It is difficult to imagine a modern comfortable home without an air conditioning system. Agree that it is not enough just to purchase equipment with the appropriate parameters, but you also need to know how to lay the route of the air conditioner for its normal operation.

Installation of an air conditioner and a split system has ceased to be a rarity, they are found in almost every home. A correctly laid route will ensure the reliability of the connection of the elements and ensure the most efficient operation of the equipment, significantly extending its service life.

We will understand all the intricacies of laying the route and the nuances of the work. Consider tracing methods that allow you to preserve the design of the room, even in the case when the work is performed after finishing repairs.

The content of the article:

- What is an air conditioner track?

-

How does the installation of the route begin?

- What should be considered before laying the route?

- Sequence of work

- Choosing a way to set up a track

-

Construction of the air conditioner track

- The order of execution of gating

- Calculation of the required materials

- Features of route installation

- Conclusions and useful video on the topic

What is an air conditioner track?

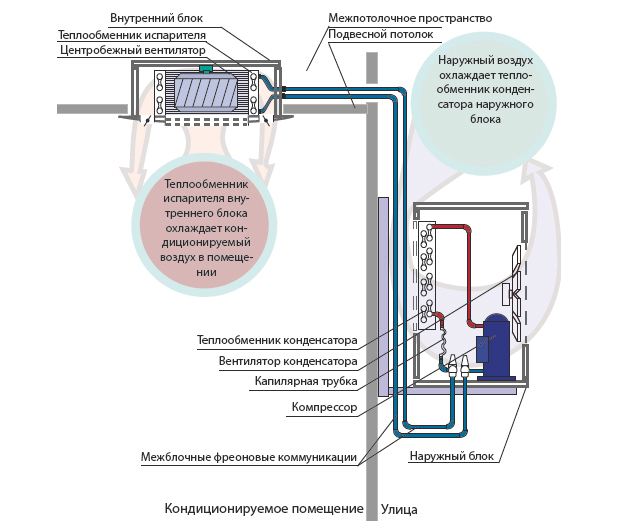

Each split system consists of at least two external and internal modules. The number of indoor modules is determined by the capacity of the equipment and depends on the area of the room.

All modules are interconnected by a system of pipelines that ensure the movement of refrigerant and drainage of condensate.

The piping system connecting the indoor unit to the outdoor unit, as well as the cable supply line, is called the air conditioner route.

In addition to piping, all modules are connected by a cable that provides power and control. It is this cable and pipeline connecting all the modules that have received the name - the air conditioner route.

How does the installation of the route begin?

It is best to start working on laying the air conditioner communications after purchasing the equipment or at least after choosing the required model. The defining component of any route is the diameter of the tubes, which depends on the model.

In addition, each of the air conditioner models has its own limit values along the length of the route. The maximum length of the air conditioner route when using wall-mounted household split systems does not exceed 20 meters. This does not mean that the system will not function. Simply exceeding the limit threshold can significantly reduce the performance of the air conditioner.

What should be considered before laying the route?

Even before starting work, it is important to accurately determine the location installation of cassette air conditioners, channel and multi-block systems, since it will be impossible to move the air conditioner even a couple of centimeters.

Before starting work, you need to determine the location of the indoor unit and apply its contour to the wall, since after laying the route it will no longer be possible to move it

The outdoor unit should be positioned in such a way as to provide easy access for cleaning and maintenance without the use of special equipment.

If convenient access to the external unit of the air conditioner is not provided, then maintenance and refueling of the system becomes impossible without special equipment and industrial climbers.

The power of the air conditioner puts a significant load on the electrical communications, therefore it is recommended to lay a separate supply line with its own circuit breaker. Before starting routing, it is necessary to choose the most optimal place for installing the indoor unit and calculate the length of the line.

When placing the equipment, the following features should be taken into account:

- Do not go beyond the height of the indoor and outdoor units. For household appliances, this figure is within 7-12 meters.

- When laying the drain, it is necessary to maintain the angle of inclination so that the condensate flows freely into the sewer. This requirement can be neglected if the drainage system is equipped with a pump, during which the condensate is simply pushed out.

- The distance from the ceiling to the top of the indoor unit must be at least 10 cm. This space is necessary to ensure normal air circulation.

- Even before installing the air conditioner, it is necessary to provide for the location of the furniture, since the flow of cold air should not be directed directly to people.

- The equipment should not be placed directly above the bedroom bed, as the air conditioner cannot operate completely silently.

