The installation of thermal equipment operating on natural gas is a widespread practice both in industry and in everyday life. But household installations are significantly inferior in power and other technical parameters. At first glance, a home gas water heater (boiler) is a simple equipment that makes a minimum of requirements for a potential owner, right?

Then why is the grounding of a gas boiler in a private house a mandatory norm and can it be ignored? We will help you figure it out - this publication discusses the reasons for grounding, the features of its implementation, the norms and rules for checking. Also shown are diagrams of the device, illustrative photos and video recommendations.

The content of the article:

- Why is it necessary to ground a gas boiler?

-

Grounding code

- Arrangement of the ground loop of the gas water heater

- How to connect the ground loop to the shield?

- Features of checking the grounding of gas equipment

- Conclusions and useful video on the topic

Why is it necessary to ground a gas boiler?

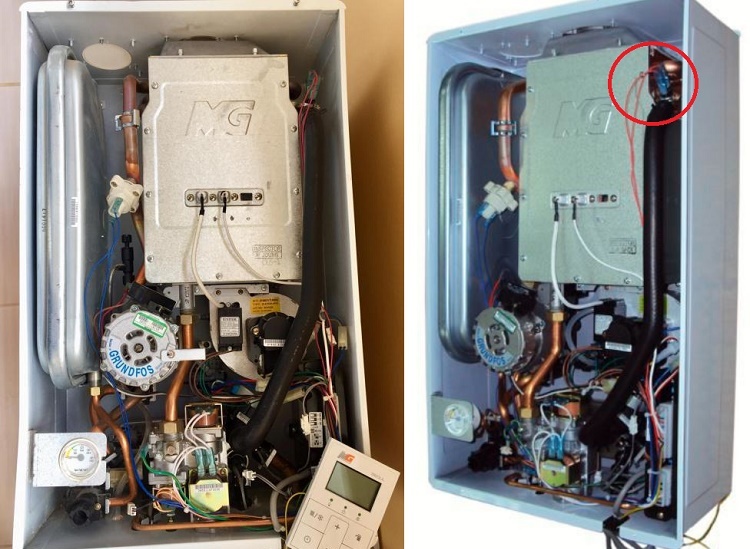

Modern gas boilers traditionally contain control elements made according to the principle of digital high-tech electronics.

The diagrams of such equipment contain:

- digital microcontrollers;

- sensitive electronic sensors,

- field-effect transistors and planar microcircuits.

For electronics of this kind, the presence of static electricity is "like death." At the most unexpected moment, the gas boiler may stop functioning due to failure of electronic components from the effects of static microcurrents.

This is one of the main reasons requiring a mandatory grounding loop in gas boiler diagram.

The need to ground the equipment of gas water heaters (boilers) is a mandatory measure, regardless of the purpose of the equipment - industrial or domestic

Another no less significant reason for the introduction of grounding is an obvious danger of uncontrolled gas ignition, which creates high risks of fire or explosion of the gas boiler. Here, again, the notorious static electricity plays its "negative" role, and only the correct arrangement of the grounding circuit will help to get rid of it. We reviewed the rules for the safe use of a gas boiler in next article.

Grounding code

Regulatory requirements and rules describing the geyser's grounding scheme are presented by an official document PUE.

According to the established standards for grounding a household gas boiler in a house, the equipment must be supplemented with earthen circuit, however, it does not specifically indicate which circuit should be used - industrial design or homemade.

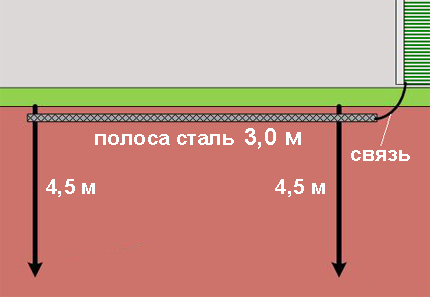

Simple execution of a loop line suitable for protecting gas equipment, in particular, a household water heater (boiler). A metal strip and one passive electrode is used

Meanwhile, regardless of the method of manufacturing the contour grounding system, it is quite specific with the PES document NS. 1.7.103 the parameters of the resistance of the contour loop are discussed.

