are several factors that determine the benefits of installing a rooftop gas boiler in apartment buildings.

First of all, this is a significant reduction in the distance from the heat generator to radiators and pipes in apartments. Due to this, heat loss during the circulation of water in the system is reduced. Rough calculations show that owners pay 30% more for heating than the real cost due to heat losses.

Residents who have once installed a gas boiler room in the basement or on the roof of a multi-storey building note a real reduction in utility bills. They are also much less likely to face the need for frequent maintenance of systems: their repair, installation and reconstruction. Modern communications are of high quality and durability.

Due to the shortening of the path that the water must travel from the central energy carrier, the heating rate of the system increases. Also, on average, the temperature of the batteries and hot water increases. Although this is largely controlled by the setting of the gas boiler.

Roof-top boiler houses are very popular due to the fact that almost always near apartment buildings there is no place for the construction of a ground structure. The location of the boiler rooms at the bottom of the house creates an additional hydraulic load

If we compare the central heating system with an autonomous one, then the second option wins in many respects. This is both efficiency and the rate of water heating in the system.

In addition, the central heating is turned on only when certain temperatures are reached. However, cold weather can persist for a long time until it reaches the required minimum. And the tenants are forced to endure the cold and suffer.

With an autonomous system, it becomes possible to maintain the desired level of heat all year round and not depend on utilities. Thermostats are usually installed on radiators and circuits, allowing the temperature to be changed depending on the needs of the users. Sometimes, setting a comfortable temperature can save you extra money.

Disadvantages of modern heating systems

As in any heating system, the autonomous one has its drawbacks. Although there are much fewer of them in comparison with the centralized one. Due to the fact that autonomous gas boiler houses are not widespread, it is quite problematic to get reliable equipment and all the units adjacent to it.

Therefore, the elements of the boiler room will cost customers a round sum. Despite the high level of comfort provided by the systems in question, not all developers are ready to pay big money for this.

In the event of an emergency, the entire heat supply system completely fails. There is up to five cubic meters of boiling water over people's heads. In case of explosion of pipes, water will go down. Therefore, there are so many requirements for gas equipment.

In addition, gas boiler rooms must be placed in separate rooms or buildings. To do this, you need to allocate an area around the house, bring the roof to the required technical conditions, or install a block structure on the roof. All of these solutions require an infusion of additional resources either from the developer or from the general fund created by the tenants.

Gas heating systems emit polluting decomposition products into the environment. Therefore, when installing boiler rooms, it is necessary to provide for the installation of filtration systems. Cleaning devices must perform their functions sufficiently so that SNiP norms are observed. This further increases the cost of purchasing equipment.

When building a new house, the developer has a choice: make an autonomous heating system or connect to the central highway. To crash into a highway, you need to obtain a number of permits. Often, solving a problem requires a round sum of money. In addition, you will need to wait more than one month until the papers are checked in all instances.

The high cost of work on connecting to existing networks, difficulties in agreeing on this procedure, as well as the presence of many hindrances that impede the rapid and efficient installation of heating networks, reduce the attractiveness of autonomous systems for developer.

Often, the installation of gas boilers on the upper enclosing structure entails the need to strengthen the floor. The total load generated by the heating system can be up to 15 tons. Such values can be avoided by installing flow-through equipment instead of capacitive

The installation of autonomous heating is also associated with a number of bureaucratic procedures. Both the initial implementation of the systems and the reconstruction with redevelopment have their own characteristic features. This is mainly due to the fact that you are going to use gas as a heating resource. All work with gas is strictly regulated by law.

Modern engineering developments effectively deal with a number of disadvantages. If you need to heat just one house, an excellent option would be to place a block boiler room in the attic of the house. The attic becomes heated, and the occupants of the top floor do not experience discomfort.

Such structures are developed in detail by engineers, are lightweight and installed on load-bearing walls. For such options, a flat roof option is required. This subtlety is usually taken into account at the design stage. Designers carry out calculations and determine in advance the place for the boiler room on the roof of the house.

The law establishes a limitation on the capacity of equipment on the roofs of houses at 3 MW. Some regions are limited to 5 MW. If this power is not enough to fully heat the whole house, then additional permits must be requested.

However, despite all the shortcomings, ultimately, the residents of the house will significantly improve their living conditions and get rid of discomfort. In addition to all the obvious advantages, autonomous systems have an increased level of security.

The new systems are equipped with warning and alarm indicators. Diverse sensors for gas boilers track many metrics. In the event of a breakdown, the reserve boiler and additional pumps are activated.

