Faced a dilemma: wall-mounted or floor-standing gas boiler - which is better? Believe me, every second buyer of heating equipment turns to consultants with such a question. And it's good if he comes across a competent and qualified specialist. It's another matter if he's an amateur ...

Since you do not know which of the consultants or sellers you will have to deal with, we recommend that you sort everything out for yourself in this matter before going to the store.

We offer a professional answer to the question of which of the boilers is better for the house and apartment, as well as in what exactly. In this comparative overview, you will learn how they differ from each other and what these differences affect in the course of work.

The content of the article:

-

Wall and floor boilers: differences

- Efficiency and energy consumption

- Heat exchanger material and service life

- Design features and dimensions

- Dependence on the power grid

- Automation and set of functions

- Heat carrier and its properties

- Burner and chimney type

- Price difference and assortment

- Which boiler is best for a house and an apartment?

- Pros and cons in comparison

- Conclusions and useful video on the topic

Wall and floor boilers: differences

To choose between the two models, you need to be aware of their differences, as well as understand - what they are fraught with in practice. Therefore, we will briefly go through all the parameters.

Efficiency and energy consumption

Modern models of floor standing boilers have an efficiency of 88-90% (models with the old configuration - about 85%). As for the wall ones, the analogous figure is higher - 90-94%. Accordingly, the energy consumption in boilers with lower efficiency is higher, which means that the energy consumption is also higher.

But it is impossible to evaluate the efficiency of the model only by the method of installation - its efficiency is also influenced by the principle of operation. In the latter case, a distinction is made between conventional and condensing boilers.

Almost all floor standing boilers are convection boilers - they are cheaper and less efficient. Although at the same time, due to the simpler internal structure, their repair is cheaper, and this is a plus.

Wall-mounted boilers are more advanced in terms of design, they have more parts, however, repairs in the event of a breakdown are more expensive.

Wall-mounted - can be both convection and condensation. In the latter, the heat generated from heated gases and combustion products is additionally transferred to the coolant. Thus, the heat is not “ejected into the chimney”, but is effectively used. The only inconvenience is that it is necessary to equip the condensate drain from the boiler.

Wherein floor models can also be condensation, but this is a slow-moving product, since their price exceeds 150 thousand rubles.

Heat exchanger material and service life

This criterion is also used to determine the reliability of the device.

In specific models, "own" heat exchangers are traditionally installed:

- The floor-standing models use durable and heavy cast iron. It is good because it is not afraid of corrosion, is durable and has a high density and thickness. This allows boilers with a cast-iron heat exchanger to work without interruption for up to 25 years.

- In suspended boilers, it is replaced with light steel or copper. Steel is a cheaper option, but thin, therefore prone to deformation and rust. Such models will last, if you're lucky, 12-13 years. Copper is more durable and conducts heat better, but is used only in expensive models.

Note that the statement as if wall-mounted boilers less reliable due to the complexity of their design, nothing more than a myth.

According to the characteristics declared by the manufacturer, the service life of wall-mounted boilers is somewhat less, but this does not mean that in life they often break down and quickly fail. With careful operation, they can work as long as floor-standing boilers.

In fact, the durability is influenced not by the number of parts and structural elements, but by the material of the heat exchanger.

So, it is in the floor models that a cast-iron heat exchanger is most often installed, which is considered the most durable material. Therefore, their service life differs from wall-mounted boilers, in which heat exchangers of their lighter materials are mounted.

Design features and dimensions

If you think that the more the better, then you are mistaken. In this case, the functionality of the equipment has nothing to do with dimensions.

The rule of "more is better" is not always the case: a small wall-mounted boiler can often have more functionality than large-sized equipment

