For the installation of gas pipelines, pipes made of various materials are used: HDPE, steel and copper. Polymer products are used only for underground laying; steel wiring is mounted inside houses and apartments.

Today, when the quality of the metal has improved and it became possible to produce products of the required thickness and length, copper pipes for gas are increasingly being installed. They are excellent for low pressure gas pipelines and have suitable characteristics in terms of strength, flexibility and wear resistance.

If you decide to assemble an in-house gas pipeline yourself, it will not be superfluous to get to know properties of copper pipes and pressfitting, learn more about assembly methods and requirements for products.

The content of the article:

-

What are the requirements for copper pipes

- Norms and regulations of standards

- Recruitment recommendations

- Features of the assembly of a copper gas pipeline

-

Pipe Installation Instructions

- How copper is cut and bent

- Connection methods: crimping and soldering

- Conclusions and useful video on the topic

What are the requirements for copper pipes

Companies that manufacture products for the installation of gas pipelines never use copper alloys with other materials in the production, as quality is lost. The purity of the metal should not be lower than 99.9%.

Grades used for the manufacture of pipes:

- at domestic enterprises - М1, М2, М1р, М2р;

- foreign analogues - Cu-DHP.

Depending on the production method and physical properties, finished products are divided into 3 categories: soft (R - tensile strength 220 mPa), semi-hard (R - tensile strength 250 mPa), solid (R - tensile strength 290 mPa).

For the installation of gas pipelines, it is recommended to take pipes of solid or increased hardness. Soft ones are only suitable for connecting to the network of gas equipment - boilers, stoves, columns

It is noticed that long-term storage affects the quality of copper - it becomes harder. You can return the former qualities by annealing. In order not to carry out additional restoration measures, we do not recommend buying assembly products with a stock.

Do not use pipe products with a wall thickness of less than 1 mm. Thin pipes are not suitable for the requirements, they can be damaged during the assembly process - when bending or crimping

According to the manufacturing technology, gas pipes are divided into 2 groups:

- welded - in the production of which welding is used, therefore, there are seams;

- seamless - monolithic, seamless products.

It is preferable to use the second group, since the seams will always be areas from the risk zone, that is, they will have reduced characteristics in terms of tightness.

Apart from the usual copper pipes and fittings they also produce products with an outer sheath made of polymeric materials - PVC or foamed polyethylene. The advantages of such products are additional external protection and a kind of disguise.

Copper products are often used as design elements, so they place the pipeline in a conspicuous place and assemble using stylized fittings and fasteners

Sewing a copper gas pipeline into a concrete wall or hiding it behind drywall is prohibited by law.

Norms and regulations of standards

The gas pipeline belongs to structures that pose a potential danger to the residents of the house, therefore production of products, and installation work are subject to the requirements set out in the regulatory documentation.

The standards of 1987 - SNiP 2.04.08-87 became the basis for modern codes of practice.

Now the information of interest on copper pipelines can be found in the following documents:

- SP 42-101-2003 - on the design and construction of gas distribution systems;

- SNiP 42-01-2002 - norms and rules of the State Registration Service;

- OST 153-39.3-051-2003 - GDS operation.

Along with the main documents, additions and clarifications should be studied that appear periodically in connection with the development of technologies and the release of new products. Suppose SNiP 42-01-2002 in 2011 was changed and supplemented with materials, including requirements for copper products. New edition - SP 62.13330.2011.

If you have entered into an agreement with the gas service for the installation and maintenance of the gas pipeline, then employees must purchase materials and assemble the pipeline in accordance with regulatory documents

The general requirements should be added to the rules for installing structures made of copper gas pipes. A sample of such a document is STO "Design, installation and operation of gas pipelines from copper pipes at gasification of residential and public buildings ", where the nuances of the gas pipeline assembly and the requirements for pipes.

You can learn more about the requirements for copper pipes and fittings from the following documents:

- GOST 617-90;

- GOST 859-78;

- GOST R 52318-2005;

- EN1057 - European standards;

- GOST R 52948-2008;

- GOST R 52922-2008;

- GOST R 52949-2008.

We warn you that if you use products that do not meet legal requirements, the operation of the gas pipeline becomes dangerous.

Recruitment recommendations

Involving amateurs in installation work is not the best solution. We advise you to contact a company that has been engaged in the installation of in-house gas pipelines for a long time and has experienced gas system installers as part of it.

If you decide to independently engage in welding, soldering or crimping copper pipes, the work should be supervised by a master with experience and admission to such work.

The qualifications of employees are documented, so you have the right to require a certificate.

Specialists who have received the 4th grade and higher according to OK 016 are allowed to soldering or welding. The conclusion is given by the attestation commission, based on the rules RD 03-495-02 and PB 03-273-99.

