For heating homes are often used gas boilers - comfortable and fairly efficient appliances running on natural gas. The correct functioning of these devices is provided adjacent devices that monitor operating mode.

Timely adjustment of the gas boiler automation improves the efficiency of the heating device, as well as to ensure the reliability and safety of operation. And it will agree, it is quite an important moment for all users.

But how to perform the adjustment and is it possible to do on their own? Together, let us try to deal with these issues. Why look at the device in detail, and the principle of automation on the example of one of the most popular models.

Also paid attention to hardware configuration and the main problems that you may encounter in the process of setting and further operation of the gas boiler.

The content of the article:

-

Types and operation of the systems for the boilers

- How to operate volatile devices?

- The operating principle of the non-volatile automation

- Elements of safety and comfortable operation

- Responsible for safety equipment

- Features Automatic keylock device

-

How to configure automatic heater?

- Problems when the ignition device

- Solving other problems when using automation

- Conclusions and useful videos on the topic

Types and operation of the systems for the boilers

By this definition is meant a system executive and control devices designed to maintain predetermined regimes, and rapid response to abnormal situations created.

This ensures safe use of boilers when minimizing the requirements for human in processes occurring in the device.

The construction of gas-fired boilers includes a variety of automatic devices (electronic and mechanical), which are designed to maintain an effective safe operation

All automation, applied for the correct functioning of the heaters can be divided into two basic groups:

- autonomous, independent from external power supply;

- devices, for which an external source of electrical current is required.

Consider each device group detail.

How to operate volatile devices?

Such systems are complex electronic components, which are required for power delivery.

At the same time, these devices allow to regulate the supply of fuel and the degree of heating by closing or opening the tap, saving heating costs.

e System operation is based on the information transmitted by the sensors to the control unit. After analysis and processing of data on the controller and the microprocessor commands are supplied to the boiler drives

Tasks that solve automatic devices:

- opening / closing of the valve of the gas delivery system;

- launching device in the automatic mode;

- predetermined or emergency shutdown of the boiler;

- level adjustment of the burner flame by means of an existing thermal sensor;

- deducing on the data screen for visual reading (air temperature, heating the water level and others).

In addition, modern automatic devices may have a number of additional functions that make it much easier to operate the boiler.

Among them are:

- Management of the equipment and supervise its functioning;

- Protect your heating system against failures three-way valve;

- Equipment frost protection (in case of sudden temperature drops in the room the device will automatically start up the boiler);

- self-diagnosis, which allows to detect defects in knots and details, and to identify failures in the functioning of the units. Such an option allows the time to identify the problem, which could cause serious damage requiring overhaul or complete replacement of the boiler.

At the same time reliable and stable operation of the electronic control devices for gas boilers can be carried out only under certain conditions.

Namely:

- no voltage surges;

- exact compliance with the recommended temperature;

- there are no problems associated with long life.

If you violate these rules of high-tech devices can quickly fail.

The market is widely represented range of such automation, which may include programming or do without it. These appliances include the following devices.

Thermostat for measuring the room temperature

temperature measurement sensor is in the room, but the cable is connected to the boiler, placed in the same or another room. The device not only monitors the room heating, but also controls the operation of the heater.

As soon as the temperature falls below a designated level, Termopribor sends a signal to the boiler, which is taking the heating equipment will automatically start to work.

The individual control units provide for connection of a temperature sensor located in the room. In this case, in the heated space is maintained automatically set temperature

Upon reaching room temperature level of the device overlaps the valve, whereupon operation of the boiler, and, hence, heating of the room is stopped, which contributes to fuel economy.

In our other article contains detailed information about the kinds and Schemes thermostat connection for heating boiler.

Daily programmer 24 hours

Like the conventional thermostat, the device controls the operation of the gas boiler, but it has advanced features.

With the help of this device, you can set the program operation of heating equipment within 24 hours, providing different levels of heating during certain periods of the day (for example, lowering the temperature in the room at night or during the absence of people).

Most devices provide automatic repetition cycle, and to change it, you need to change. Connecting the like may occur either via cable or via a special radio link.

The long-term weekly programmer

Unlike the above-described device enables the device week beforehand paint operation of the boiler once for seven days.

