Gas equipment is the most common option in the organization of autonomous heating. It is characterized by an acceptable cost, economical fuel consumption and high efficiency. However, any technique has its own service life and, over time, requires restoration.

The simplest repair of a gas boiler can be done with your own hands. And any owner is simply obliged to cope with the implementation of regular preventive measures on his own. We will tell you how to return the equipment to working capacity and how to extend its working life.

The content of the article:

- What can be repaired without gas workers?

- Self-diagnosis methods of malfunctions

-

Major malfunctions and their elimination

- The gas boiler does not turn on

- Filter and pump problems

- Heat exchanger cleaning procedure

- The solution to the problem of poor traction

- Replacement of components and elimination of leaks

- Conclusions and useful video on the topic

What can be repaired without gas workers?

There are several main causes of malfunctions. This is the improper operation of gas equipment, the presence of an unacceptable microclimate in the boiler room, untimely maintenance of all systems or low-quality components.

When repairing yourself, be sure to follow safety precautions and strictly follow the instructions. First of all, the user should decide which parts of the gas boiler can be and which cannot be repaired on their own.

During the repair of gas equipment, the main danger is a possible gas leak. Therefore, it is necessary to carry out with care all the manipulations on the installation and dismantling of units and parts of the device. Particular attention should be paid to replacing components associated with the fuel supply system.

Knowledge of the typical malfunctions of gas boilers and methods for their elimination allows you to make simple repairs yourself. It is worth remembering that a serious repair can only be carried out by gas workers, but there are procedures available to independent home craftsmen

Boiler manufacturers strongly recommend calling gas service personnel to fix malfunctions associated with breakdowns in the gas supply system and built-in electronic devices. An inexperienced person will not be able to independently configure, repair and restore the functions of specific automation in a gas boiler.

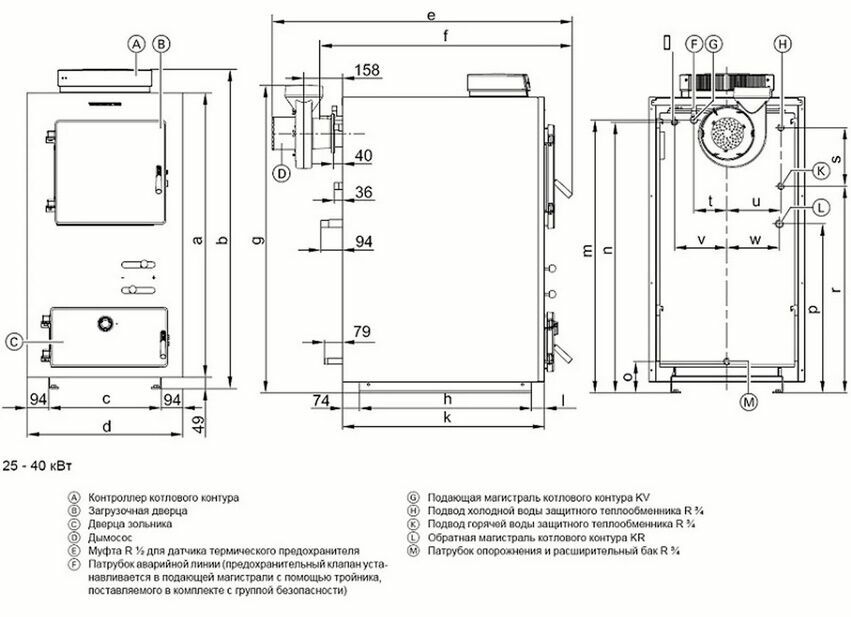

There are three main elements in the construction of a typical gas boiler, these are:

- Closed / open type gas burner;

- Specific safety blocks;

- A heat exchange system consisting of one or two internal devices, the number of which is determined by the number of circuits serviced.

If all components involved in the operation of the boiler are classified by functional purpose, then they can be divided into the following groups: system devices controls, hydraulic system devices, burner and gas supply unit, chimney, boiler control devices, multi-level supply systems security.