Pressure testing can be performed by workers with grade 3 and higher, who have experience in assembling copper gas pipelines and have passed certain tests. In order to get admission to practice, the contractor must perform at least 3 high-quality press fittings tested by the commission. Control of the work performed is determined according to the rules of SNiP 3.01.01.

Features of the assembly of a copper gas pipeline

The assembly and connection of copper pipes for an in-house gas pipeline differs from installation work carried out with other types of products - for example, polymer or steel.

For soldering copper elements, hard solder is used. It differs from the soft one in that it has a higher melting point - from + 600 ° C and above

Solid solder is used without flux; popular materials include PMFOTsr6-4-0.03 and PMFS6-0.15 - copper-phosphorus compounds.

If soldering is used advantage for in-house wiring, then at the entrance to the house, where large-diameter pipes are mounted, the connecting work is performed by argon-arc or gas welding.

Other rules for installation work on the device of a copper gas pipeline:

Image gallery

Photo from

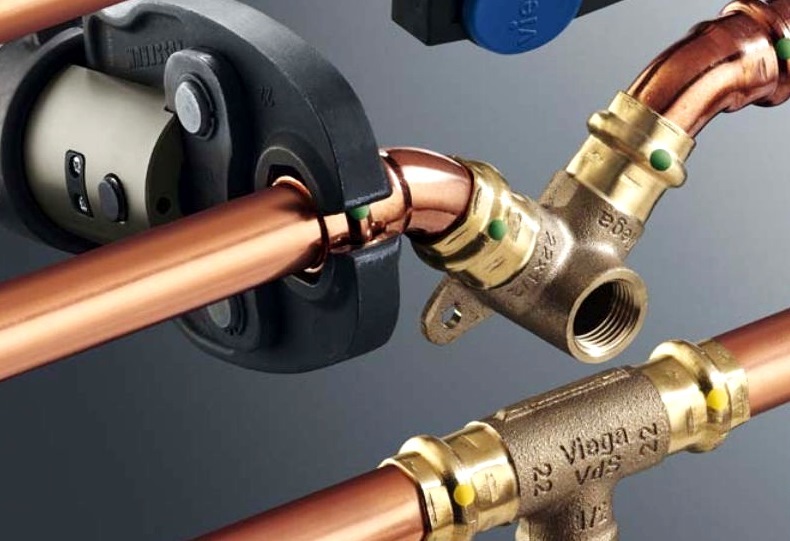

To distinguish the fittings for the gas pipeline from others, they are marked with indelible paint in yellow or green, and yellow O-rings are inserted from the inside.

Ideally, the connectors should be made of the same material as the pipes - copper. Fittings are fixed by crimping; for pipes with a diameter of 54 mm above, other connection methods are used

Direct contact between copper and steel pipes is prohibited, as corrosion occurs as a result of the interaction of metals. To connect dissimilar parts, it is recommended to use dielectric spacers or brass products

According to the rules, a copper gas pipeline must be located above the floor at a height of at least 0.6 m. fittings - valves, plugs, taps - should be installed in a visible place and provide free access

Part marking in yellow

Copper fittings for connection

Connection of copper and steel elements

Place of installation of a copper gas pipeline

Do not use plastic brackets or other polymer fasteners. If grooves are cut out for arranging internal wiring, then they cannot be closed from the outside, and the space around the pipes in the groove must be free.

Pipe Installation Instructions

The gas pipeline installation includes 3 stages:

- design;

- preparation of pipes;

- mounting.

At the end, a test run is carried out and the pipeline is checked for leaks.

We will analyze the main methods of preparing parts for installation - bending and cutting, as well as two popular ways of connecting pipes - pressing and soldering.

How copper is cut and bent

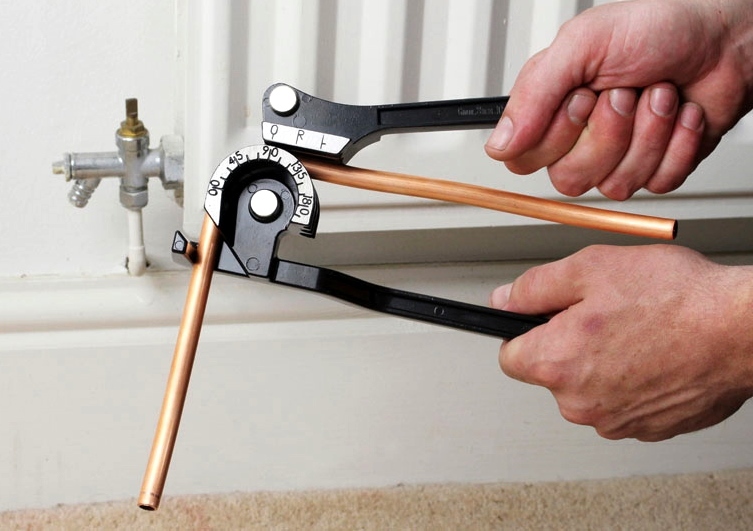

Before the start installation works it is necessary to prepare the pipes. Completely straight gas pipelines are rarely found; more often they consist of combinations of straight and bent elements. This means that the pipe material must be cut, and some parts must be carefully bent at a predetermined angle, 90 ° or blunt.

