Earlier, when installing industrial and household communications, pipes made of cast iron, steel, copper were used. With the advent of polymers that are not inferior to metal products in terms of strength, wear resistance and inertness to impact chemicals, pipe material began to be produced from polypropylene, polyethylene, polyvinyl chloride, polybutylene and NS.

Polyethylene pipes for gas pipelines have proven themselves well - they are practical, flexible, lightweight, and significantly facilitate transportation and installation. If you decide to gasify a private house, then it will not be superfluous to learn in more detail about the technical characteristics, conditions and methods of installing polyethylene pipes.

The content of the article:

-

HDPE pipes for gas pipeline

- Types and sizes

- Specifications and markings

- Advantages and disadvantages of polyethylene

-

Installation of polyethylene gas pipes

- Overview of pipe connection methods

- Rules for the arrangement of the HDPE gas pipeline

- Conclusions and useful video on the topic

HDPE pipes for gas pipeline

Low-pressure polyethylene is used not only for the manufacture of gas pipeline elements. It is also used for the device of other communications - water supply, sewerage, protective technical pipelines. Types of pipes differ in composition, characteristics, marking.

Let's dwell on products for gas transportation, the production of which is subject to the requirements GOST R 50838-2009 (outdated edition - GOST R 50838-95).

Types and sizes

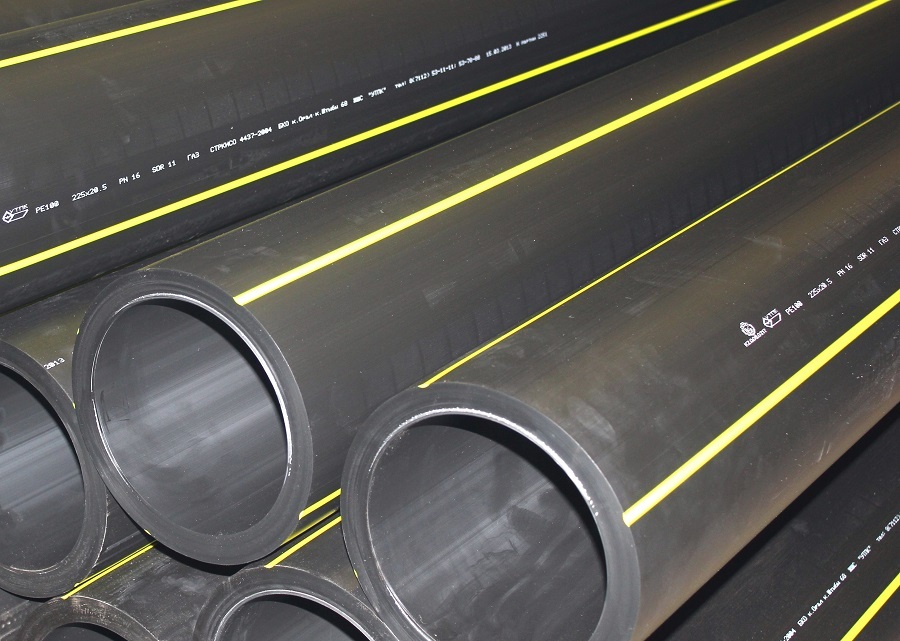

Polymer pressure pipes for gas can only consist of polyethylene or be reinforced with additional layers.

Thus, there are three types:

- polyethylene, including those marked with yellow stripes;

- polyethylene with coextrusion layers located inside or outside;

- polyethylene with a thermoplastic protective sheath, which must be removed before installation.

All types of pipe material are intended for the transportation of various gases that meet the standards of GOST 5542 and are used as raw materials or fuel for industrial and domestic needs. Limitations for the use of pipelines are accepted: max slave. pressure - 1.2 MPa, max work. temperature - / + 40 ° С.

Pipes are sold in packages of various types: products with a diameter of 200 mm and above - only in straight sections, thinner ones - in coils or coils

Industrial products are delivered in sections of 5-24 m, multiples of 0.25 m, but more often of medium length, convenient for transportation with special equipment - for example, 13 m. the bay assumes different lengths, but more often you can find skeins of 200, 500, 700 m.Production of products of other lengths is also possible, but only by agreement with customers.