Classification and features of roof boiler rooms

If we talk about heating one particular house, then one of the best options for the location of a boiler room with a decentralized system is a flat roof. The text of SNiP describes in detail all permitted types of boiler rooms. In the technical documents, special attention is paid to the requirements for heating equipment intended for installation on a ceiling.

Operation and installation of heating systems is negotiated separately for two types of structures: built-in and block-modular. Separate requirements, specifications and restrictions apply to each option. Also, these two types of boiler rooms have their own characteristics: advantages and disadvantages.

According to the rules, it is unacceptable to install heating equipment directly above living quarters. This means that a technical floor should be provided in an apartment building.

Speaking about the advantages of installing an autonomous boiler room on the roof, the following should be highlighted:

- There is no need to purchase a plot for a boiler room next to the house;

- Reduces the hydraulic load that the boilers are exposed to;

- There are no difficulties associated with the calculation of the structure and the conduct of chimneys;

- The task is greatly facilitated boiler room ventilation;

- Roof-top boiler houses have no restrictions on the type of fuel, and the use of gas is one of the most profitable options.

The combination of the advantages of installing the considered structure on the roofs determines the high frequency of application of this solution when planning autonomous heating.

Installation of the boiler room on the roof is advisable only if all the requirements and restrictions described in SNiP and PPB are taken into account. Consider further each of the available types of roof-top autonomous boiler room.

Block-modular boiler rooms

Block or modular boiler rooms are compact in size and take up a small area. Special blocks are brought to the site on the roof of the house, which are then connected into a finished and workable structure. Each element of the structure is completed at the factory and equipped with all the necessary equipment, which is connected into a common system.

After assembly, the heating station is ready for operation. All the necessary equipment is provided by the manufacturer and is installed in the module. It also provides for the presence of separate rooms for service personnel.

Modern roof-top boiler houses operate all year round in automatic mode and do not require constant monitoring and the presence of personnel. Therefore, the heat supply is carried out without interruption.

All equipment is selected for the required technical parameters and complies with the standards. Blocks are usually equipped with high-quality insulation and a reliable ventilation system.

They can also have attractive looks and unusual designs. During installation, the main task of specialists is to correctly connect all nodes and to check the operability of all elements.

Designers and engineers foresee in advance the future installation of a boiler room for gas equipment on the roofs of multi-storey buildings. They minimize the weight and dimensions of the building frame as much as possible. Usually professionals assemble a boiler room in a few working days.

Installation of a modular roof boiler house consists of several stages. First of all, it is necessary to conduct an examination that will determine the bearing capacity of the building and the necessary procedures to increase it. If it turns out that it is necessary to reinforce the structure, then these procedures are carried out first.

Then a platform is installed, which will rest on the load-bearing walls of the building. This is necessary for the stability of the unit. The next step is to create a fire resistant coating underneath the gas boiler room.

Usually, a layer of concrete is poured to solve this problem. You should also ensure safety by installing railings around the perimeter of the roof. Occasionally, procedures to improve sound insulation are necessary.

Block gas boilers are fully factory-equipped. Manufacturing companies give a quality guarantee. The blocks are sent to the roof almost ready for launch and assembled in a short time

Block boilers are suitable for installation in buildings where there was originally a centralized heating system. However, for their arrangement, it is necessary to purchase equipment with acceptable technical conditions and have a project.

Built-in boiler room on the roof of the house

The layout of such boiler houses fits into the design documents in advance. Even at the design stage, each element of the built-in roof boiler room is thoroughly described. Engineers calculate many different indicators and, based on the calculations, design a safe and efficient heating system.

These indicators include the value of the load on the walls, the level of fire safety, the required boiler power and others. It is much easier and cheaper to carry out these calculations at the design stage than to convert a centralized system into an autonomous one.

Simultaneously with the construction of the building, a number of events are being carried out. These include:

- providing sound insulation and suppression of noise emitted by heating equipment;

- protection of the boiler room from vibrations;

- providing protection against ignition, explosions and gas leaks.

Carrying out these procedures during the construction phase increases their efficiency. Most of the houses were built for a centralized heating system, and only in the last 5-10 years, built-in boiler houses are provided for in projects.

Stationary gas boiler houses are built from materials similar to those used to build a building. For these purposes, prefabricated structures of the "sandwich" type or various reinforced concrete blanks are used.

Experienced engineers are engaged in the design of built-in boiler rooms. This is due to the need to comply with safety and legal regulations.

