Household maintenance costs a lot, and you probably know that. Agree that while prices are rising, it would not hurt to optimize costs. You have definitely heard about insulation as one of these options. For example, if we talk about extruded polystyrene foam, the characteristics are at a fairly high level at a relatively low cost. It would be nice to know about all the properties of this material, right?

Putting off household issues until later can be a rash decision. You can understand the main properties of all heaters by giving only 10 minutes to each. Do not forget also that sometimes it takes a long time to redo something before starting something again. Keep in mind: A material as simple as extruded polystyrene foam can hold most of the waste heat.

The extruded polystyrene foam sold is not always the same, so it would be good to know what the difference is and how to choose the best material. In this article, we are talking about exactly this, as well as about the scope of its application and various physical features. We have provided you with the information you need in the most convenient form.

The content of the article:

-

The main properties of extruded polystyrene foam

- Pros and cons of penoplex

- Material selection criteria

- Applications of extruded polystyrene foam

- Conclusions and useful video on the topic

The main properties of extruded polystyrene foam

One of the types of polystyrene is expanded polystyrene. They are a mass of small air bubbles in shells. Distinguish between extruded polystyrene foam (extruded, expanded polystyrene, EPS, extrusion), normal or non-pressed, pressed, autoclaved and other types.

The usual version of expanded polystyrene consists of polymer - 2% and air - 98%. The extruded material has a solid content of about 10%. Strength penoplex more by 2.5 times, and it grows as the number of sheets increases.

Polyfoam is a class of materials of synthetic origin with a pliable or solid structure. There are polystyrene, polyvinyl chloride, polyurethane, formaldehyde and other foams

In the USA, Western Europe and Russia today extruded polystyrene foam is less harmful. In European countries, insulation with ordinary foam is increasingly prohibited, since it emits more harmful substances when it burns.

Penoplex is characterized by the following parameters:

- thermal conductivity: 0.029-0.034;

- water permeability: 0.2-0.4%;

- specific gravity: 25-45 kg / m³;

- bending strength: 0.3-0.45 MPa;

- compressive strength: 200-500 kPa.

Penoplex is made by extrusion. That is, through mixing the pellets at high pressure and temperature, with further extraction from the extruder.

First, the base in the form of styrene copolymers is melted, and then a hydrocarbon or nitrogen-containing blowing agent is added. Then the mass is processed with tools, squeezed and shaped. In the process, the cells of the material are saturated with carbon dioxide or natural gas. The cells are closed, and the surface of the insulation is relatively flat and smooth.

At the same time, penoplex and other types of expanded polystyrene can be produced from the same raw materials.