Depending on the wall thickness and slave. pipe pressures are divided into two types:

- PE-80. Wall thickness - 2-3 mm, slave. pressure - 3-6 MPa; suitable for gas and water pipelines;

- PE-100. Wall thickness - 3.5 mm, work. pressure - 8-12 MPa; it is an improved version of PE 80, characterized by heat resistance and increased density.

PE (variants - PE, PE) in the name is polyethylene, numbers 80 and 100 are polyethylene grades.

From the point of view of economic feasibility, the PE 100 brand is used when installing a high-pressure gas pipeline or in special cases - for example, for the reconstruction of an old worn-out line or the construction of experimental branches with a pressure of 0.6 MPa and higher.

Specifications and markings

Factory-made polyethylene pipes are subject to the requirements listed in GOST R 50838-2009. Among them are recommendations for appearance and technical properties.

Externally, the pipes should have a smooth surface, free of bubbles, cavities and cracks. Foreign inclusions visible to the naked eye are also excluded. Only slight waviness and longitudinal stripes are allowed

In terms of color, the possibility of variability:

- PE 80 - yellow;

- PE 100 - yellow, orange, black with yellow / orange stripes evenly distributed.

The document prescribes norms and characteristics such as resistance at constant internal pressure, elongation at break, resistance to crack propagation, thermal stability, and weldability.

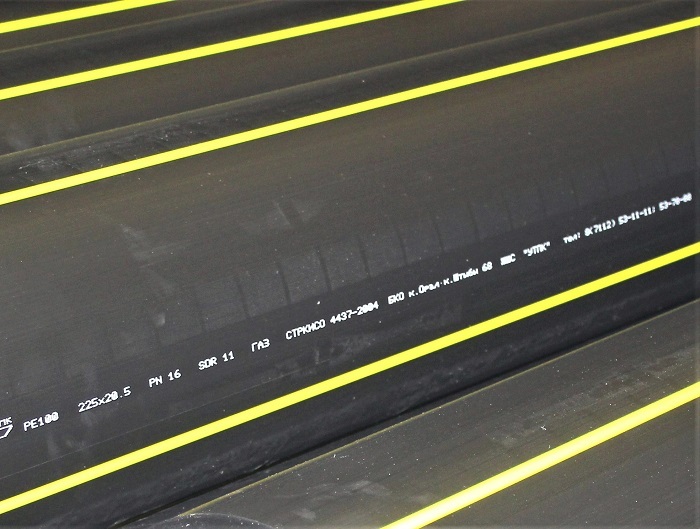

Manufacturers apply marking in various ways: thermal embossing, color printing, thermal embossing with dyeing. The interval between characters is no more than 1 m

The marking should not affect the quality of the material, that is, provoke cracks, swelling, etc.

Letters and numbers should be easy to read, legible and understandable. The obligatory ones include:

- manufacturer's trademark or name;

- pipe symbol;

- date of manufacture;

- nominal diameter / wall thickness;

- appointment;

- GOST.

The rest of the data is the name of the country, the batch number, etc. - applied at will.

For example, let's analyze one of the samples:

Sphere LLC PE 80 SDR 11 - 150x10.5 GAS GOST R 50838-2009

- LLC "Sfera" - manufacturer

- PE-80 - type of polyethylene pipe

- SDR 11 - Standard Dimension Ratio

- 150 - diameter

- 10.5 - wall thickness

- GAZ - appointment

- GOST R 50838-2009 - normative document

By marking, it is easy to determine whether the pipes are suitable for domestic or industrial use, whether they correspond to the purpose and diameter.

Advantages and disadvantages of polyethylene

Due to the advantages of polyethylene, it is used to transport such a dangerous type of fuel as natural gas.

The main advantages include such qualities as:

- Electrical insulating properties. Polyethylene is a full-fledged dielectric, does not conduct electric currents. No grounding is required during installation.

- Resistant to aggressive chemicalsthat may be contained in the soil or in production.

- No corrosion, the ability to use in a humid environment.

- Plastic, thanks to which the pipeline is protected from ground movements, expansion during freezing, water hammer.

- Passivity to the transmission of acoustic vibrations.

The degree of wear resistance is quite high - manufacturers of modern PE pipes for gas give a guarantee from 30 to 50 years.

