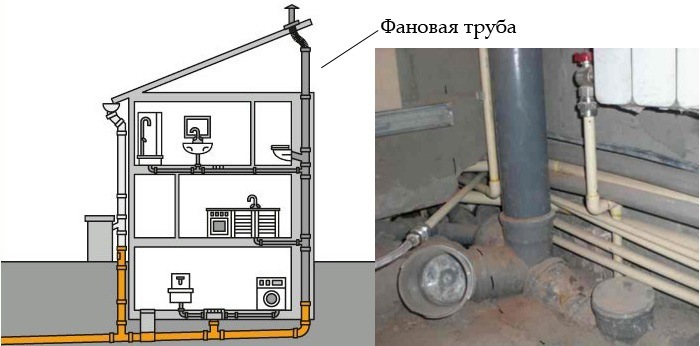

The fan pipe is a sewerage component, without which it is impossible to equip a bathroom. It is designed to communicate the sewer riser with the atmosphere, prevents the formation of wastewater and the appearance of an unpleasant odor in the bathroom.

The toilet water pipe installed in the washroom prevents vacuum in the sewer system and ensures the smooth operation of the water seals. In our material, we will understand what kind of fan pipes are, and also tell you about the rules for their installation.

The content of the article:

- Varieties of fun products

- What is a waste pipe used for?

-

Installation rules and features

- What is required to install a toilet?

- Installation instructions for the riser

- Heat insulation and sound insulation of the pipe

- Check valve for funnel systems

-

Connecting a toilet without corrugation

- Installation of a toilet bowl with vertical outlet

- Plumbing installation with horizontal outlet

- Installation of plumbing fixtures with oblique outlet

- Features of the repair of fan systems

- Conclusions and useful video on the topic

Varieties of fun products

Waste pipes are classified according to the material of construction used in the manufacture of products.

The classification divides funnel pipes into 2 types:

- metal;

- plastic.

The metal (cast iron) version can be mounted in a sewer system made of a similar material. Plastic products can be installed in both plastic and cast iron pipelines.

When repairing funnel pipes, it is recommended to replace the cast iron elements with plastic counterparts. This material is much more durable than cast iron

When installing a plastic element, a flexible sewer drain pipe, a monolithic elbow or a compact adapter is obtained. Cast iron products are not flexible and do not differ in a variety of shapes.

What is a waste pipe used for?

According to the building codes in force today, the process of constructing a sewerage system for a one-story house can be carried out without a fan pipe. This is due to the insignificant amount of one-time drains.

