The problem of the lack of hot water is relevant not only in remote villages and townships, suburban houses of the private sector, but also in apartments of apartment buildings. That is why water heaters remain in demand and are in demand.

However, like all technical means, malfunctions appear in gas water heaters for certain periods of use that interfere with normal functioning. One of the most common problems is that the flame does not ignite in the gas column Bosch. In our article, we will consider the causes of this problem in various types of geysers and how to eliminate them.

The content of the article:

-

Features of ignition of Bosch gas water heaters

- Therm 2000 O series

- Therm 4000 O series

- Therm 4000 S series

- Therm 6000 O Series

- Therm 6000 S and 8000 S series

-

Why does the column not light up or go out?

- Problem # 1 - the flame won't ignite on the first try

- Problem # 2 - gas column wick decay

- Problem # 3 - speaker attenuation during operation

- Problem # 4 - the igniter of the gas column goes out

- Prevention of geyser malfunctions

- Conclusions and useful video on the topic

Features of ignition of gas columns Bosch

The flow-through gas water heater, which received the household name "gas water heater", is a technical a device in which water is heated with the help of energy released during the combustion of domestic gas.

Different models of the brand's water heaters, differing in functionality and design, also have a different type of ignition. Therefore, the reasons for the problems with the ignition of the flame may differ. But, in order to diagnose them, for a start, it is advisable to get acquainted in general terms with speaker device.

The basic scheme of a geyser used for all models produced by Bosch. The main difference between the models is the type of ignition and the location of the modulation control knob

Gas water heaters Bosch, despite the many modifications differing in the type of ignition and performance, it corresponds to the general assembly scheme and consists of the following elements:

- gas fittings - a curved metal tube through which gas flows and gas supply control elements;

- gas wick - device for ignition of a flame;

- burner - the place where the gas combustion process takes place;

- heat exchanger - a special tank through which a tube with running water passes; this is the place where the water is heated;

- combustion gas temperature sensors - a necessary element to monitor the correct working capacity of the column;

- button piezo ignition — required to start the column;

- column modulation knob - it is used to increase the power of gas supply;

- combustion products removal.

Columns of various series may differ in the type of ignition, a set of sensors and other structural elements. Next, we will get acquainted with the main ones, which are important in the case of self-diagnosis of a malfunction.

Series Therm 2000 O

Affordable version. Average productivity: in 1 minute it heats up to the required temperature of 10 liters of hot water. The device of this series is equipped with automatic ignitionpowered by batteries.

Also included in the design are sensors and sensors for gas supply control, flame control, traction control.

The Therm 2000 O model is mechanically controlled and limited by heating temperature. The modulation knobs on the front panel can be used to manually adjust the required gas force

Series Therm 4000 O

Models of this series are produced in 2 versions: with automatic ignition from batteries and piezo ignition. Different in power, they can heat from 10 to 15 liters of water per minute.

Geysers of this model have a number of advantages:

- uniform regulation of the column modulation, which allows you to maintain the set water temperature;

- heats water even at low pressure of the flow head (sufficient pressure - 0.1 Atm).

To distinguish the type of ignition in the designation of these gas water heaters, the letters are used B - columns with automatic ignition, and P - columns with piezo ignition.

The regulator of the power supply of gas in the column of the Therm 4000 O series allows you to more accurately set the water temperature. They are also equipped with the highest quality copper heat exchangers. Their serviceability has been increased to 15 years.

Series Therm 4000 S

Columns of this series are often installed in apartments with problematic chimney routing. The intake of air and the removal of combustion products takes place in the wall located on the outside coaxial chimney.

Also installed on the front side electronic control panel. This makes it possible to monitor the performance of the column (in the event of a violation on the panel information about the malfunction is displayed), and also set the minimum error of the water temperature - 1 degree.

The capacity is in the range of 12-18 liters of water per minute. The main disadvantage is that in the absence of electricity, the column will not work.

Columns of the Therm 4000 S series do not require a chimney to be installed. Due to the presence of a fan, forced draft is provided. Installing a coaxial chimney requires specialist assistance

Series Therm 6000 O

Used in this series of gas water heaters built-in hydrogenerator allows for automatic ignition of the flame when opening the tap with water.

On the front side there is a liquid crystal display that displays the temperature of the leaving water. However, this parameter is set mechanically by means of a regulator. Productivity of water heaters of this series is 10, 13 and 15 liters of water per minute.

The water heater of the Therm 6000 O series is equipped with HYDRO POWER technology, thanks to which there is no need for batteries or a piezoelectric element for ignition. The maintained water temperature is displayed on the front panel

Series Therm 6000 S and 8000 S

These models were made for public use (kitchens in restaurants and canteens, public baths, showers in factories, hospitals, factories). They are able to provide hot water up to 5 points without loss of degree. The display is used to make settings. Firing up this type - electric.

