The durability of a private house made of any building material largely depends on the regular ventilation of the space located under the lower ceiling. The ideal option is when the ventilation of the subfloor in a private house is designed and implemented during the initial stage of construction. Then it is calculated and arranged correctly.

You will learn all about the competent organization of a system designed to remove excess moisture from structures partially or completely buried in the ground in the next article.

We will tell you about the important functions of ventilation. We will show you how to correctly position and install the components for the removal of exhaust air and the supply of fresh air.

The content of the article:

- The need for underground ventilation

-

Features of the ventilation device

- Underground ventilation in a wooden house

- Air exchange rate

- How to improve air exchange in an already built house?

- Forced ventilation device

- Features of the combined system

- Seasonal maintenance of the ventilation system with air vents

- Additional moisture reduction

- How to choose a ventilation scheme?

- Materials for the system device

- How to install an air duct?

- Conclusions and useful video on the topic

The need for underground ventilation

The organization of underground ventilation in a private building is mandatory for the following reasons:

- From the temperature difference outside and under the floor, condensation settles on the logs with floor beams and on the plinth. Without ventilation, acidic water droplets destroy concrete, brick, wood, causing corrosion of building materials.

- Moisture contributes to the appearance, settlement and development of mold and mildew, affecting both wood, metal, and concrete. Mold that has already appeared with natural normalization of the moisture level does not disappear anywhere, and with its subsequent increase it will begin to develop more actively in the affected areas;

- The closed space of the subfloor accumulates carbon dioxide, especially if autumn harvests with the harvested harvest are stored in it.

The humidity of the underground increases due to contact with soils, which always contain water in different proportions.

Moisture is especially felt at the soil level, i.e. soil and vegetation layer up to 40 cm thick, actively absorbing precipitation and regularly irrigated during irrigation.

In the absence or insufficiently effective operation of the ventilation system, the subfield will be damp. Due to the lack of oxygen, a favorable environment will be formed for the development of anaerobic bacteria. In addition to everything, carbon dioxide will accumulate

Underfloor ventilation is essential for almost any design solution. An exception is the construction of a floor on the ground, according to which beams or slabs are placed directly on the sand or gravel dump, and do not block the spans between the walls of the foundation with them.

Features of the ventilation device

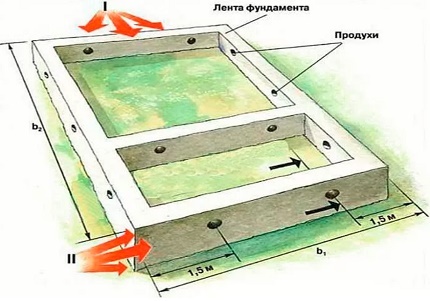

If space remains under the floor of the house, its ventilation is most often organized using a device for air vents inside the basement. Ventilation openings are designed at a precisely calculated distance from each other, from the ground level, from the corners of the building and taking into account other factors.

Ventilation openings are covered with ventilation grilles to protect against rodents. This is a traditional solution for organizing a natural ventilation system.

For greater efficiency of the ventilation process, the air vents are selected from the leeward side and in the wall of the basement / foundation, located opposite. Vent holes should be opposite each other. With this solution, the thrust is naturally enhanced.

Wind blowing into a hole on one side will fly out into vent hole on the other side, carrying with it moisture, volatile carbon dioxide molecules and a musty smell. During further operation, you only need to ensure that ventilation openings were not obstructed by any objects from the inside and did not overgrow outside.

In strip foundations, vents are placed opposite each other to ensure a stable natural air flow

If there are partitions inside the foundation, each of them is also made ventilation holes. In order for the movement of air masses to be stable and free, the inner vents are placed directly opposite the vents selected in the outer walls.

If it is impossible to choose the required number of holes in the walls of the basement or foundation, the area of each mini-opening is increased. It is important that the total ventilation area meets regulatory requirements.

Adequate air flow must be ensured for proper ventilation of the subfloor - ventilation openings must be in accordance with regulations

You can make a series of holes of the same size, or you can make one wide window with a lattice or opening sash. When installing a window, there must be a passage or a hatch inside the structure that can be opened for periodic volley ventilation.

Cut through ventilation openings in the foundation / plinth of an already erected structure, you can use a mobile drilling rig designed for horizontal drilling and drilling of walls. To form a hole, you will need a projectile equipped with a diamond crown.