In devices of this type, as a rule, there are several different modes, as well as have the opportunity to create their own programs functioning heaters.

Easy programming Auraton-2025 instrument has 3 factory and user modes 7, allowing optimally adjust the air temperature. The light sensor turns off the display at night, thus saving energy

All data are transmitted to the backlit display that allows you to comfortably monitor the information. Since the radius of the programming action is 30 meters or more, it can be placed in the living room.

The operating principle of the non-volatile automation

At the same time, some parts of boilers operating control function, do not need to use electricity.

Their adjustment is made by hand, as well as under the influence of geometrical changes that occur in the mechanisms under the influence of heat.

In mechanical devices start boiler is made by pressing the washer on the valve. As a result, the latter opens in enforcing mode, letting the fuel that goes to the igniter

Despite the large range of models with electronic equipment, mechanical control options also enjoyed considerable popularity.

Which is explained by several factors:

- Reasonable cost. The prices of such devices is much lower than on fully automatic analogs.

- Ease of use. Ease volatile automation devices used in mechanical models, it allows you to quickly understand the settings, even a man who has no relation to technology.

- Reliability. Mechanical devices are independent from power surges or total power failure, so they can operate without a stabilizer, which is desirable when dealing with volatile equipment.

The disadvantages of these models also include the less accurate the adjustments, as well as the need to monitor the boiler.

As for the setting, it is done manually. Each mechanical unit is provided with temperature scale, numbers which indicate the limits of value (min to max). Operating temperature is specified to select the desired level of gradation line.

After starting the unit responsible for its functioning thermostat. The active element of this device is a rod which, being compressed under cooling valve opens gas supply, and then increases in size because of higher temperature and overlaps the intake blue fuel.

You may also decrease or increase the level of heating by a similar process.

Elements of safety and comfortable operation

The group of automatic devices for boiler includes a plurality of elements that can be split into two groups: mechanisms to ensure safe operation, and devices to facilitate comfortable operation boiler.

For safe operation shall be liable following details:

- thermostat;

- traction control sensor and the flame;

- safety valve.

flame monitoring sensor It consists of a thermocouple a gas valve and elemtromagnitnogo overlapping or comprising the gas supply.

The flame temperature (thermostat) Maintains the desired temperature of the coolant and also provides protection against overheating. This module enables or disables the boiler as soon as the coolant reaches a critical level (maximum or minimum).

Traction Control Module stops gas supply to the burner, as soon as the temperature changes from an elevated location bimetallic plate (which bends when heated, blocking the tube through which feed is being fuel).

In more detail the temperature sensors, traction, pressure and flame we reviewed in this article.

Through adjustment of the safety valve is held, and overlapping distribution of the gas flow

The heating system safety valve - inseparable components pipeline valve, which is important in controlling the coolant volume involved in the circuit.

The opening in the valve, through which the movement of the gaseous fuel, called saddle. To turn off the device it is necessary to close the disc or piston.

Depending on the number of operating positions gas valves may be one-, two- and three-stage, as well as modeling:

- Single-stage devices only have two positions: on / off.

- The two-stage device is provided with one input and two outputs, wherein the valve is opened by turning it in an intermediate position, whereby switching takes place more smoothly.

- Boilers provided with a three-stage device, in which the two power levels are provided.

- Modulating valves are used for continuously variable power indicator devices.

Automation that is used for convenience, includes options that are typically performed by users of heating systems. These include burner avtorozzhig, self diagnosis, selection of optimum operating mode and others.

Responsible for safety equipment

According to the rules laid down by the regulations (SNIP 2.04.08-87, SNIP 42-01-2002, SP 41-104-2000), In the gas boilers should be provided security. The purpose of this block is the extra fuel overlap in the case of any failure.

At present scheme provides automatic control system to regulate the function of the gas devices with a detailed picture of all components

The basis of the principle of safe operation of the gas boiler automation system put control of the instrument readings.

The control unit monitors the following factors:

- gas pressure. When it falls to the critical level of supply of combustible material is immediately terminated. The process takes place in an automatic mode by means of valve mechanism configured to advance a certain value.