Several fans are used simultaneously to provide the operating power of the Therm 6000 S series gas water heaters. The Therm 8000 S models use condensation technology for efficient heating of the water flow.

Why does the column not light up or go out?

Periodic malfunctions in the operation of these devices are not associated with technical defects, but with depreciation during operation. Like any technical means, gas water heaters must be periodically carried out Maintenance.

List of major faults:

- it is impossible to start up from the first ignition attempt;

- attenuation of the wick;

- attenuation of the igniter when changing the power of the water supply by the tap on the mixer;

- weak heating of water;

- the igniter goes out periodically;

- weak water pressure through the gas column pipe system.

In the event of these malfunctions, it is not necessary to contact the master, because some of they can be solved independently by performing a certain algorithm of work and observing the rules security.

To solve the arisen problems, it will be necessary to remove the outer casing of the speaker. Regardless of the type, before removal, you must unscrew the fasteners

Problem # 1 - the flame won't ignite on the first try

To begin with, it is worth performing the most elementary measures - check the position valves for water and gas supply. If there is no supply of one of them, the work of the column is blocked automatically.

If batteries are used to start the column, then it is necessary to check their performance. And in case of discharge replace with new batteries.

Provided the problem persists, the next step is to check the chimney. Any ingress of debris and even a volumetric accumulation of soot on the walls of the chimney can lead to a malfunction - lack of draft. Keeping the chimney clean is a necessity that will prevent carbon monoxide from entering the interior.

If there is no thrust sensor that constantly monitors the level of thrust during operation, you can check its presence yourself. It is enough to use a burning match, which must be brought to the hole in the column. The absence of flame displacement will indicate clogging of the ventilation system. We turn off the column and clean the chimney.

Another reason could be weak water pressure. This is visually detected when opening the tap.

If the pressure is of sufficient strength, the problem may be:

- in the contamination of the mesh filter of the water system;

- in the pollution of the water system itself;

- finding a blockage in the mixer filter.

If the first problem can be easily solved by washing the strainer, then to solve the second and third problems, it will be necessary to unscrew the pipes at the inlet, after turning off the gas and water supply, and flush system. special cleaning agent.

To solve the problem of contamination of the mesh filter, it is necessary to remove the water unit, disassemble it, thoroughly clean and rinse the mesh

The next reason is weak gas pressure. This malfunction must never be rectified by yourself. You should definitely contact a specialist.

Incorrectly tuned igniter may be the reason for the malfunction of the column. This occurs when the gas pressure in the line does not match the type of igniter. In the case of low pressure, the gas required for ignition goes down. For a more stable operation of the ignition system, it is necessary to mount the electrode that generates a spark to the center of the burner.

Problem # 2 - gas column wick decay

The problem is when the wick goes out when working in a Bosch gas water heater, it may be caused by a weak gas supply. This problem can be caused by dirty ignition tube dust particles and carbon deposits.

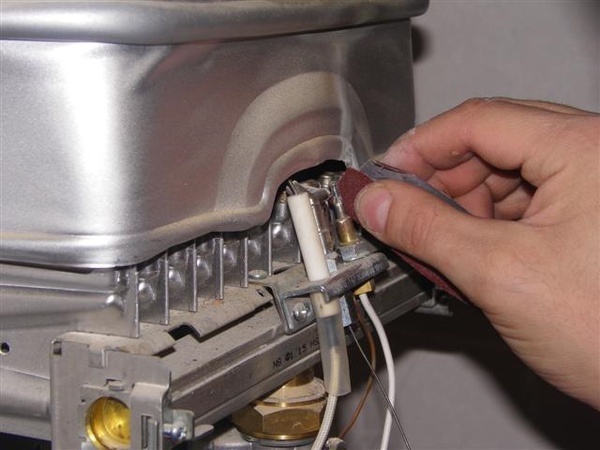

To solve it, you need to remove the gas column housing and correctly disconnect the ignition pipe. To clean the inside of the tube, it must be blown out. The edge on which carbon deposits have accumulated is cleaned with emery paper or other abrasive material.

In the event that, when switching on, pops uncharacteristic for normal operation appear, the position of the ignition wick flame should be checked. Pops appear when the fire is not immediately ignited, due to which excess gas accumulates. This problem should be fixed immediately by calling the wizard

When reinstalling, it is necessary to restore the tightness of the pipe, connecting it to the required limit with the gas supply pipe.

Problem # 3 - speaker attenuation during operation

There are situations when the brand's gas water heater Boschsuddenly goes out and stops working, it is necessary to identify how long after ignition this happens.

If the shutdown immediately after starting (after 3-5 seconds), then most likely the matter is breakage of the ionization sensor. In this case, it is necessary to check the wiring between the sensor and the control board and, if it works, replace the sensor.