Ideally, air vents in the outer and inner walls of the foundation, passages and large openings for ventilation pipes should be laid before pouring the solution into the formwork

If there is an additional foundation inside, for example, under brick oven or a massive floor-standing gas boiler, then the number of holes inside the outer plinth must be increased by 1.5-2 times.

The vents can be not only round, but also square, rectangular and even triangular. The main thing is not to reduce the total section specified in the building codes. The size of the hole should not impede the flow of the required amount of air.

It is never too late to make vents in the foundation or plinth. They can be punched with a hammer drill or drilled with a mobile machine with a diamond core bit.

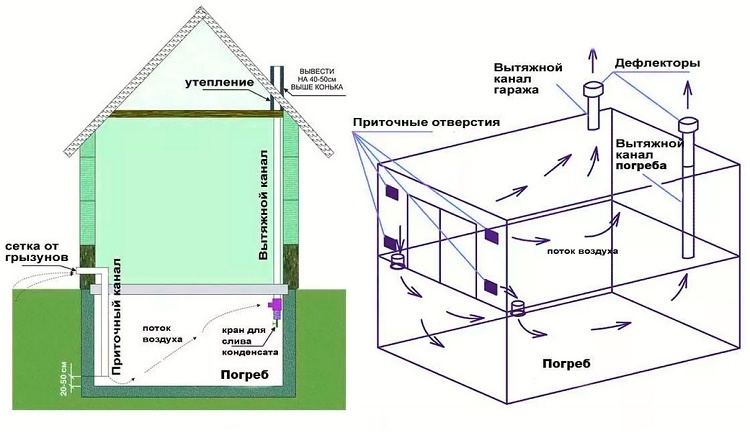

The second method of organizing a ventilated space is more laborious and more resource-intensive. Extraction is organized from the subfloor through the ventilation pipe to the roof. In this case, air enters the system through the grilles in the rooms.

In this case, no air is made in the foundation, however, external insulation of the foundation, basement and blind areas. This is the best option if you plan to build a well-insulated eco a house in the construction of which the principles of energy saving were used.

Underground ventilation in a wooden house

The log house of a wooden house is most often erected on a columnar base. A lower crown is mounted on it, which served as a kind of grillage for laying floor beams. The gaps between the foundation pillars are most often not laid with anything at all, which provides natural ventilation.

Houses made of logs or beams are now also placed on strip foundations made of bricks and concrete sides. When building a base from piece materials, openings are formed during the masonry process

If the floor in the house is decided to be finished with a non-wooden floor covering, then it is arranged using floating technology, i.e. the subfloor has no connection with the walls. In this case, a small gap remains between the cover and the crown, through which the ventilation of the underground and the floor will take place.

The gaps are covered with skirting boards, but the presence of small gaps allows for full ventilation. On opposite sides of the rooms, you can place special skirting boards with ventilation holes.

The flooring in a wooden house is laid in a floating pattern, i.e. with a gap around the perimeter. Moist air escapes from the subfloor through this gap. In addition, ventilation vents with grates are arranged in the floor.

In addition, in the corners near the walls, you can leave slots in the floor for ventilation, covering them with ventilation grilles. This solution will also help to improve air circulation under the floor of the building.

Air exchange rate

How to organize ventilation of the underground? It is necessary to lay ventilation holes at the foundation construction stage.

To ensure stable air exchange in the space under the lower ceiling, the following rules should be observed:

- When installing vents 15-20 cm below the upper edge of the tape (in case the base is located low), a pit is made in front of the hole.

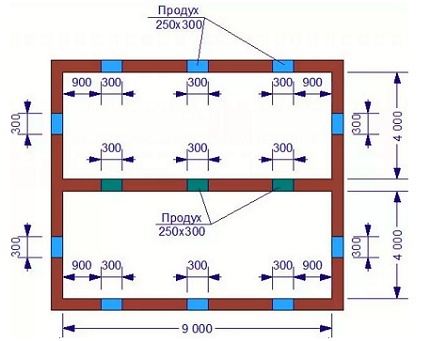

- The step between adjacent openings should not exceed 3m.

- The holes in the plinth / foundation are located at a distance from the corner up to 1 m.

If the house is built on a hillock, for sure, it is well blown from either side. In this case, the number of ventilation holes can be slightly reduced.