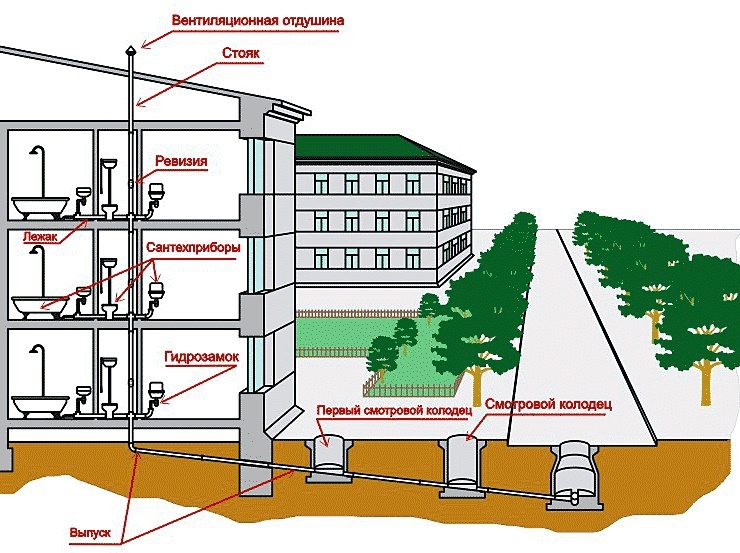

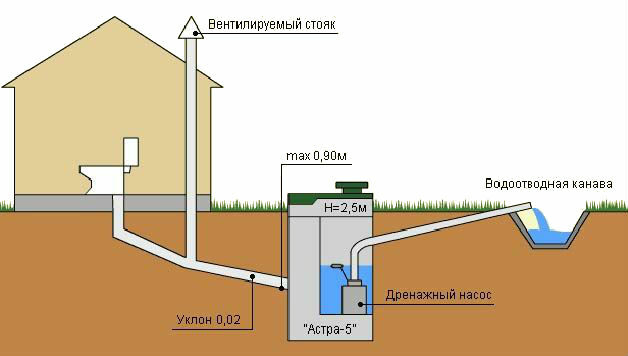

If the building consists of two or more floors or the housing is equipped with several bathrooms, then in order to ensure stable pressure in the sewage system, a drain pipe is required. This element connects the riser to the atmosphere, maintaining a stable atmospheric pressure even in the event of a volumetric ejection of water from the toilet cistern, which provokes a vacuum in the outlet line.

According to accepted building codes, in a one-story building with one bathroom, there is a minimum amount of drains, so the installation of a fan pipe in the bathroom is optional.

If there are several toilet rooms in the living area, then the situation changes dramatically and the drain pipe installed on the toilet is a vital necessity.

This rule applies in the following cases:

- the house has 2 or more levels, which are equipped with a sewerage system and water supply;

- cross-sectional diameter of the sewer riser - 50 mm;

- inside the building there is a pool or water equipment that drains a significant amount of waste into the sewer;

- a septic tank is located close to the house, which can cause a rather unpleasant odor.

In the above cases, vacuum without a drain pipe can lead to rapid emptying of the siphons. under the toilet or sink, which will ensure direct contact of the "atmosphere" of the septic tank with the microclimate of the room.

Thus, the installation of a funnel in the sewer system ensures a stable pressure in the outlet pipeline and maintains the integrity of water drains in siphons under special drain holes that cut off the unpleasant aroma of septic tanks from home microclimate.

Installation of a fan pipe is mandatory if the building has 2 or more bathrooms, which are used by all family members at the same time.

The construction of a sewerage and ventilation system with drain pipes is rational in the following cases:

- when installing a sewer riser in a private house with a diameter of 50 mm;

- if there are two or more floors in the house, each of which has bathrooms;

- a private house is equipped with plumbing equipment, for example, a swimming pool that generates powerful water drains;

- an autonomous sewerage system is located next to the residential building.

Usually toilet installation is carried out on a sewer pipe with a typical diameter of 110 mm. The section of the drain hole in the cistern is 70 mm. As a rule, a pipeline with a diameter of 50 mm is supplied to the bathroom. It is connected to a riser with a siphon section of no more than 110 mm.

It follows from this that when one bath or toilet is in operation, the inner diameter of the riser will not be completely blocked.

A drain pipe for a toilet is necessary in the case of simultaneous use of several bathrooms, when a single drain can completely block the cross-section of the sewer pipeline

A washbasin, sink or household appliances (dishwasher, washing machine, etc.) connected to the sewer system are not able to significantly change the volume of a one-time drain.

One-time drains of the above devices are insignificant, so they cannot radically affect the situation. In these cases, the drain pipe is mounted to the toilet at the request of the property owner.

Installation rules and features

Fan pipes are made from sewer pipes of the required diameter. They serve as a continuation of the riser in the bathroom and end with an entrance into a special channel equipped for ventilation of the sewer system.

Often, concepts are replaced, and an adapter (cuff, eccentric) connecting the plumbing fixture with the bell of the sewer pipe is called the toilet pipe.

Connecting the funnel system allows you to successfully solve the urgent problem of the occurrence of unpleasant, pungent odors in the toilet during the full operation of the sewer and ventilation systems. This is due to the small size of siphons in modern plumbing fixtures, due to which an insufficient supply of water (water seal) can form in them.

If the shower drain or plumbing fixture is not used for more than 2 days, it may result in drying of the water seal, which will provoke the unhindered penetration of air from the sewer into bathroom. At the same time, the waste pipe not only effectively sucks in air, but also ventilates the sewer pipeline.

When warm air rises through the riser, a vacuum occurs, due to which it partially enters the atmosphere through a previously dried siphon.

Installing a cast-iron or plastic pipe in a private house makes the unpleasant odor that arose when the siphon dries up less saturated

According to building codes, the fan pipe must be carried out in a warm room, if necessary, the product must be insulated. If it freezes, the fumes will not dissipate quickly and efficiently. For this reason, after a year of use, the upper part of the element will be covered with a greenish bloom.