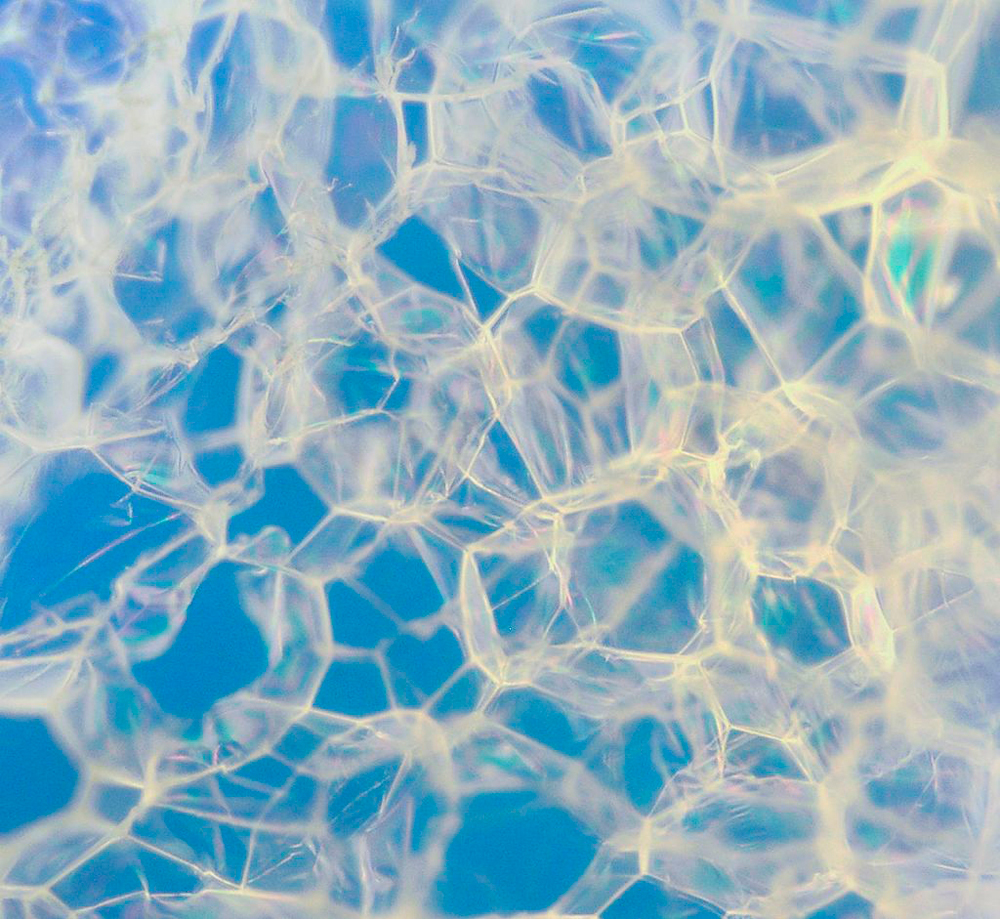

Various polymers are used in production, and on this basis the finished raw materials are differentiated. This is how styrene polymers look under a microscope

High-quality foam is characterized by a closed-type porous structure with a uniform surface and cells of 0.1-0.2 mm. Due to the air-containing composition, penoplex has low thermal conductivity, which gives the material ideal thermal insulation properties. It retains heat 3 times better than wood and up to 20 times better than other building materials.

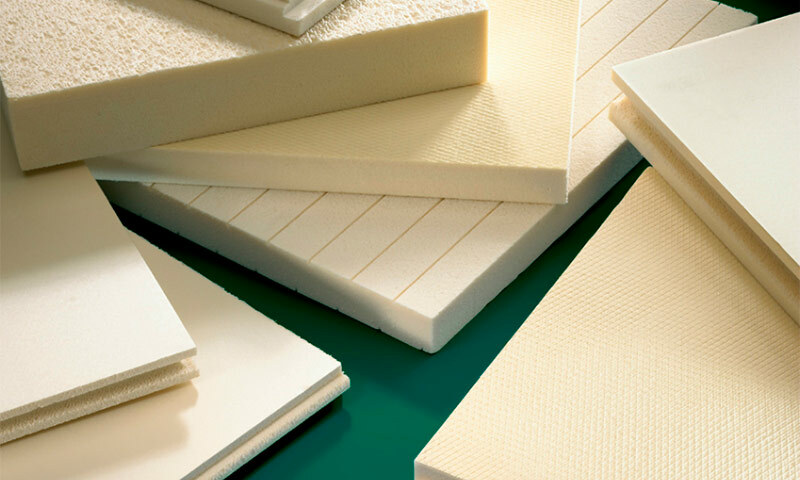

The extruded material has high mechanical resistance, low water and vapor permeability. It allows less air and moisture to pass through than regular foam, and when using it, you can do without vapor barrier. Extrusion is made in the form of slabs, flexible material and rolls.

Extruded polystyrene foam has a great advantage over mineral insulation and the like, after all, it hardly changes when exposed to water, while mineral materials generally come into disrepair. In general, the mineral insulation will need 3-4 times more than extruded polystyrene foam.