If the house is built in a region with low wind activity, is located in a lowland or surrounded by forest, the number or size of vents should be increased.

In the basement or foundation of a house built in a lowland, the total cross-section of the ventilation openings should be increased: either in number or in area.

Dimensions (edit) holes for foundation ventilation and undergrounds are regulated SNiP number 41-01-2003 or an updated version of the rules of SP 60.13330.2012.

The area of all vents must be at least 1/400 of the entire area of the subfloor. That is, if the house is 9 m by 9 m in size, then the area of the subfloor is 81 m2. In this case, in the foundation, the total area of the vents should be 81/400 = 0.20 m2 or 20 cm2.

The minimum air area should not be less than 0.05 m2. That is, rectangular holes should have a size of 25 × 20cm or 50 × 10cm, and round holes should have a diameter of 25cm.

If in a private house such air vents look too large, they can be made 2 times smaller by increasing the number ventilation holesso that their total area is not less than the calculated one.

Sleeves for the formation of ventilation holes, as well as for the passage of all types of pipes, are laid in the reinforcement cage before pouring the solution into the formwork

When installing air vents in the strip foundation, the embedded ones are fixed after the installation of the reinforcing frame. These can be plastic or metal pipes or asbestos cement pipes. Their edges are brought out on the same level with the formwork and are well fixed.

To prevent the concrete from flattening the plastic during pouring, sand is poured into the pipes and closed with plugs. After formwork such mortgages remain in place. Rectangular vents are made using boxes from knocked down boards. The wooden box is also installed in the reinforcing frame, after the concrete has set, it is removed.

Easier to do ventilation holes in a brick base. In this case, you can cut the bricks or put a half instead of a whole brick. In the plinths erected from concrete blocks, you can take several blocks with a couple of large holes, make them through and put them instead of normal ones. If the construction material is reinforced concrete blocks, airflows are made at the joints.

If the house is installed on a bored, pile or columnar foundation, there is no need for a ventilation device. Even if the perimeter is sewn up with siding, ventilation is carried out through the seams and gaps in the structure or perforated elements

If in a columnar foundation the gap between the supports is closed with bricks or concrete blocks, the required number of holes is left in the building material. It is necessary that their area is equal to one four hundredth of the area of the subfloor.

How to improve air exchange in an already built house?

If the house is already standing, and the available air is not enough, high humidity is felt all the time underground and a fungus has begun to form, you can take action.

To enhance air flows and improve ventilation, you must:

- Drill new vents or increase the size of old ones. The easiest way is to drill many holes around the vent perimeter with a hammer drill with a thick drill. Then the remaining gaps are drilled and the walls are leveled. However, a more productive way is drilling with a diamond bit without shock loads, after which even and neat holes remain;

- Improve ventilation draft by routing several pipes from the exhaust openings to the roof. The thrust will increase due to the greater pressure drop;

- Set up automatic forced ventilation with a timer;

- Build a channel at the base of the stove, combined with a blower. Then the air will be drawn from below, providing the stove with the oxygen it needs for combustion. However, this option is applicable only for buildings with brick stoves, and then only at the stage of construction or alteration of the unit.

- Reduce the penetration of groundwater by means of a strong waterproofing device. A method that does not allow to abandon ventilation, but reduces the level of humidity typical for structures buried in the ground.

Waterproofing materials, thick construction polyethylene or polymer membrane, must be installed with overwhelm by 10-15 cm, placing it on the walls by 20-30 cm and securing it with a bar. To prevent damage to the film, a 3cm skinny screed is poured onto it.

With insulated foundations, plinths, blind area the effect in combination with the ventilation pipe will be multiple. Without insulation, condensation will collect on the film, which, having made a slope, can be taken away from the subfloor.

To reduce the temperature difference within the underground, it is better to cover the subsoil with expanded clay. It is undesirable to lay polyethylene on the ground, anaerobic bacteria will be divorced under it, a persistent swamp smell will appear

But expanded clay, due to its voidness, will itself draw water from the enclosing soils. Therefore, it is possible to fill up this material only if the GW level does not rise above a mark of 2.0 m from the day surface. If not, you will have to arrange ventilation of the subfloor in the house according to the above described scheme, adhering to standard principles.

