Bottled gas is referred to as a "summer cottage" fuel supply option and is used where it is not possible to connect to the gas main. If one cylinder with propane-butane is enough for the stove, then several have to be connected to service the boiler.

It is simple to use tanks filled with liquefied gas, but problems can arise in winter - the gas freezes or falls out in the form of condensate. As a result, the stove or boiler ceases to function. Let's figure out how to insulate a gas cylinder outside in winter so that the fuel supply to the house is stable.

The content of the article:

- Rules for installing gas cylinders

-

Methods for insulating cylinders on the street

- Method # 1 - thermal insulation materials

- Method # 2 - heating cable

- Method # 3 - electrical devices

- Alternative method - warm room

- How to warm up gas when it freezes?

- Conclusions and useful video on the topic

Rules for installing gas cylinders

The need to heat gas cylinders arises when the low outside temperature cools them, which slows down the production of gas. As a result, the working volume of fuel is reduced, it is necessary to produce more

refueling.In addition, there is a risk condensationwhich also makes it difficult for gas to flow to burners - for example, a stove or boiler.

The traditional way of installing gas cylinders is in a metal cabinet (casing) on the street, in the immediate vicinity of the home gas equipment to which the connection is made

The metal walls of the cabinet protect the cylinders from mechanical damage, wind and moisture, but do not heat them. The air temperature inside the enclosure is the same as the outside temperature. The cold is transferred to the body of the tanks and cools the fuel, which is in a liquid state. At low temperatures, the transition to the gaseous state is difficult, condensate falls out, the properties of the fuel change.

The most negative consequence of the cold is the stoppage of the fuel supply to the house, which can block all economic activities.

Sometimes the consequences of exposure to cold are obvious: the bottom of the cylinders is covered with frost. This does not mean that the gas will necessarily stop flowing to the stove, but it signals the possibility of such an outcome.

For filling cylinders, two components are used - butane and propane. They differ in characteristics: liquefied butane loses its properties at low temperatures, and propane, on the contrary, does not work in the heat.

By combining the components in standard proportions, an optimal mixture is obtained for use in the climatic conditions of a particular region. For more information on the proportions of different types of gas in the mixture, see GOST 20448-90.

Considering that the temperature amplitude, depending on the warm or cold season, changes sharply, two types of gas are used - winter and summer. They differ in the percentage of propane and butane

The regulatory documentation does not say anything about the technologies of cylinder insulation. For example, in SNiP 31-02 - the main document on the gas supply of a country house - the requirements are set forth only for the installation of fuel sources, there is no information on thermal insulation. That is why employees of the gas service recommend not to insulate the cylinders.

Methods for insulating cylinders on the street

To save gas mixtures in working order, the cylinders are insulated in all sorts of ways. Some are effective, others are useless, and still others can be life-threatening.

We will find out the best way to insulate a gas cylinder on the street in winter, so that there are no problems with the fuel supply, and the residents do not have to worry about their own health.

Method # 1 - thermal insulation materials

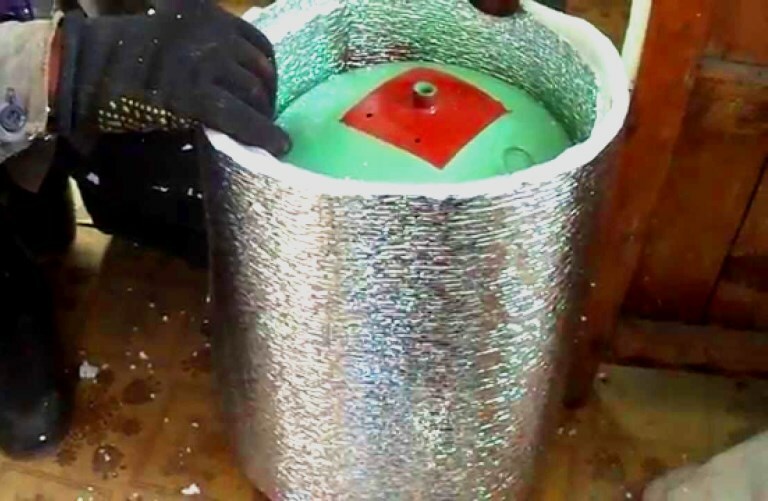

Despite the bans of the gas service employees, the owners of private houses often "wrap" the cylinders with all kinds of insulation: mineral wool and glass wool, sheets of expanded polystyrene and foamed rubber - that is, household heaters that are actively used in the construction of houses, erection of roofs, flooring floors.

One of the options for "warming" a gas cylinder. The metal tank is wrapped with insulation in the hope that it warms up and stops freezing at low temperatures

In fact, wrapping containers with insulation is a frankly primitive and ineffective way to warm gas in cylinders.

Why doesn't this method work? The point is that insulating blankets are good if the object generates heat on its own.

Conventionally, such objects can be attributed to the human body or a heated room: energy is constantly converted into heat, and the task of heat-insulating materials is to save it.