Most often, users have problems of the following nature: the boiler emits an unpleasant smell of gas, does not turn on, turns off during operation, does not heat pipes or smokes

Most of the listed items cannot be changed or repaired by yourself. In the event of intervention in the boiler structure, its owner loses the right to restore its operability at the expense of the manufacturer during the warranty period. But what and how do the craftsmen from the organization with which the service contract assembly and gas supply, you need to know.

However, the owner of gas equipment, seeking to extend its service life, can independently produce:

- Chimney cleaning. It is produced in cases of weakening traction by mechanical manipulation or using chemicals.

- Checking the tightness of the water supply connections, gas supply lines, heating circuit branches.

- Installation voltage regulator.

Once again, we warn you that all actions for which you need to remove the casing from the boiler must be performed by a representative of the gas service.

However, if the guarantee is not important to you, then you can do it yourself:

- Manual external cleaning and internal flushing of the heat exchanger / heat exchangers. They are easy to dismantle, carry out the necessary procedures, and then install them back. In this case, it is effective to use homemade aqueous solutions of citric acid (100g / 1l) or suitable household chemicals that can dissolve calcium deposits.

- Blower fan service. Replace the fuse or the fan itself, check the electrical circuit connected to it, lubricate the bearings with technical fluid.

- Cleaning the injectors. Clogged nozzles cause low burner flame. They periodically need to be cleaned with fine sandpaper and dirt should be removed with a rag with household chemicals.

- System pressure regulation.

- Search for a problem due to which the boiler does not turn on.

In order to determine how and how to repair a gas boiler, you need to visually inspect it and, if necessary, carry out a number of diagnostic procedures. Self-repair is possible in cases where the manufacturer's warranty has already expired.

If you smell gas, you should immediately forget about your own intervention. It is necessary to shut off the gas supply, immediately carry out a salvo ventilation and call an emergency gang. The rules for operating gas equipment are detailed in next article, the content of which we strongly advise you to familiarize yourself with.

Self-diagnosis methods of malfunctions

Often the user is in a situation where he is not sure what exactly broke in the gas boiler. In such cases, there is no need to rush to remove and repair something. It is risky and dangerous. Before work, you should diagnose the equipment and identify the exact causes of malfunctions.

If the boiler smokes, then usually the reason for this phenomenon is the consumption of low-quality gas or a lack of air. You can check the cause of the malfunction yourself

Modern gas boilers are equipped with various sensors, which reflect a number of important functional indicators of the unit. They track changes in temperature, pressure and other parameters. In the event of a malfunction in modern models of boilers, an automatic shutdown of the device is provided.

The source of the breakdown is identified by the consequences it causes. For example, you can visually see fumes, smudges, sparks. You can smell a gas leak or a short circuit that has occurred. By the changed sound of the gas boiler, it becomes clear that the unit has malfunctioned.

The instructions accompanying the purchase of the device describe the most common malfunctions in the purchased model of the boiler and how to detect, diagnose, and eliminate them. It also indicates what a specific means. error code and flashing lights on the dashboard.

So the light can flash in different modes: fast or slow. Or burn constantly. The light bulb can be red, green or yellow.

The manufacturer's instructions indicate all possible error codes that may appear on the display. It also explains how to troubleshoot the problem.

You should not throw out the instructions from the device, as it can be useful to the gasman you called to fix the breakdown. It indicates the characteristic features of the gas boiler model, the size and location of units and parts.

Major malfunctions and their elimination

After carrying out diagnostic procedures and determining a specific problem, you need to start solving it. This will require some tools and accessories, depending on the situation. Most problems are easy to fix with a tool that is always at hand.

Before starting work, it is important to disconnect the gas boiler from the electrical network. You also need to shut off the gas supply by turning off the gas valve. Even in cases where the repair procedures do not affect the parts that come into contact with the gas, the fuel must be turned off in accordance with safety regulations.

