Even the most luxurious interior and attractive decor will not delight households if they have to suffer from damp and cold. Agree that a comfortable temperature is the main guarantee of comfort. Therefore, the installation of a Protherm gas boiler becomes the key to the complete improvement of an apartment or house. But how to do it correctly and can you do it on your own?

In this article, we will talk in detail about installation features boilers, about the nuances and connection diagrams of popular brand models. Only if the norms and requirements for installation are observed, the brand's gas equipment serves for many years without interruption, providing housing with heat to every house.

The content of the article:

-

Features of installation of gas equipment Protherm

- General requirements for the installation of boilers

- Lines of wall mounted gas boilers brand

- Series of floor standing gas boilers Protherm

-

Diagrams and stages of connecting a wall-mounted boiler

- Stage # 1 - getting acquainted with the installation diagram

- Stage # 2 - hanging equipment on the wall

- Stage # 3 - installation work

- Stage # 4 - connecting the boiler to the power supply

- The subtleties of setting and operating the boiler

- Conclusions and useful video on the topic

Features of installation of gas equipment Protherm

Installation of gas boilers Proterm, like the installation of any heating equipment, has its own characteristics. Depending on the type of boiler, the consumer will have to take into account some of the nuances that affect the safety of operation and energy efficiency of equipment.

General requirements for the installation of boilers

When installing wall-mounted Protherm gas boilers, the minimum permissible distance between the boiler, ceiling and floor must be observed. When hanging the boiler to the ceiling, there must be at least 50 cm, to the floor - 80 cm.

If the wall on which the boiler is being installed is made of combustible materials, it must be additionally equipped with a metal sheet with a thickness of at least 3 mm.

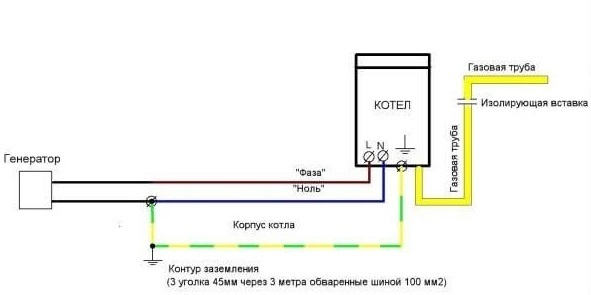

Beforehand, it is worth paying attention to the wiring. The cable from which the Proterm boiler will be powered must be stretched without bends and kinks. Please note that the wiring will only ensure the operation of gas equipment, you cannot connect other equipment to it. Provide boiler earthed.

The diagram shows a diagram of a standard grounding for a gas boiler. The ground loop can be equipped with your own resources

After unpacking, flush the pipes before installing to remove any dust from all cavities. Dirt can clog the Protherm boiler system, therefore preliminary cleaning is mandatory.

If the choice fell on a heavy floor model, it is recommended to make a screed or lay concrete slabs at the installation site. It is important that the finished platform is set strictly in level. We have resulted in more technical standards and requirements for the installation of floor standing boilers in our other article.

If the model requires a chimney connection, be sure to check the draft before connecting to the system. In addition, it is worth completely inspecting the patency of the chimney, cleaning its shaft.

Gas units produced by a Slovak company differ in the type of installation and capacity:

- Wall mounted boilers have less power, but are significantly cheaper. At the same time, the characteristics of technology allow you to fully heat a private house.

- Floor standing gas boilers Protherm have higher performance, are more expensive, and take up significantly more space during installation. A separate foundation may need to be poured prior to installation. Therefore, the models are less popular among households, but they are still in demand among owners of large houses.

The popular series and models of gas boilers are discussed in more detail below.

Lines of wall mounted gas boilers brand

Due to their attractive price and relative compactness, wall-hung boilers are in great demand. Protherm produces several lines of equipment for creating an efficient heating system in a private house or apartment in a multi-storey building.

In the offices of official representatives, you can get acquainted with the product lines of the plant in a comfortable conditions, having looked at the technical characteristics and having received, if necessary, a professional consultation

Three lines are in demand on the domestic market.

