Agree that information about a boiler malfunction can speed up the restoration of its operability. After all, determining the cause of the breakdown is half the battle. Right? Moreover, the error code of the Immergas gas boiler is always indicated on the display and it just needs to be deciphered.

And how to do it correctly, we described in detail in our article. After getting acquainted with which the owner of the Italian boiler will be able not only to identify malfunctions, but also to assess the situation, make a decision on how to restore its performance.

The content of the article:

-

Immergas boiler error codes

- Problems with firing up the boiler

- When overheating is to blame

- Malfunction of the ventilation system

- Fan problems

- Blockage due to overheating of the coolant

- System depressurization signals

- Unstable operation of the power grid

- Other kinds of errors

- Conclusions and useful video on the topic

Immergas boiler error codes

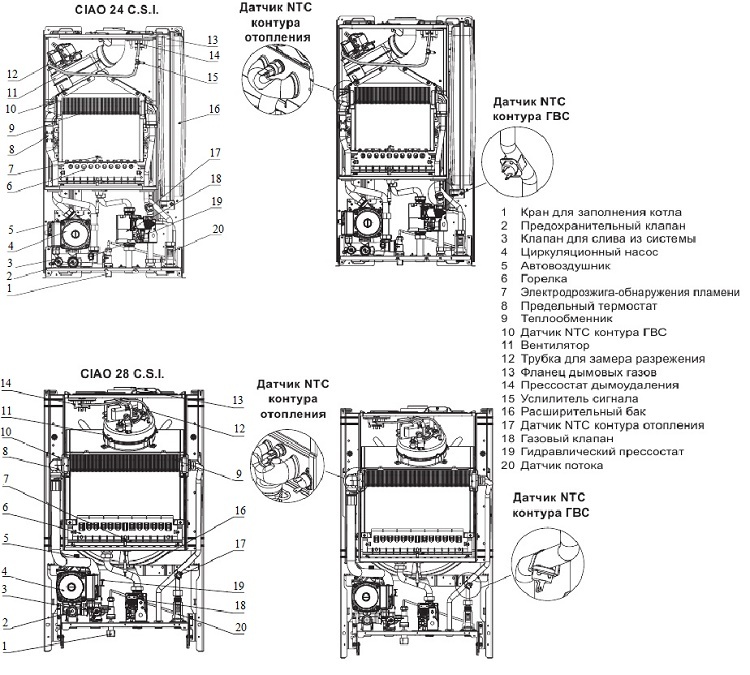

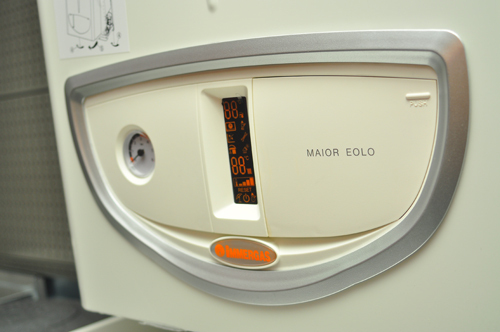

The equipment of the indicated Italian brand belongs to modern, therefore, the determination of the reasons that lead to inoperability occurs automatically, with further indication on the display.

But you should use such information with caution, and also remember that the owner of the boiler is responsible for its safe operation, timeliness, completeness and quality of repairs. And if his actions are found to be wrong, the owner of the equipment may be punished. This is stated in the Code of Administrative Offenses (Art. 7.19), and in more serious cases, sanctions will be imposed according to the Criminal Code.

The decoding of error codes is traditionally indicated in each instruction attached to the boiler. But it should be remembered that the manufacturer Immergas provides information on faults to specialists. That is, ordinary users can use codes solely at their own peril and risk. Therefore, it is better to entrust the elimination of malfunctions to the master.

An important feature of this Italian manufacturer is that different software is used on its models. As a result, it happens that the same warning signals are indicated by several kinds of codes. But they can all be grouped into several categories.