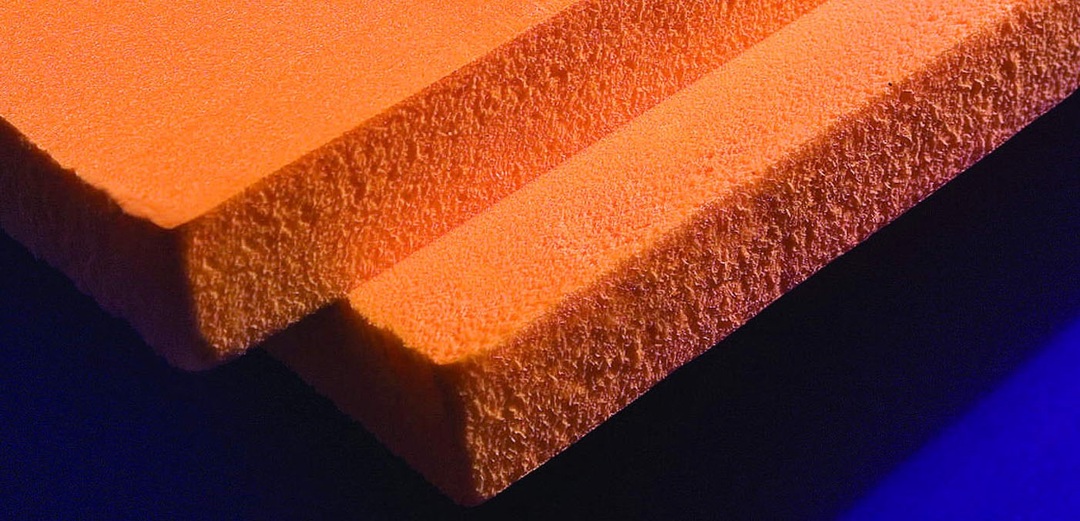

Both penoplex and ordinary polystyrene foam are lightweight and have good technical parameters, they are convenient for installation work. Penoplex is denser than many other types of foam.

Extruded polystyrene foam sheets have a thickness of 1.2 to 20 cm, which allows the material to be used for different purposes and in various industries

TO thermal insulation make high demands on safety, stability and technical parameters.

There is a method for determining durability. It provides for matching the capabilities of the foundation blocks. For them, the service life normally ranges from 40 years. Materials that cannot be replaced during the process must provide the same service life. The period of operation of extruded polystyrene foam in potential reaches more than half a century.

IN Federal Law No. 123 regulated indicators of toxicity of combustion products. According to it, extruded polystyrene foam is included in the flammability groups G3 and G4.

The best polystyrene foam has a G2 index - moderately dangerous. In fire hazardous places and with high requirements for fire safety, Penoplex G3 is chosen. At the same time, the material must retain the same service life - 40 years.

In modern polystyrene there are fire retardants, the function of which is to neutralize the action of pyrenes. The material burns quickly, but does not support the flame and goes out. Any type of polystyrene foam has this quality, but the decay rate can vary greatly. Sometimes not in favor of extruded material.

Pros and cons of penoplex

Extruded polystyrene foam has many positive qualities.

It has low thermal conductivity - this is the main feature that makes the material an ideal insulation.

Penoplex does not attract microorganisms, is resistant to mold and mildew, even if it is in close proximity to these formations

Penoplex retains its original properties for a long time. Thermal performance remains the same after 1000 freeze / thaw cycles. The thermal resistance changes by no more than 5%. Physical and mechanical properties remain unchanged for a long time even when the temperature changes in the range of -50... + 75 ° C.

Penoplex is easy to use. Its installation is simple, and the need for tools is minimal.

Extrusion is resistant to a number of substances and factors common in everyday life: vegetable oils, ammonia, cement, organic and inorganic acids, rodents, dyes, alkalis. Biological degradation of the material is also not threatened. Unlike conventional expanded polystyrene, the extrusion does not crumble after being compressed, stretched, or bumped.

Extruded polystyrene foam minimizes water absorption. Penoplex immersed in water will be filled with moisture no more than 0.5% by volume. It will completely stop absorbing it after 10 days. It's about quality material.

To the advantages, and at the same time to the disadvantages, it is worth adding low vapor permeability. By its ability to pass steam, 1 extrusion layer 2 cm thick corresponds to 1 layer of roofing material. In this regard, extruded polystyrene foam is better than all other materials of its type.

Even extruded polystyrene foam is exposed to solvents, therefore, in the case of painting or varnishing, you need to carefully check the composition of the solutions used

As with all materials, extruded polystyrene foam has weaknesses.

When arranging saunas and heated roofs, the use of this material is usually not available. If the temperature near the penoplex exceeds 75 ° C, it will begin to release many harmful compounds. The material also has a vulnerability to sunlight. Penoplex also ignites, and self-extinguishing lasts about 10 seconds.