- Series "Panther" includes six powerful models from 12 to 35 kW with KTV, KOV and KTO markings. The KTV range is equipped with a forced exhaust system of combustion products, therefore it is suitable for rooms without a chimney. Models of the KOV series are connected to a natural chimney.

- Line of boilers "Lynx" It is presented in three models with a power of 24 and 28 kW with a forced exhaust system of combustion products.

- Double-circuit boilers "Gepard" 23 kW include 23 MOV and 23 MTV models. Modifications differ in the removal of combustion products: in 23 MOV it occurs naturally, in 23 MTV it is forced.

The unit must be selected based on its potential performance, heated area, installation requirements.

Series of floor standing gas boilers Protherm

Products for floor mounting have serious power, therefore they are used for heating large rooms with a high level of heat loss.

Three popular lines of Proterm equipment do an excellent job with the tasks and have their own characteristics that should be taken into account during installation.

Boilers "Bear" and "Grizzly"

Floor standing boilers with a cast iron heating circuit differ in their characteristics.

Floor-standing models Proterm are more suitable for heating industrial premises. However, this equipment can also be installed at home.

Each of the models has its own functional features.

- The KLZ range is characterized by an efficiency of 90-92% and a capacity of 20-50 kW. The devices are equipped with a built-in 90 l boiler and an electric ignition system.

- Single-circuit models of the KLOM series have an efficiency of about 92% and provide for the connection of a tank indirect heating.

- The PLO line, like KLOM, allows the addition of a boiler to the system. The power of the equipment is 20-60 kW, it allows heating the coolant up to 90 degrees.

- The TLO series technology combines single-circuit models with a power of 20-50 kW, equipped with a single-stage atmospheric burner. Discharge of flue gases is natural.

Another area of industrial use, which differs from the "Medved" in greater power (65-150 kW) and the type of fuel consumed. The equipment runs exclusively on natural fuel. The boilers are equipped with a staged burner, natural smoke extraction and electric ignition.>

Floor standing boilers "Bizon"

Industrial floor standing boilers with two-pass reversible flue gas duct with an astonishing power from 70 to 3500 kW can operate on both natural gas and liquid fuel. With a fairly moderate flow rate, the devices have an efficiency of about 92%.

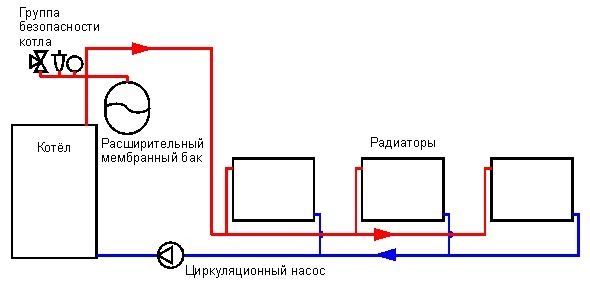

But before you connect the floor-standing gas boiler Protherm of the Bizon series, you should take care of the arrangement forced circulation systems coolant.

A detailed diagram of the forced circulation of the coolant is clearly shown in the schematic figure. The drawing shows the need to install a circulation pump

The equipment connection is quite complicated, but the increased power fully justifies all the costs of installation and maintenance of the unit.