Problems with firing up the boiler

Codes errors 01, E00, E02 indicate that the operation of the boiler is blocked, and the reason for the blockage is the lack of ignition.

It is possible to restore the unit's performance after blocking due to lack of ignition by pressing one button. But you should not rush to do this, since initially you should make sure that there is no smell of gas, the presence of traction, ventilate the room and only then try to resume the operation of the boiler

Often, such a problem occurs after a long downtime of the gas unit, for example, in the off-season, due to the accumulation of air in the gas supply channels.

To restore performance, you should:

- Repeat launch;

- If after 10 seconds the ignition does not occur, then the Reset button should be pressed. This operation will lead to automatic unblocking of the boiler.

As a result, residual air will be removed from the gas supply pipelines and the heating equipment will start up.

When overheating is to blame

Codes errors 02, 12, E12, b 19 indicates that the operation of the boiler has been suspended by a signal from thermostat due to overheating. In addition, malfunctions in the flame monitoring system can lead to the listed errors.

During use, the channels of the heat exchanger quickly become clogged with scale, rust particles, which leads to a violation of heat transfer. Therefore, cleaning should be performed every couple of heating seasons without waiting for a warning signal on the display.

The cause of the problem can be identified by tightening the contacts, as well as checking the integrity of the wires.

In the worst case, the sensor itself will have to be replaced.

Malfunction of the ventilation system

Signal with code 11 indicates that there is insufficient draft in the flue system. This error code cannot be ignored. It appears on the display after the third blocking of the boiler by the automatics for the indicated reason, and in a row.

The photo shows a structural element of the smoke exhaust system, the inner channel of which is almost completely clogged with soot, which reduces the boiler's performance

More precisely, after each case of turning off the gas equipment, it is automatically started. But if thrust sensor again signals that the situation has not returned to normal, then the electronics immediately re-disconnects.

The danger of the situation is indicated by the fact that simultaneously with the code 11, the display turns red.

There are two ways to eliminate the cause. Which include:

- cleaning channels of ventilation and smoke removal systems from soot, third-party items;

- changes in the design of ventilation and smoke removal systems. This will have to be done if cleaning does not give the desired long-term effect.

In this case, the boiler can be unblocked and started by pressing the restart button.

The photo shows frost on the smoke exhaust pipe. Moreover, such formations in severe frost can grow in a matter of hours. At the same time, the boiler can be returned to its working capacity by chipping or melting the ice.

Before proceeding with any action, be sure to make sure that there is traction.

Another problem in the ventilation system is indicated by code 03. In this case, the boiler is blocked by a command from the flue gas outlet control sensor.

If an error code with number 03 appears on the display of the gas boiler, it means that there may be carbon monoxide in the room. Therefore, troubleshooting the problem should be approached with the utmost seriousness.

Causes:

- a decrease in the efficiency of the chimney due to the accumulation of soot and other combustion products on the inner surfaces of the channels. And under difficult climatic conditions, the boiler is turned off due to the occurrence of ice;

- fan malfunction, if provided.

In the first case, you can identify a malfunction of the Immergaz gas boiler simply by looking into the chimney. If it is revealed that the inner channel is completely or partially blocked by third-party objects, soot, ice, then you will need to clean it.