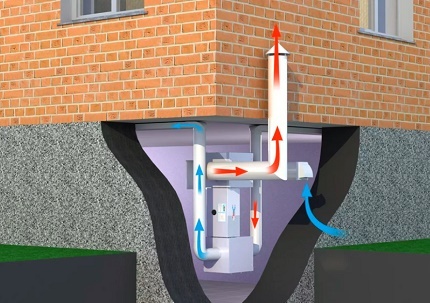

Forced ventilation device

Natural circulation of air currents can not in all cases provide the necessary drying of the underfloor space. Then a mechanical ventilation unit or supply ventilation valves are mounted.

Mechanical compulsion of air to movement is required:

- If the house is built in a valley between hills.

- If the natural movement of air masses is impossible due to the climatic features of the area (high humidity, for example).

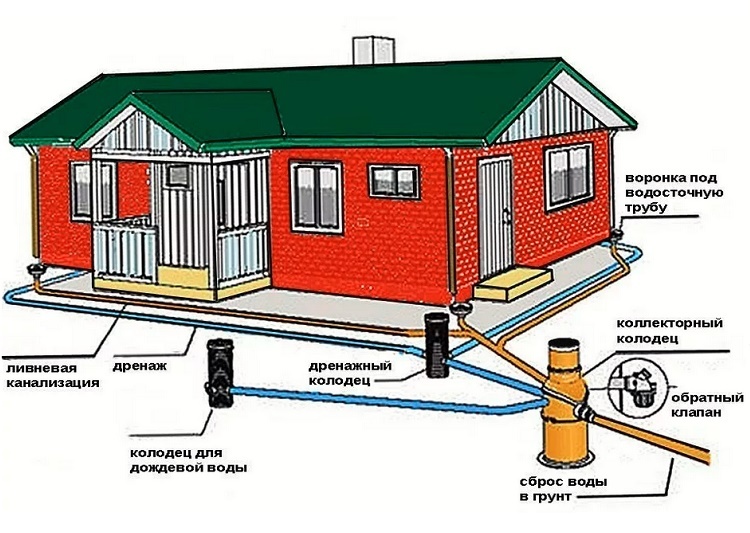

- If the base of the building is buried in soils with low filtration properties, due to which atmospheric water weakly seeps into the underlying rocks. It can be determined by stagnant puddles after rains, poorly drained flood waters. In this case, in addition to ventilation, effective wall drainage is needed, which can be built even after the construction of the house.

Forced ventilation systems are characterized by the presence of installed supply / exhaust fans in the openings of the ducts, contributing to a more intensive circulation of air masses. The most common and economical option is to install one exhaust fan.

If the owners of the house are not limited in funds, it is better to arrange a forced system with fans for a full air exchange within the subfloor.

It is enough to turn on such fans for half an hour once a day. It is possible to install a system of automatic on / off ventilation devices. With periodically high humidity - for example, during the spring thawing of snow, you can use heating equipment to quickly drain the subfloor.

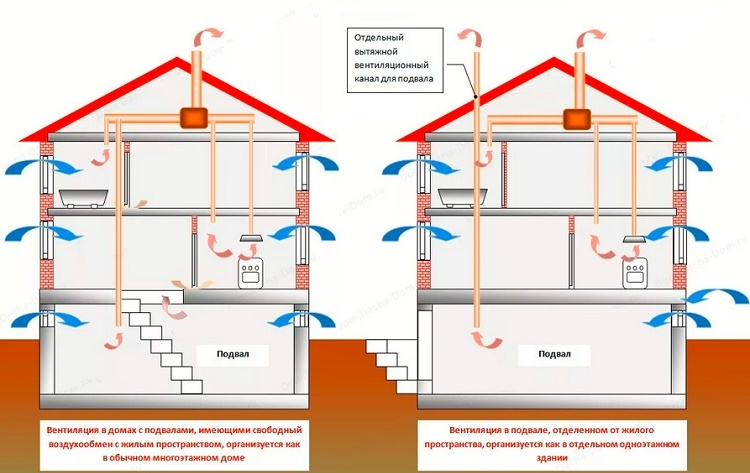

Features of the combined system

Combined basement ventilation system is set if ventilation system the natural type does not cope with its tasks, and it is too expensive to use only the mechanical one. A huge plus of the combined system is that it is not influenced by natural factors and temperature differences and it can function all year round.