When the column goes out after several minutes of operation, this may be due to:

- weak gas thrust;

- the sensitivity of the alarm relay.

You can check the gas draft in the entire gas system by turning on the gas stove. If the gas supply is visually normal, then the problem is in the gas supply system to the column. To solve it, you need to call a specialist.

Also, the draft problem can be caused by a blockage of the chimney or by the heat exchanger tubes clogged with scale.

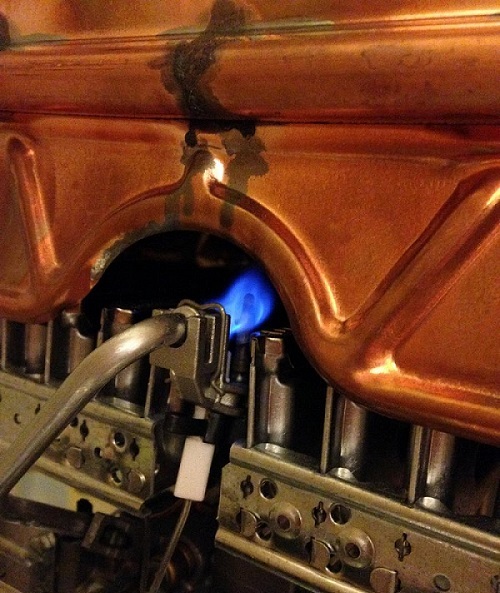

When scale, soot and soot accumulate on the walls of the heat exchanger, the color of the burning flame changes. Instead of blue, it turns yellow. To eliminate the malfunction, it is necessary to remove the casing and clean the heat exchanger.

Another reason could be broken functionality alarm relay. To do this, you need to open the windows and ventilate the room with high quality. Then try to start the device again. If the column is working again, then the matter is precisely in the sensitivity of the relay. This element needs to be replaced.

Mixing a stream of hot water with cold water can also cause column attenuation. In order to eliminate this problem, it is necessary to perform the adjustment correctly.

Problem # 4 - the igniter of the gas column goes out

One of the important elements of the water heater is the igniter. It is necessary for the smooth functioning of the device, therefore it must work continuously.

To understand why the gas water heater goes outigniter, you need to check the following probable reasons:

- thermocouple malfunction;

- the appearance of external air flows;

- chimney pollution.

To stop the unstable operation of the gas column, an element is used - thermocouple. This is a safety device, the function of which is to timely shut off the gas flow. If the igniter goes out, it shuts off the gas supply.

Thus, when a thermocouple burns out under prolonged exposure to fire, its tip becomes loose, its physical properties are lost, and an involuntary triggering of the protective function occurs. The defective part must be replaced.

Another reason for insufficient heating of the thermocouple is the clogging of the gas nozzle orifice with dust. After completing the cleaning, the operability is restored.

When eliminating the problem of extinction of the gas column igniter, you need to be focused and soberly assess your capabilities. If you are unsure of your abilities, it is better to consult a specialist.

In the event of improper ventilation, the resulting air currents can blow out the pilot burner. It is important here not to confuse this phenomenon with a lack of draft due to fouling. To fix the problem, you need to check that the protective cover of the column is correctly attached and that there are no external sources of air exposure.

It should be remembered that modern devices contain a lot of electronic devices, sensors and modules. A separate malfunctioning of any of them can lead to a failure in the operation of the device. Special equipment is required that can identify the malfunction.

Prevention of geyser malfunctions

In addition to troubleshooting, you need to know how to properly disassemble the gas column. These skills are required to conduct DIY maintenance. Why do you need to know not only the constituent elements, but also the sequence of actions when disassembling the column.

You can complete all the maintenance points of the gas column without the help of a wizard. The main thing is to follow the sequence of actions and do everything carefully enough.

Periodic maintenance throughout the entire operational life of the gas water heater will contribute to correct operation.

Annual cleaning is recommended in the technical documentation by the manufacturer. After all, it is the lack of cleaning with prolonged use that can lead to all of the above problems.

Conclusions and useful video on the topic

This video shows how to properly clean the ignition tube:

In order to understand the complete step-by-step disassembly, just watch this video:

Gas water heaters Bosch are widely used to solve an important domestic problem - the lack of hot water. In order for these devices to operate smoothly for longer, they need to be serviced. And malfunctions arising during operation can be eliminated independently, it is enough to know the correct algorithm of actions.

Do you want to tell about your own experience in diagnosing and repairing a Bosch brand gas water heater? Share the intricacies of troubleshooting, add unique photos - the feedback form is located below.

If a flame does not light up in your Bosch gas water heater and you cannot find the cause in any way, and you don’t want to call a specialist, ask our experts and other site visitors for advice.