Volatile boilers often break down with voltage drops. As a result, not only settings are reset, but also sensitive sensors become unusable.

In some cases, it is impossible to roughly estimate the duration of the required repairs. If in such a situation the outside temperature has a minus value, then a significant decrease in the room temperature is possible. And consequently, the water in the system will freeze.

To prevent the formation of ice plugs in the boiler coils, the anti-icing system is never switched off for a long time. For example, if the boiler is not used for one or two days, all volatile devices are turned off, except for this function. It is possible to completely disconnect it from the power supply only if the unit is stored for a long time.

Also, before you start repairing the boiler and dismantling its internal components, you need to make sure that the working surface of the device has an acceptable temperature. During operation, the boiler casing and devices heats up significantly, and contact with some parts can lead to burns.

The gas boiler does not turn on

Sometimes, when you try to turn on the boiler, you find that the device simply refuses to work. First of all, you should make sure that the device is connected to the electrical network. Then you need to check if the switch is turned on in the dispensing machine.

If after inserting the plug of the boiler into the socket and turning it on, the machine knocks out, then pull the plug out of the socket. Then you need to inspect the wiring for faults.

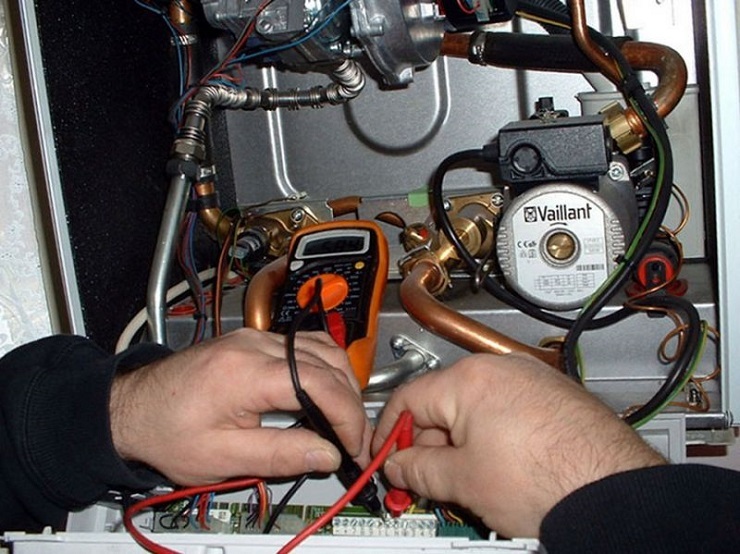

If it turns out that the device is connected to a working outlet, but still does not start, then you need to disconnect the boiler from the network and carefully remove its protective cover. It is necessary to carefully inspect the internal elements of the boiler for signs of a short circuit. These signs include the presence of a smell of burning and soot on the internal elements.

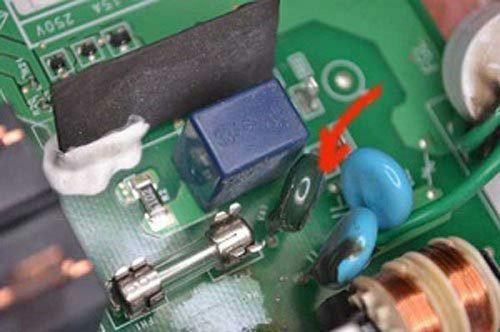

If there are no signs of a short circuit, then the fuse and electronic board need to be inspected. If a blown fuse is found, you need to install a new one, turn on the boiler and check its performance. Sometimes, after replacement, the new fuse will blow out immediately. This usually indicates a serious breakdown inside the boiler or a problem with the wiring.

A common problem with electronic boards is getting wet. It is better to dry it with an ordinary home hair dryer, and then leave it for a couple of days until the moisture finally evaporates.

Electrical wiring must be checked for correct connection and wiring. You need to make sure that there are no exposed wires, short circuits.