- gas supply. Responsibility for this property is volatile instruments carries a maximum or minimum relay. The mechanism of operation is the flexing of the membrane with the rod by increasing the number of atmospheres, resulting in the opening of the heater contacts.

- The absence of flame in the burner. When damping fire thermocouple cools, due to which the current output is stopped, and the gas supply is stopped due to the overlapping of the electromagnetic valve of the gas valve.

- Presence of traction. When reducing this factor bimetallic strip is heated, causing a change in its shape. Modified element presses the valve, which is locked by stopping the supply of fuel gas.

- coolant temperature. C by a thermostat able to maintain this factor at a predetermined value, thereby preventing overheating of the boiler.

The above-mentioned possible fault can cause attenuation of the main burner, whereby there is a possibility of penetration of gas into the room, leading to fatal consequences.

This figure is a schematic of the work operation unit is controlled automation designed to avoid overheating the system or other violations in its work

To avoid this, all models of boilers must be equipped with automatic devices. This is especially true for older models, where such devices have not yet been specified by the manufacturer.

Features Automatic keylock device

Typically, manufacturers use a special control units, which include a packaging device listed above. With external difference they all operate on the basis of the same principles. To get acquainted with the best models and automation manufacturers go on this link.

The most widespread products of Italian brand EuroSIT. The most popular model is Eurosit 630, which is characterized by an easy functionality, compatibility with designs from different manufacturers, reliability and durability.

It is an example Eurosit 630 a closer look at the automatic block.

DETAILED device Eurosit automatic control unit 630 which is equipped with a large portion of modern gas boilers produced by different manufacturers

The device is a casing, inside which are all the structural components (spring valve, pressure regulator module, cutter), making it much easier installation.

It is brought to the housing tube through which feed gas is carried out, as well as cables from the sensors and other devices.

In addition to the 630 block Eurosit on the market are also other models: SABC, "Vakula» SIT, Dungs, Honneywell, which include sets of valves, pressure regulators, filters, regulators temperature

During installation and configuration of the device, there are some difficulties, but adapting, you can almost not worry about the work of the gas boiler.

How to configure automatic heater?

Adjusting EUROSIT provides adjustment of the controller 630, which supports the temperature control liquid in the circuit, and with an emergency gas supply blocks.

Before setting up the automation of different models of gas boilers, installation of equipment should be carried out strictly following the drawing. It is important to check the packaging of parts of devices, which should coincide with the stated instructions.

Adjustment is carried out using the handle that allows you to control the transfer of the boiler in three positions:

- off;

- ignition;

- setting temperature (1 to 7).

To turn on the ignition device the lever needs to be translated to a second position, setting it against the icon with the image of a spark.

Pressing the button will be used pezorozzhigom, whereby lights pilot burner. When the lever is required to keep the adopted position for 10-30 seconds. After releasing the button the pilot work should be discontinued.

When the ignition flame thermocouple is heated, whereby it begins to produce voltage (25 mV). This leads to the formation of chain links which are in the sensor and solenoid valve

Pressing the lever is opened electromagnetic valve and the gas is supplied to the igniter (it should be left open, and after releasing the handle).

In this case, the thermocouple must be protected against the penetration of return fire. Sensors are circuit elements are closed in the operating position. After receiving the signal they are opened, causing a shutdown.

Problems when the ignition device

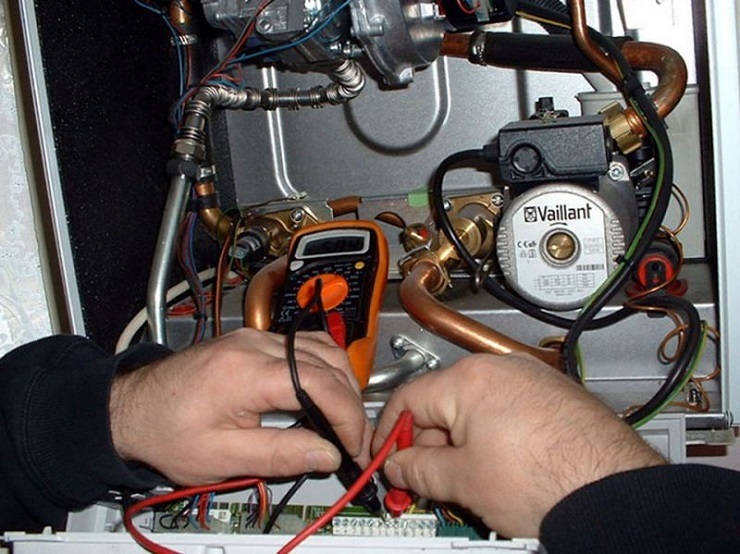

In case of difficulty when the device can use the following instructions. First, you need to stock up on necessary equipment such as open-end wrench, screwdriver, multimeter, pliers, alcohol, to clean parts.