Diagrams and stages of connecting a wall-mounted boiler

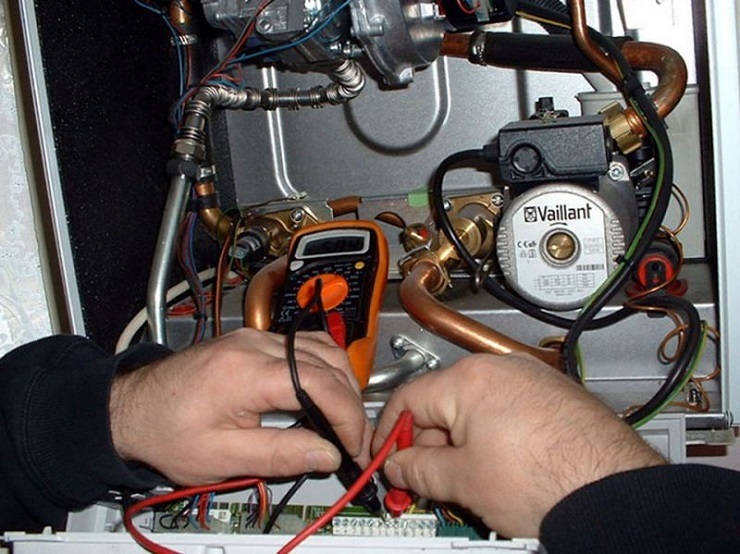

The installation of gas equipment must be carried out by a specialist. However, the connection diagram of the wall-mounted gas boiler Protherm should be accessible and understandable to the average user. Since the Panther series is the most popular due to the fast heating of water using the Aquafast technology and the ability to install equipment in a room without a chimney, consider the subtleties of connecting boilers using an example KTV series.

Stage # 1 - getting acquainted with the installation diagram

The first step is to carefully consider the design features of the model and the installation scheme. All this information is in the user manual supplied with the equipment.

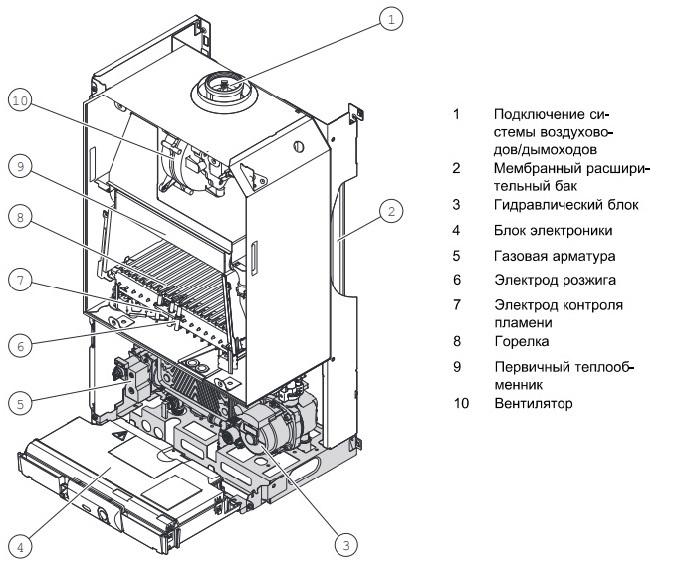

The device itself is shown in the diagram below.

A detailed diagram of the device of the wall-mounted boiler Proterm is provided in each instruction from the manufacturer

Before direct installation, you must carefully consider the routing of all pipes.

The installation diagram is discussed below.

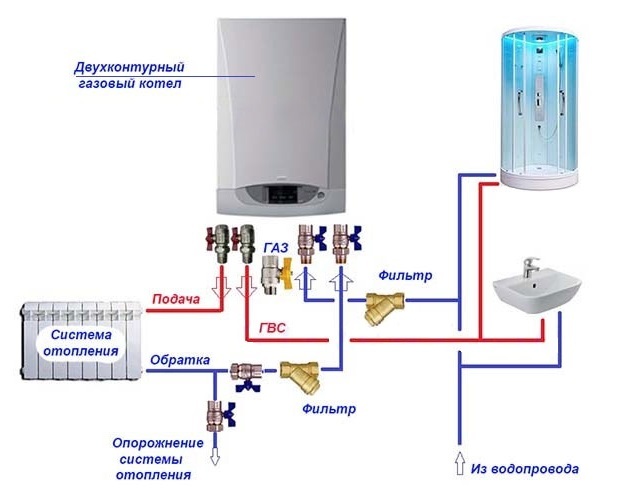

Such a boiler can become the center of the entire individual heating and water heating system, an approximate wiring in which is shown in this diagram

Stage # 2 - hanging equipment on the wall

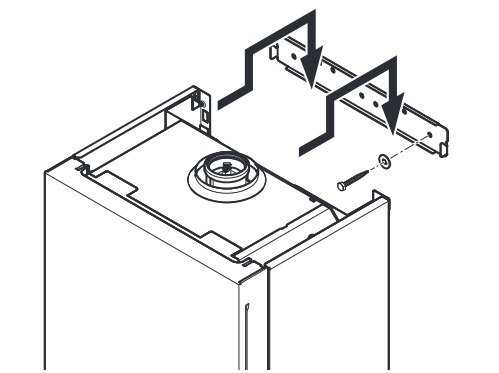

After checking the delivery for completeness and choosing an installation location corresponding to safety requirements, a mounting template can be used to define the drilling locations holes.