For a system built at home or with the use of a team of specialists, the following requirements are relevant: grounding... at any time of the year there should be no more than 5, 10 and 20 ohms, respectively, at line voltages of 660, 380 and 220 V of a three-phase current source (380, 220 and 127 V for a source single-phase current). In this case, the resistance to spreading of the ground electrode of each of the repeated groundings should be no more than 15, 30 and 60 Ohms, respectively, at the same voltages. "

In practice, gas service representatives require that the resistance does not exceed 10 ohms.

According to the standards of the PES document, it is categorically unacceptable to use the following elements for grounding for a household gas boiler:

- line "ground" of stationary household outlets;

- surfaces of heating pipelines;

- surfaces of pipes of sewer networks;

- pipes of stationary gas lines and other pipelines of flammable or explosive liquids, gases, mixtures.

It is allowed to use metal water pipes laid in the ground, reinforced concrete as a natural ground electrode foundation structures with reliable waterproofing, metal structures of structures located in the ground, etc. (NS. 1.7.109 PUE).

If there is nothing suitable for the role of a ground electrode nearby, it is imperative to equip an individual ground loop.

Arrangement of the ground loop of the gas water heater

So, in case you still doubt whether it is necessary to ground a household gas boiler in a residential building, the answer is unequivocal - necessary. Moreover, immediately upon the installation of new gas equipment, followed by verification of the correctness of the "ground" device.

Therefore, it is worth considering the traditional design of the device, the materials and components required to organize the "contour ground", as well as the verification features.

Diagram of the organization of the grounding circuit for a gas water heater (boiler) for household use. Uses two electrode pins and a straight piece of metal (steel) strip

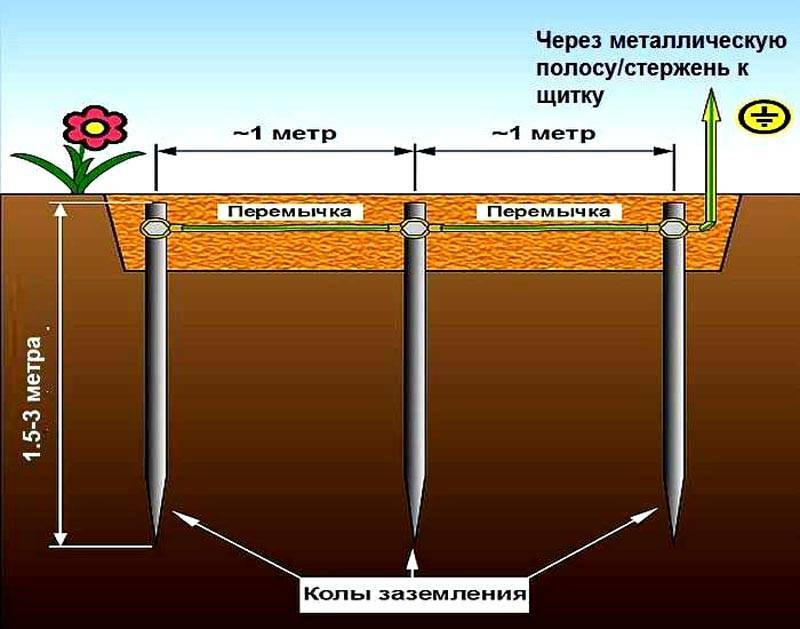

The outline of the contour, as a rule, is the classic version of the manufacture of the form. "Triangle"immersed in the ground to a depth of at least 0.5 meters. In this case, the corner points of the "triangle" are metal (preferably coated with a layer of copper) electrodes.

The optimum immersion depth of metal pins-electrodes is 4.5 meters. A metal strip is used as a connecting material between the electrode elements.

Thus, the construction of the "earth triangle" contour encompasses the process of driving three metal pins-electrodes into the ground, with the subsequent manufacture of a loading trench between them, where a metal strip is laid and welded to pins-electrodes.