Taking into account all the above features, you can start laying the highway and carrying out installation work.

Sequence of work

Lack of work skills is not a reason to refuse to lay the route on your own. Knowing the principle of operation of the equipment, and having a set of tools in your arsenal, you can easily install the air conditioner yourself.

In addition to equipment, the following materials will be required:

- Copper tubes of appropriate diameter with brass nuts;

- Heat insulating material;

- Sealant.

Protective equipment will not interfere, since when chipping the walls, even when using a household vacuum cleaner, there will be a lot of dust. And when the air conditioner is charged with refrigerant, it may leak, which can negatively affect the respiratory system.

When using an industrial wall chaser with a vacuum cleaner, you can completely avoid dusting the room and even do without protective equipment

The preparatory stage is the most important, since it is at this stage that it is necessary to correctly orient the placement of blocks and elements of the route.

The work is carried out in the following order:

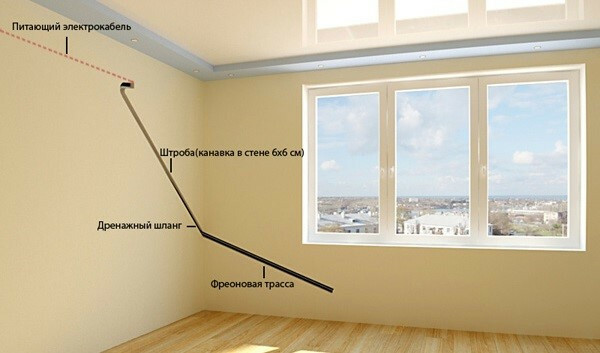

- Marking on the wall of the location of the indoor unit;

- Marking of grooves in the walls, taking into account the slopes;

- Slitting holes in the walls;

- Refrigerant piping;

- Drainage pipe lining;

- Electrical cable laying and installation sockets for air conditioner;

- Slitting a hole in the wall for connecting the indoor unit.

This procedure for performing work is the most difficult, but at the same time it is considered the most practical, as it allows you to maintain a decent aesthetic appearance of the room. Pipes to the indoor unit are mounted into the wall and go from behind, only one plastic panel remains in sight.

It should be borne in mind that the slitting method is more laborious and expensive.

Choosing a way to set up a track

There are two ways of laying a track for a split system - installation of communications into walls or boxes.

Mounting in boxes has a number of advantages:

- Reduced labor intensity. Fastening the box to the wall is much easier and faster than chasing.

- No dust. When working with a grinder or a wall chaser, it is impossible to avoid dusting the room.

- The speed of work. You can drill holes and fix the box in just a couple of hours, but you don't have to cut the track one day when it comes to installing several split systems and their considerable distance from the external block.

At first, it may seem that the box device looks preferable. However, in reality, all of these advantages outweigh the disadvantages that cannot be neglected.

Weighty disadvantages are that:

- The drainage line must be inclined towards the drain by at least 3 degrees. With a standard height of 3 m, the slope should already be at least 9 cm, and such a skew will be too conspicuous, violating the aesthetic appearance of the room.

- One box is not enough. The pipe and the electrical cable must be hidden in separate ducts placed parallel to each other. Thus, a part of the wall will be occupied, which complicates the solution of issues during cosmetic repairs, the use of hinged furniture and decorative elements.

- If it is necessary to drain the drainage into the sewer system, the box will have to be laid through all the rooms of the apartment or house.

After considering all the weaknesses of each of the methods, it becomes obvious that the disadvantages of flush mounting are not so significant.

The boxes successfully hide the air conditioner route, but spoil the aesthetic appearance of the room and cause difficulties when carrying out cosmetic repairs

With high-quality performance of work on laying pipes and compliance with standards, you do not have to worry about a violation of the integrity of the system and the need for repair.

Construction of the air conditioner track

The first stage of the installation of the route for connecting the split system with the external block is the marking of the groove. It can be done in a variety of ways.

At the stage of marking the grooves, it is necessary to take into account the location of other communications in order to avoid their damage

When marking, it is necessary to take into account the location of other communications in order to avoid their possible intersection or damage.

The order of execution of gating

The method of marking the groove depends on the characteristics of the drainage system and the place where the condensate is drained:

- With a parallel arrangement of the drainage and freon pipes, the recess should be made with a slope of at least 3 degrees to prevent stagnation of condensate.

- If the drain pipe is located separately with the condensate drain into the sewer system, then the slope is required only for the drainage device. The refrigerant line can be positioned without slopes and can be wall or ceiling mounted.

