It takes ~ 4 minutes to read

It takes ~ 4 minutes to readProfessional kitchen requires the presence of hoods. This complex design with a duct system ensures a favorable and safe microclimate in the working area (near stoves, ovens, cooking surfaces). Appreciated the benefits of exhaust systems and housewives. Therefore, hoods are increasingly becoming one of the main elements of home cooking equipment. We previously considered models without duct, and in this article we will tell you how to properly install the hood in the kitchen.

Functions of exhaust devices in the kitchen, their difference from ventilation

The importance and necessity of using the equipment in question is confirmed by the tasks that it solves:

- Contaminated air with particles of combustion products, fumes, smoke and odors is discharged from the area adjacent to the stove.

- An inflow of comfortable, clean air, which has less humidity and temperature, is provided in place of the discharged air with pollution.

- Thanks to the operation of the hood, conditions are not created for the undesirable emergence and reproduction of harmful microorganisms.

- Significant or complete discharge of air contaminated with grease, soot and dirt helps for a long time maintain a presentable appearance of kitchen furniture, home decoration, household appliances, increases their durability.

- Favorable comfortable conditions are created not only for those working in the kitchen, but also for family members and guests of your house who are in neighboring rooms and premises.

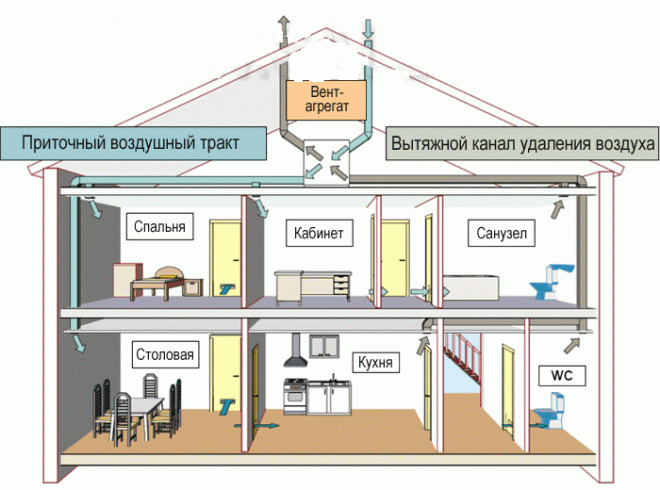

The air vent provided by exhaust systems cannot be replaced by classical ventilation. The latter only creates the conditions for air exchange in some limited space. The removal of air saturated with combustion products and vapors is not carried out. This problem is solved by the installed hood. Connecting with special pipes to the ventilation shaft, it ensures the removal of polluted air to the outside.

Important! The ventilation pipe connected to the exhaust pipe must have a section matching or exceeding the cross section of the pipe itself (in the latter case, a transitional connection is required shaped element). Compliance with this condition makes air venting more efficient.

Types of kitchen hoods, their important parameters

Mounted kitchen hoods are represented by the following types:

- Outboard - budget, the most common devices for mounting under the shelf.

- Recessed - in good harmony with the kitchen furniture; a retractable panel makes them compact.

- Dome - universal hood type hoods with the ability to work in flow and recirculation modes.

- Island - used in large kitchens with a central location of the stove.

Before buying, hoods are required to remove the linear dimensions (length x width) of the cooking surface of the stove. For the purchased product, these sizes should be slightly larger or at least match. With a smaller area, the efficiency of air exhaust will be reduced. This will immediately affect the overall microclimate of the kitchen and will cause some disappointment with the purchase. The next parameter - productivity - depends on the volume of the room (which is easy to calculate by multiplying the area of the kitchen by its height). Productivity (m3/ h) must be 10 or more times the obtained value of the volume.

The hood should be installed 65-75 cm from the hob of the electric and induction cookers. Above the gas stove, this distance increases by 10-15 cm. Reducing the height of the device will lead to inconvenience of work near the stove and can create a fire hazard due to overheating of the equipment.