Extrusion has low frost resistance - sometimes small cracks appear in the structure. Most of the thermal insulation materials are better preserved in frost than penoplex.

Loss of integrity also occurs due to contact with hydrocarbons such as PVC. Penoplex is susceptible to oxidation in air, but regular foam oxidizes even faster.

Material selection criteria

Expanded polystyrene is lightweight, comfortable, warm and relatively cheap material. However, it can vary considerably in quality.

Check the material standard. Ideally, take with GOST compliance. Manufacturers also have products according to their own specifications.

In the second case, the properties may differ significantly, and the specific gravity of the same modification may be in the range of 28-40 kg / m³. Therefore, ask for documents indicating the physical parameters.

Chips often form on the sheets of foam, and their corners can be grinded, so you should take care of careful transportation and good conditions for installation

Be sure to feel the material and make sure it is strong. It shouldn't lose integrity if you clicked on it but didn't put in significant effort. In normal extrusion, no balls will be visible at the fracture site, but only polyhedrons of the correct shape. In addition, the penoplex can be easily cut with a knife.

At the point of sale, you can check the storage location of the penoplex. Styrofoam should not be left uncovered in the open air, and sometimes ordinary fabric is enough, the presence of packaging is not necessary. Make sure that there is no acetone, dichloroethane, benzene, paints and varnishes near the penoplex.

Check all certificates, inspect the packaging, if any, for integrity. Find the marking sticker. It is placed on the packaging or on the material itself if it is not packaged. It is better not to buy a product without a sticker with markings.

Pay attention to the color. Only pure shades are suitable, and the less they approach a uniform color, the lower the initial quality of the penoplex, or the storage option was inappropriate, and the material deteriorated. The smell of extrusion shouldn't be unpleasant.

Check the thickness of the sheets. Determine if the granules are the same in each of them.

Choose penoplex depending on the intended use:

- for the roof, take penoplex with the highest specific gravity: from 33 to 45 kg / m³;

- for arranging the floor, an indicator of 33 kg / m³ is enough;

- for internal walls, 28 kg / m³ is sufficient.

Give preference to XPS Penoplex, grade 40 and above. Keep in mind, the ideal extruded material is strong yet resilient and slightly pliable.

Penoplex can be cut with a string, hand file, using curly cutting, but it will be most convenient to work with a painting knife

According to GOST 30244-94, Styrofoam is the most hazardous material in the event of fire - because of the emitted substances. In this case, the material dies out, unlike wood. Extrusion is usually more resistant to ignition, but decays more slowly. Its red-hot burning pieces will spread the flame, and in the case of a strong fire, the self-extinguishing property will not help in any way.

Expanded polystyrene with increased fire safety is designated by the letter "C". They contain flame retardants that protect against burning. Despite the fact that such a material is included in the G2 flammability group, it soon becomes corresponding to G3-G4.

Fresh foam gives off some styrene. At temperatures above 80 ° C, in addition to styrene, carbon monoxide, benzene, ethylbenzene and toluene are released.

The thickness of the sheet should be calculated correctly. Large numbers do not guarantee high reliability. It often happens that on thick sheets, microcracks and irregularities are more likely to form.

In European countries, it is not customary to use foam sheets with a thickness of more than 3.5 cm on the outer surfaces of buildings.

Determining the ideal sheet thickness will not be so easy: you need to take into account the climate, material density, wall thickness and the desired effect of thermal insulation

Remember that styrofoam has sound insulation properties. It is possible to reduce the spread of noise by using a more or less thick layer of material.

Applications of extruded polystyrene foam

It is used in frame construction according to LSTK technologies and methods of wood construction. In Europe, expanded polystyrene is preferred in 80% of cases when it comes to insulation for construction.

Penoplex is used for layered masonry, on roofs, for example, inversion, and in flooring. The ideal option for thermal insulation with polystyrene foam or ordinary polystyrene foam is to create a layer in the thickness of the building wall.

Insulation of the facade with foam is difficult due to the low adhesion of the material, low vapor permeability and problems with dew point calculation.

