The Proterm brand has long been known in the Russian market: gas equipment regularly performs its functions for heating and hot water supply of both residential buildings and small industrial facilities. Sometimes the equipment fails. If the reason is a factory defect, then it is better to replace the boiler immediately, but small troubles are usually eliminated on their own.

We will tell you how you can repair the Proterm gas boiler with your own hands, focusing on self-diagnosis data and manufacturer's recommendations. We will show you how to identify a malfunction of the equipment by code. We will advise you how to accurately determine the cause of the breakdown by decoding.

In the article presented by us, you will find a description of the popular positions of the model range of boilers of this brand. Get acquainted with typical irregularities in the operation of units for heating systems and with troubleshooting methods.

The content of the article:

- Overview of the series of the brand "Proterm"

-

Error codes and how to fix them

- Models "Jaguar 11" and "Jaguar 24"

- Floor-standing boiler "Bear"

- Wall-mounted boiler "Cheetah"

- Conclusions and useful video on the topic

Overview of the series of the brand "Proterm"

If we consider equipment operating on gas, then at the place of installation, all boilers can be divided into two large categories:

- wall - Lynx Condence and Lynx, Panther, Jaguar, Gepard;

- floor - "Bear" (series KLOM, KLZ17, PLO, TLO), "Bison NL", "Grizzly KLO", "Wolf (Volk)".

Despite the Turkish and Belarusian assembly, the quality of the equipment is European-style high.

Among wall models - 1- and 2-contour, atmospheric and turbocharged, with a capacity of 11-35 kW.

Floor-standing models are made of steel or cast iron, equipped with injection or fan burners, and can operate on natural and liquefied gas. The power range is wide - 12-150 kW - therefore it is not difficult to choose a device for specific conditions.

The main purpose of the equipment is the organization of hot water supply and heating in private residential buildings, and some units are designed for industrial use

Each of the series has distinctive features regarding design, dimensions, installation method, technical characteristics, additional functions:

- "Lynx" - condensing models work 12-14% more economically than non-condensing ones, therefore they are recognized as energy efficient devices for heating country houses and cottages.

- "Panther" - latest models come with convenient eBus communication and updated security system

- "Jaguar" - the main advantages are the low price of the unit and the possibility of separate regulation of two circuits - heating and hot water supply.

- "Cheetah" - a popular wall model that can be installed both outside the city, in the country or in a cottage, and in a city apartment.

- "Bear" - among the representatives of various series - reliable units with built-in boiler, cast-iron heat exchanger and power up to 49 kW.

- "Bison NL" - universal models for the fuel used: they work equally effectively on gas, fuel oil or diesel fuel, power - up to 71 kW.

- "Grizzly KLO" - capable of heating private houses and office premises with an area of up to 1500 m², maximum power - 150 kW.

- "Wolf" - an electrically independent boiler with a steel heat exchanger, stably supplies heat to summer cottages and residential buildings even in the absence of electricity.

According to consumer reviews, Proterm units are reliable, efficient, easy to install and operate, and with regular maintenance they almost never fail.

However, durable materials, good fuel and excellent assembly do not guarantee perfect service, therefore boilers of all listed series sooner or later require replacement of spare parts, cleaning or repair.

Error codes and how to fix them

Thanks to the self-diagnosis function, modern boilers themselves determine malfunctions, and information in the form of digital or alphanumeric codes is displayed on an electronic display. Having understood what is hidden under this or that code, you can from the table posted in the installation and operating instructions.

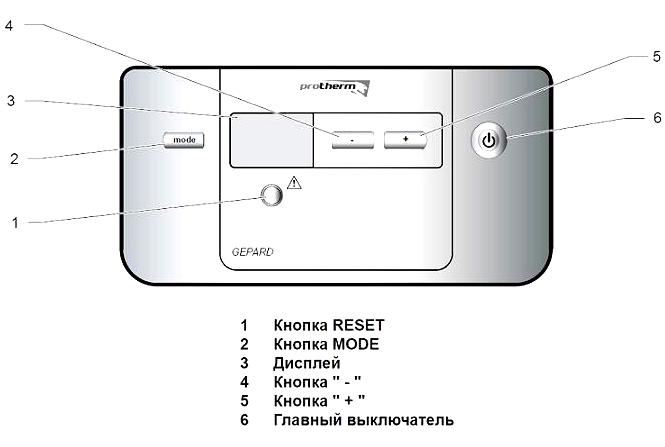

An example of an electronic display of a Panther boiler with three digital blocks. The two lower digital displays show error codes for heating and hot water systems

The Proterm brand produces many modifications under different series, and the error codes for different models may not coincide. To clarify the meaning, be sure to study the documentation for your unit.

Consider the errors of gas boilers "Proterm", which are most common in popular models.