One of the significant advantages is the light weight of the pipes, which simplifies transportation, storage and installation. Often there is no need to use special equipment, which reduces the overall cost of gasification of facilities

The disadvantages include such a property of polyethylene as photodestruction. This means that the material quickly ages and crumbles under the influence of ultraviolet radiation. To somehow improve the resistance of polyethylene to solar radiation, black pigment is added to the material as a stabilizing agent.

Other disadvantages include a small operating temperature range of the transported substance, oxygen permeability, and the dependence of technical characteristics on external temperature.

Due to the listed disadvantages, gas pipelines made of polyethylene pipes are used only in the ground, metal analogs are installed in open areas.

Installation of polyethylene gas pipes

It is prohibited to independently install a gas pipeline to a private house or industrial facility. This should be done by an organization that has a license and a license justified by the right to carry out this type of work. She also carries out maintenance in the future - checks, tests or repairs.

Usually a team of workers is involved in the construction of the main gas pipeline according to a pre-developed plan. Almost always, you cannot do without heavy equipment and special tools.

First, they receive permission to carry out construction work, create a package of design estimates and build a geodetic alignment axis. Then they carry out preparation, which includes route planning, earthworks, transportation and laying of pipes, installation welding tool. And only then proceed directly to the installation work - pipe laying and welding.

Overview of pipe connection methods

Polyethylene differs in that when heated it changes its properties and melts. This quality is used to create permanent gas pipeline connections - that is, for pipe welding.

There are two welding methods:

- butt, without the use of shaped elements;

- electrofusion, with the use of electroresistor fittings.

The first method is used for industrial purposes, for welding large-diameter pipes, the second - for creating household gas branches from the central highway.

If a detachable connection is required, then the third method is used - compression. The ends of the pipes are connected with compression fittings, which can be removed or replaced if necessary.

Compression technology is relevant for temporary solutions or projects that are planned to be upgraded in the future. But more often detachable connections are used for water pipes.

First, let's look at how welding is performed. Preparatory work takes place according to one plan:

- Selection and verification of materials for installation and tools. Heaters, scrapers and trimmers are cleaned, remove polyethylene residues and dust, and wipe with a solvent. Rubbing surfaces and units are lubricated. Bushings and clamps suitable for the diameter are selected.

- Selecting welding parameters. The tools are programmed, they enter certain parameters into the memory of the heating equipment.

- Site preparation. The ends of the pipes are cleaned of sand, adhering clay, dust, and wiped off. The free ends are covered with plugs. The oxidized ends are cleaned with scrapers.

- Fixing and centering pipes. Before welding, it is necessary to eliminate ovality, therefore the ends of the pipes are centered and then fixed in the desired position - exactly opposite each other.

- End machining. Chips 0.1-0.3 mm thick are removed from the surface at the ends. The gap between butt-connected segments should be no more than 0.3 mm. After cleaning, it is necessary to weld without contamination.

After preparatory work, welding is performed.

Butt-weld joint occurs due to the "fusion" of the melted ends. Reflow can be achieved using a disc heating tool.

When welding, it is important to consider criteria such as reflow temperature and time, end pressure force, length of upsetting period, pressure during upsetting and cooling time.

Work order:

Image gallery

Photo from

The elements are selected according to the size of the pipes, while the diameter is of decisive importance

The ends of the pipes for welding are placed on the working tool and secured to check the readiness for welding.

Install the facing tool and, rotating the handle, operate the facing tool to remove the top layer of polyethylene and prepare the pipes

After facing, remove the removed shavings, check the quality of stripping the ends, degrease them and check the accuracy of the edge adhesion

Clamping the heating element between the ends, they warm up and make the first burr

Remove the heater and quickly reattach the molten ends by increasing the pressure

At the welding site, until the seam has cooled down, they put the stamp of the welder, who is responsible for the quality of work

After the time required for the cooling phase has been maintained, the pipe is removed from the apparatus.

Step 1 - installing the reduction bushings

Step 2 - installing pipes in the centralizer

Step 3 - facing butt sections

Step 4 - cleaning the work area and checking alignment

Step 5 - installing the heating device

Step 6 - Seam Settlement at Increased Pressure

Step 7 - marking the weld

Step 8 - dismantling the welding equipment

Signs of a reliable seam are an even, uniform scar, the impossibility of separating the pipe by applying force. The fusion welded joint is considered to be very strong and does not require additional sealing measures.