Gas cylinders do not generate any heat, therefore, even wrapped in three layers of mineral wool or expanded polystyrene, they remain the same cold. Accordingly, the liquefied fuel inside does not change its characteristics - that is, no positive changes occur.

Conclusion: if the gas cylinder does not generate heat on its own, this function should be performed by a conventional "heater" - a device that receives electrical power.

Let's move on to heat-insulating technologies that can really change the situation and warm up gas in cylinders in winter.

Method # 2 - heating cable

Provided that a serviceable vessel is used, and its installation is made in accordance with all the rules, use the heating of a gas cylinder with an electric heating cable.

There are many options for thermal insulation systems - from purchased ones self-regulating cables to homemade products assembled from a wire and a thermostat.

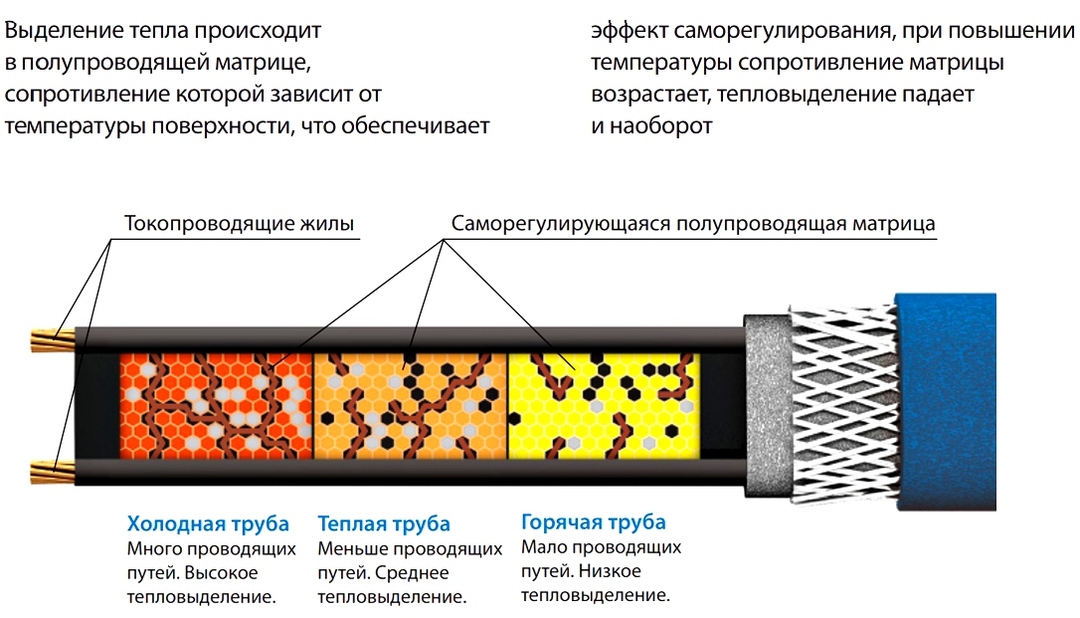

The principle of operation of self-regulating cables is simple: they generate heat depending on the ambient temperature. The colder it is outside, the more heat the electric cable gives off.

To be able to adjust the temperature, the wire is connected to the thermostat. Mechanical models can be used to manually set operating parameters. Self-regulating cables work in automatic mode and do not require constant monitoring.

To create a homemade insulation system for 3 cylinders, you will need:

- 9 meter electric wire 3 * 1.5;

- 3 thermostats - 1 for each cylinder;

- 25 m of thermal insulation material "thermofol";

- 3 m PVC film;

- 3 m IR film;

- 12 ties for fixing the insulation;

- mounting kit.

First, the balloon is wrapped with ordinary PVC film, then with an infrared film, to which a supply wire with a thermostat is connected. To keep warm, a “thermofol” cover is put on top and fastened with ties.

The advantages of a home-made "heater" are constant heating of the cylinder when the air temperature becomes low. When heating is not needed, it is enough to remove the plug from the socket

The method cannot be called the safest, because the proximity of electrical cables and a gas reservoir is risky under certain conditions.

But if you follow the installation rules and safety precautions, the device can be used throughout the entire cold season.

Method # 3 - electrical devices

The principle of heating with a heating cable was taken into account, and in connection with the unquenchable demand for gas cylinders, the most enterprising manufacturers began to produce electric "heating pads". They guarantee high-quality thermal insulation of the cylinders and the preservation of the properties of the gas, in which it does not lose its working functions.

There are two effective and safe devices:

- thermo blanket for a gas cylinder;

- heater.