Image gallery

Photo from

Toilets are connected to the outlets and risers of the sewer system using rigid or flexible (corrugated) extension cords

The extension cord is selected in accordance with the diameter of the sewer outlet to which the toilet is to be connected. The material of the funnel itself does not matter in this case.

Depending on the type of toilet outlet, the connection is made using rigid corner, straight elements, parts with corrugated sections and with an offset of the center of symmetry

Extensions with corrugated sections are suitable for all types of toilets, regardless of the release variant. They allow you to displace the toilet bowl relative to the outlet and increase the connection distance if necessary.

Connecting the toilet to the sewer riser

Outlet for connecting the toilet to the sewer

Part for connecting a toilet bowl with oblique outlet

Universal extension cord option

When installing a funnel pipe, two basic rules must be observed:

- The diameter of the product must be greater than the diameter of the riser on which the sewer pipe is mounted (regardless of the material used in the manufacture of the pipe).

- It should end 40-50 cm from the edge of the roof ridge, so that unpleasant odors will quickly be removed to the atmosphere.

The system outlet must be outside the residential area. More precisely, the funnel pipe for the plumbing device (toilet bowl) should go beyond the bathroom and stretch through the attic to the roof of the building. Otherwise, fetid odors from your septic tank will seep into your living space.

What is required to install a toilet?

The scheme for connecting a plumbing device to a common sewage system involves connecting the toilet bowl to the pipeline using pipes, bends, corrugated or eccentric cuffs.

The elements that are necessary to connect the toilet in the bathroom are a rubber cuff (2), a corrugation (3) and a plastic outlet (1). One is suitable, but sometimes you have to combine several

It should be borne in mind that the installation of any toilet model using reliable and durable cuffs has a number of requirements:

- it is absolutely impossible to cut pipes and change their geometric shape;

- corrugated cuffs can be freely stretched in length, and also bent at the required angle;

- eccentric collars must be rotated relative to the axis, this allows you to compensate for the deviation from the alignment of the plastic pipes connected to each other.

Making a pipe connection using pleated cuff has its advantages. This is a unique opportunity to connect a toilet bowl to a common sewage system in hard-to-reach places. In these cases, the sewerage system is equipped with various receiving sockets.

Installation instructions for the riser

When replacing a pipeline in a country house or apartment, you must first dismantle the sewer system. Cast iron products are considered obsolete, so they must be replaced with plastic counterparts, observing certain rules.

Today, in the houses of the old foundation, the dismantling of the old cast-iron pipe is often carried out. Plastic elements have better performance and durability

Dismantling is carried out by disconnecting the sewer riser with the subsequent disconnection of all structural elements. Before replacing, it is recommended to use the advice of specialists, which will allow you to find out if the replacement of the element will entail cast-iron riser on plastic unpleasant consequences, expressed in a decrease in the strength and reliability of the sewer systems.

The new pipe is mounted from the lowest stiffness point located in the area of the main riser. Installation in a country house begins from the site on which the foundation of the building is located. It is required to drill holes in the supporting structures, after which a pipe with a diameter of 110 mm is installed and secured with clamps. After installing the plumbing fixture, a special branch is brought to it.

When installing the riser, it is necessary to use exclusively metal clamps, which will ensure reliability of the design and will reduce deviations from the marking lines arising in the process assembly.

Metal clamps, which are used when installing the fan pipe, ensure the strength of this structure and allow you to adjust the elements connected to each other

The stud on the metal clamp features a functional screw structure that allows precise adjustment of the connecting elements.

Heat insulation and sound insulation of the pipe

When installing plastic elements, one must not forget about important measures to protect the system - sound insulation and thermal insulation of the pipe. Thermal insulation is carried out using a tubular cover made of foam insulation, which is worn from the outside.

To arrange the soundproofing of the system, the place of contact between the floor slab and the pipes is filled with polyurethane foam or other sealed material.

The fan pipe is surrounded by a sealed material with excellent soundproofing qualities. Due to this, vibration from moving through the sewage pipe does not transfer to the walls of the house

Noise insulation of the funnel pipe can be carried out using a mineral plate or special mounting foam. More often, polyurethane foam is used, which is easier to use, however, if the structure is dismantled, it will not allow it to be collected back.