It often happens that the extrusion version is used externally, but only at the level of the base. For internal insulation, extruded and ordinary polystyrene foam may not be suitable due to a shift in the dew point and the associated inconveniences. Experts consider the use of expanded polystyrene inside a building without an intermediate layer inappropriate and risky.

Penoplex is often used in basements and at the level of the foundation, not least because mice do not gnaw on extruded materials. It will be just as useful when arranging the roof.

When installing insulation on any type of surface, dust cleaning must not be neglected so that adhesion is acceptable and thermal insulation is not broken

On balconies and loggias, penoplex will be better than ordinary foam. Usually these rooms are not spacious, so the extruded material will save space there. Large and thick sheets of foam, on average, 5 cm thinner than conventional foam.

The floors are insulated with both penoplex and ordinary polystyrene foam. The benefits will be approximately the same: whether in residential, technical or business premises.

In developed countries, extruded polystyrene foam is widely used in the construction of railways and highways. The material reduces the likelihood of freezing of the subgrade soil and further swelling of the soil.

Penoplex perfectly copes with the tasks that stand in the construction of sports surfaces, ice complexes, refrigeration units. A variety of material with a density of 38-45 kg / m³ is used in the construction of airfields and runways.

Spheres of construction where penoplex is used:

- Private, civil, industrial. Foundations, roofs, floors, walls, fences, utility lines, underground structures.

- In agriculture. In greenhouses, hotbeds, storage facilities, greenhouses, farms.

- Road. Repair, reconstruction and construction of runways, roads and railways.

Extruded polystyrene foam is used as the main material in refrigeration units, containers, refrigeration sections.

Edible and inedible food is packed in it. All kinds of sandwich panels used in architectural elements are made from this insulation.

Such an isothermal container using extruded polystyrene foam will be useful for fishing enthusiasts: the temperature inside will rise by less than 1 ° C per day

Penoplex is combined with different materials, and it has a multipurpose purpose:

- thermal insulation of pipelinesand sewerage: pipeline, expanded clay or gravel, penoplex, soil;

- insulation of the foundationunder groundwater pressure: geotextile, extruded polystyrene foam, waterproofing, foundation wall;

- external insulation of the foundation or basementa: soil, penoplex, waterproofing, wall, floor, polymer cement protection;

- pitched roof: waterproofing, lathing, extruded polystyrene foam, rafter system, drywall;

- flat roof reconstruction: gravel, filtration layer, penoplex, new waterproofing, old waterproofing, heat-insulating material, reinforced concrete slab;

- inversion roof insulation: gravel, filter layer, foam sheets, waterproofing, plate;

- thermal insulation of the ground floor: dense soil, sand cushion, waterproofing, extruded polystyrene foam, screed;

- creating a warm floor: finishing floor, penoplex, rough floor, logs;

- construction of heated floors: penoplex, heating pipes, separator layer, screed;

- wall cavity insulation: facing brickwork, pressure washer, wire anchor, extruded polystyrene foam, wall;

- internal wall insulation: drywall, guides, penoplex, wall.

For facade insulation, plaster and dowel mesh are required. But the main thing is that the dew point is not on the border of the insulation.

Otherwise, the plaster can collapse due to condensation, followed by thermal insulation. On the facades, it is more appropriate to use ordinary polystyrene foam.

Penoplex on the facade without a protective coating and correct dew point calculations will not last long, and the chances of making a mistake are very high

The operation of expanded polystyrene from the outside provides for their protection from ultraviolet rays and atmospheric phenomena. To do this, use plaster with the addition of cement.

The coating is made dense, without the slightest gaps. If neglected, direct and reflected rays of the sun can ruin the entire thermal insulation.

Conclusions and useful video on the topic

Thermal insulation of the floor with penoplex - analysis of the process:

Testing of different types of extruded polystyrene foam for strength:

Nuances of attic insulation with penoplex:

Extruded polystyrene foam has long been known as an effective thermal insulation material. It is denser than regular polystyrene foam and other types of foam. Consider all the positive and harmful properties of the extruded version and polystyrene foam in general.

In most cases, Penoplex should be fine. On the street and where the impact of external aggressive factors will be low, you can use ordinary polystyrene foam.

Write comments on the topic of the article. Perhaps you have some questions or information that will be of value to other readers. The feedback form is located under the article.