Modern pipelines are pipelines assembled from different materials with different pipe diameters. This became possible for one reason - the variety of connecting elements (fittings). One of them is very popular today. This is a brass adapter.

The content of the article:

-

Where is the brass adapter used?

- Brass adapter for connecting pipes of different diameters

- Brass adapter for connecting pipes made of different materials

- What are the advantages of a brass adapter

- Types of brass adapters

- Why a protective coating is applied to the brass adapter

Where is the brass adapter used?

Most often, this type of fittings is used in the assembly process of household plumbing (cold, hot) and heating networks. But with an increase in the quality of products, they began to be used in other engineering communication systems:

- drainage on a personal plot;

- watering systems for the garden and vegetable garden;

- Summer shower;

- pool water supply.

By purpose, this element is divided into two groups:

- For connecting pipes of different diameters.

- For connecting pipes made of different materials.

Brass adapter for connecting pipes of different diameters

It is a double-sided coupling, divided into 2 parts by a turnkey fitting. One part has a larger diameter, the other has a smaller one. Such products can be for connecting hoses (that is, smooth) and for threads. In the latter, it is cut as an external connecting element.

Fittings are often used when switching from the main line to the internal one, where pipes of a smaller diameter are installed. To make the connection, it is necessary to select the right part for the diameter of the pipe sections to be connected.

Usually, the joint is a tee, matched to the section of the main pipe line. To switch to a pipe of a smaller diameter, an adapter is mounted in the tee.

If a squeegee was welded to the main steel pipe, then an adapter is used, a smaller part of which has an external thread, a large internal one. The photo below shows this fitting.

Connecting piece with external and internal thread

Brass adapter for connecting pipes made of different materials

There are different situations that violate the technology for assembling pipe structures. It is believed that it is best to use pipes made of one material to form utility networks. But imagine a situation when the common water supply system is a steel pipe, and plastic products are laid inside the apartment. Brass plumbing adapters are indispensable here.

Other situations:

- It is necessary to reduce the cost of some section on which cheaper pipes are installed.

- Lack of required tubular products. Installation time is running out. Install those pipes that are available.

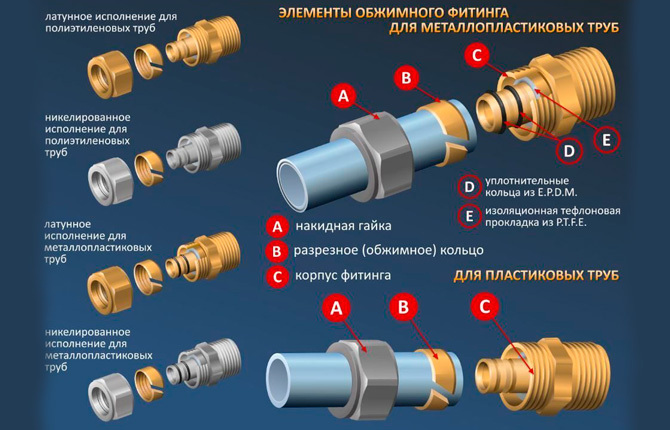

Brass fittings of this type are classified as combined. In addition to brass, they also include polymer. On the first side, it connects to a metal pipe, on the second - to a plastic one.

What are the advantages of a brass adapter

The initial raw material for production is L59-1 or L58-2 brass. Basically, it is a combination of two metals: copper and zinc. So in these grades of copper 57-60%, which determines the technical characteristics of the material:

- high strength and wear resistance;

- 100% hygienic safety;

- easy to process (cutting, drilling, etc.);

- ease of installation;

- corrosion-resistant material;

- compared to other metals, brass is cheaper;

- the brass adapter can withstand temperatures up to +200 ℃ and pressure up to 2.0 MPa, which is sufficient for most engineering systems.

Brass fittings are manufactured using injection molding technology with subsequent processing. It is the casting process that makes the metal homogeneous if all the technological stages are carried out correctly. The workpiece, ready for processing, is drilled out and the thread is cut.

Types of brass adapters

Brass fittings are collapsible type connectors. It is impossible to connect pipes “tightly” with their help. Brass can be soldered, but not welded. The adapter will simply melt under the influence of an electric arc.

As for the species, there are only two of them:

- threaded;

- non-threaded.

An example for the latter is a brass hose adapter, with which rubberized products of the same or different diameters are connected. It is often used by gas welders, who thus lengthen the hoses.

Brass fitting

There is a so-called brass fitting, which is also an adapter. On the one hand, in its design there is a branch pipe for a hose, on the other, there is an internal thread with which it is connected to the pipe.

One of its varieties is a brass adapter faucet. This is a standard brass ball valve with two different connections. There are three options:

- both connections are designed for hoses;

- one for a threaded connection, the other for a hose;

- both threaded.

The connection is simple. The hose is pushed onto the branch pipe and clamped with a clamp. There is a variety that uses a crimp nut. It comes as an addition to the basic design.

Crimp option

Why a protective coating is applied to the brass adapter

Pure copper brass loses in anti-corrosion resistance. But this problem can be easily solved today. Brass products are coated with protective compounds. Usually it is either nickel or chrome. The former is used in most parts, so nickel-plated adapters are more common.

The protective composition is applied in a layer with a thickness of 12.6-15.3 mm. If it is thinner, the anti-corrosion properties are reduced, which leads to the appearance of rust on the surface of the adapters. And this lowers the quality of the product and its service life. If the layer is thicker, it will crack quickly.

Chrome-plated products can be installed in pipelines through which corrosive media flow. The optimum thickness of the chrome layer is 0.327-1.47 mm.

Brass adapters, threaded and unthreaded, are products that are often used today for laying, reconstructing and repairing engineering pipe systems. They have good technical characteristics, which provide a service life of up to 50 years (depending on operating conditions).

Have you ever used similar parts for laying the pipeline? Write in the comments. Share the article on social networks and save it to bookmarks.

How to choose a brass fitting? Theory and practice in the video below.

Sources:

- https://www.san.team/articles/naznachenie-i-sposoby-montazha-latunnykh-perekhodnikov

- https://santehstandart.com/poleznye-materialy/perekhodnik-latunnyy