Essential tool

For equipment installation and preparatory work, you may need:

- punch or drill with impact function;

- screwdriver;

- electric jigsaw;

- building level;

- roulette, ruler;

- hammer;

- set of screwdrivers.

Correct installation of the purchased hood: how to install and secure

Consider the most common installation methods.

Included with the purchased hood is a circuit for installing an electrical appliance in the kitchen. Be sure to familiarize yourself with it before carrying out installation work.

Cabinet installation

The method provides for the permanent location of the appliance in a hanging cabinet above the stove. If the installation of the hood coincides with the general work on the arrangement of the kitchen, it is logical to order a special cabinet with all the furniture according to an individual sketch. The main feature of the furniture unit is the absence of a bottom and a securely fixed, durable middle shelf, which will bear the entire load after attaching the appliance body to it. The distance from the bottom of the cabinet to the shelf should correspond to the height of the purchased device. All shelves and the top cover are ordered to have holes of the desired shape for the duct. Dimensions are determined depending on the used pipe for air exhaust. Holes are not made for devices operating on the principle of recirculation (the air cleaned by filters again enters the room).

If the furniture was installed earlier, you will have to independently mark and make the necessary cutouts in the shelves and cabinet covers with an electric jigsaw. Ideal accuracy is not required - after installation, possible flaws will be hidden.

Depending on the set of fasteners supplied, the hood is fixed to the shelf with self-tapping screws or a screw-nut connection through holes pre-drilled in the shelf. After hanging the cabinet on the wall, put on and fix the duct pipe on the outlet pipe. It is advisable to bring the electrical outlet and place it in the cabinet itself. Sagging wires and other unaesthetic details will be hidden by a closed door.

Installation under the cabinet

This method is very similar to the first option. Only equipment is attached down to the cabinet. Such fastening is used to reduce the distance from the hood to the stove to effectively absorb contaminated air. Appliances are selected that will easily look in the kitchen interior. If you want to hide the front panel of the hood, install a decorative false panel made of a material similar to the facade of the cabinet door.

How to mount to the wall

Located above the stove, the furniture is exposed to high temperatures and steam. Because of this, its appearance may suffer, and the service life will decrease. Therefore, a gap between the elements of furniture often forms above the stove. In the absence of cabinets above the hob, the hood can be mounted on the wall. This is a simple and reliable way.

First, the height of the electrical appliance is determined and the level is horizontal. Now the hood is applied to the wall at the required height and marks are made for drilling through the holes of its rear panel. After marking, drilling of the seats for the dowels is performed (minimum depth - 50 mm). Then the upper screws are twisted and the hood is hung. If it is located without deviations and hangs securely, the lower screws are screwed through the panel openings.

In the absence of places for mounting on the rear panel, the hood is installed on a specially made frame from the corner. The frame itself is attached to the wall with self-tapping screws. If it is not possible to fix it close to the wall (in this place there is a pipe or other communications, a wall with a casing), for fixing the frame, collet studs or long self-tapping studs are used (a self-tapping screw with a thread under the nut on the other side products).

Electrical Installation Features

The wiring for the installed equipment is planned and laid in advance.

Depending on the method of connecting the hood to the electrical network and the integrated design of the kitchen, the solution to the problem may be as follows:

- The standard electric cord of the hood is quite short. Therefore, when connecting the plug to the outlet, the latter must be provided and installed in advance. Wiring or extension cord with a socket can be neatly laid behind the furniture or covered with a PVC box.

- Connection through an automatic machine (permanent) is made in phase break.

- Grounding is always connected first.

The second and third paragraphs are mandatory.

Types of pipes used

Corrugated aluminum products are the basis of metal rings covered with foil in several layers. The main advantages of the corrugation: low cost, ease of installation, the ability to easily bend and avoid obstacles, folded "accordion" extends with increasing length by several times, the ability to tolerate heating up to + 250 ° C, easily grows with the help of metal scotch tape. Described in more detail in this publication.