Check valve for funnel systems

During the installation process, the funnel pipe is inserted into a previously prepared ventilation duct. If the project provides for the presence of a minimum number of ventilation risers, then the outlet for the toilet is brought out horizontally to the wall, without deteriorating the interior of the bathroom.

An important element of the system deserves special attention - a check valve, the functions of which include:

- preventing waste from returning to the toilet;

- the valve prevents rodents from entering the sewage system;

- correction of the situation in the event of an incorrect pipe slope;

- an obstacle to the return of mechanical impurities to the toilet.

If a non-return valve is being installed internally, the pipe must first be cleaned and thoroughly degreased. Then a special insert is installed - it must be purchased in advance, since it is not included in the kit with a check valve.

When installing the valve, it must be taken into account that its location should be opposite to the return flow, and the petals are bent towards the plumbing element.

The check valve can be installed in various places in the sewer system. Internal installation requires preliminary preparation and some space

When installing the valve, do not use lubricants or silicone products, even if they are intended for drainage systems. The installation process must be carried out exclusively dry.

If the sewer pipe has a typical diameter of 110 mm, then valve installation assumes the use of a special adapter. If a connection to a gray pipe with a sawn-off socket is planned, the valve is installed in the pipe.

A cylindrical check valve with a cover must be installed in the outlet pipe immediately after installing the plumbing device in the bathroom

When flushing the toilet, the valve cover opens and then it is automatically closed by a stainless steel spring. Due to this design, the lid does not open from the outside with fecal masses, which prevents them from falling back into the toilet.

The tightness of the connection between the valve and the sewer pipes is achieved using rubber rings. The valve has a long service life (over 50 years).

Connecting a toilet without corrugation

If the owner decides not to use corrugation when connecting a plumbing device, you must adhere to the basic rules: it is necessary use an adapter or pipe, the toilet bowl is connected to the adapter in different ways, depending on the release of the plumbing devices.

A smooth rigid cuff is an important element that is used to connect a plumbing device of any modification without using a corrugation

Depending on the internal design, the toilet bowls are classified into 3 types, which also differ in the features of installation and connection:

- Plumbing equipment with oblique outlet. The installation of the plumbing device is carried out into the pipe at an angle of 90.

- Plumbing fixtures with vertical outlet. Plumbing installation is carried out in the floor.

- Plumbing fixtures with horizontal outlet. Installation of products is carried out in the sewer pipe horizontally or with a slight slope.

If the release of plumbing and the entrance of the sewer network do not coincide, then it is necessary to install pipes-adapters bent at the desired angle or choose the optimal model of the toilet.

Plumbing devices for the toilet room can have a different type of release - oblique, horizontal (straight), vertical. The first option was widely used in the last century, but today the horizontal is supplanting it.

Before choosing the optimal design, it is worth considering the features of installing plumbing equipment of each type.

Installation of a toilet bowl with vertical outlet

Such models of plumbing are widely used in European countries. This is due to the fact that a vertical outlet pipe and a siphon located in the bowl of the sanitary ware are built into the plumbing equipment. Convenient design allows installation of the product at any distance relative to the wall.

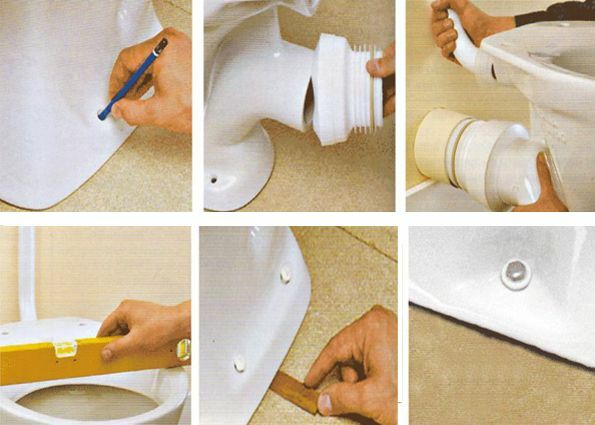

Installation of plumbing fixtures with vertical outlet is relatively simple:

- marking is performed on the floor of the toilet room;

- a screw flange equipped with a special retainer is installed according to the marking;

- the sewer pipe is mounted in a round hole located in the center of the flange;

- a toilet bowl is mounted on the previously installed flange, then it is turned until the equipment is fully fixed.