Models "Jaguar 11" and "Jaguar 24"

The main problems faced by users relate to either sensor breakdowns, or changes in performance indicators to critical ones. Consider the errors of the Proterm Jaguar gas boiler, represented by two popular models with a capacity of 11 kW and 24 kW.

For example, when the coolant overheats to + 98 ° C, the boiler stops its operation, and an error is displayed on the display F01.

Functioning often improves when the temperature returns to acceptable operating parameters. To resume activity, you need to restart the boiler by pressing the "reset" or "start" button

Ignition often does not take place, and when trying to ignite the flame again, an error appears F04. There can be two reasons: breakage of the ionization electrode or interruption of the gas supply.

The easiest way is to check if the gas cock is open. If everything is fine with the fuel supply, the point is in the ionization system, which not everyone can repair on their own. The manufacturer recommends contacting the service center.

About blocked gas boiler chimney signals the code F05. If the air supply is restored, the unit will continue to operate. The same error indicates changes in voltage: if it falls below 165 V, the boiler stops working until the operating parameters stabilize.

Codes F02, F03, F09 notify about malfunction of various sensors.

If, when the hot water sensor breaks down, the device is still working, then the failure of the remaining sensors will stop its functioning.

Replacing elements requires skill and experience - and if you do not have them, we recommend contacting a service center.

An error appears quite often on the display F10associated with pressure. One of the reasons is a breakdown of the pressure sensor, the replacement of which is better to entrust gas workers with whom contract signed for service and gas supply. But if the matter is in changing the pressure parameters, the situation can be corrected independently.

The working pressure range is 1-2 bar. If the value falls below 0.3 bar or rises above 2.7 bar, the unit stops. To return it to work, you need to return the operating parameters.

How it's done:

- find the make-up valve in the lower part of the boiler, near the contour pipes;

- turn it counterclockwise until the pressure returns to normal;

- close the valve by turning it clockwise - when not closed, the pressure will continue to rise.

It is better to aim for the 1.5 bar indicator - the positive results of the actions will immediately be reflected on the display. If you overdo it and raise the pressure to 2.5 bar, the boiler will stop working again. During make-up, you must not block the branch pipes to which the DHW and heating pipes are connected.

Floor-standing boiler "Bear"

Most of the malfunctions of the "Bear" gas boiler are eliminated in two ways:

- automatically, after elimination of the cause (for example, F.10 - short circuit of the temperature sensor in the water supply circuit, F.73 - short circuit on the body or disconnection of the hydraulic pressure switch, etc.);

- by pressing the fault clearing button located on the control panel (for example, F.20 - signal from the temperature limiter, F.28 - lack of ignition at the 1st start, etc.).

Some breakdowns or malfunctions can be adjusted / repaired manually without contacting the representatives of the gas supply and service company.

If the boiler refuses to turn on and work, does not heat the water, there are many reasons for this "behavior".

Perhaps the gas tap is simply closed or the power supply is turned off - then it is enough to turn the handle of the tap or resume the supply of electricity, and then repeat the ignition procedure

Sometimes the boiler “protests” due to incorrect temperature settings - it is necessary to adjust the flow temperature, as well as the hot water temperature. If there is not enough pressure, you need to add water, and if there are air locks, release air from the radiators.

The situation changes if one of the functions remains in effect and the other fails. For example, the unit heats water in the DHW circuit, but refuses to heat the house. Most likely, the program settings have gone astray and the boiler "thinks" that the room is already warm enough. It is necessary to adjust the calculated temperature value in the house, and the heating circuit will start.

If, on the contrary, the heating is normal and cold water flows from the hot water tap, it is necessary to increase the temperature of the hot water.

One of the most alarming signals is water under or near the unit. This indicates a violation of the tightness. Most likely, you cannot cope on your own, and specialists will be required to solve the problem

If the boiler turns off unexpectedly and the display shows the code F.20, the manufacturer recommends unlocking the high limit safety cut-out.

Procedure:

- Wait for the unit to cool down.

- Using the device diagram, remove the front casing from the body.

- Find the fuse under the junction box.

- Turn and remove the cap.

- Press in pin as deep as possible.

- Press the fault clearing key.

- After making sure that the boiler is working, replace the front panel.

If the problem recurs regularly, it is better to contact the service.

Wall-mounted boiler "Cheetah"

Error codes and recommendations for correcting them are similar for all wall-mounted boilers "Proterm", but there are slight differences, since the technical characteristics are also different.

For example, the operating pressure range is from 0.8 bar to 2 bar, therefore, only after the reading drops below 0.8 bar, the unit will generate an error. To make the device work again, you need to add water to the heating system.

How to fill the heating system:

- Open the thermostatic valves.

- Open the filling device.

- Slowly pour in water until the network pressure reaches the operating parameters.

- Remove air from radiators.

- Close the filling device.

During the procedure, do not forget to monitor the changes in pressure values on the display.

The maximum threshold upon reaching which the boiler stops is 2.8 bar. If this happens, the pressure must be reduced by draining the water through the safety valve.