According to the same PUE rules, the grounding "triangle" should be installed at least 1 meter from the wall of a residential building. The classical distance between the elements of the circuit electrodes driven into the ground is 2.5 meters.

However, instead of the "triangle" option, it is also quite suitable (PES is not prohibited) just a straight metal a strip between two electrodes immersed in the ground, the length of which is not less than 3 meters (schematic solution is shown below). The dimensions of grounding conductors and grounding conductors laid in the ground are also indicated in PUE table 1.7.4.

The classic version of the circuit design is the so-called "triangle". This version of the circuit is characterized by the fact that it allows to obtain the optimal resistance to the spreading of currents without additional manipulations.

The appearance of the installed contour grounding in the form of a "triangle, which is recommended to be used to protect gas boilers (columns) for household use.

Separately, it is worth noting the technology of immersing metal pins-electrodes into the ground, given the immersion depth of 4.5 meters.

To immerse a relatively thin diameter metal pin-electrode to such a depth, several short lengths are used, which are connected to one another as the immersion proceeds. Connections are made using special couplings or by welding. (the second option is preferable).

We recommend that you familiarize yourself with detailed guidance on the choice of a suitable material and arrangement of grounding with your own hands.

How to connect the ground loop to the shield?

The manufactured and installed contour element for a domestic gas boiler must be correctly connect to the switching unit of gas equipment (usually a three-pin mains socket or shield management).

PES standards allow the use of different types of conductors as a communication line, but stipulates the diameter of the wire depending on the wire material used: copper, aluminum, steel.

Connecting element of the contour system and the power panel (power outlet), from where the gas boiler is powered. For communication, a conductor is used, the cross-section of which is specifically stipulated by the rules of the PUE

Allowed as a part of power switching equipment of a gas boiler install an RCD (residual current device), but only strictly if there is a loop grounding system. It is also allowed to apply RCD sockets. This point is marked by the PES rules.

Features of checking the grounding of gas equipment

In a situation where a gas service representative checks the correct installation of the boiler, its connection and operation, the question of checking the correct grounding of the home gas boiler is not worth it. However, in practice, some kind of technical incidents often occur.

Indeed, the electrical grounding scheme, in fact, is seen as the prerogative of the representatives of the service responsible for the power supply. This means that the circuit is checked by the electrical service, which is also confirmed by the rules of the PUE.

Laboratory testing of resistance to spreading currents on the grounding loop. As a rule, to carry out such measurements, specialized organizations are involved, authorized to issue acts based on the results of testing.

To perform the test, special electrical equipment (laboratory) is required. By means of the electrical measuring laboratory, not only the measurement of the current spreading resistance in the circuit is carried out, but also the degree of lightning protection.

However, this option is usually applicable to industrial equipment. For the domestic sphere, as practice shows, much in terms of verification depends on the local rules of each individual region.

Federal legislation specifically mentions only the standards for periodic inspections ( PTEEP Appendix 3, clause 26), and also stipulates the rules for equipment preparation and commissioning (PTEEP, PUE).

According to the regulations, it is required to check the boiler grounding at least once a year. Based on the results of the inspection, the owner of the gas equipment is issued an appropriate document (ACT on the inspection performed). We examined the methods for measuring grounding resistance in this material.

Conclusions and useful video on the topic

The video below demonstrates the sequence in which the event is carried out to create the protection of gas equipment.

Thanks to the video, you can get a complete picture of the required work, the tool used and other subtleties of the process:

It is possible and necessary to supplement a household boiler with a grounding component, as practice demonstrates. Even if the production of such works will require some financial costs from the potential user, it is worth it.

By equipping the gas water heater with a grounding loop, the user of the equipment not only multiplies the reliability of the equipment, but also ensures a high level of his own safety..

Would you like to supplement the above material with useful comments? Or do you still have questions about arrangement of the ground loop? Feel free to ask our experts and other site visitors for advice, write your comments - below, under the article, there is a feedback form.