Combined ventilation, like natural ventilation, is equipped with inlet / outlet openings. A fan is installed in the exhaust opening, which quickly removes stagnant air from the underfloor. If the subfloor area is large, the fan is also installed in the supply air duct.

The natural type of ventilation can be easily converted into a combined version by installing a wall ventilation valve on the supply or exhaust opening

In small subfloors, this is economically impractical, since there will be an overconsumption of electricity. The fan will help to quickly drain the space if natural ventilation cannot cope with this problem.

Most often, fans with a power of up to 100W are taken to equip a combined system. Both centrifugal and axial devices can be selected. Axial ones are more economical, in addition, they provide a sufficiently powerful air flow, while spending a moderate amount of electricity. When installing axial devices, a check valve must be installed in the pipe.

Seasonal maintenance of the ventilation system with air vents

The main controversy when caring for the ventilation system is the question - to close the vents for the winter or not.

There are 2 points of view here:

- With open vents. Through them, moisture will be removed, falling out in the form of condensation in heated overly insulated rooms. The floor directly communicating with the ground in them will always be cold, which means that the formation of "dew" will increase during the heating season. However, if you invest in floor insulation, this can be avoided.

- With vents closed for the winter. Warm, humid air from the living space will come into contact with cold subfloor surfaces (basement walls). Condensation will drain into the ground. In the spring / summer, it will evaporate, increasing the humidity, therefore, the subfloor will need to be dried with heating devices.

The air vents will have to be closed if the house is wooden, but the flooring is done floating technology, i.e. there are gaps near the walls, and ventilation holes with grilles are also selected in the floor. Otherwise, the floor will be strong cool.

It is not recommended to close the air vents for the winter; ventilation of the underground should be carried out under any weather conditions. It makes sense to reduce the air flow using the method shown in the photo.

In other cases, you can consider both options. In addition, in winter it is necessary to regularly clean the basement of snow so that the ventilation openings do not completely fill up. Indeed, even when closed, they will contribute to ventilation, even if in a reduced state.

In the rest of the year, caring for ventilation system simple:

- in the spring - open the vents and dry the subfloor;

- in the summer - make sure ventilation holes did not fill up with garbage and they were not overshadowed by grown plants;

On all types of vents, it is necessary to install ventilation grilles (preferably metal) so that rodents and raccoons do not get inside, and regularly clean them of debris so that the air flow does not decrease.

Additional moisture reduction

So that the ventilation system does not have to be strengthened by increasing the total section or installing fans, the following work must be carried out:

- Device efficient drainage system - drainage of water from the foundation.

- Waterproofing the base of the house and basement. There are many types of waterproofing: it can be rolled, welded, coated, etc.

- Thermal insulation. The best material in terms of economy and efficiency - EPPS. this one good heat insulatorwhich does not allow water to pass through. He is not interested in rodents and does not rot. EPPS can be insulated and blind area.

The listed activities do not cancel, but only supplement ventilation. Only in a complex it is possible to achieve perfect drainage of the space in the basement compartments.

If the house is built on a ground base that does not drain water well, in addition to the ventilation system, drainage and storm drainage are required. The drainage system will collect water from the soil and the upper layers of the soil, storm water will collect and divert precipitation

When the system is arranged according to a forced scheme, the costs of installation, maintenance and service will be higher than in the case of a natural type of organization. It should be borne in mind that in winter, condensation can form on the walls of the ventilation pipes themselves, and in cold weather, the cross section can even clog kurzhak.

To avoid this, the pipe can be insulatepenofol. At the lower turn of the pipe, you can come up with condensate trap - for example, drill a hole or put a tee instead of the angle.

How to choose a ventilation scheme?

So, we figured out whether an underfloor ventilation system is needed, and now it remains to decide which scheme to choose for specific conditions. There are several important points to consider when choosing a system. The operation of ventilation largely depends on the type of climate in a particular area, the average outside temperature, etc.

In a natural ventilation device, the main rule must be observed: the supply openings are located below the exhaust openings. The greater the altitude distance between them, the more efficiently the system operates.

Natural ventilation is more effective in winter, since it is at this time that a large difference is recorded between the temperature inside the subfloor and outside, due to which good air circulation is ensured masses.

However, with an even greater decrease in temperature, there is a possibility of an excessive increase in air exchange, which is also not particularly good, since it can lead to freezing of structures. Therefore, with a significant decrease in temperature, the air vents must be closed.