If the fuse is found to be in order, then the varistor should be inspected. This device protects the boiler from voltage surges. Perhaps there was a serious power surge earlier and the varistor exploded. Only a small part of it can remain. To solve this problem, you will need to re-solder the varistor using a blowtorch and the right material.

The varistor is a semiconductor resistor. If the voltage rises to too high a level, then it redirects it through itself, thereby protecting the device.

In cases where the boiler is accurately connected to the electrical network, and the fuse and varistor are in good order and after inspection failed to find visible causes of startup problems, you should call a gas repair technician boilers. Most likely there is a serious internal problem that will be problematic to fix at home.

A number of models of gas boilers, in which the display is provided error code on the dashboard, do not turn on and do not issue an error code at the same time. This problem often manifests itself when the circuit of the temperature sensor installed in the room or outdoors is broken.

It is necessary to inspect the room sensor, it may be unplugged or the batteries are dead. Then you need to replace the batteries or insert the plug into the outlet. If the temperature is not displayed on the boiler panel, then most likely there is a problem with the thermostat and it is advisable to start looking for the problem from it.

Filter and pump problems

The boiler may malfunction due to a clogged cold water filter. To clean it, you need to turn off the water supply and pull out the filter mesh. Rinse it under running water or replace it with a new one.

The coarse filter of the water supply system provides reliable protection of the boiler system from large foreign particles. If contaminated water enters the water supply, the filter often clogs

Boiler users may also encounter pump problems. The pump stops pumping water when the rotor is broken or air accumulates inside it. First of all, the serviceability of the rotor is checked. To do this, unscrew the nut from the pump and drain the water. Then you need to insert a flat screwdriver into the slot and forcibly rotate the axis. Sometimes the pump gets stuck or stuck.

If it turns out that the pump is broken, then you will need to disassemble it yourself, find out the cause of the breakdown. Having determined which part is broken, you need to order it from a store with gas equipment or from a boiler seller. Pump parts are changed at home or in a workshop.

If air has accumulated in the pump, then it is necessary to slightly open the air outlet and wait until the excess air comes out. The air outlet is closed with a tight-fitting cap. The process of releasing air is accompanied by a characteristic sound.

The pump is often installed when conducting heating systems in private houses. It allows you to drive warm water in a closed loop and ensures the same heating of all radiators

If the arrow of the pressure gauge is in the immediate vicinity of the red zone, then it is necessary to turn on the boiler and heat up the water in the system. If, with low heating, the pressure rises strongly in the range from 0.7 to 1.5 bar, then you need to carry out the procedure for adding air to the expansion tank.

Air is added after the pressure in the system has been released to zero. This is done by opening the tap and draining the water. Then, using a pump or compressor, the pressure in the tank is pumped up to 1.3 bar. After that, you need to bring the pressure in the system to 1.5 bar.

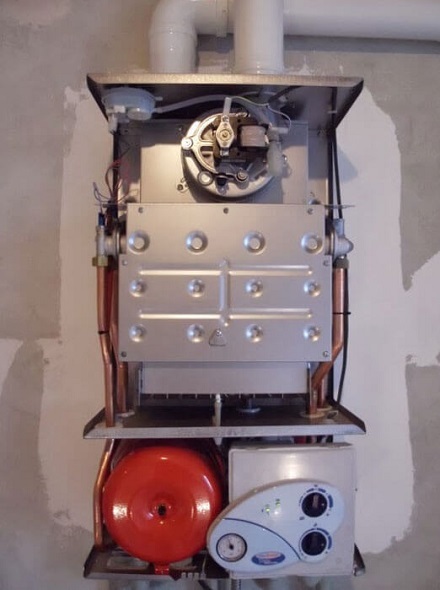

Heat exchanger cleaning procedure

The cause of boiler overheating is often faulty automation or a clogged heat exchanger. If gas boiler automation most likely it will have to be repaired in the service, then the heat exchanger can be cleaned of blockages at home. To do this, turn off the boiler and wait until it cools down. Turn off all taps and remove the cover of the device.