Useful information! If the corrugated pipe does not have a maximum extension, exhaust a working system produces a characteristic noise. Its reason is the roughness of the inner surface, which creates additional resistance to the exhaust air flow.

Plastic elements of exhaust pipes have the following advantages:

- Light weight does not burden kitchen furniture, does not create difficulties for installation alone, eliminates additional supports and fasteners.

- The mounted design is characterized by high strength and tightness.

- Simplicity of assembly of shaped and linear elements.

- Aesthetics of assembled structures.

- Good soundproofing.

- The material (PVC, polyurethane, polypropylene) is environmentally friendly, not subject to corrosion.

- Grease and dirt do not accumulate due to the smooth inner surface of the pipes. For the same reason, they are almost silent.

- Durability.

The most popular section of pipes used is round. Plastic pipes can also be rectangular. They are easier to lay near the wall, they have a more aesthetic appearance.

Features of duct assembly

The correct choice of the exhaust device, calculations and selection of pipes, transition elements, connecting devices may not give the expected result. All the efforts of the previous stage are easily crossed out by elementary errors or negligence of the subsequent assembly and installation of the pipeline to the ventilation shaft. For the correct and correct operation of the exhaust system, the following points should not be overlooked:

- Assembled from standard elements, the pipeline should be as close as possible to a straight line. Deflections and swings on its flat areas are not allowed. When using a corrugated pipe, watch for its maximum stretching.

- Be sure to use sealant to handle the joints between the pipes and the adapters, pipes, and each other.

- The radius of the bends of the pipeline should exceed the value of the diameter of the corrugation itself. Violation of this condition leads to a decrease in pressure and overall system performance.

- An optimum pipeline is considered to be no longer than 3 m with a minimum number of turns and bends (the desired angle of rotation is obtuse).

- The use of special adapters helps keep the duct intact if it is routed through the wall.

- Long corrugated pipes are fixed with clamps every 1-1.5 m. This helps to exclude their possible deflection and swaying during operation of the exhaust system.

- At the junction of the laid pipe and the exhaust shaft, it is desirable to use a special frame. On it is a valve (check), a flange for fixing the edge of the pipe, the remaining area is occupied by the ventilation grill. The principle of operation - when the kitchen equipment is not used, nothing interferes with the air circulation through the grill (valve open); when the hood is turned on, the valve closes and the exhaust air with impurities cannot get back into the kitchen the room.

- The entire system must be earthed to protect against static electricity.

Remember! The performance of a working exhaust system is reduced by 10% with each bend of the duct at an acute and right angle. With several such areas, the operation of the hood becomes ineffective and occurs with overloads. If it is impossible to change the route of the pipeline, you need to increase the power of the installed equipment and the nominal cross-section of the pipe.

How to hide the exhaust pipe?

Accurate installation of the duct is not a guarantee of getting its design into the concept of the design of the kitchen. Especially if it was going from a brilliant corrugation that attracted attention. Decorating or masking the mounted structure in this case cannot be avoided. Read more in detail here.

The main ways to hide the pipe are:

- A predefined special plasterboard or plastic box.

- Stretch and suspended ceiling structures, which also help to hide the external elements of other utilities.

- If possible, the pipe is passed through a prepared niche in hanging furniture.

- To close the communications, false panels with the decor of a furniture facade or an adjoining wall help. Usually they are mounted or mounted on hanging blocks of kitchen furniture.

Video

Properly selected elements and components of the air exhaust system, their competent connection and installation allow you to create a kitchen area in which cooking becomes a safe and enjoyable task.

With great interest I always read your comments to my articles. If you have any questions, feel free to ask them, leave, you are welcome, Your feedback in the form below. Your opinion is very important to me. Thanks to your criticism and thanks, I can make this blog more useful and interesting.

I would be very grateful if you rate this post and share it with your friends. This is easy to do by clicking on the social media buttons above. Do not forget the article you like Add to bookmarks and subscribe to new blog posts on social networks.