In summer, the temperature difference inside and outside the subfloor is minimized, so air circulation may stop. Therefore, natural ventilation even with supply and exhaust system - not the best option for hot regions. Here you should install the combined ventilation system with pipes.

If the house has a supply and exhaust ventilation, it makes sense to connect the hood from the basement to the general scheme. So the air outflow will be stimulated in any weather.

For the arrangement of the combined ventilation systems for a small subfloor, it will be enough to install one pipe. In order for it to provide both output and reception of air masses, it must be divided vertically into 2 channels.

These ventilation pipes are sold in hardware stores. Each channel has its own valve to adjust the flow rate. The functioning of such ventilation is checked quite simply: you need to attach a sheet of paper to the outlets in turn.

Materials for the system device

For the arrangement of supply and exhaust ventilation ducts, 3 types of pipes are used:

- Asbestos-cement - durable, corrosion resistant and cold resistant. They are of sufficient length, therefore, during installation, you can do without connections;

- Steel galvanized - resistant to corrosion, easy to install, lightweight. However, the price of metal components ventilation systems usually higher than plastic and asbestos-cement;

- Plastic They are characterized by a smooth inner surface that provides easy and fast air flow. Plastic pipes do not rust, they do not need to be cleaned, and their service life exceeds a couple of decades. One drawback is flammability.

The determining factor for efficiency ventilation systems is the proportionality of the section of the installed air duct of the area of the room in which it is mounted. Heating engineers recommend adhering to the following norm when calculating: for 1 m2 subfloor requires 26 cm2 section.

The most practical option for laying the exhaust part of the ventilation system in the cellar is to be assembled from polymer pipes. In addition to an affordable price, it is also attracted by the opportunity to build a pipeline with your own hands.

There is the following formula for calculating the required pipe diameter:

(Cellar S × 26) ÷ 13.

That is, if the area of the subfloor is 9 m2, then you need a pipe with a diameter of 18 cm: (9 × 26) = 208 ÷ 13 = 18 cm. For single-pipe ventilation, the diameter should be even larger, for example 20 cm.

How to install an air duct?

Most often for the organization of supply and exhaust ventilation systems 2 air ducts are used. To make the circulation of air masses more uniform, pipes of the same diameter are taken. To speed up the air outlet, a slightly larger chimney can be installed.

Install the air ducts at as much distance from each other as possible on opposite walls. Along the route of the pipes, it is necessary to reduce the number of bends as much as possible.

The exhaust pipe is mounted in one of the corners and its lower end should be near the ceiling itself so that all the warm air going upward is removed through it. The air duct can be combined with a kitchen exhaust ventilation system and bring it to the roof one and a half meters above the ridge.

The street duct must be insulated, we wrote about this above. The most aesthetic option is to put another pipe on the pipe, but of a larger size, and put any insulation in the resulting space. It is better to install a special ventilation deflector on the pipe head, which helps to increase the draft.

Mechanical ventilation ducts passing through the basement should be insulated so that, due to the temperature difference between the air passing through them and the air mass inside, condensation does not fall out on the pipes

The supply air duct is mounted in the opposite corner of the subfloor, and its open end should be as close to the ground as possible. The inlet must be lower than the outlet. Likewise, a pipe can be run through the house.

If a supply air duct is led out through the roof, its intake opening must be below the exhaust pipe. Outer edge possessive pipes are raised on the roof up to 20-25cm.

Also, the supply pipe can be brought out near the wall of the house from the outside. In this case, the hole should ideally be raised 80cm above the ground. Inside, each air duct is equipped with dampers that regulate the intensity of air movement.

Introduces the rules for the ventilation system in the attic of a private house next article, illuminating in detail the principles of the device and the nuances of the structure.

Conclusions and useful video on the topic

The following video will introduce the rules and principles of ventilation in the subfield:

Foundation Vent Guide:

How to deal with dampness in a country house:

Underfloor - closed unventilated a space in which all favorable conditions have been created for the development of mold, dampness, fungus, and condensation. To get rid of destructive processes will help to create an effective ventilation systems. This problem can be solved both at the stage of building a house, and later - at the stage of operation of the building.

Want to talk about how the ventilation system works in your subfield? Do you have any methods to improve its effectiveness that are worth sharing with your site visitors? Please write your comments in the block below, ask questions, post photos on the topic of the article.