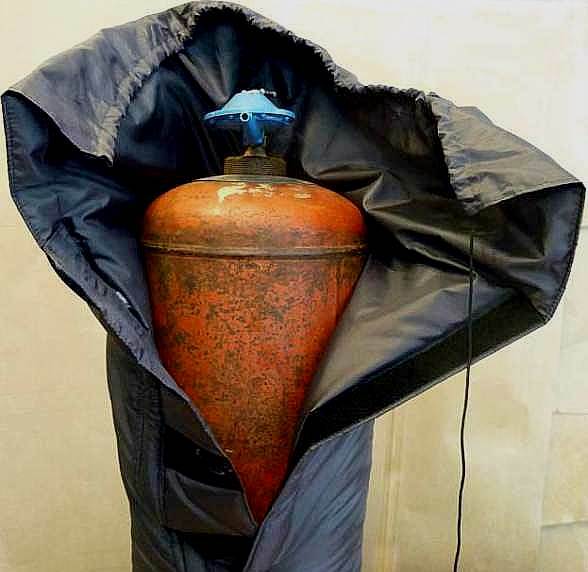

Thermo blanket designed to heat standard 50 liter gas cylinders. It is estimated that in the cold season it allows you to save up to 30% of liquefied fuel due to the fact that evaporation of propane is stable, condensate does not fall out and refueling has to be done much less often.

The cover is sewn from durable synthetic materials with a padding polyester insulation, an electric cable in a silicone sheath is placed inside, distributing it evenly over the entire area. For fastening use "Velcro"

Electric blankets vary in size. In addition to standard covers for cylinders, products are also produced for heating gas tanks. Maintained temperature - +40 ° С (± 5 ° C), power - about 160 W. Energy consumption is economical: when the outside air temperature is -15 ° C, the blanket consumes no more than 80 W / h.

Electric heater differ from the thermo blanket in size: it does not completely cover the balloon, but only its lower part. But the principle of operation is the same: electricity generates heat, which is continuously transmitted to the cylinder body.

An example of a heater for a gas cylinder is the Polish model Koma PG 2. Advantages: the ability to use 95% fuel, uniform and complete evaporation, economy

Heaters are produced for 27 and 50 l cylinders, heating temperature - +40 ° С. The degree of protection is IP 44, that is, the product can also be used outdoors, provided that the cylinders are enclosed in a metal cabinet.

Alternative method - warm room

In order not to look for ways to insulate tanks installed on the street, you can do an easier thing - transfer the cylinders to a heated room. In comfortable conditions, the cylinders "give" almost the entire volume of fuel, so refueling should be done less frequently, and there are no problems with the movement of gas inside the supply system.

The main thing is to follow the rules of installation and operation:

- the balloon is installed vertically;

- the vessel must be accessible for maintenance, inspection or replacement;

- the distance from the tank to the stove is not less than half a meter, to the radiator or stove - not less than 1 m;

- if the firebox is located opposite, the distance is increased to at least 2 m.

One of the main requirements concerns the choice of the room for installation.

Do not install in bedrooms, living rooms or other living rooms. The cylinder is installed in the room where the gas-consuming equipment is located - the stove, that is, in the kitchen

A container with liquefied gas is usually installed either right next to the stove, or in an adjacent non-residential area, by throwing the fuel supply hose through the hole in the wall.

The cylinders must not be kept in basements, basements and any other rooms that are not equipped with ventilation or a ventilation system.

And remember an important condition: if your house has more than 2 floors, the placement of any gas containers inside the building is prohibited!

How to warm up gas when it freezes?

Let's consider the last questions: what to do if the gas is already frozen and how is it allowed to heat the gas cylinder in winter?

If you notice that the vessel body covered with frost, the flow of fuel to the burners is difficult or has completely stopped, you can try to warm up the cylinder.

In no case should open flame sources be used - bring lighters, burners, blowtorches, a burning torch, etc. to the body. As a result, an explosion can occur with unpleasant consequences.

The result of the "meeting" of a gas cylinder with an open fire. The sudden heating causes an increase in pressure, expansion and a powerful explosion that ruptures the metal shell

Methods that can be used for disposable, emergency heating:

- Pour hot water over the vessel or use hot steam. The procedure must be performed slowly, with the valve closed. At the end it should be purged reducerto remove moisture.

- Use a chemical or saline heating pad, as is done in the field. Chemical heating pads are disposable and last 6-7 hours. Salt ones are reusable, but the heating temperature is up to +50 ° С, while the recommended one is +40 ° С.

- Temporary transfer of the vessel to a warm room. Heating will be more efficient if the cylinder is placed near the radiator for a short time.

The above measures will not save the fuel source from subsequent freezing, but they can help out in an emergency.

Conclusions and useful video on the topic

The simplest insulation with a self-regulating cable:

An example of a homemade heater - video instruction:

Cylinder box heating option:

The question of whether it is possible to heat a gas cylinder on your own remains open. If you determine that the fuel supply system has stopped working due to the cooling of the vessel, we recommend using safe and authorized methods, taking into account all requirements.

Otherwise, you can "earn" penalties from the gas service or, even worse, endanger the lives of residents.

Please share your experience if you have ever heated a cylinder in the winter. Leave your comments, make suggestions - the contact block is located under the article.