The advantages of such boiler houses include the absence of the need to spend money and time on capital construction. Also, the customer purchases a ready-made, proven and well-established structure that will heat the residents of the house for many years.

Thanks to modern developments, there is the possibility of almost complete automation of control. This allows for a minimum number of maintenance personnel. The environmental friendliness of the built-in gas boiler rooms is ensured by modern filtration systems.

Integrated or built-in boiler rooms are usually installed within a few days, which is very beneficial for the developer.

Autonomous boiler room device

Residents do not always buy a ready-made block boiler room. In some cases, the assistance of specialists in the assembly of an individual system is required.

The arrangement of a gas boiler house plays an essential role in its efficient operation. It is imperative to provide a separate roof area. There must be no flammable materials around the site.

Domestic boilers are less popular due to the fact that they offer users a low level of autonomy and automation. Experts advise purchasing equipment from European manufacturers

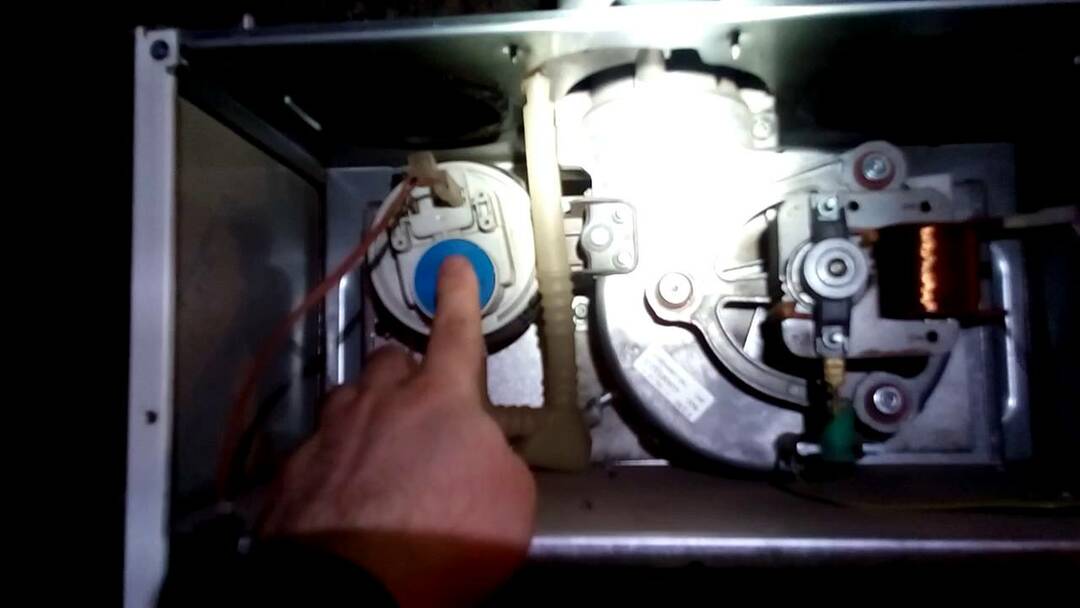

For safety reasons, boiler rooms do not have more than two boilers: the main one and the backup one. Boilers are usually installed in the center of the room. This makes it easier to approach the equipment for systematic maintenance and repair.

The walls, and with them the entrance doors, are sheathed with non-combustible materials, for example, steel sheets. The floors are poured with a concrete screed, then a non-combustible non-slip coating is laid on top of it.

The principle of operation of an autonomous gas boiler house is the processing of natural gas. Thanks to automatic installations, an uninterrupted supply of fuel is ensured. The boiler room safety system shuts off the gas supply if the sensors detect a leak or breakdown.