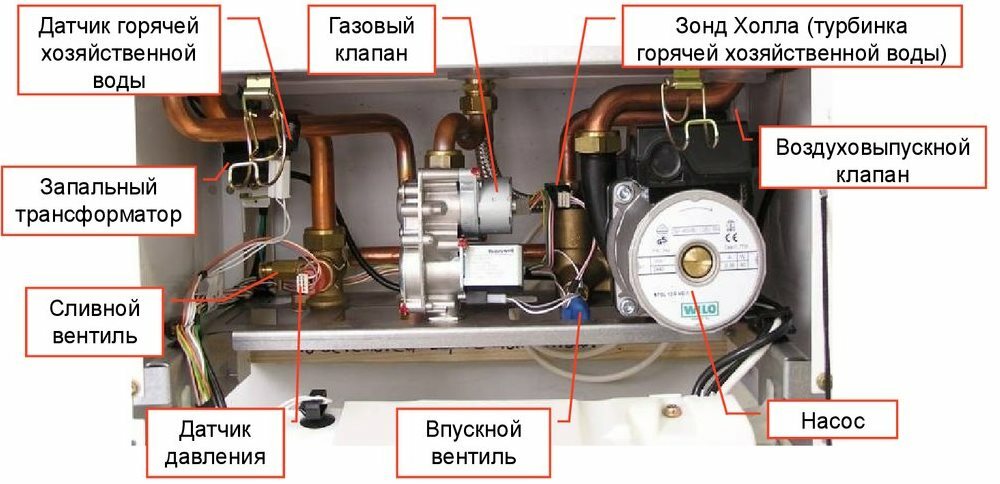

Surprisingly, it is a fact: wall-mounted boilers of more complex configuration are smaller in size than more primitive floor-standing ones. The first ones are whole mini-boiler houses.

In the design of gas single-circuit and double-circuit wall-hung boilers depending on the tasks to be solved, the following are used:

- one or two circulation pumps;

- closed expansion tank;

- pressure gauge;

- thermometer;

- air vent;

- safety valve.

The second ones are distinguished by a simpler design and require a separate installation of an expansion tank and a pump, which in some cases can be completely dispensed with.

Dependence on the power grid

If you want to competently choose a gas boiler, you should take into account the specifics of the supply of electricity in your region. The non-volatile model will work even in the event of a power outage. If there are problems, choose floor-standing models. About half of them are non-volatile.

The only drawback is the piezo, which must be done manually. However, for a situation with unstable energy supplies, you can close your eyes to this minus for the sake of stable operation of the boiler.

The advantage of non-volatile floor-standing boilers is the possibility of their use in regions with unstable electricity supply. Since any wall-mounted boiler runs on electricity, problems will arise in case of interruptions.

As for wall-mounted boilers, there are no options here: they all require an electrical connection, and if if you want to make the heating system non-volatile - you will have to additionally install a generator or UPS (uninterrupted power supply unit), which, of course, will result in additional expenses.

Automation and set of functions

The automation of wall-hung boilers is more perfect, so they are more convenient, safe and convenient to use. For example, they are equipped with an anti-freeze mode, protection against overheating, pump blocking, lack of traction, and self-diagnostics.

The process of heating water in hinged boilers is fully automated. The start and stop of the equipment, as well as the interruption of work in the event of a dangerous situation occurs without the participation of the owners.

From the functionality of floor modifications, it is necessary to mention gas control and prevention of overheating. Auto-ignition is less common.

Heat carrier and its properties

Here, again, the choice will depend on where the heating system will be installed and how often it will be used:

- Floor standing boilers can work with any coolant. Antifreeze is also suitable, so if you need to heat a summer cottage or a house in which you do not constantly live, you should choose floor configurations with antifreeze as a coolant. Thus, you will not be afraid that the system will freeze or depressurize.

- Wall mounted appliances cannot run on antifreeze. The reason lies in the viscosity and fluidity of the substance, as well as in its negative effect on the state of steel or copper heat exchangers, which are just used in mounted models.

If you focus on this criterion and decide whether to choose a floor or wall model of a gas boiler, which unit is more reasonable to prefer, then floor structures will definitely win.

Burner and chimney type

In wall-mounted boilers, simulated burners are always installed (even in inexpensive ones), while in floor-standing ones, one- or two-stage ones.

Let's briefly explain what this means:

- Single stage. Those that can only be on or off, and do not imply intermediate modes.

- Two-stage. They can be operated at 50% or 100% power regulation.

- Modulated. The user can at his own discretion choose the operating mode from 20% to 100% power.

"Ideal" is considered to be a mode in which fuel is constantly burned at minimum power. More advanced modulating burners allow more accurate temperature setting and economical gas consumption.

For the installation of floor-standing boilers, the organization of a boiler room is required. Installation in a hallway or corridor with organized natural ventilation is acceptable. Most wall-mounted gas appliances are allowed to be placed in kitchens

As for the chimney, in 90% of cases with floor-standing boilers, it must be equipped separately. This is because they are equipped with an atmospheric burner and an open combustion chamber, i.e. the air that is taken from the premises must be subsequently “taken out” to the street.

In wall-mounted models, the combustion chamber is closed, so air is drawn in and out through coaxial chimney. Discharge of gas processing products by floor models with a turbine burner is also performed by a coaxial system.

Installation of models with a two-pipe chimney is simple and less troublesome, but in case of severe frosts (from -15 ° C and above), condensation forms in it. This can lead to icing and shutdown of the heating system.

If it is necessary to prepare hot water, then it is better to supplement the floor-standing gas boiler with a boiler. You can purchase a floor-standing unit, heating and coolant, and hot water, but in this case, the quality of preparation decreases

Therefore, according to this criterion, it is impossible to unequivocally answer which gas boilers are best for you personally - wall-mounted or floor-standing. As you can see, you will have to tinker with the chimney longer with the outdoor one, but in the future you can be calm about its stable operation even in severe frosts.