- In the absence of the possibility of realizing the movement of condensate by gravity, it is necessary to ensure the installation of additional pumping equipment.

After drilling a hole in the wall to connect the route to the already installed outdoor unit you can start marking the route by moving from the hole in the wall to the bottom corner of the indoor block. When making turns, sharp bends should be avoided. The slope is best kept constant along the entire length of the highway.

To ensure an even groove in the wall, it is better to cut the edges before chasing with an angle grinder. After that, you can perform chasing with a puncher.

When chipping the walls with a perforator, it is almost impossible to get smooth edges, it is better to first cut through them with a grinder. The ideal option in the absence of a wall chaser can be considered the use of a nozzle on a grinder

Usually it is enough to make a groove 6 cm deep. If necessary, you can reduce the depth by half, but at the same time expand the strobe to 8 cm. In this case, the communications will be laid in the furrow not in depth, but in width.

Calculation of the required materials

For household appliances with a power of up to 3 kW, depending on the model, copper pipes are used for arranging the air conditioner route with a diameter of 1/4 or 3/8 inches, which corresponds to 6 and 10 mm.

When calculating the length of the tube, one should take into account the distance under the internal block of about half a meter, the thickness of the walls, the length of the groove, the distance from the outside from the wall to the block valves. It is also better to make the length of the pipe outside at least half a meter to ensure smooth bending.

The size of the electrical cable is calculated in a similar way. The only difference is that the length under the indoor unit is about 1.2 m, and the length outside is 0.2-0.3 m longer than the pipes. It will not be superfluous to provide for the laying of an additional cable, which can be used to connect additional sensors.

For the device of the drainage line, it is preferable to use a corrugated hose with a diameter of 16 mm. The calculation of the length is similar to the calculation of the length of the pipeline, taking into account the length under the indoor unit about 0.5 m, the length outside - about 1.2 m.

Features of route installation

It is best to start laying the route from the edge that faces the street. We form a bundle of tubes and electrical cables, put on a flex on it and wrap it with tape on the part of the length that will pass through the wall. This is necessary to prevent damage to the insulation.

Before pulling the pipes and cable into the street, you need to form a bundle of them, put on a flex and wrap with tape in order to avoid damage to the insulation

After that, the tourniquet must be pulled through the wall, taking into account the previously calculated length of the outer part.

Further, all materials must be placed in the strobe, observing the following rules:

- The drainage hose should be sloped along the entire length of the track;

- Drainage should be located to the left of the tubes at the outlet of the groove when connected to the indoor unit;

- Copper tubes up to 10 mm in diameter can be gently bent by hand. For pipes with a larger diameter, a pipe bender must be used.

- The track laid in the gate must be fixed with mounting tape and fixed with dowels. It is necessary to control that communications do not protrude beyond the strobe, as this can cause difficulties during finishing work.

- To check the route, it is advisable to perform a pressure test of the system - pumping from a nitrogen cylinder under pressure. This will help to check the integrity of the system and the tightness of the installation.

After pressure testing, it is necessary to remove the remaining liquid from the system and you can connect the units and charge the refrigerant.

To carry out a pressure test, nitrogen must be pumped into the system and left for 30 minutes. Then you can drain the nitrogen and dry the system.

After checking the operation of the system, you can start closing the groove with a mortar.

After pressure testing, and even better after charging with refrigerant and checking the operation of the air conditioner, you can close the strobe with a building mixture

The building mixture must be selected depending on the material from which the walls are made. For brick and concrete walls, cement-based mixtures are ideal. He will acquaint you with the choice of the optimal time for the installation of the air conditioner next article, which we advise all potential buyers of equipment to read.

Conclusions and useful video on the topic

Rules for laying the air conditioner route, materials and equipment required for the work:

Laying the air conditioner route is a very important event, since the performance and durability of the climatic equipment largely depends on the correctness of the work. It is quite possible to do most of the work with your own hands; this does not require any special skills and special equipment.

If you go further, you can independently carry out the pressure testing and filling of the system, but here you already need to carefully consider and decide whether it is worth spending money on the purchase of additional equipment or resorting to the services of installers.

But the cost savings will be obvious anyway, because the laying of the route is a rather expensive undertaking, especially if the chasing is used and the pipes are hidden in the walls.

Would you like to share your own experience gained during the construction of an air conditioner track? Do you have any useful information on the topic of the article that is worth sharing with your site visitors? Please write your comments in the block below, post photos and ask questions on the topic of the article.