All electrical assemblies and parts, pump and control devices must be tightly covered with plastic wrap so that water does not accidentally get on them. By opening the tap or valve of the gas boiler, you need to drain the remaining water from it.

Next, you need to dismantle the burner block with the manifold, remove the fan from the seat, disconnecting the fasteners fixing it to the combustion chamber. Then the return pipe is disconnected from the heat exchanger.

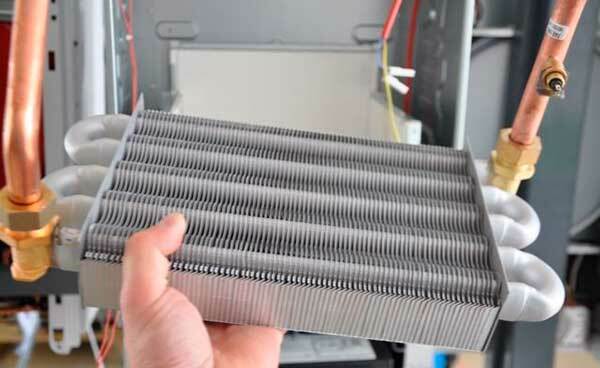

Water heats up unevenly due to a violation of thermal conductivity. This is due to the accumulation of a large layer of scale on the walls of the heat exchanger. Uneven heating causes water supply to alternate at different temperatures

To remove the heat exchanger, you must first disconnect the overheating sensor, then remove the combustion chamber. For this, three screws are first unscrewed, after which the camera, together with the cap, is pulled towards itself. After that, the cap is detached from the chamber and the heat exchanger is detached.

The heat exchanger itself is first mechanically cleaned with a brush and emery cloth. Then you need to hold the part in a 10% solution of citric acid or household chemicals that dissolve mineral deposits. Soaking in the solution should take about 10-15 minutes.

Next, the solution is poured into the internal pipeline and kept there for a period similar in length. Then everything is drained and washed thoroughly with running water. The assembly is carried out in the exact reverse order. In order not to forget the sequence, it is recommended to take a photo of each step on the phone during dismantling.

If you first familiarize yourself with the recommendations for cleaning the heat exchanger and instructions for disassembling the gas boiler, then the preventive cleaning process will not take much time.

It is recommended to clean the heat exchanger every one and a half or two years.

The solution to the problem of poor traction

Boilers with an open combustion chamber sometimes lose thrust. To determine the cause of this malfunction, it is worth looking directly into the combustion chamber. Perhaps it is clogged with carbon deposits, soot or decay products. You need to brush and vacuum this part with a vacuum cleaner.

Closed chamber models are equipped with coaxial chimneyswhich have the following disadvantages. In cold winter time, drops of water from the outer pipe fall into the inner pipe, and there the water freezes and turns into an icicle.

Frost in the space between the pipes blocks the access of air to the gas boiler and, consequently, the supply of the portion of fresh air required for combustion is reduced. To solve this problem, the outdoor part of the chimney is insulated or holes are drilled in the outer pipe to drain the condensate.

There are situations when foreign objects and waste get into the chimney. In such cases, you need to carefully dismantle the pipe and clean it of excess content. Gas boiler malfunctions occur when the coaxial flue gas outlet becomes excessively clogged. The soot must be cleaned out at regular intervals. Then the boiler will work for a long time and efficiently.

It should be noted that the accumulation of soot in a gas boiler is a rather rare occurrence. The combustion gas does not give off too much combustion. Therefore, the manufacturer usually recommends cleaning the chimney every two or three years.

The pipe cleaner is fairly easy to make yourself. However, it can also be purchased from the store at an affordable price.

Chimney cleaning is carried out as follows. It is necessary to turn off the boiler, shut off the gas and water supply and wait until it cools down. Remove the external protection of the boiler and disconnect from it chimney. Cleaning can be done mechanically or chemically.