Fan problems

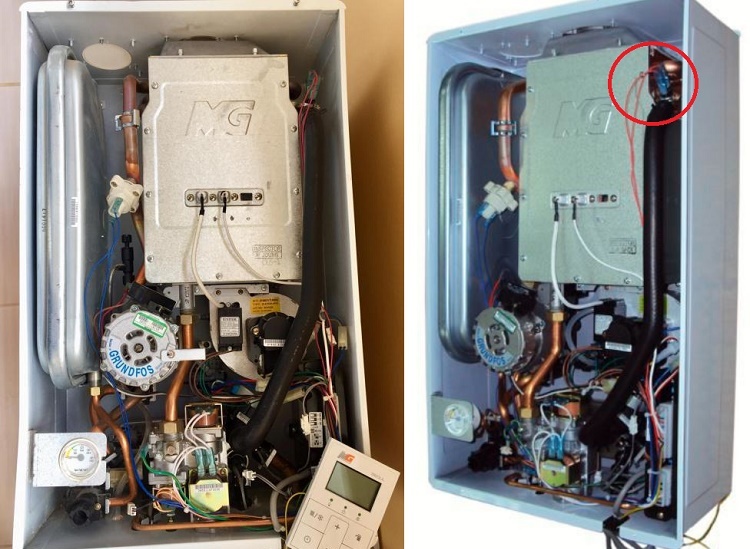

Emergence of codes errors 16, E29, b 28 / b 29, b 65 caused by a shutdown or breakdown of the fan or Hall sensor.

The reason is a malfunction of the product itself or a problem in the circuit. For example, it can be the weakening of contacts. In addition, it is recommended to diagnose fuse F3.

If it didn’t work to return it to work using any of the above methods, then you will have to diagnose the electronic module.

The E65 error code can be seen on the display when the fan loses its performance. Namely, if it produces less than 900 rpm.

Fans of turbocharged boilers are another weak point of any such unit. Therefore, you always need to be ready to repair or replace it.

If this fact is confirmed during the diagnosis, then the fan must be replaced.

Blockage due to overheating of the coolant

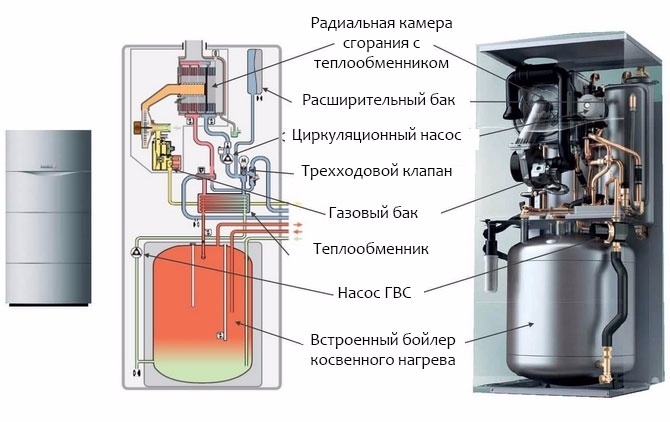

Codes errors 27, E18 / E19 indicate that a boiler shutdown has occurred, the cause of which is overheating. Moreover, caused by violations in the process of fluid circulation in the system.

The reasons that triggered the appearance of this warning signal include:

- airing the heating system. To eliminate it, it is necessary to remove excess air;

- closed position of taps;

- jamming or breakage circulation pump. In the first case, its impeller must be cleaned of dirt and foreign particles, which in many cases returns the product to work. In the event of a breakdown, replacement will be required;

- contamination of filters that should be dismantled and inspected. If the suspicion is confirmed, then the filter element should be cleaned. In such cases, the cause of contamination is often ferric iron (rust particles), which is effectively removed by soaking in a citric acid solution;

- contamination of the heat exchanger channels, which during operation are covered with a layer of scale, similar to that which is deposited on the walls of kettles (in regions with hard water). As a result, after every couple of years of use of the boiler, its heat exchanger should be cleaned.

The heat exchanger can be cleaned mechanically, that is, using brushes and other similar devices, as well as using special equipment and chemicals.

A detailed article on cleaning the heat exchanger of a gas boiler can be read here.

In case of errors with numbers E18 / E19, one of the solutions for restoring the boiler's performance may be to add water to the system. This is easy to do, since all you need to do is open a special valve on the control panel.

Error codes b 24, b 30 on the display indicate that the thermistors in the supply lines and in the return circuit give different values, with a difference of 10 ° C.

Eliminate this problem by cleaning the heat exchanger from scale and other deposits.