The second way is electrofusion - differs in the presence of connecting elements - couplings, adapters, bends, tees. A metal spiral is fixed on the inner surface of the fittings, which heats up from an electric current and melts the polyethylene. As a result, the fittings “grow together” with the pipes, forming permanent joints.

When choosing elements for connecting polyethylene gas pipes, as well as during the procedure, it is important to take into account parameters such as voltage, welding and cooling times.

The technology is simpler than that of butt welding, and occurs in the following order:

Image gallery

Photo from

Before starting work, you need to prepare a set of tools: a trimmer, a cutter, meters, a marker, a tape measure, as well as a liquid for degreasing

To make the cutting site perfectly flat, use a special tool - it is installed on the end of the pipe and turned several times

The adapter must fit the pipes to be connected in all respects. Be sure to take into account the diameter and wall thickness

Having measured the length of the coupling and dividing it in half, mark the ends of both pipes for further chamfering

A special apparatus is installed to remove the top layer of polyethylene and, by rotating it, remove the shavings from the surface

They mark the boundaries of the welding area, and then degrease all involved areas - the inner surface of the coupling and the outer surface of the pipes

The pipes are put into a sleeve and connected to each other as tightly as possible. The coupling is located exactly in the middle of the working area

Electrodes are inserted into special holes in the coupling and an electric current is connected. Polyethylene melts, resulting in a monolithic connection

Step 1 - preparing tools and materials

Step 2 - cutting pipes for connection

Step 3 - selection of the resistor coupling

Step 4 - marking the butt sections for cleaning

Step 5 - facing butt sections

Step 6 - degreasing the coupling and pipes

Step 7 - installing the clutch in the operating position

Step 8 - welding polyethylene pipes

Modern welding machines are equipped with a control panel with a display. The procedure is carried out according to the program selected depending on the type of pipe.

Detachable connections when constructing a gas pipeline, they are used extremely rarely. Fittings are also used for this, but they are fixed mechanically, without heating.

The connecting elements consist of two parts - the ferrule and the body. As a result of tightening the threaded parts, a strong but unstable connection is obtained. If additional reliability is required, parts of the fitting are twisted with bolts and nuts.

Rules for the arrangement of the HDPE gas pipeline

During the installation and operation of polyethylene pipes, many rules must be observed to ensure both the serviceability of the gas pipeline and equipment and the safety of users.

There are many bans on the laying of highways. For example, it is impossible to conduct gas with the help of HDPE pipes in rocky and highly loamy soils, as well as soils of type 2 subsidence. If the area is prone to earthquakes and there is seismicity higher than 6 points, it is necessary to use other material for laying communications.

Polyethylene is not used in industrial and residential buildings, outdoors, in collectors and canals. Instead, steel pipes are installed

If it is allowed to use HDPE pipes, a number of conditions must be met. For example, on steep slopes, it is necessary to secure the gas pipeline from possible erosion of trenches and take additional measures to strengthen them.

When crossing underground collectors or channels, sewer or power communications, wells, polyethylene pipes are enclosed in metal cases. The distance from the surface of the gas pipeline to the inner wall of the case is at least 10 cm.

Two or more gas pipelines can be placed in one trench, but with access to each branch for maintenance or repair.

In the northern regions, where the temperature drops below -40 ° C, the installation depth increases to 2.0-3.2 m.

He will acquaint you with how the gas pipeline is laid in a case with its introduction into a gasified house next article, which we advise all owners of suburban property to read.

Conclusions and useful video on the topic

Electrofusion welding rules:

On the features of butt welding:

How does the HDPE pipe welding machine work:

The use of polyethylene pipes for gasification of industrial and residential facilities has become traditional.

HDPE is a durable and reliable material that does not cause fear. But the installation of the gas pipeline should be carried out exclusively by the installers of gas networks who have experience and know the technology of welding polyethylene.

Please leave comments in the block form below, post photos on the topic of the article, ask questions. Share your own experience in the construction of a polyethylene gas pipeline. It is possible that the information and recommendations provided by you will be useful to site visitors.