Carefully remove the instrument terminals: they are closed together, and then are pressed with pliers. To determine the cause of the problem you want to include a pilot light.

If ignition occurs normally, most likely it is a failure in the sensor rod. In this case it is necessary to unscrew the active element (to prevent overheating surrounded paronite gaskets).

During the external inspection unit should pay attention to his contacts that need to be securely fastened to the body and does not have a trace on the surface oxidation. The temperature in the open state must be equal to 75 ° C

Thereafter, using the tester need to measure the resistance component which must be equal to 2.1 ohms. When identifying faults this part needs to be replaced. If the element is operating normally, it is enough to wipe it with alcohol, and then the return device assembly.

To detect malfunctions in tyagopreryvatele thermocouple terminals are removed, after which the resistance is checked, the index of which must be equal to 3.

If the value obtained is optimal, it is necessary to unscrew the nut using №9 key, which fixes the thermocouple to tyagopreryvatelyu, then the key to unscrew the latter №12 half-turn.

Then you need to get the plastic insert with the contacts, then the item is completely unscrewed. Thermocouple wires checked: it must be connected to the solenoid valve and secure key №9. If after ignition is still not possible, the problem lies in this part.

To solve the problem the nut fixing the thermocouple to the igniter, unscrew key №10, after which the element is installed in the correct position.

To evaluate the result of the work to be measured electromotive force (it must be equal to 18 mV), then cleaned with alcohol and a contact thermocouple elements tyagopreryvatelya. The final step - assembling the device.

Solving other problems when using automation

A common cause of lack of ignition is the contamination of the insulator on which is laid a wire extending into the combustion chamber. Such failure is easy to remove by wiping the part with a soft cloth. If heavily soiled, you can moisten the solvent, and then wipe dry.

The obstacle integrating igniter can serve and plaque from the soot, which is formed within the combustion chamber. This defect is easily eliminated by tapping the tube, the feed gas to the burner.

After a break in operation, check your pipes. The lack of work they can twist socket spiders or other insects fall, because of which the gas supply can be inhibited.

The high-tech model of gas-fired boilers are equipped with sophisticated electronics. As a rule, information on faults are displayed in the form of a code with a specific error

Bad water heating may be indicative of too much sediment on the walls of the heat exchanger. To solve this problem it is desirable to rinse with hot water circuit with the addition of mineral substances solvent.

If this does not work, it is best to contact the experts, as the reason may be damaged electronics or flow sensor.

In boilers too powerful effect may occur "clocking", which manifests itself in too frequent inclusions caused by intense heating of the gas. To remedy the situation it is recommended to reduce the fuel consumption, which is supplied to the burner.

this can be achieved in a mechanical device by rotating the lever for adjusting the gas valve, and electronic models is enough to use the control panel, where the corresponding parameter is set work.

To extend the life of equipment and gas boiler, we recommend regular inspection and maintenance to perform. How to perform maintenance we reviewed next article.

Conclusions and useful videos on the topic

In the presented video you will find brief instructions for installing a gas boiler with an automatic Eurosit system.

Modern gas boiler - a rather complicated structure, which provides a variety of useful functions. Automation of most models greatly facilitates their operation, takes control mechanisms and monitoring their performance.

This considerably improves safety in the operation of the heating system, and increases its efficiency by selecting an optimal mode.

You need to adjust your automatic gas boiler? You want yourself to address this problem and want to clarify some points? Do not be shy - ask your questions for this article, and our experts will try to help you.

Or you have successfully coped with the adjustment of automation and want to share your experience with others? Send us your tips, add photos depicting the highlights - your recommendations will be very useful to other owners of the same boiler.