As for the wall - there will be less hassle during the installation process, but more - when the thermometer drops below -15 ° C.

Price difference and assortment

Suspended structures, even despite their more modern and laconic design, as well as a more complex device, are cheaper than floor ones.

This can be explained by the fact that the market for mounted models is more competitive, as well as by the fact that spare parts for them and maintenance are cheaper. There is more demand for them - naturally, manufacturers offer more options and a price difference.

Which boiler is best for a house and an apartment?

It is difficult to give a universal assessment, since each situation is individual, but basically in practice it happens like this:

- floor structures are bought for heating the private sector (houses, summer cottages);

- hinged - for apartments in view of their small size and visual appeal.

Although it is important to make a reservation here. In all senses, unambiguously, floor-standing mini-boiler rooms are more reliable, since they have a more durable heat exchanger, and they are also not whimsical to operate even at critically low temperatures outside.

Plus, add non-volatility to everything, and then you will understand why many people prefer to install them even in apartments.

Hinged boilers are good because they can be built into kitchen sets, they take up a minimum of usable space in small urban kitchens

But if you are limited in living space and live in a region where severe frosts are very rare, it is more rational to install a wall modification. It will also be cheaper.

Pros and cons in comparison

Before buying a boiler, carefully study the strengths and weaknesses of both types of equipment. They differ not only in appearance, weight and gas consumption, but also in operational characteristics. To learn more about such differences, the table below will help.

The advantages and disadvantages of a floor-standing boiler will be presented in the following table:

| pros | Minuses |

| 1. High performance due to the large volume of the combustion chamber. | 1. Great weight. Especially when it comes to industrial models, although household ones also do not differ in compactness. |

| 2. Reliable heat exchangers made of thick-walled steel or cast iron, which guarantee a long service life. | 2. The classic type of chimney. This means that you will have to punch a hole into the street and bring a pipe to it with a far from aesthetic appearance. |

| 3. Non-volatile. They can even heat objects without electricity. | 3. Impressive dimensions that can take up most of the living space in a room. |

The following table will acquaint you with the strengths and weaknesses of wall-mounted boilers:

| pros | Minuses |

| 1. Profitability. Allows you to save up to 10-15% of gas compared to the floor version. | 1. Volatility. It is equipped with pumps, sensors and automation, which operate from the mains. |

| 2. Closed combustion chamber. This results in two advantages - compactness, lightness and the ability to install almost anywhere. | 2. Sensitivity to voltage drops. Often, at the slightest jump, the controller burns out, and such a breakdown requires expensive repairs. |

| 3. Multifunctionality. The latest models are equipped with weather-dependent automation, Internet access and can be controlled by a remote control or a smartphone. | 3. Installing and configuring such equipment is a complex and time-consuming process. In addition, there are really not so many competent specialists who can do it correctly. |

We propose to consider the differences between these modifications of gas equipment on real models, which are currently in high demand and are available from most suppliers.

| Proterm Medved 20 KLOM (floor) | Proterm Lynx Condens 25/30 MKV (wall-mounted) | |

| Ignition | Electrical | Electronic |

| Heating capacity (natural gas / LPG) (kW) | 11,9-17/11,2-16 | 6,3-26,5 |

| Efficiency (not less) (%) | 90-92/89-91 | 104 |

| Heat exchanger material | Cast iron | Aluminum-silicon alloy |

| Rated voltage / current frequency (V / Hz) | 230/50 | 230/50 |

| Dimensions: width / length / height (mm) | 335/600/880 | 700 / 390 / 280 |

| Weight without water (kg) | 90 Kg | 32 |

| DHW | No | there is |

Take seriously the choice of the type of equipment, since in the future, replacing, for example, a floor-standing boiler with a hinged one and vice versa, will not be cheap. You will have to pay for the production of new project documentation and registration.

Finally, I would like to note the following market trend: gradually mounted boilers are replacing models that are installed on the floor.

This must also be taken into account, since the further - the more difficult it may be to find details for floor boilers, as well as find craftsmen who can provide qualified assistance in case of their breakage.

Conclusions and useful video on the topic

The expert from the video below will tell in detail about what myths exist regarding both types of equipment and what are their features during operation. This information should finally help you make your choice.

Each type of equipment has its own advantages and disadvantages, so it is impossible to single out a clear leader in this comparative review. It all depends on the conditions and at what facility the boiler will be used.

Share what you were guided by when buying a gas boiler for arranging your own country house or city apartment. It is possible that your recommendations will be useful to site visitors. Please leave comments in the block below, post a photo and ask questions.