Error code b 25 indicates that the flow temperature is rapidly increasing. Usually, such a signal indicates an insufficient amount of liquid in the heating system, which is eliminated by topping up.

System depressurization signals

Codes errors 28, b 26 indicate that an unpleasant malfunction such as a leak has occurred in the hot water supply circuit of the Immergas gas boiler. Moreover, with a simultaneous increase in temperature in the DHW and heating circuits.

Any faulty mixer can become the reason for the low pressure of the coolant in the system. Therefore, on them, in the case when the error code 28 is displayed, you need to pay first of all

To identify the problem, the first step is to pay attention to the serviceability of the mixers. If no leak is found, then an inspection of the entire heating system (pipes, radiators, connections) should be carried out in order to identify leakage.

Code errors 10 appears if the boiler heating circuit pressure dropped below the set level, which is usually 0.9 bar.

Initially, it is recommended to restart the unit over a new one, and if the presence of a malfunction is confirmed, then the location of the circuit depressurization should be identified.

This procedure can be performed by visual inspection. In this case, remember that replacing the leaked part will be the most practical solution.

After restoring the tightness of the circuit, it must be filled with a coolant.

To do this, use the so-called make-up lever. To achieve the desired result, it must be turned counterclockwise, after which water from the centralized system can enter the boiler heating circuit.

A common cause of leakage is the joints of the heating system structural elements. This is especially true for radiators and pipes.

The filling procedure is terminated when the pressure reaches 1.3 bar by turning the make-up lever to its original position.

Unstable operation of the power grid

Code errors 37 is a warning that there are significant voltage surges in the network, and with its decrease to critical values (175-197 V).

The consequences of this problem can be eliminated only by installing voltage regulatorand of high quality.

Other kinds of errors

Code errors 15 indicates an incorrect boiler configuration. In this case, it is strongly recommended to contact the service center.

Code errors 20 warns of the presence of a parasitic flame. And the danger of the situation is that it often occurs in the event of a gas leak.

Therefore, when code 20 is detected on the display, it is necessary to turn off the gas supply, and then open the windows for ventilation, then make sure that there is no leakage, which is revealed by the specific unpleasant odor of special additives to gas.

If the presence of a leak is confirmed, then it is immediately necessary to notify the duty service of the gas department. If there is no danger, then to eliminate the causes, you should contact the service center.

E04 - the most unpleasant code, which indicates that there is a malfunction, but its cause has not been identified.

The E04 error code mostly indicates that the electronics have not identified the source of the problem. Therefore, it is only clear that it is serious, since in this case the automation does not even try to restart it.

Therefore, you can immediately call a specialist at home, since in order to eliminate the consequences, it may be necessary to diagnose all systems and components of the unit.

Code errors 08 signals a malfunction of the gas boiler unblocking button. This problem is usually eliminated by replacing the failed structural element.

Code errors 09 on the display indicates that the gas boiler setting mode is activated, and its cancellation will signal the disappearance of the specified set of numbers from the display.

Code errors 31 is rare, as it indicates that the electronic board is incompatible with the model of the boiler on which it was installed. That is, the specified problem usually occurs after the replacement is performed.

Electronic boards of modern gas boilers are designed for effective control and management, but it often happens that they themselves break

Sometimes code 31 is displayed after incorrect input of the boiler model name during assembly. Therefore, this procedure should be repeated. If the functionality is not restored, then the board should be replaced again.

Conclusions and useful video on the topic

In the first video, you can learn how to resolve error 02:

The following video shows you how to troubleshoot error 01:

Immergas boilers are high-tech and efficient gas equipment. In addition, they are safe to use, as evidenced by the ability to diagnose malfunctions and signal them to the user by displaying the appropriate code. This helps to avoid danger, as well as to quickly eliminate the breakdown.

Have you ever encountered breakdowns of Immergaz boilers? Please share with our readers what error occurred in the operation of the equipment and how we managed to fix the problem. Leave your comments in the block below the article.