But first you need to make sure that the selected wall is able to withstand the load and weight of the product, and the purchased fasteners can be used on a specific surface material.

The principle of hanging a gas boiler is shown in the diagram.

Gas boilers Proterm are hung on the wall in a standard way, like other wall-mounted gas-using models

Stage # 3 - installation work

The main installation work takes place in several steps.

- The crimp threaded connection from the kit is installed on the gas pipeline.

- Then it is checked whether the volume of the built-in expansion tank is sufficient. If its capacity is insufficient, the structure should be equipped with an additional expansion tank, installing it on the return line of the heating system, as close to the boiler as possible.

- If there is a need to install an additional tank, it should also be installed at the boiler outlet check valve.

- All supply lines must be thoroughly flushed before installation.

- The cold water pipeline is equipped with a shut-off valve and a non-return valve.

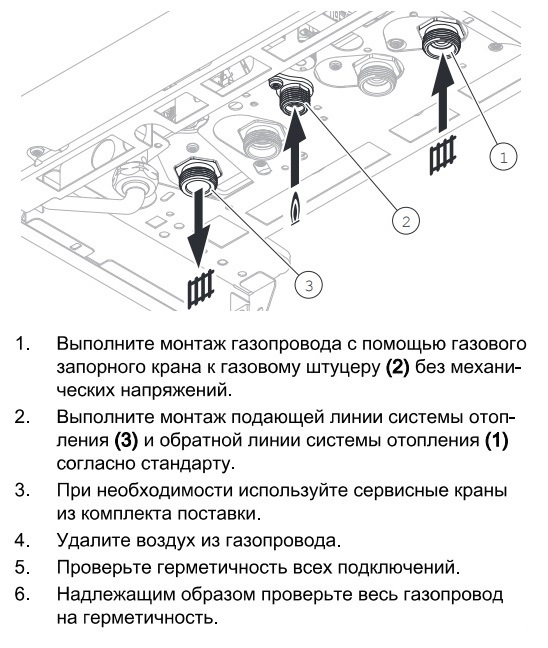

After that, you can check the gas meter: this unit must be designed to pass the expected gas flow rate. If the meter meets the specified characteristics, you can connect the gas system to the flow or return of the heating system. This process is clearly shown in the diagram.

Connecting the gas system to the boiler requires special care and compliance with all safety standards. These actions must be carried out by a gas service representative with a special permit.

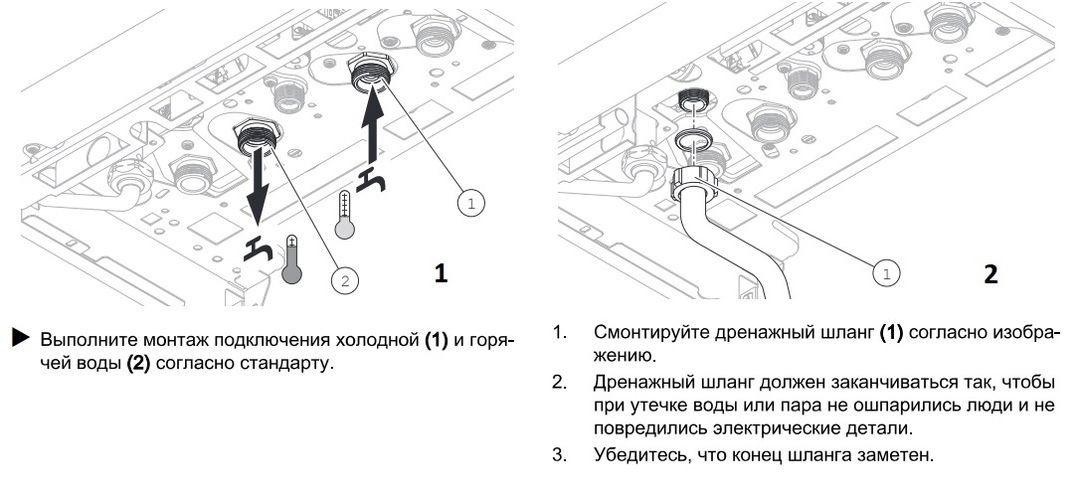

The hot and cold water connections, as well as the hot water cylinder and the drain hose, are made according to the following standards.