For cutting, you can use a hacksaw for metal, a circular electric saw, but a pipe cutter is considered the most acceptable tool.

Pipe cutters are distinguished by the fact that they make a perfectly straight cut perpendicular to the direction of the pipe. Cutting is done quickly and accurately, and the smooth edge of the workpiece does not require additional processing

During the cutting process, make sure that the pipe does not deform - any bulges, cracks or dents will pose a threat to the tightness of the gas pipeline.

Bending can be done cold and hot. The first is used for thin pipes, more often used in everyday life, with a diameter of up to 22 mm. The hot method is used for products with a large diameter. The pipe is heated by filling the fold with sand. This is necessary so that there are no creases.

For cold bending, pipe benders are used - special machines. In everyday life, spring devices are used, into which thin pipes are first inserted, and then they are carefully bent

For heating, experienced craftsmen use a burner, acetylene-oxygen or acetylene-air. Working temperature - from + 650 ° С. The readiness of copper is determined by its shade: as soon as it becomes dark red, it can be bent. The procedure is carried out quickly, but neatly.

Connection methods: crimping and soldering

If you have time, skills and experience, you can try to solder copper pipes yourself. This method is longer than crimping, but it is inexpensive and reliable.

Soldering should be done under certain conditions: in a ventilated room, at a temperature of -10 ° C to + 40 ° C, and better - at room temperature.

Procedure:

- Preparation of parts: cutting and bending of pipes, flaring and calibration, if necessary.

- Cleaning the ends of the segments to be joined, eliminating any defects.

- Inserting the end of one pipe into the flared end of the other.

- Heating up the soldering area to the melting point of the solder.

- Solder feed into the gap between two parts.

- Cooling the soldering area and cleaning the joint to a shine.

After soldering, a diagnosis is made. System tightness testing is carried out by a special commission.

The connection using press fittings is a reliable modern method, the main advantage of which is the fast assembly speed of the gas pipeline.

Instructions for connecting pipeline elements by pressing:

Image gallery

Photo from

All elements of the future gas pipeline for internal wiring must match in diameter and wall thickness. Copper and brass fittings and adapters can be used for connection

When assembling, it is impossible to use copper products intended for water supply or other communications. Products for the gas pipeline are marked with yellow markings - dots, stripes, stamps

When performing pressing, special press tongs are used. The universal tool is completed with a set of heads for pressing fittings of various diameters

Before connecting pieces of copper pipes with fittings, they must be prepared - cut into the desired fragments and, if necessary, bent according to a previously prepared diagram at a given angle

The ends of the segments connected by fittings must be smoothed using a special tool to make the connection tighter.

You need to take a fitting that is suitable in diameter and put it on the prepared end of the pipe. For accurate crimping, a strip is drawn along the edge of the fitting with a black marker

The head is put on the fitting, fixed and pressed - press the lever or handle. The procedure takes place in automatic mode

For an initial check, you can inspect the place of crimping - the copper elements should touch tightly around the circumference, when you try to disconnect them with effort, keep the position

Step 1 - buying pipes and fittings

Step 2 - labeling products for gas

Step 3 - preparing the crimp tool

Step 4 - preparing pipes for pressure testing

Step 5 - stripping pipe ends

Step 6 - joining pipe and fitting

Step 7 - crimping the connection with press tongs

Step 8 - checking the tightness of the connection

If the hand is full, then when assembling a small fragment, first connect several elements with fittings, and then press them in one go. It is recommended to assemble the indoor gas system in parts - first, separately complex sections with a large number of bent elements, and then between them.

Collet (crimp) fittings are also used in the connection of copper pipes, which are practically not used in the assembly of gas lines due to the not too high reliability of the collapsible assembly. The most reliable are the joints formed by soldering.

However, to implement brazing copper pipes experience and appropriate tools are required: a blowtorch for a low-temperature connection, a propane or acetylene torch for a high-temperature connection.

Conclusions and useful video on the topic

An example of installing a copper gas pipeline in a country house:

How to perform crimping with copper fittings:

On the advantages of replacing pipes with copper ones:

A home gas pipeline made of copper pipes is reliable and aesthetically pleasing. It is considered one of the best options for installation in a private house or apartment. But, when planning to install a copper structure, do not forget about safety: if you do not have experience with pipes, it is better to entrust the installation to specialists.

Do you want to share your own experience in assembling copper pipes? Do you have valuable information on the topic of the article that can be useful to site visitors? Please leave comments in the block below, ask questions on points of interest and controversy, post a photo.