The outlet is equipped with an O-ring. Due to the presence of this element, the branch pipe is automatically pressed tightly against the sewer pipe. For more details on connecting a plumbing product with a vertical outlet, read Further.

Toilets with direct (vertical) floor outlet are mounted using special spare parts. The sewer junction is usually located under the ceilings, and the pipes do not require walls and partitions

Plumbing installation with horizontal outlet

Connecting toilet models with direct (horizontal to the floor) outlet is relevant for the conditions in our country. This is due to the fact that the bathroom is tied to a specific wall of the toilet room due to the specific layout of sewer pipes in typical Russian houses.

Since the release in these models is directed to the rear, it is located at the rear of the product. The outlet is attached to the pipe using a sealing collar.

The connection diagram of a modern plumbing device with a horizontal outlet in the bathroom of an apartment or house includes six main stages

During installation, you should pay special attention to fixing the plumbing fixtures to the bathroom floor. The legs of the plumbing bowl with horizontal outlet have specially cut holes designed to securely fix the toilet bowl to the floor.

The connection of plumbing fixtures with direct outlet ends with an installation process, during which screws and dowels are used. Fastening must be done carefully, since in the case of a strong "pulling" the screw, the integrity of the surface of the sanitary ware can be damaged.

Installation of plumbing fixtures with oblique outlet

The process of installing and connecting plumbing equipment with an oblique outlet is carried out in stages:

- Before connecting the plumbing to the sewer system, the outlet of the device with grooves located inside should be lubricated with a mixture of red lead with drying oil (or sealant).

- Above, you need to carefully wind the resin strand. The tip of the appendage 0.5 cm long should remain free, as the ends of the strand can fall into the hole and cause a blockage.

- The wrapped resin strand is smeared with red lead.

Then the toilet is installed, during which the outlet branch is fixed in the socket of the sewer pipe.

Connecting a toilet equipped with an oblique outlet can serve as a visual aid for self-assembly of equipment. It can be cut directly into a riser or connected to a sewer pipe

Installation of plumbing equipment with oblique release - a simpler process due to the absence of a fixed point for connection in a certain place. If, when arranging the sewer system, the outlet is not located accurately, this is not considered a problem.

Features of the repair of fan systems

Installation of the internal sewerage system is carried out "in the bell". This greatly facilitates the process of installation and dismantling of all pipeline elements.

Repair work is necessary in case of physical damage to the drain or sewer pipe. Due to the excellent stiffness indicator (pipe bending resistance - 80 MPa) and the long service life of the plastic (up to 60 years), there is a low probability of physical damage to the pipes.

When performing the repair of funnel pipes, the master must take into account the following rules:

- the end of the waste pipe is positioned in such a way as to ensure effective dissipation of an unpleasant odor;

- the diameter of the pipe must be the same or larger than the riser on which the installation is performed;

- the pipe is laid in warm rooms, and the installation is completed in a cold zone, since the temperature difference provokes a pressure drop in different sections of the pipe.

Repair work involves the connection of the drain pipe to the sewer riser. At the same time, vacuum valves are installed on other risers - rubber seals equipped with springs.

Replacement and repair of funnel pipes should be carried out according to project documentation, taking into account the rules for installing risers in the sewer system

During operation, the sewerage system creates a vacuum in the valve, as a result of which it opens and sucks in air from the room. After the pressure in the riser has stabilized, a special spring automatically closes the check valve, preventing the release of an unpleasant odor into the atmosphere.

Conclusions and useful video on the topic

The videos are useful for a general understanding of how the sewer system works in your home.

The role of the waste pipe in the sewer system and the principle of operation of vacuum valves:

Replacing a cast-iron toilet pipe with a plastic one:

How to replace the tee yourself:

We figured out what a waste pipe is and what is its role in the sewage and ventilation system. You can do it yourself, but if difficulties arise with installation or calculations, it is better to contact the specialists.

If, after studying the material, questions have arisen or you have valuable information on the installation of fan pipes, please share it with our readers. Leave your comments, ask questions, share your experience.