It is convenient to clean the lower part of the chimney, directly adjacent to the boiler, with a metal brush with a long handle, and then use a brush. Then chemical solutions can be used. After cleaning the inside, it is necessary to start cleaning the outside of the pipe.

There are several ways to clean the chimney with your own hands while on the roof. Most often, a special metal brush is used on a rope with a weighting agent attached to it. In this case, the circumference of the cleaning tool must correspond to the circumference of the chimney.

By alternately lowering and raising the mechanism, the pipe walls are cleaned. The soot falls down and needs to be shaken out, removed or vacuumed from the inside of the chimney.

Also clean the chimney you can use a powerful vacuum cleaner specially designed for similar procedures. Such a device has pockets for sucking in waste. And the hose is long enough to clean the entire chimney.

In special cases, it is worth calling a chimney sweep who has a vacuum unit designed to clean chimneys. This expensive device will completely clean the chimney from contamination without damaging the system.

When cleaning the chimney and other elements of the boiler, it is imperative to wear a mask on your face. It will protect the wearer from inhaling soot and getting harmful microelements into the lungs.

If you do not solve the problem of weak traction in a timely manner, then you can face a number of negative consequences:

- The ingress of carbon monoxide into the room and harm to the health of residents;

- Accumulation of soot increases the risk of fire;

- Due to carbon deposits on the walls of the boiler, heat loss and gas consumption increase.

Possible problems indicate that regular preventive cleaning of the gas appliance is necessary.

Replacement of components and elimination of leaks

If leaks and water leaks are found at the connection points of the gas boiler, shut off the water supply. Then, using a wrench, you need to unscrew the connection, remove the remaining tow and check the thread for damage. Then you need to apply a new layer of tow or FUM tape and screw the pipes tightly.

If, as a result of inspection, it is found that the water pipe is damaged, then you need to replace it yourself or call a plumber.

The use of FUM tape, plumbing thread, liquid or anaerobic sealant protects pipe connections from leaks. Before re-screwing the pipes, thoroughly clean the threads from foreign elements.

If you smell gas in the air, turn off the lights and all sources of ignition. Open the window and ventilate the room. You can check the leak with a soapy solution. After its application, a soap bubble appears on the pipe. A gas leak is repaired in the same way as on a water pipe.

Sometimes, after carrying out diagnostics, it turns out that it is necessary to replace the burner in the gas boiler. You can replace the burner yourself, but you should install exactly the same burner model. It is necessary to disconnect all communications, and during dismantling it is imperative to remember the correct location of all elements connected to the burner.

If the boiler refuses to maintain the set temperature regime, then the broken sensor is usually to blame. Temperature sensors can be surface-mounted or submersible. Overheads are easily mounted on pipes and can be replaced without difficulty. When installing the immersion sensor, drain the water from the boiler and, after installing the sensor, seal the thread.

In order to maximally secure your own space and exclude the possibility of excess toxins due to the operation of gas equipment, it is recommended to use at home carbon monoxide sensor. The principle of its operation, the rules for selection and installation are described in the article we recommend.

Conclusions and useful video on the topic

How to flush the heat exchanger of a gas boiler:

Detecting and correcting gas boiler malfunctions:

Gas boilers are high-tech and safe devices. Like all equipment, they have their own expiration date. With timely preventive maintenance, the boiler will last a long time. If the boiler starts to junk or does not work well, it is necessary to immediately inspect and diagnose it, to identify the cause of the malfunction.

There are a number of common boiler faults. Sometimes the unit simply refuses to turn on or its operation deteriorates due to a too dirty coarse filter. Also, users are faced with the problem of contamination of the heat exchanger and chimney. When carrying out repair work, you must always observe safety precautions.

Do you want to share your own experience in restoring the working capacity of a gas boiler? Do you have any useful information on a topic that is worth sharing with your site visitors? Please leave comments in the block form below, post a photo, ask questions.