The connection of hot and cold water is shown in the diagram in the instructions for the Protherm boiler (diagram 1). A clear connection of the drain hose is shown in Figure 2

Next, the combustion products removal system is connected. The KTV boiler, on the example of which we are considering the installation process, is equipped with a closed combustion chamber. The exhaust and intake of air in it occurs forcibly through a coaxial system, for which a turbo chamber with a built-in fan is provided in the design.

The manufacturer offers several ways installation of a coaxial chimney, among which you can choose the most suitable option. The main thing is to ensure that condensate flows out of the system or to specially installed condensate traps.

Stage # 4 - connecting the boiler to the power supply

The supply line for connecting the boiler must have stabilizer and a circuit breaker.

The gas boiler is wired in the usual way:

- The connecting wires are routed through the cable gland and shortened to an acceptable length.

- The corresponding plug is screwed onto the cable, stripped of the insulation and braiding.

- When all the wires are firmly inserted into the plug terminals, the plug itself is inserted into the corresponding socket on the board.

- At the end it is necessary to secure all cables with special clamps.

Any sensible master will cope with such manipulations. However, installation work carried out by a certified specialist is safer and meets the requirements of the manufacturer.

The subtleties of setting and operating the boiler

To create an optimally comfortable microclimate in the house, any boiler from Proterm must be configured. Automation of the models allows you to fully adapt the operation of the device to your needs and preferences and independently adjust the temperature regime in each room.

Thus, the "electronic brain" of the boiler makes it possible to:

- diagnose malfunctions, save the last 10 errors in memory;

- regulate the flame level in the burner thanks to a temperature sensor;

- autonomously start the operation of the heating system;

- monitor temperature readings;

- completely shut down the boiler operation due to the preliminary settings in an emergency or if necessary, etc.

The electronic system is configured according to the factory instructions supplied in the kit. For safety reasons during operation, the setting should be entrusted to the master.

Protherm is responsible for the maintenance of its equipment and the qualifications of the craftsmen. Therefore, it is not uncommon for specialists to undergo official certification from the manufacturer.

To increase the efficiency of a gas boiler, you should familiarize yourself with a number of subtleties of its work.

There are certain nuances, the understanding of which will be useful to every owner of Protherm boilers:

- In order to more delicately regulate the temperature of the thermal carrier, you can connect room thermostat to the gas boiler.

- A thermostat connected to a room temperature sensor will also allow you to easily set the desired temperature in a specific room.

- If the pressure in the Protherm unit has dropped slightly, its level can be restored by a regular restart of the boiler.

- In order to fill the coolant reservoir as much as possible, the first start-up of the system must be performed with the setting of the maximum possible temperature.

- If the boiler efficiency has dropped, it is necessary to exclude the presence of soot and scale, diagnose the system for the absence of air locks. The installation of a thrust limiter will also be useful. We recommend that you familiarize yourself with the best ways to improve efficiency.

- With a persistently insufficient pressure in the heating system, it is required installation of a circulation pump.

These subtleties will allow you to optimally configure the operation of complex equipment.

Conclusions and useful video on the topic

The nuances of connecting a turbocharged boiler Protherm are described in detail by a professional master in a short and clear video:

The heating system with boilers Proterm is reliable and durable. The wall-mounted equipment has an attractive design and is intuitive to operate: all information is shown on the display, thanks to which you can easily monitor each stage of work technology. A gas boiler installed by specialists, subject to operational standards, will delight its owners with stable operation and a comfortable microclimate.

Would you like to supplement our material with useful tips for installing a boiler? Or tell about the problems you faced when deciding to independently connect gas-using equipment? Write about your experience, participate in discussions - the comment block is located below.