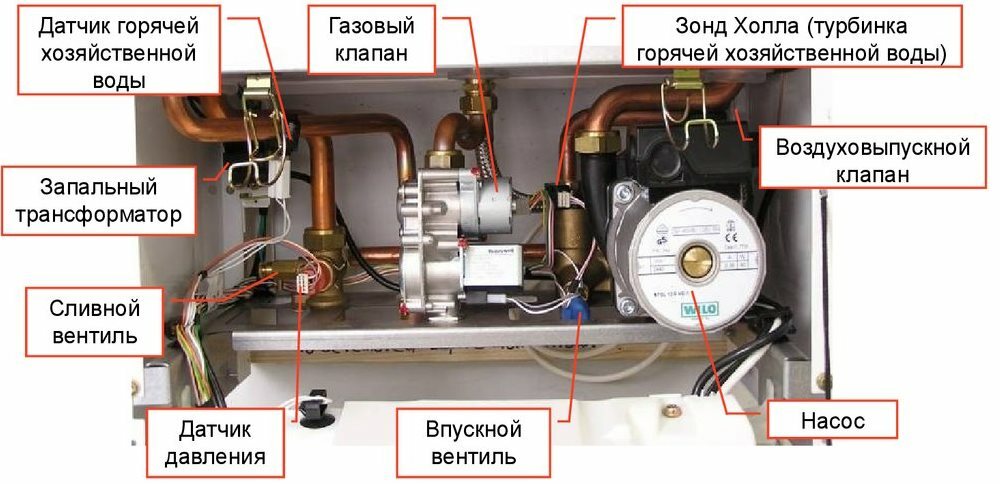

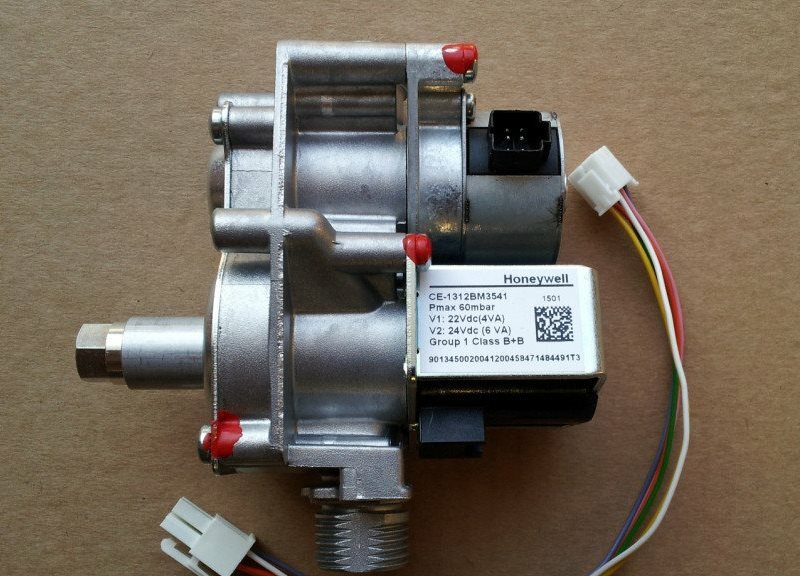

One of the most common mistakes is the failure of the gas pressure regulating valve (error F.28-29), so we will analyze how to fix the Proterm gas valve on our own.

Disconnect the inlet gas supply and power supply. Then remove the front metal panel, find for repair gas valve and carefully unscrew it.

The gas valve is a complex part, consisting of several small parts - some of them can be removed for cleaning or replacement

If the valve is simply clogged with poor quality fuel, you need to disassemble it and wipe all the elements, being careful. If the blockage is due to wear and tear of parts, the valve must be replaced. Most often, plastic elements break, which can simply be changed.

The reason may also be hidden not in the valve itself, but in the power supply system - you need to check all the contacts and make sure that the power supply is stable.

To correct the errors of the Proterm Gepard gas boiler, you need to refer to the technical documentation, which contains the manufacturer's advice. In case of failure gas boiler sensors and other elements require their replacement.

If you are unable to replace the temperature sensors, electronic board, fittings on your own, it is better to contact the service center. While the unit is under warranty, you also cannot repair yourself.

Conclusions and useful video on the topic

Recommendations for the repair of the Proterm Gepard boiler:

Potential problems of the "Panther" boiler and their solutions:

Cleaning and diagnostics of the "Bear" boiler:

Two categories of people are engaged in self-repair: home craftsmen who enjoy it, and equipment owners who are trying to save money on calling a specialist. If you do not belong to these groups, we recommend that in case of a serious breakdown immediately contact the service center.

Professional repair is always more expensive, but more reliable. A guarantee is given for the installation of new parts, and a representative of the service organization assumes responsibility for all replacement, repair or cleaning actions. In general, safety is increased as a result of the actions of experienced professionals.