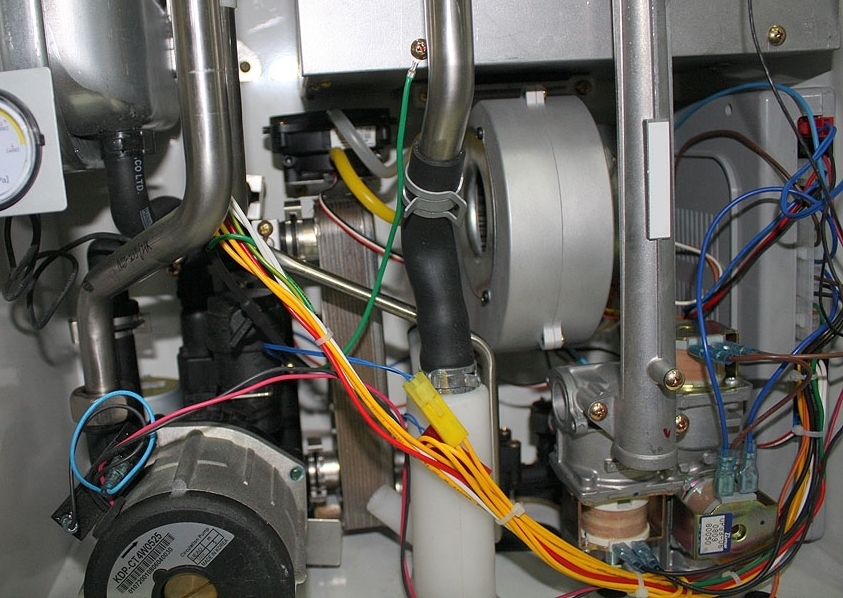

Key components of the boiler room

The operation of an autonomous boiler room is ensured by the presence of the following elements:

- Gas boilers providing heating;

- Central gas main supplying gas to the system;

- Ventilation system and chimney that removes gas combustion products;

- Cold water and electricity supply system;

- Security system with a number of instruments and sensors measuring various indicators;

- Built-in automation.

For heating an apartment building, the power of a wall-mounted unit is not enough, therefore, in this situation, floor-standing gas boilers are used. Single-circuit boilers only provide heating of the coolant for supplying it to the radiators. Double-circuit boilers simultaneously used for heating and hot water supply.

When choosing the right equipment, you should focus on the power of the boiler. Also pay attention to the availability of licenses and registrations. The boiler must be suitable for the specific operation in your area.

The boiler can be with a closed or open combustion chamber. For an open type, it is necessary to conduct a smoke duct. Closed boilers are equipped with coaxial chimney.

Thanks to modern technology, it is possible to almost completely remotely control the heating system while maintaining a high level of security.

The benefits of remote control include:

- Possibility of setting an individual temperature regime for each apartment;

- Availability of a notification system about the values of the main indicators of the equipment operation;

- Innovative weather-compensated control system.

Modern smart boilers have outdoor sensors that measure the temperature outside the home. If the air temperature drops, the boiler automatically starts increasing the water temperature in the system and vice versa.

What needs to be considered?

Before arranging an autonomous boiler room, it is necessary to take into account a number of factors. If a single-circuit gas boiler is purchased, then to supply hot water, you will need to install a storage type of water heater - a boiler.

For a branched system of an apartment building, a distribution manifold is required. Thanks to this device, constant pressure and temperature will be maintained in all circuits. Together with the manifold, install circulation pumps and hydraulic arrows.

When the water in the system heats up, it expands. In order to maintain a constant pressure and compensate for expansion processes, a expansion tank.

The regulations assume different minimum chimney heights above the highest point of the roof. When calculating this indicator, the power of the boiler and the structures located on the roof are taken into account.

It is important to think over the layout of the chimney for the removal of gas decomposition products. For security purposes, safety valveas well as a mechanical or automatic air vent. A make-up tap must be installed in front of the heating system.

If automation is built into the system, then the need for human maintenance of the system will be reduced to routine checks of the system's performance.

The installation of an autonomous gas boiler house has a number of nuances and difficulties. However, this version of the heating system for an apartment building has a number of comparative advantages over a centralized system.

The main problems that developers and future tenants will have to face are related to obtaining permits from the administration and the gas industry for the arrangement of a gas boiler house.

It takes time and requires certain resources. Residents of houses with centralized heating will face even greater problems. First of all, they will have to get an agreement to shut down old systems and get technical specifications for the installation of new ones. Utilities do not always meet halfway on such issues.

Conclusions and useful video on the topic

Review of the roof-top boiler house of the Novy Gorod TDK:

The installation of a gas boiler house in Svetly has resulted in great cost savings:

The purchase of modular boiler houses is one of the most profitable options for developers. Their delivery and installation takes a short period of time, and the prices for the equipment are reasonable. This allows you not to devote a lot of time to this issue.

Residents who decide to install autonomous heating protect themselves in the future from the disadvantages of centralized systems, guarantee themselves continuous heating and hot water supply all year round.

Please write your comments in the block below, post a photo on the topic of the article, ask questions. Tell us about your experience in the design and / or operation of an autonomous gas boiler house in a high-rise building. It is possible that your advice will be extremely useful to site visitors.